The role of lignin extracted from patchouli fiber waste in sustainable ternary biopolymer blends

Syaifullah Muhammad , Rahul Dev Bairwan

, Rahul Dev Bairwan , H.P.S. Abdul Khalil

, H.P.S. Abdul Khalil , Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

, Rahul Dev Bairwan

, Rahul Dev Bairwan , H.P.S. Abdul Khalil

, H.P.S. Abdul Khalil , Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

DOI: 10.3144/expresspolymlett.2025.42

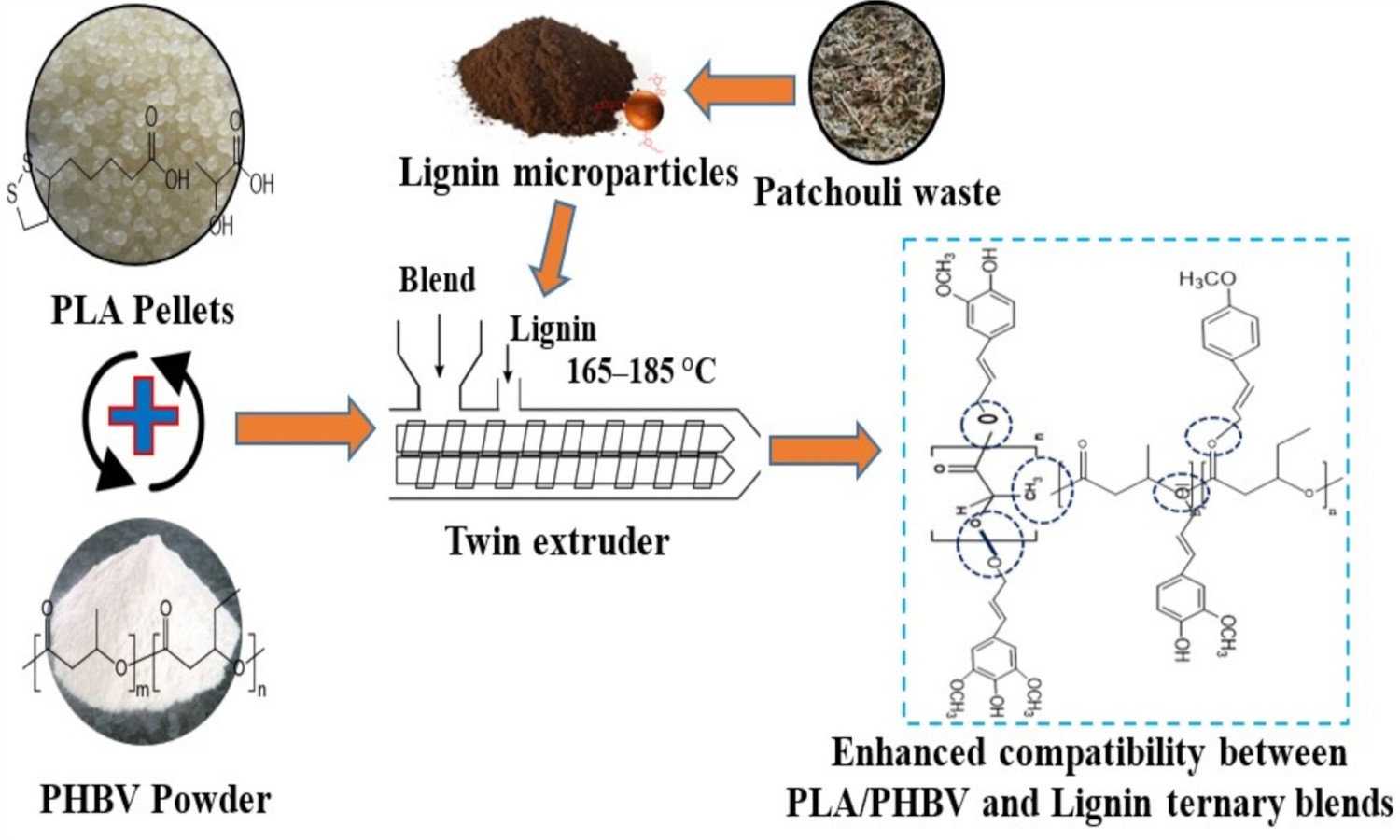

GRAPHICAL ABSTRACT

ABSTRACT

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

RELATED ARTICLES

Xuecheng Lu, Ke Feng, Zhiqiang Zhang, Xuyan Lü, Yujie Xiao, Haijun Wang

Vol. 20., No.4., Pages 371-382, 2026

DOI: 10.3144/expresspolymlett.2026.29

Vol. 20., No.4., Pages 371-382, 2026

DOI: 10.3144/expresspolymlett.2026.29

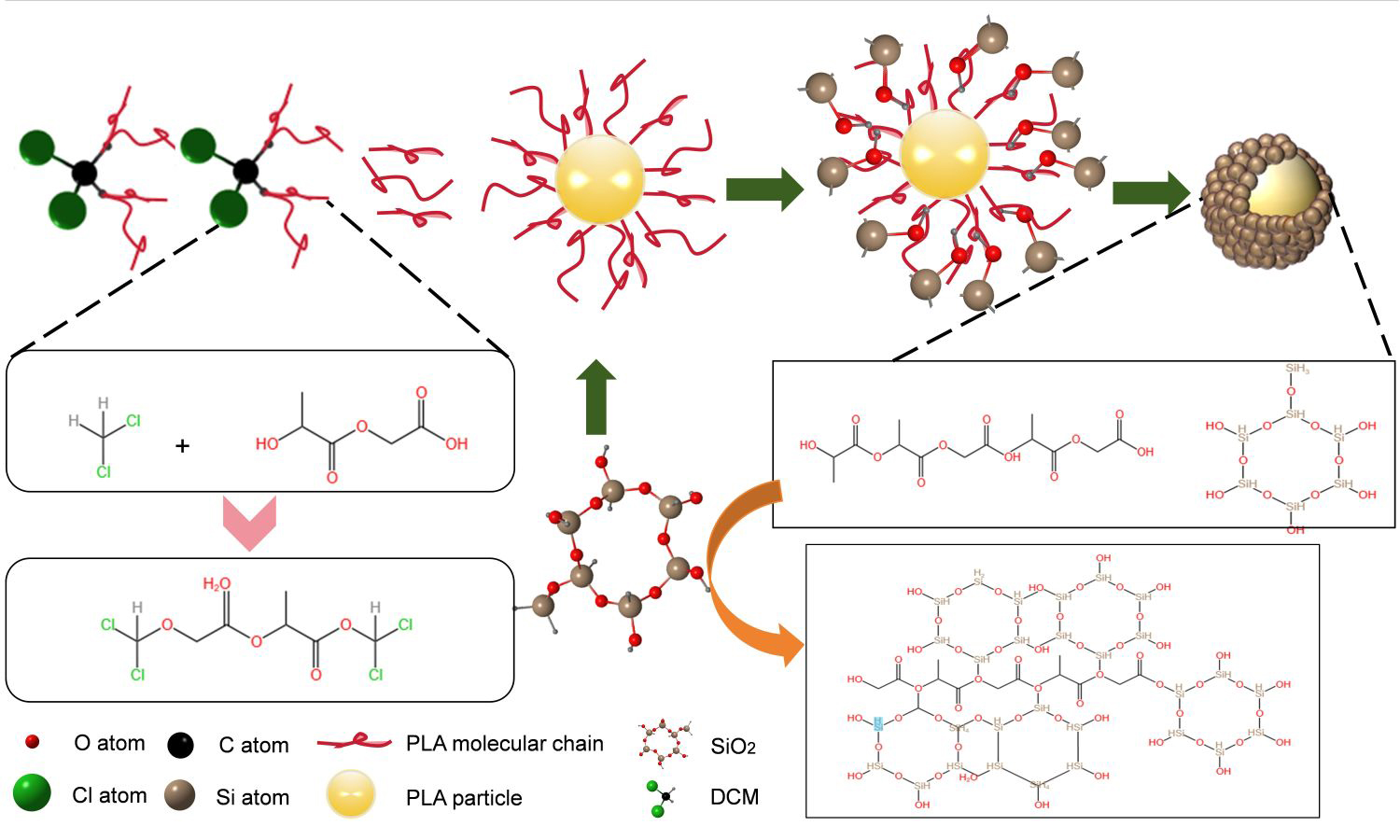

To improve the toughness, thermal stability, and melt processability of polylactic acid (PLA), this study introduced chlorinated polyethylene-polyethylene glycol (CPE-PEG, 10 wt%) into the PLA matrix and investigated the effect of the content of nano-SiO2 surface-modified with the silane coupling agent KH570 (K-SiO2) on the composite properties. Composite filaments were prepared via single-screw extrusion, and standard specimens were printed using fused deposition modeling (FDM) technology. Comprehensive characterization indicated that the composite achieved optimal mechanical properties at a K-SiO2 content of 1.5 wt%; simultaneously, the material’s thermal stability and crystallization behavior were optimized. Rheological behavior demonstrated that K-SiO2 could regulate the melt viscoelasticity, broadening the FDM processing window. This study provides an effective strategy for developing high-performance PLA composites for FDM printing.

