Eco-friendly biocomposite foam from natural rubber latex and rice starch for sustainable packaging applications

Vol. 18., No.1., Pages 27-40, 2024

DOI: 10.3144/expresspolymlett.2024.3

DOI: 10.3144/expresspolymlett.2024.3

GRAPHICAL ABSTRACT

ABSTRACT

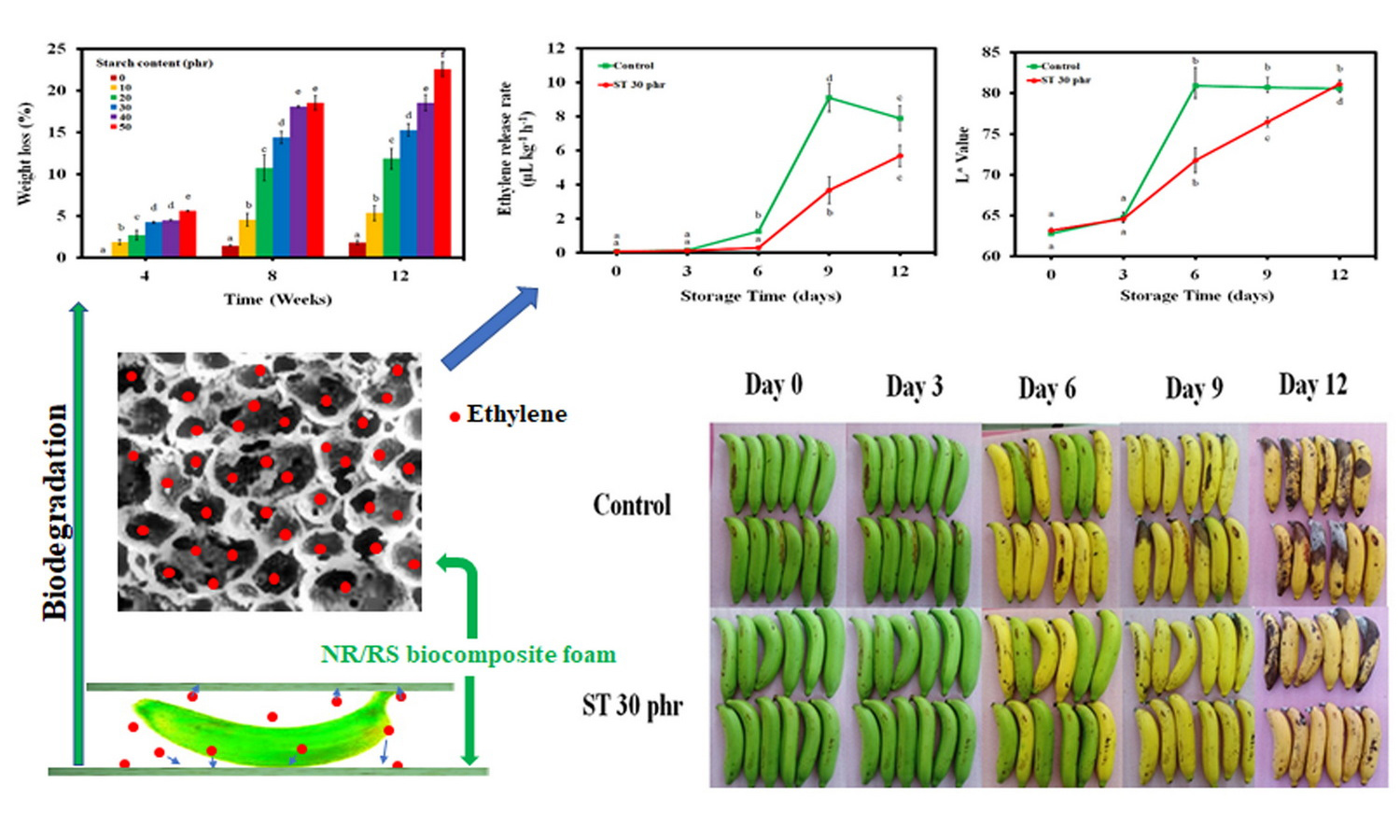

An environmental pollution problem is caused in part by packaging materials made from non-biodegradable synthetic polymers derived from petroleum. In this study, eco-friendly biofoams derived from natural rubber (NR) latex and rice starch (RS) were manufactured on a laboratory scale using the Dunlop process. Rice starch content was varied from 0 to 50 phr. The morphological, thermal, physical, mechanical, and biodegradability properties of the NR/RS biocomposite foams were characterized. Scanning electron microscopy (SEM) was used to assess the morphology of the foam cells. Dynamic mechanical thermal analysis (DMTA) and Thermogravimetric analysis (TGA) were used to investigate the thermal characteristics. When RS was present, it was discovered that the biocomposite foams had decreased thermal stability and enhanced biodegradability. Introducing RS into the NR/RS biocomposite foams also decreased tensile strength, elongation at break, and rebound resilience but increased the 100% modulus, hardness, compression force deflection (CFD), and compression set. The NR/RS biocomposite foams better preserved the banana fruit than the absence of foam, with lower ethylene accumulation, lower total soluble solids (TSS), higher pulp firmness, and good color preservation. This demonstrated that these NR/RS biocomposite foams helped to preserve banana fruit quality during storage and could be used in sustainable packaging applications.

