Basalt fibers as a sustainable alternative to glass fibers in the reinforcement of polyamide 6 for gear applications

Vol. 19., No.11., Pages 1133-1143, 2025

DOI: 10.3144/expresspolymlett.2025.83

DOI: 10.3144/expresspolymlett.2025.83

GRAPHICAL ABSTRACT

ABSTRACT

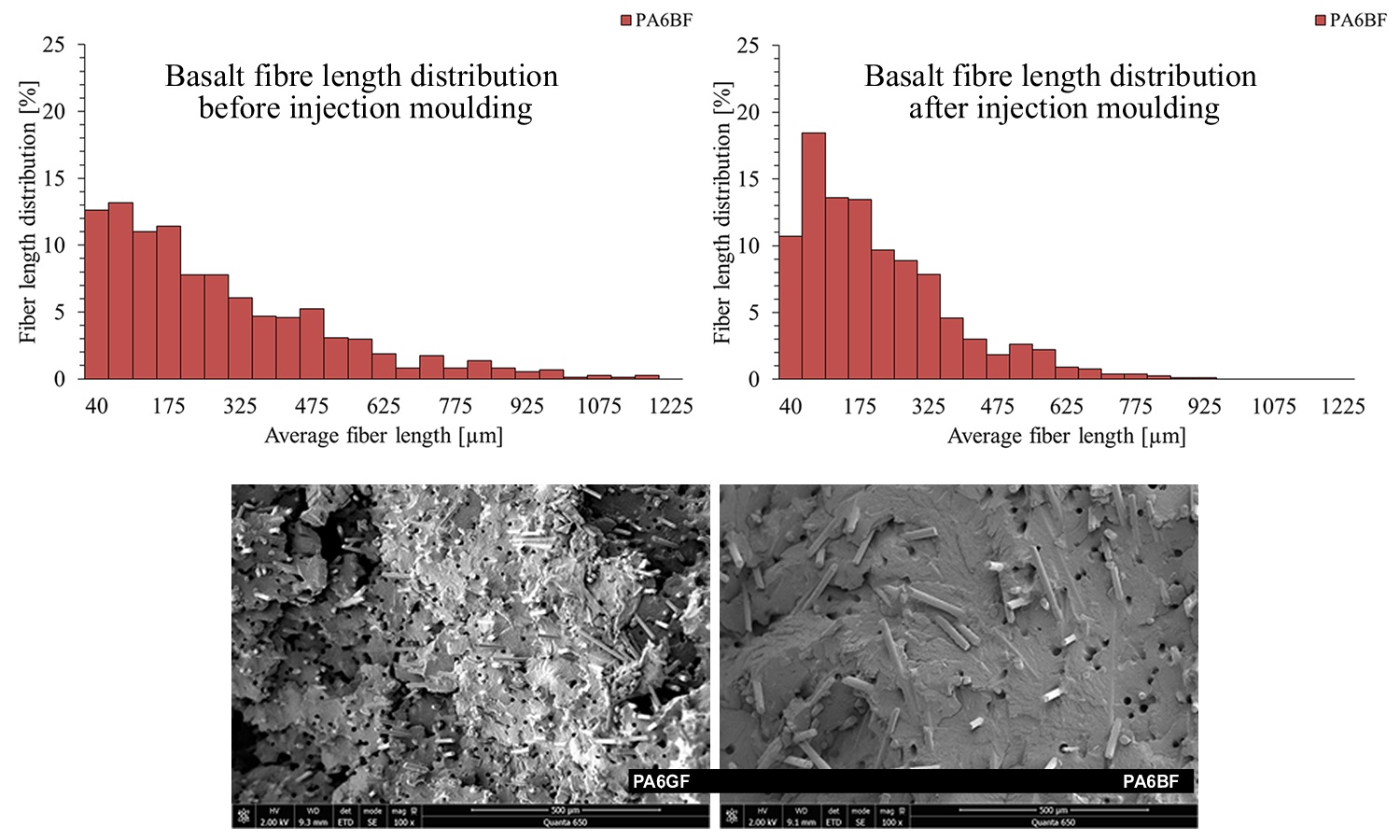

With the increasing use of e-mobility, the demand for high-quality materials to produce polymer gears is growing. Due to the tendency towards using natural materials and reducing carbon footprint, basalt fibers (BF) are tested as a substitute for glass fibers (GF). For this purpose, composites of polyamide 6 (PA6) with GF and BF, with and without compatibilizer and polytetrafluoroethylene (PTFE) are produced, tested, and properties compared. The mechanical, thermomechanical, thermal, and tribological properties of the composites, as well as the size of the fibers after the production of the composites and after injection molding, are determined. The compatibilizer improves the impact strength, while the glass fibers have a better reinforcing effect. The fibers increase crystallinity, but the effect is minimal. The thermal conductivity increases approximately the same for both fibers and is highest at composites that, in addition to 30% fibers, also contain PTFE. The tribological properties are comparable but slightly better for glass fibers. The fiber length is greatly reduced during the production of the composites and is around 200–300 μm in both cases. SEM imaging and mapping analysis show good dispersion of the fibers in the polymer and relatively poor compatibility with PA6.

