Strategy for reducing rubber wear emissions: The prospect of using calcium lignosulfonate

Michaela Džuganová , Radek Stoček

, Radek Stoček , Marek Pöschl

, Marek Pöschl , Ján Kruželák

, Ján Kruželák , Andrea Kvasničáková, Ján Hronkovič, Jozef Preťo

, Andrea Kvasničáková, Ján Hronkovič, Jozef Preťo

, Radek Stoček

, Radek Stoček , Marek Pöschl

, Marek Pöschl , Ján Kruželák

, Ján Kruželák , Andrea Kvasničáková, Ján Hronkovič, Jozef Preťo

, Andrea Kvasničáková, Ján Hronkovič, Jozef Preťo

Vol. 18., No.12., Pages 1277-1290, 2024

DOI: 10.3144/expresspolymlett.2024.95

DOI: 10.3144/expresspolymlett.2024.95

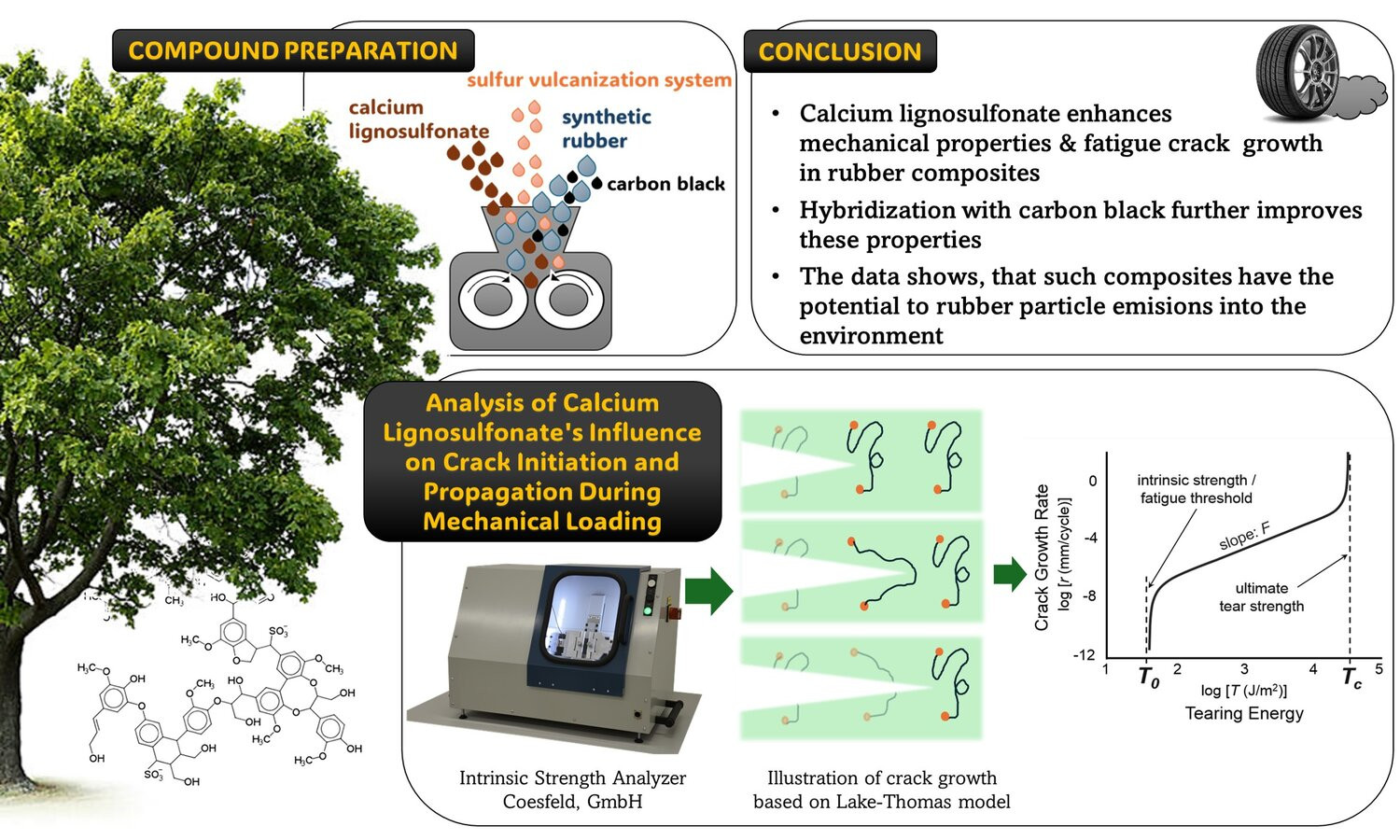

GRAPHICAL ABSTRACT

ABSTRACT

This study explores the transformative potential of calcium lignosulfonate (CaL) as a sustainable additive in rubber composites based on nitrile rubber (NBR) and styrene-butadiene rubber (SBR). Through comprehensive mechanical testing, fatigue crack growth (FCG) analysis, and scanning electron microscopy (SEM), we evaluated the tensile strength, elongation at break, surface morphology, and crack growth behavior of these innovative composites. By incorporating CaL into carbon black-reinforced rubber compounds (RUB/CB) based on nitrile rubber and styrene-butadiene rubber, we achieved good dispersion of both components as well as satisfactory morphology, resulting in tensile strengths of 16.3 and 12.7 MPa, respectively. While the CB/CaL hybrid did not significantly influence the intrinsic strength of the rubber samples, the ultimate strength of these compounds increased drastically – over five-fold compared to RUB/CB – indicating great potential for real-life applications. This study underscores the promise of lignin-based additives in the development of eco-friendly, highperformance rubber materials.