Yi-jie Yang, Qiang Dou

Vol. 20., No.4., Pages 349-370, 2026

DOI: 10.3144/expresspolymlett.2026.28

Vol. 20., No.4., Pages 349-370, 2026

DOI: 10.3144/expresspolymlett.2026.28

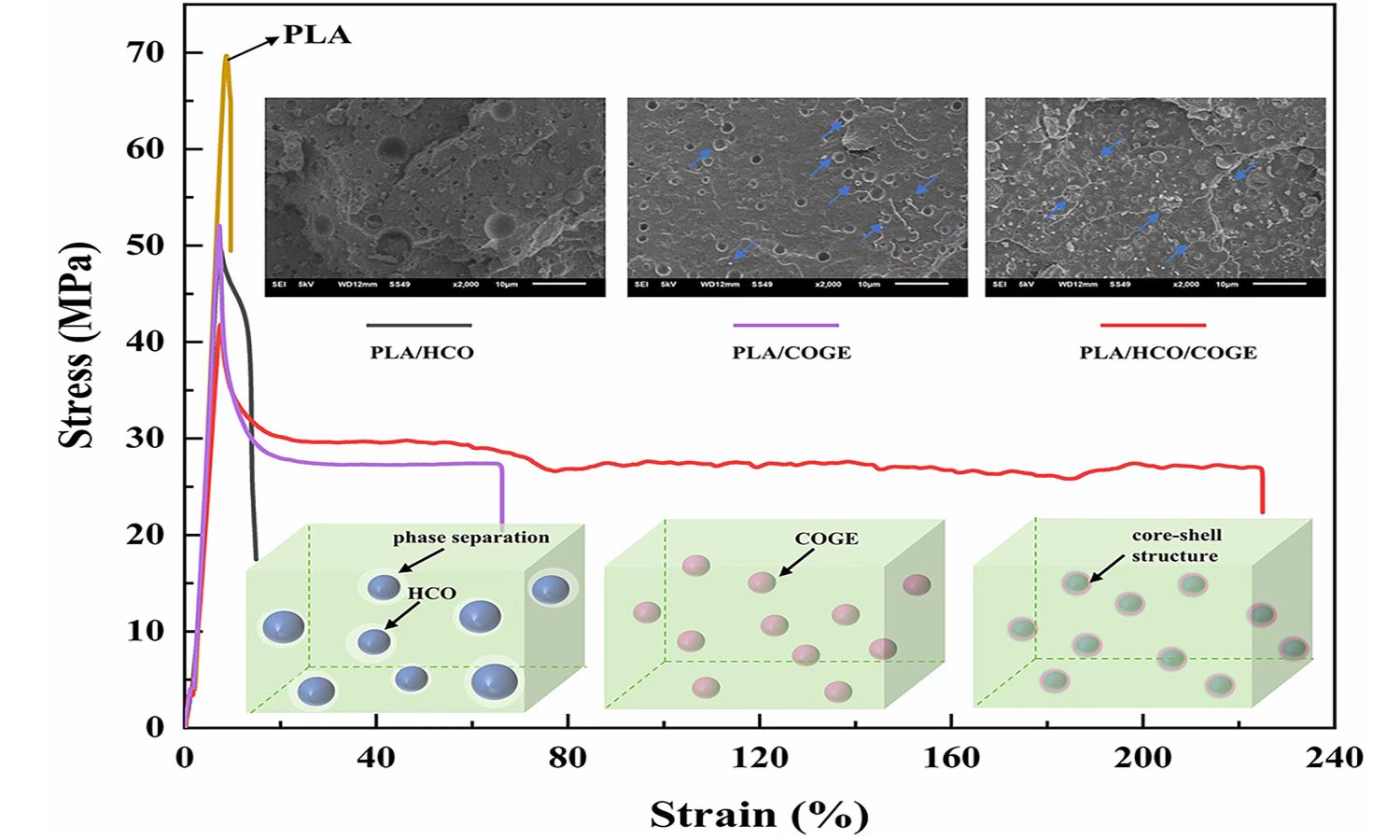

Poly(lactic acid) (PLA) has attracted much attention and shows promising applications in numerous fields. In this study, PLA was plasticized using bio-based castor oil derivatives - hydrogenated castor oil (HCO) and castor oil glycidyl ether (COGE). These eco-blends were measured using a Fourier transform infrared spectrometer, a scanning electron microscope, a contact angle test, rheology, a differential scanning calorimeter, thermogravimetry, polarized optical microscopy, and a tensile test, respectively. The findings show that a core-shell morphology of COGE-HCO encapsulation is formed in PLA matrix, and the hydrogen bonding interaction and ring-opening chemical reaction among functional groups of the components greatly improve the compatibility, ductility, cold crystallization ability, and thermostability of the eco-blends, but the melt crystallization ability is hindered. The incorporation of HCO improves the hydrophobicity and oleophobicity of the eco-blends. Due to the combined effect of HCO and COGE, the melt viscosity reduces, and the Newtonian behavior enhances; the nucleation density and spherulitic growth of PLA increase. The strain at break of the PLA/HCO/COGE (90/7.5/2.5) blend reached 221%, which is 22.6 times higher than that of the neat PLA. These eco-blends present appropriate rheological, thermal, and mechanical properties, showing application scenarios in biodegradable packaging and disposable appliances.