RELATED ARTICLES

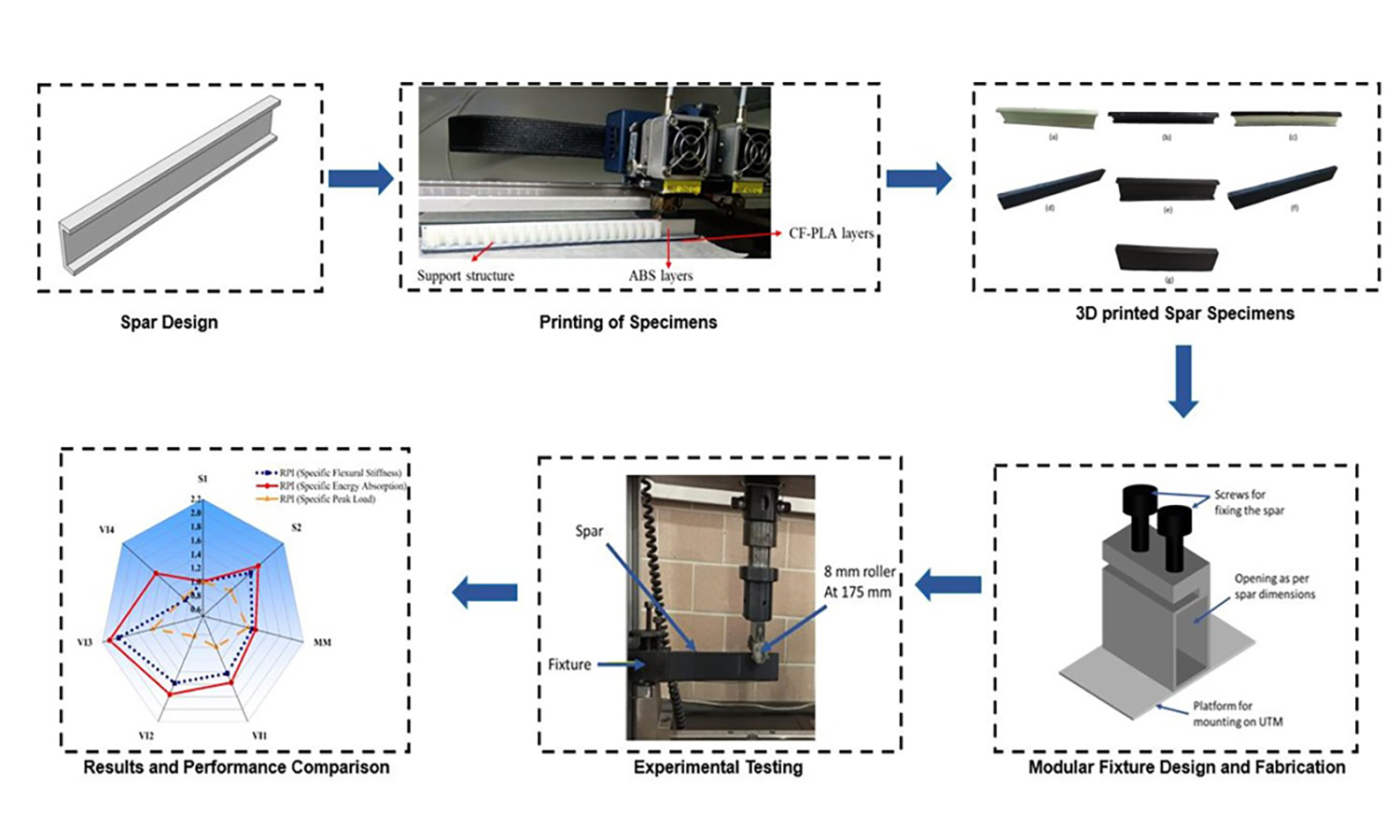

Hamza Qayyum, Borhen Louhichi, Malik Hassan, Babar Ashfaq, Muhammad Sulaiman, Muhammad Bilal Khan, Nashmi H. Alrasheedi, Ghulam Hussain

Vol. 19., No.11., Pages 1173-1187, 2025

DOI: 10.3144/expresspolymlett.2025.86

Vol. 19., No.11., Pages 1173-1187, 2025

DOI: 10.3144/expresspolymlett.2025.86

To reduce fuel consumption and extend flight time, the aerospace industry has focused on lightweight design. Achieving this without compromising structural integrity has been challenging. However, innovative additive manufacturing offers new opportunities for practical solutions. This study presents two methods: multi-material additive manufacturing (MMAM) and variable infill density additive manufacturing (VIDAM), aimed at reducing structural weight while maintaining mechanical performance. These methods were applied to a wing spar, a test geometry based on stress distribution principles from laminated beam mechanics. The structures produced with these new approaches showed improved mechanical responses compared to those made with traditional additive manufacturing techniques. A maximum increase of 91% in load-carrying capacity and a 34.8% increase in specific energy absorption were observed. scanning electron microscopy analysis revealed that layer bonding and material diffusion greatly influenced the mechanical performance. Although the study was conducted on small-scale models, the design concepts can be adapted to large-scale industrial applications that benefit from lightweight structures, such as the aerospace and automotive.