RELATED ARTICLES

Mpho Phillip Motloung, Mokgaotsa Jonas Mochane

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

Vol. 19., No.11., Pages 1092-1132, 2025

DOI: 10.3144/expresspolymlett.2025.82

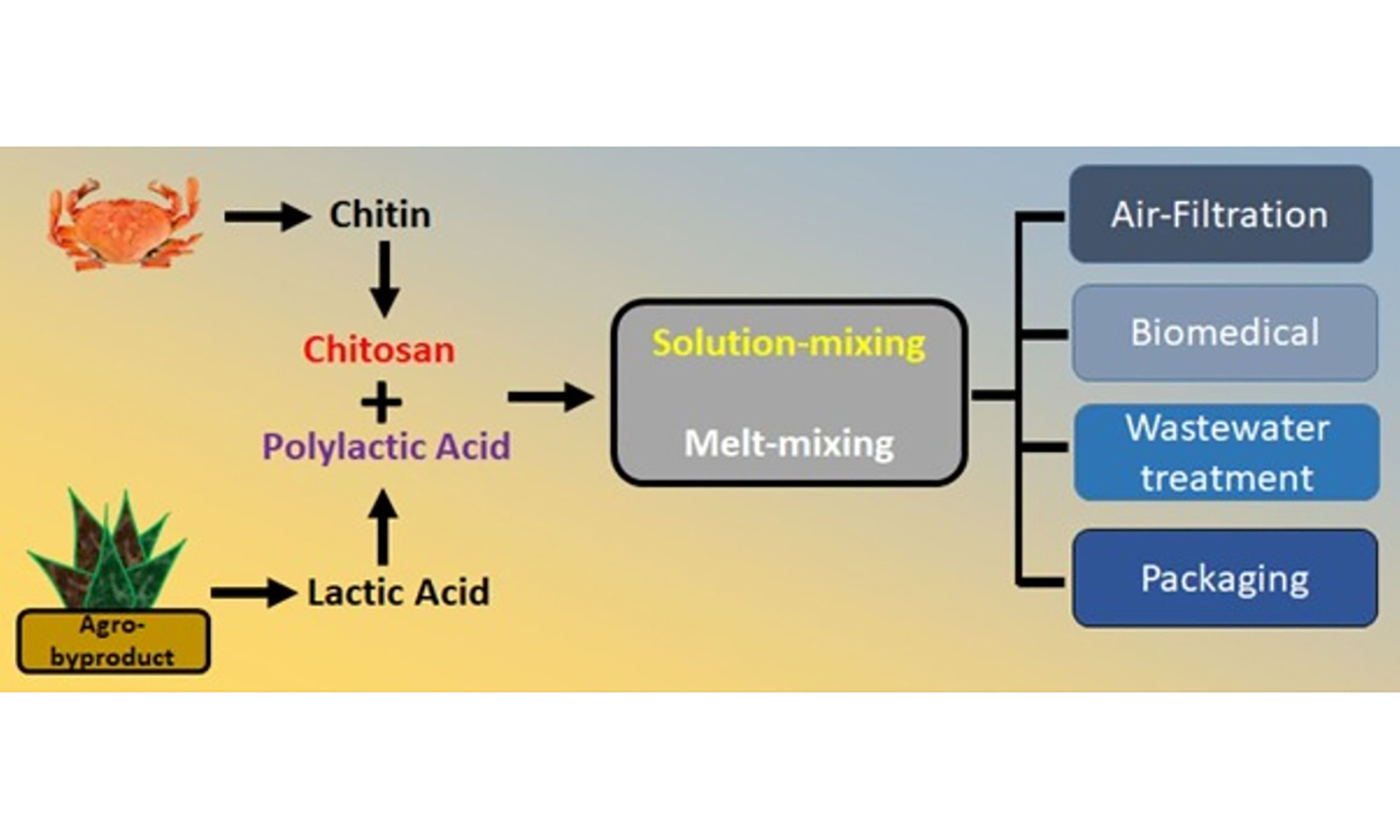

Polylactic acid (PLA) is one of the most widely used biopolymers, and it has demonstrated a huge potential for replacing some of the conventional plastics in certain application fields. However, due to a lack of other attributes such as antimicrobial properties and slow degradation rates, it is often blended with other polymers to impart these properties. Chitosan has desirable features including antimicrobial and antioxidant properties, biodegradability and biocompatibility, and environmental friendliness. Thus, it is widely blended with PLA to generate materials that can be applied in various fields. In recent years, PLA/chitosan blend composites and nanocomposites have been produced to develop sustainable and ecofriendly materials that can be suitable in active food packaging, water treatment, air filtration, and biomedical applications. This review provides an overview of the recent advancements in the development of PLA/chitosan blend composites and nanocomposites for various applications. The processing strategies, mechanical and thermal properties, together with utilization in biomedical, air filtration, water treatment, and packaging applications, are provided.

Kinsuk Naskar

Vol. 19., No.10., Pages 977-978, 2025

DOI: 10.3144/expresspolymlett.2025.73

Vol. 19., No.10., Pages 977-978, 2025

DOI: 10.3144/expresspolymlett.2025.73

This is an editorial article. It has no abstract.

Katalin Litauszki, Tamás Tábi, László Mészáros

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

Vol. 19., No.5., Pages 455-456, 2025

DOI: 10.3144/expresspolymlett.2025.33

This is an editorial article. It has no abstract.