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

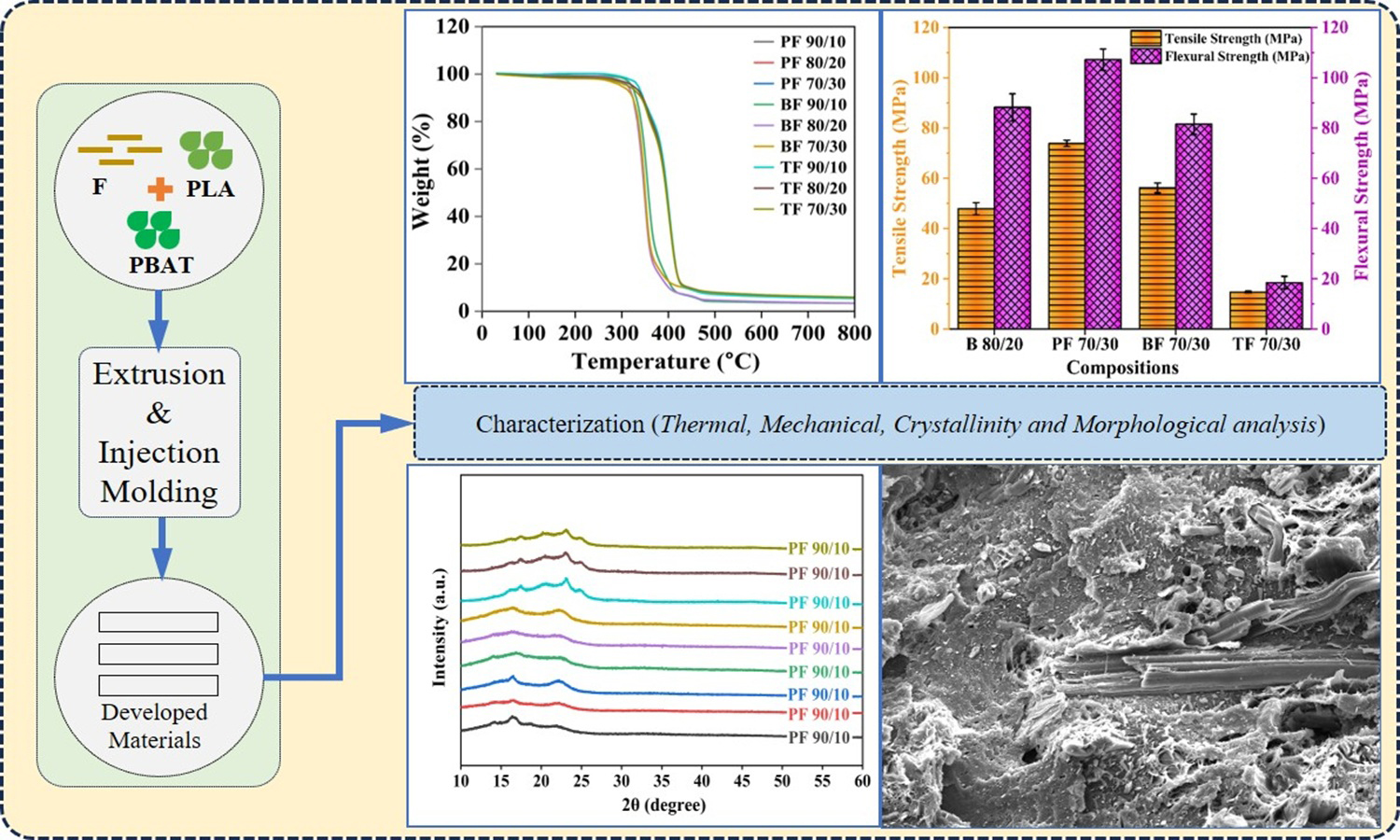

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Isabel Milagros Gavilan-Figari