RELATED ARTICLES

Jutatip Makmanee Treitler, Diew Saijun, Kritsada Phatcharasit, Suwat Rattanapan

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

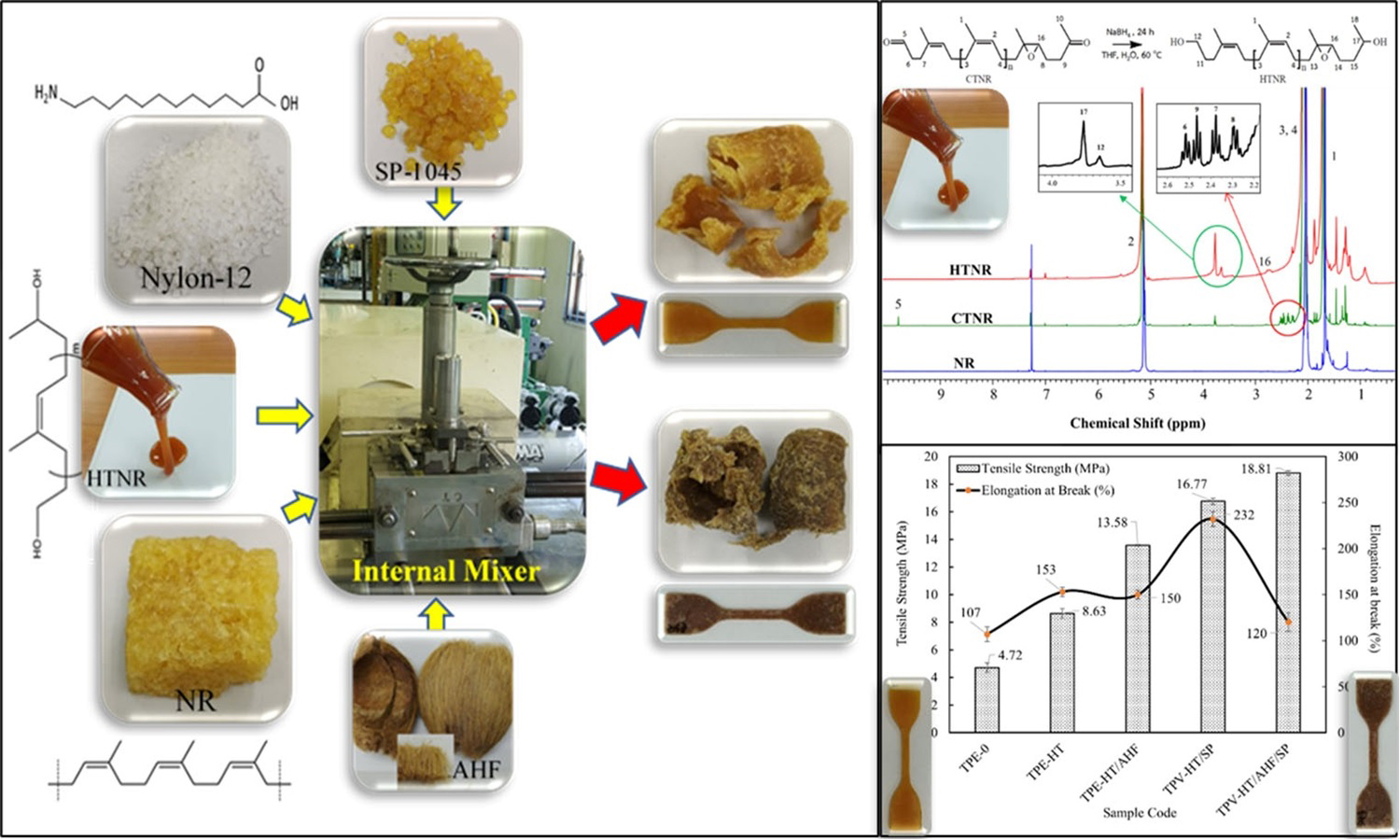

This work introduces an innovative method to enhance the compatibility of nylon-12/natural rubber thermoplastic elastomers by utilizing hydroxyl telechelic natural rubber as a reactive compatibilizer and natural fibers as reinforcement. Hydroxyl telechelic natural rubber was synthesized from natural rubber via oxidative cleavage to carbonyl telechelic natural rubber, followed by reduction with sodium borohydride. Proton nuclear magnetic resonance (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) verified the structure. Incorporating hydroxyl telechelic natural rubber into nylon-12/natural rubber (40/60 wt%) blends significantly enhanced interfacial adhesion, improving tensile strength and elongation at break compared to the uncompatibilized mix. Dynamic vulcanization using phenolic resin achieved an optimal balance of strength and ductility. The incorporation of areca husk fiber enhanced tensile strength, hardness, and solvent resistance, with a slight decrease in ductility and tear strength. Rheological analysis indicated that hydroxyl telechelic natural rubber increased melt viscosity due to improved phase interactions, while dynamic vulcanization reduced the melt flow index through network formation. Solvent uptake experiments confirmed that hydroxyl telechelic natural rubber, areca husk fiber, and SP-1045 vulcanizing agent minimized swelling in isooctane, toluene, and diesel oil.

Guilherme Ribeiro de Carvalho, Rafael Affonso Netto, Camila Delarmelina, Marta Cristina Teixeira Duarte, Liliane Maria Ferrareso Lona