Ju Li, Lize Yang, Shuo Chen, Guotao Sun

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

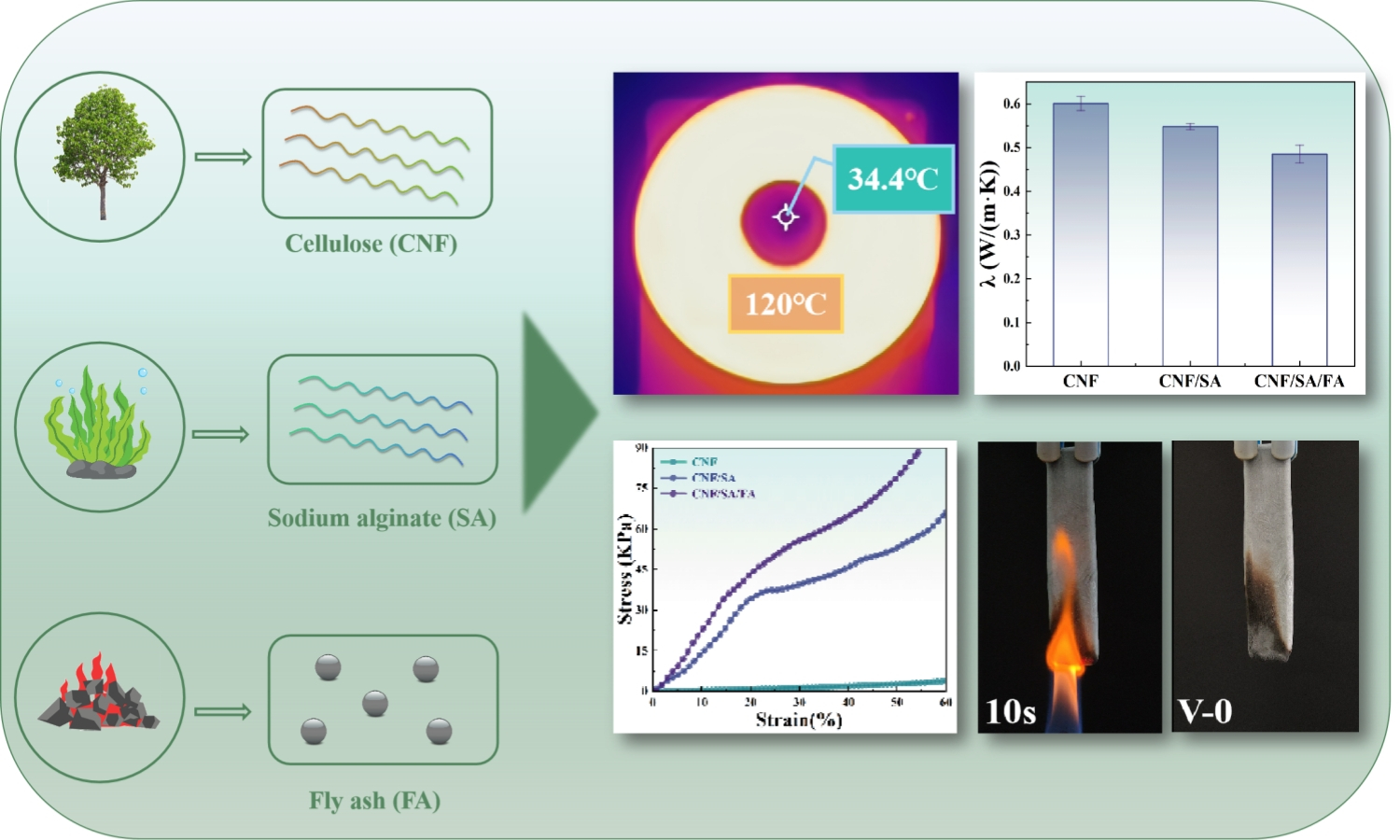

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

Ivy Gan, Wen Shyang Chow, Siong Hui Khoo, Mohamad Danial Shafiq

Vol. 18., No.7., Pages 689-704, 2024

DOI: 10.3144/expresspolymlett.2024.51

Vol. 18., No.7., Pages 689-704, 2024

DOI: 10.3144/expresspolymlett.2024.51

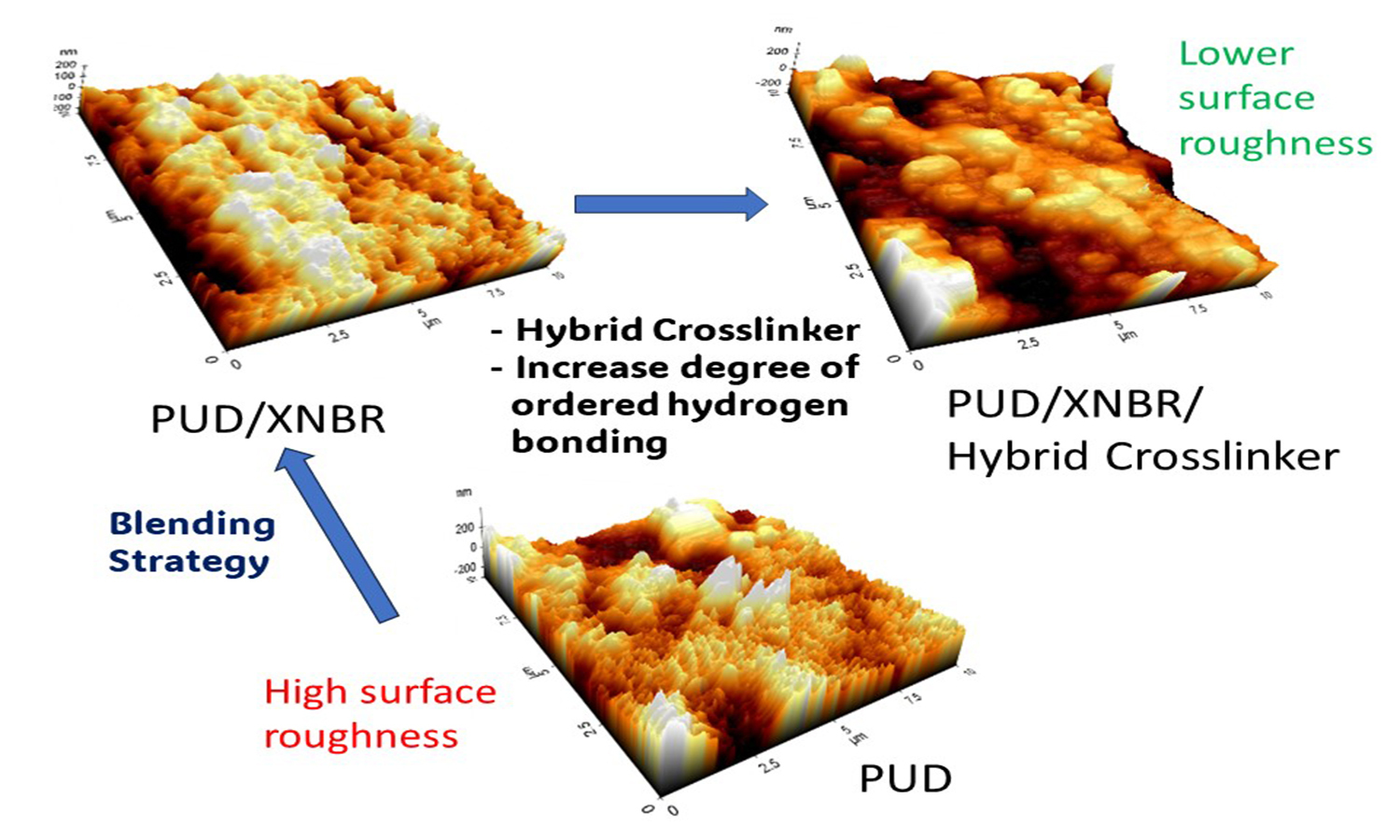

This study focuses on producing polyurethane dispersion (PUD)/carboxylated nitrile butadiene rubber (XNBR) blends with different types of crosslinkers without both accelerators and sulphur. Two types of crosslinkers: epoxide crosslinker and organo-modified siloxane, are introduced in the PUD/XNBR (blending ratio of 80:20). The zeta potential and particle size of the PUD/XNBR blends were determined using a dynamic light-scattering nanoparticle analyser. The chemical interaction and surface roughness of the PUD/XNBR blends were evaluated using Fourier transform infrared spectroscopy (FTIR) and atomic force microscopy (AFM). The zeta potential and particle size of the PUD were influenced by XNBR blending and the types of crosslinkers. FTIR observations indicate that the XNBR and the crosslinkers facilitated intermolecular hydrogen bonding and different extents of ordered hydrogen bonding. A higher degree of ordered hydrogen bonding can be associated with a higher surface roughness of the PUD/XNBR blends. Nevertheless, the hybrid crosslinkers can be used to achieve reasonable surface roughness for the easier donning of latex gloves. The research findings can be applied to design glove products with desirable surface roughness and intermolecular bonding.