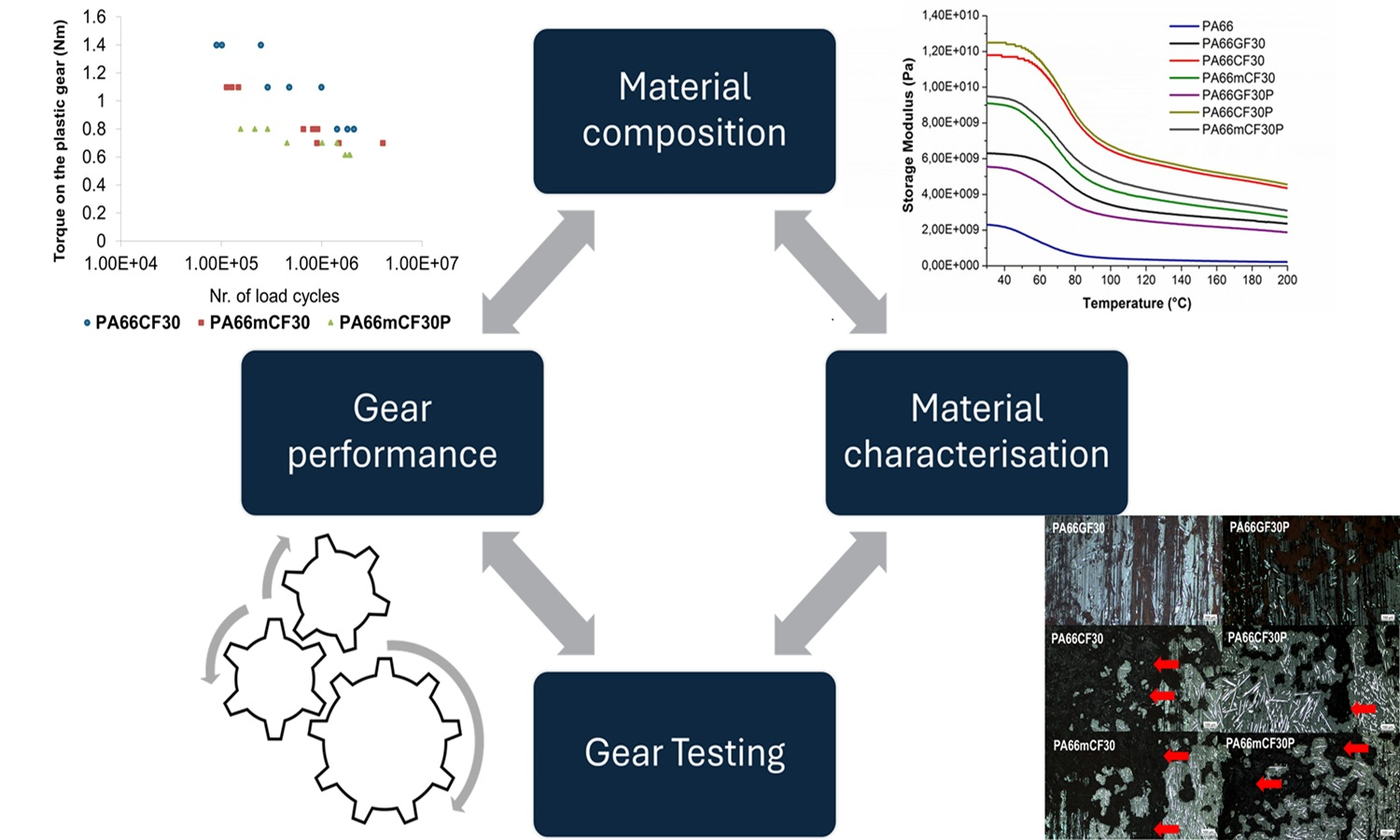

Rebeka Lorber, Janez Slapnik, Borut Černe, Andreas Hausberger, Jan Sumfleth

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

The study investigates the use of repurposed milled carbon fibre (mCF) as reinforcement for polyamide 66 (PA66) in gear applications, addressing environmental and cost concerns of virgin carbon fibres. Neat PA66 and PA66 composites reinforced with mCF, glass fibres (GF), and carbon fibres (CF), with and without polytetrafluoroethylene (PTFE), were injection moulded and evaluated for microstructure (fibre length), thermal, mechanical, surface, and tribological properties, as well as gear performance under VDI 2736 guidelines. CF reinforced composites showed the highest modulus and tensile strength, followed by mCF and GF. PTFE reduced modulus and strength in binary composites. All reinforced composites significantly lowered the coefficient of friction (COF) and wear rate compared to neat PA66, with mCF showing the most notable improvements. PTFE slightly improved tribological performance only for GF (wear) and CF (COF) composites. In gear testing, binary composites outperformed neat PA66, with CF performing best, followed by mCF and GF. Ternary composites had slightly lower performance than their binary equivalents. Correlation analysis showed that gear performance is closely linked to structural integrity. Failure analysis revealed higher crack susceptibility in mCF reinforced gears due to shorter fibre length. The findings highlight mCF reinforced PA66 as a sustainable, cost-effective material for durable polymer gears.