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

Vol. 19., No.7., Pages 686-696, 2025

DOI: 10.3144/expresspolymlett.2025.52

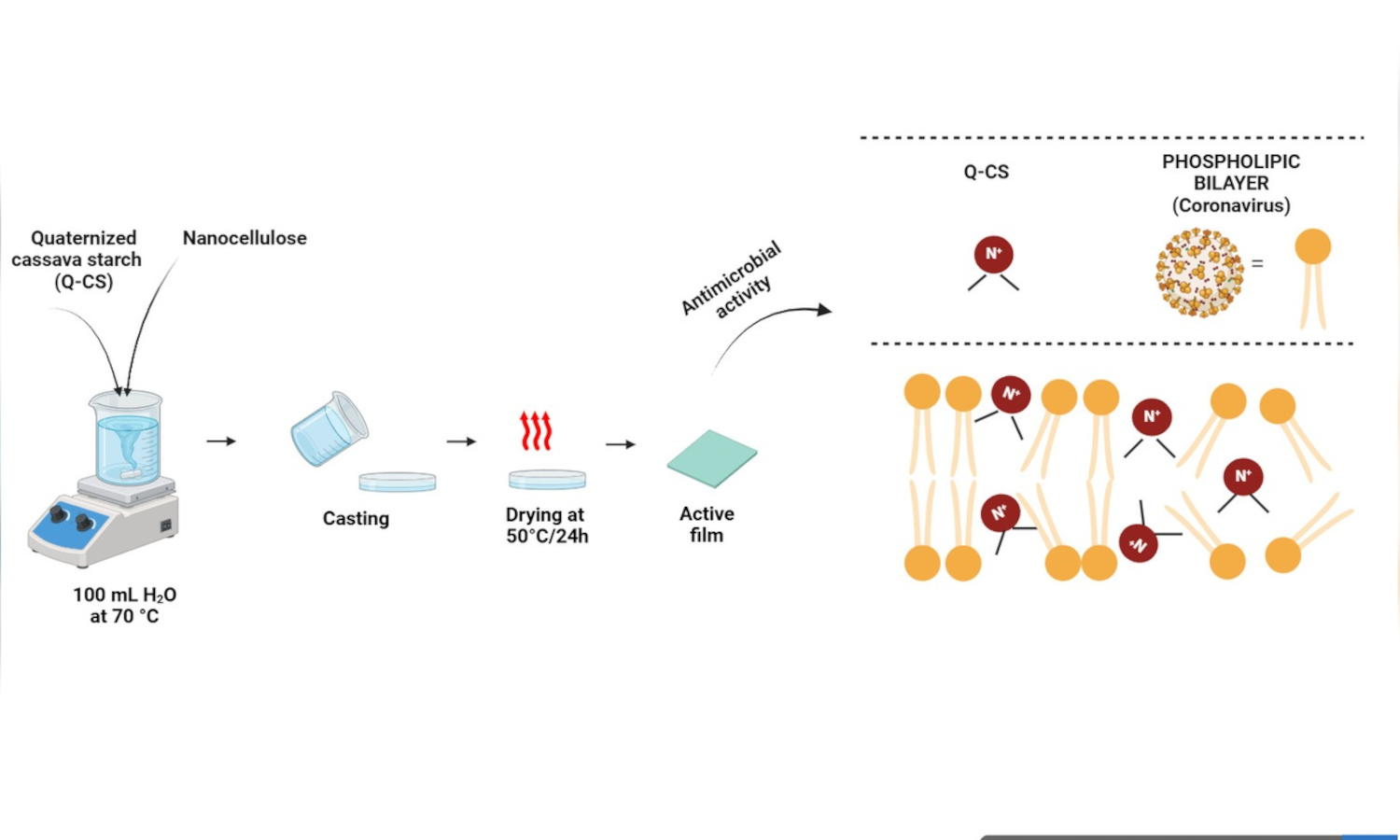

In this study, a new plastic film with antiviral and antibacterial properties was developed using modified cassava starch with glycidyltrimethylammonium chloride (GTMAC) and reinforced by crystalline nanocellulose (CNC), called Q-CS/CNC. For comparison, a control film (Q-CS) was produced without the addition of CNC. Elemental analysis revealed a degree of substitution (DS) of 0.552, indicating the replacement of the OH groups of starch by the NR4+ groups of GTMAC during the quaternization reaction. The addition of CNC resulted in significant increases (p < 0.05) of 38.9, 38.2, and 43.1% in thickness, opacity, and water vapor permeability measurements, respectively, compared to Q-CS. Incorporating CNC also contributed to an increase of 43.6% in tensile strength and 109% in stiffness but slightly decreased thermal stability. The Q-CS/CNC film demonstrated efficacy by inactivating 99% of the coronavirus in 1 min and inhibiting the growth of Staphylococcus aureus and Escherichia coli. This action is attributed to the electrostatic interaction of quaternary amino groups, grafted onto starch, with the phospholipid membrane of microorganisms, resulting in the inactivation of these microorganisms. Therefore, these results highlight the potential use of Q-CS/CNC film as antimicrobial packaging, especially against coronavirus.