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

Vol. 20., No.1., Pages 72-81, 2026

DOI: 10.3144/expresspolymlett.2026.6

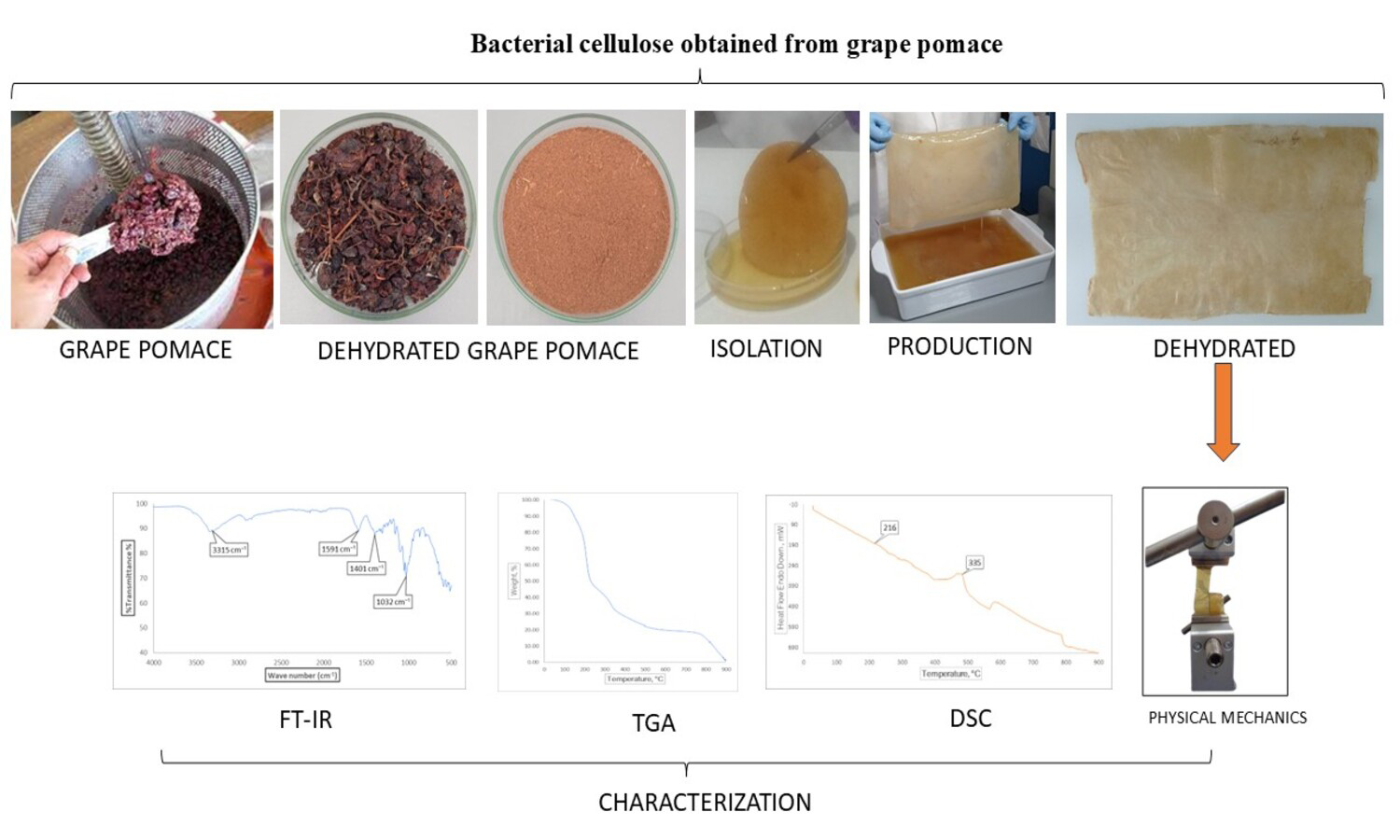

Bacterial cellulose (BC) is an eco-friendly biopolymer with outstanding structural and functional properties, offering promising applications in sustainable packaging and bio-based materials. In this study, we demonstrate the feasibility of producing BC via spontaneous fermentation, using grape pomace supplemented with sucrose as the sole carbon source, nutrient substrate, and microbial inoculum, without the addition of commercial strains or nitrogen supplements. Fermentation was conducted under static conditions, yielding biofilms with stable structural characteristics and BC production of up to 14.1 g/L, thereby confirming the efficiency of this low-cost, residue-based process. The films obtained exhibited well-organized polymeric networks, with thermal stability in the range of Tg ≈ 159–266 °C and mechanical resistance comparable to or higher than conventional biopolymers. Characterization confirmed reproducible chemical profiles, thermal stability, and measurable variation in mechanical performance, with a tensile strength ranging from 0.0001 to 105 MPa and an elongation at break of 15±5%. The process highlights a resource-efficient and sustainable pathway, adaptable to rural contexts and aligned with circular economic principles. While minor variations among replicates reflected the intrinsic variability of biological systems, mean values and standard deviations demonstrated reproducible physicochemical and mechanical properties. These findings demonstrate that BC derived from agro-industrial residues can be produced under simple, low-input conditions, opening opportunities for scalable valorization in functional and sustainable materials.

Emiliano González-Rodríguez, Grecia Michelle Ramírez-Paredes, Ulises Figueroa-López, Elvia Patricia Sánchez-Rodríguez, Andrea Guevara-Morales