Lilla Bubenkó, Násfa Németh, Sára Frey, Tamás Molnár, Károly Belina, Orsolya Viktória Semperger

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

Vol. 19., No.7., Pages 726-735, 2025

DOI: 10.3144/expresspolymlett.2025.55

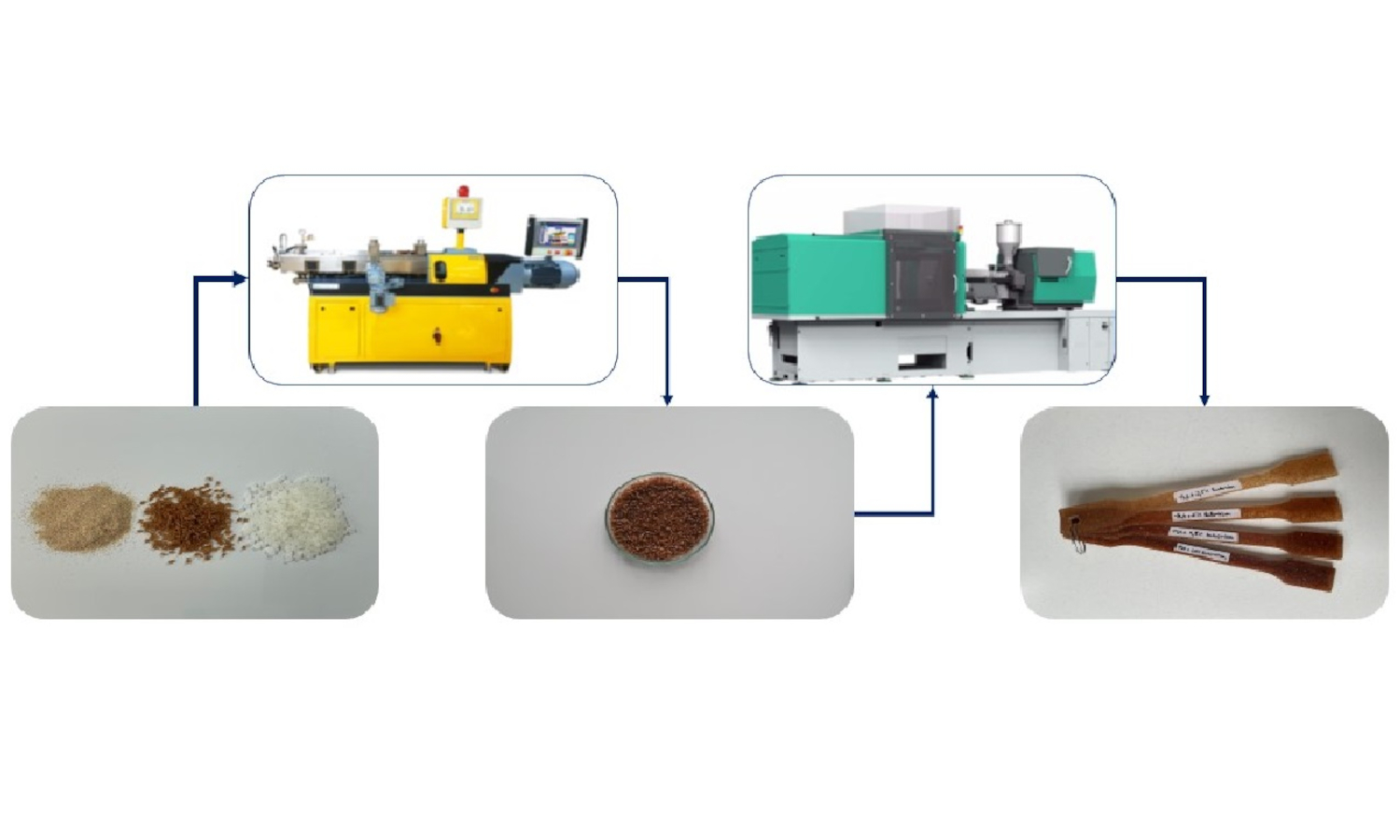

Biocomposites have recently received more attention because of raising environmental awareness and the drive toward sustainable technologies. The most common biodegradable polymer is poly(lactic acid) (PLA), which has an excellent balance of physical and rheological properties, but there is some limit to its usage. PLA properties can be improved by adding different types of fibers or fillers that come from agricultural waste. In this study, corn cob and lavender stem were used to reinforce PLA without any coupling agent, and the properties of the composites were investigated. The melt flow rate (MFR) values decreased with the corn cob content and increased with the addition of lavender stem. Mechanical tests showed that the tensile and flexural modulus of the composites increased and the strengths decreased with the reinforcement material content. The rigidness of PLA slightly decreased with the addition of fillers. There was no significant effect on the thermal properties. The unremarkable improvement of the reinforcement was due to the lack of appropriate adhesion of the two phases. The structure of the compounds was found to be homogenous on the scanning electron microscopy (SEM) micrographs. The incorporation of corn cob and lavender stem can reduce the production cost of materials.

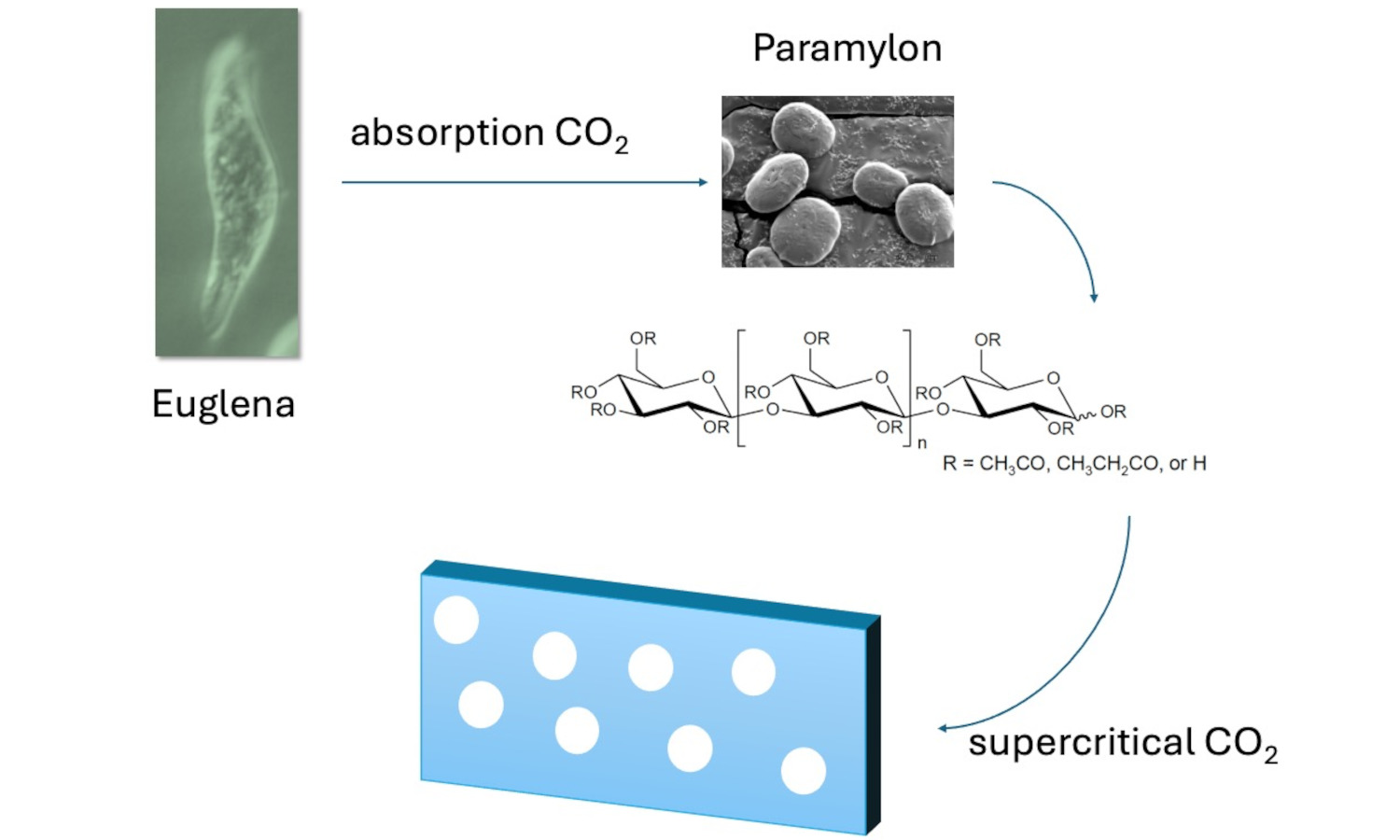

Seisuke Ata, Takumi Ono, Motonari Shibakami

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

This study demonstrated, for the first time, the successful formation of porous paramylon esters, which were made from euglenoid polysaccharide known as paramylon and short-chain fatty acids, through supercritical CO2 processing. By maintaining a constant ester functional group attached to the paramylon and varying its proportion, distinct porous structures were selectively produced. Solubility parameter estimations indicated that changes in esterification had no significant effect on the solubility of the paramylon esters used in the experiment. Thus, these structural differences are likely attributed to variations in the viscoelastic properties of paramylon esters under supercritical CO2 conditions. Furthermore, thermal conductivity measurements revealed reductions of up to 20%. Intriguingly, substantial decreases in thermal conductivity were observed even at low foaming ratios, achieved through precise control of the porous structure.