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

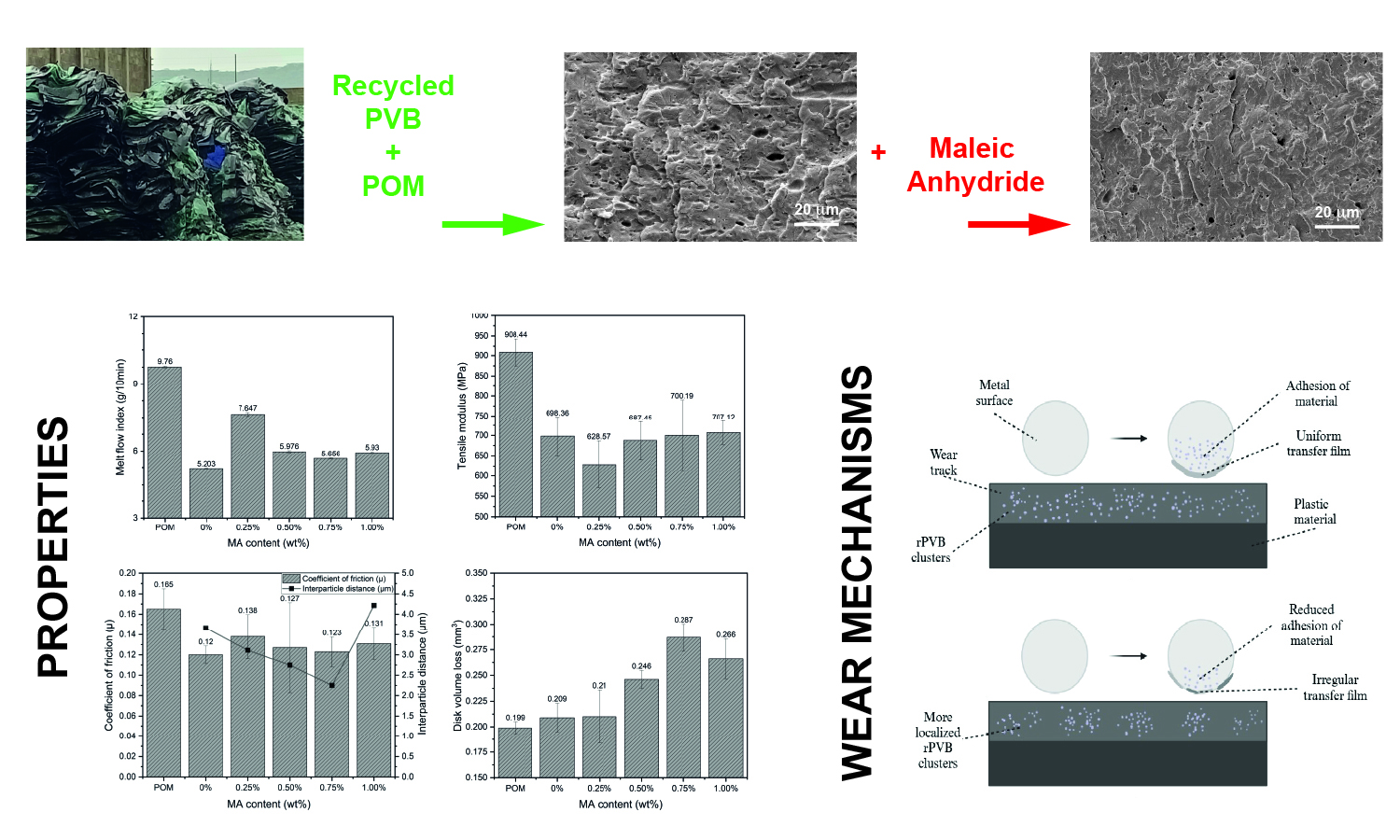

Maleic anhydride (MA) is widely used to modify plastics and as a compatibilizer in recycling. This study examines the effect of varying MA concentrations on blends of polyoxymethylene (POM) and recycled polyvinyl butyral (rPVB) from automotive windshields. Morphological analysis showed that MA contents between 0.25 and 0.75 wt% led to smaller, more closely dispersed rPVB particles, indicating enhanced phase miscibility. Rheological and thermal analyses revealed up to a 47% increase in melt flow index at lower MA concentrations, and improved interfacial interactions and crystallinity at higher levels. The tensile modulus dropped by 10% at 0.25 wt% MA but increased with further additions; tensile strength and Shore D hardness remained unaffected. Impact strength improved by up to 65% with MA addition, mainly due to increased ductility and a morphology characterized by larger rPVB domains and shorter interparticle distances at low MA contents. The coefficient of friction decreased with rPVB but increased with MA, along with higher volume loss. Microscopic wear analysis confirmed that rPVB dispersion, influenced by MA, was key to transfer film formation and surface lubrication. Thus, MA optimization enables tailored mechanical and tribological properties in POM/rPVB blends.