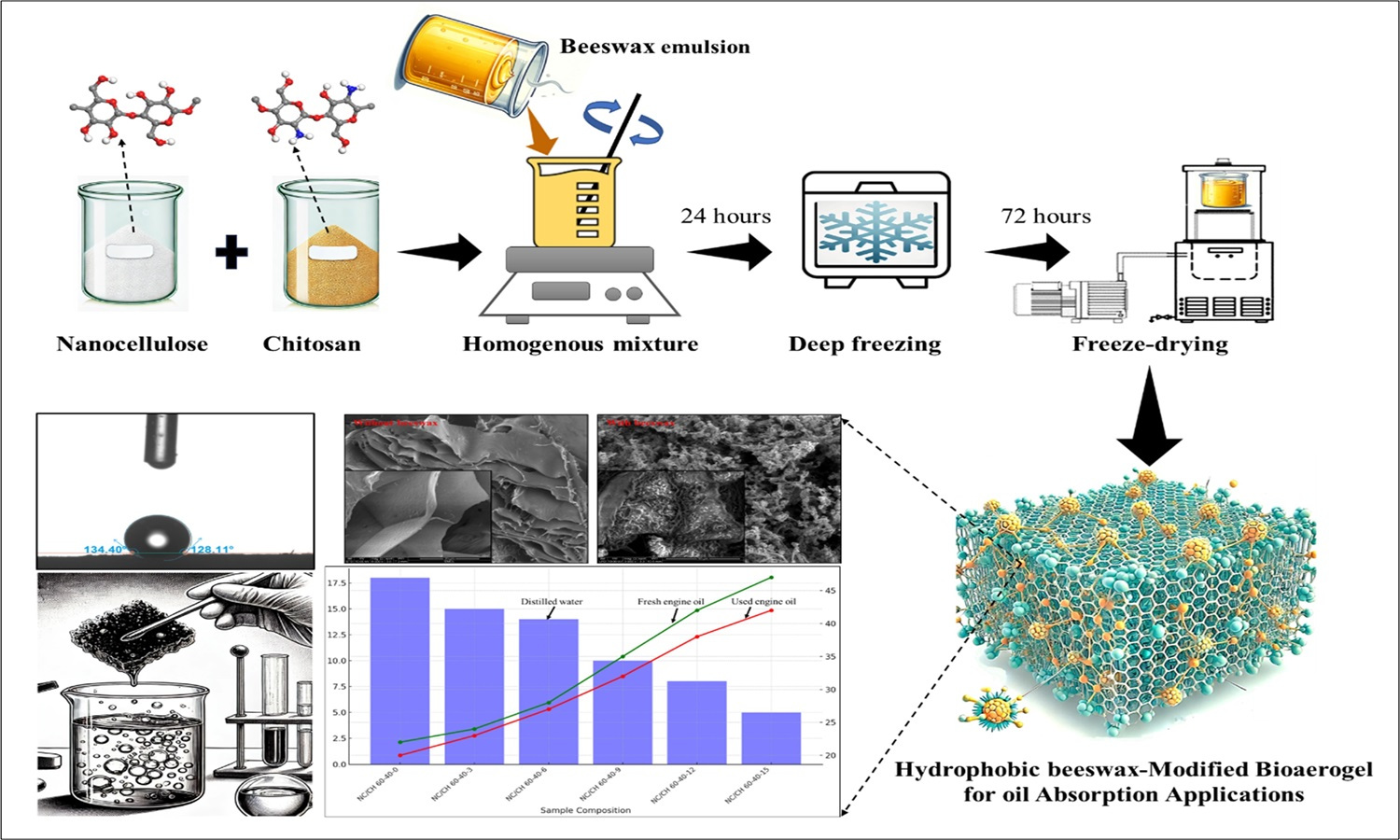

Waleed Y. Rizg, Yonss Mbrook Albadn, Abdul Khalil H.P.S., Majed A Alghamdi, Osama A. Madkhali, Mohammed Baradwan, Fayroz Medhat Shazly, Marwan Marwan, Esam Bashir Yahya

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

Vol. 19., No.5., Pages 544-553, 2025

DOI: 10.3144/expresspolymlett.2025.40

This study presents for the first time a sustainable approach to hydrophobic modification of nanocellulose/chitosan bioaerogels using beeswax emulsion. The incorporation of beeswax into the aerogel matrix resulted in increasing the density from 35.1 to 298 mg/cm3, while the porosity decreased from 96.4 to 62%. Fourier transform infrared spectroscopy (FT-IR) analysis confirmed the successful integration of beeswax into the nanocellulose/chitosan matrix, with distinct peaks corresponding to the characteristic functional groups of beeswax, such as C–H stretching vibrations, further validating the hydro - phobic modification. The mechanical properties showed increased hardness, from 0.24 to 0.95 N/mm2, indicating that higher beeswax content enhanced the rigidity of the aerogels. Contact angle measurements confirmed a dramatic improvement in hydrophobicity, with angles increasing from 47.68 to 134.40 and 128.11° for NC/CH 60-40-15. Water absorption capacity decreased from 17.5 g/g in the control sample to 8 g/g at the highest beeswax concentration, while oil absorption increased significantly, with fresh engine oil absorption rising from 3 to 45 g/g and used engine oil absorption from 2.5 to 40 g/g respectively. These results confirm the successful green modification of bioaerogels using beeswax, providing a sustainable and eco-friendly approach that enhances hydrophobicity, mechanical strength, and selective absorption properties.