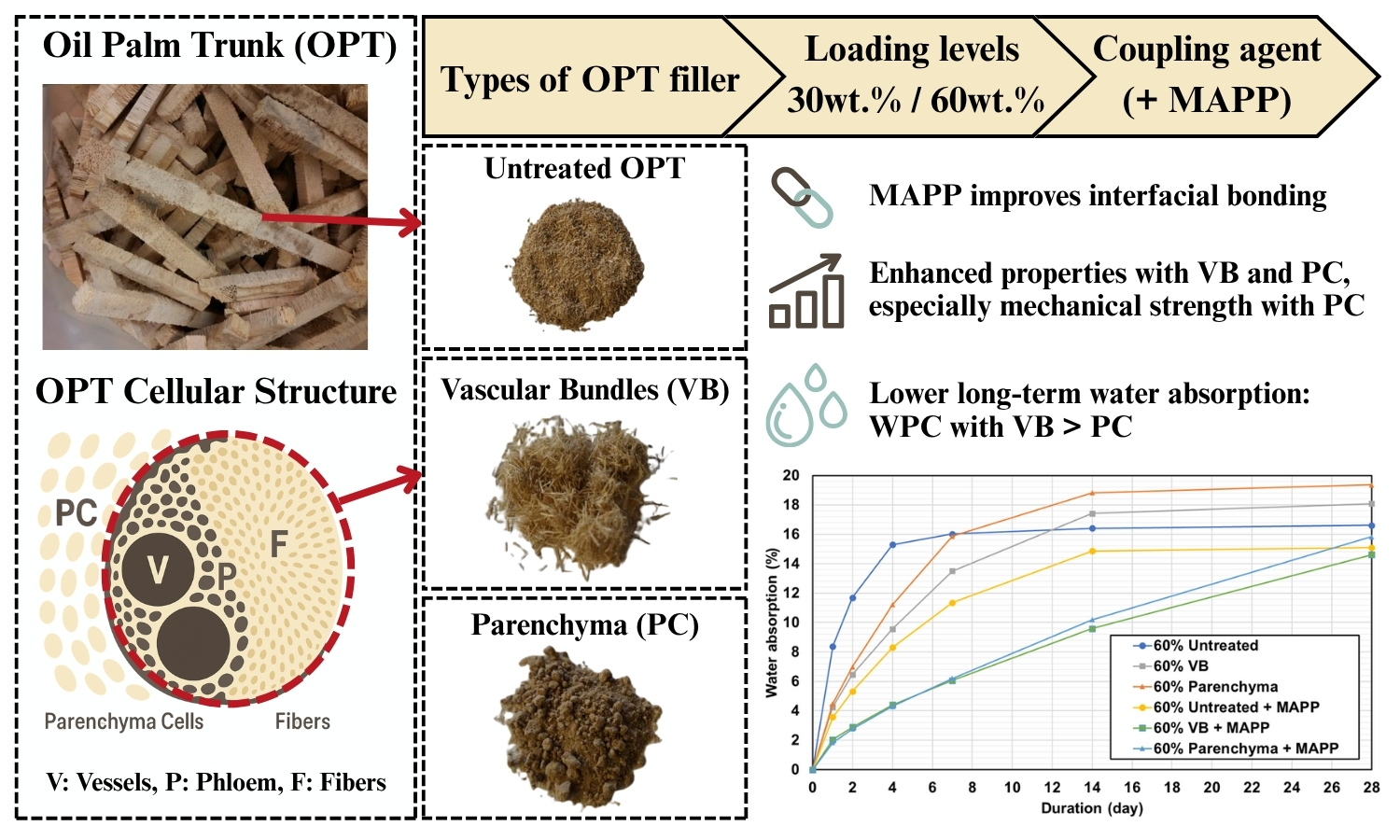

Kanokorn Sae-Ueng, Charoen Nakason, Andreas Krause

Vol. 19., No.10., Pages 994-1011, 2025

DOI: 10.3144/expresspolymlett.2025.75

Vol. 19., No.10., Pages 994-1011, 2025

DOI: 10.3144/expresspolymlett.2025.75

This study explores the mechanical properties and water resistance of polypropylene (PP) composites reinforced with oil palm trunk (OPT) components, specifically vascular bundles (VB) and parenchyma cells (PC) particles, at 30 and 60 wt% content levels. The research addresses challenges posed by the inherent variability in density and moisture sensitivity of OPT in composite formulation. Utilizing a hot-pressing technique, we examined the effects of OPT type, filler content, and the addition of a maleic anhydride-grafted polypropylene (MAPP) coupling agent. The findings reveal that VB- and PC-reinforced PP composites show enhanced density, moisture resistance, and overall mechanical performance relative to untreated OPT. Notably, while increasing OPT content improves modulus and density, it negatively impacts tensile and flexural strengths due to poor interfacial bonding. The incorporation of MAPP significantly enhances interfacial adhesion between the PP matrix and OPT fillers, leading to reduced moisture uptake and dimensional swelling, particularly at higher filler loadings. These results highlight the potential of VB and PC as sustainable reinforcement materials for wood-plastic composites (WPC), providing critical insights for optimizing composite designs aimed at improving durability and water resistance.

Joanna Szymańska, Wojciech H. Bednarek, Włodzimierz Urbaniak, Paweł Brzęk, Dominik Paukszta

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

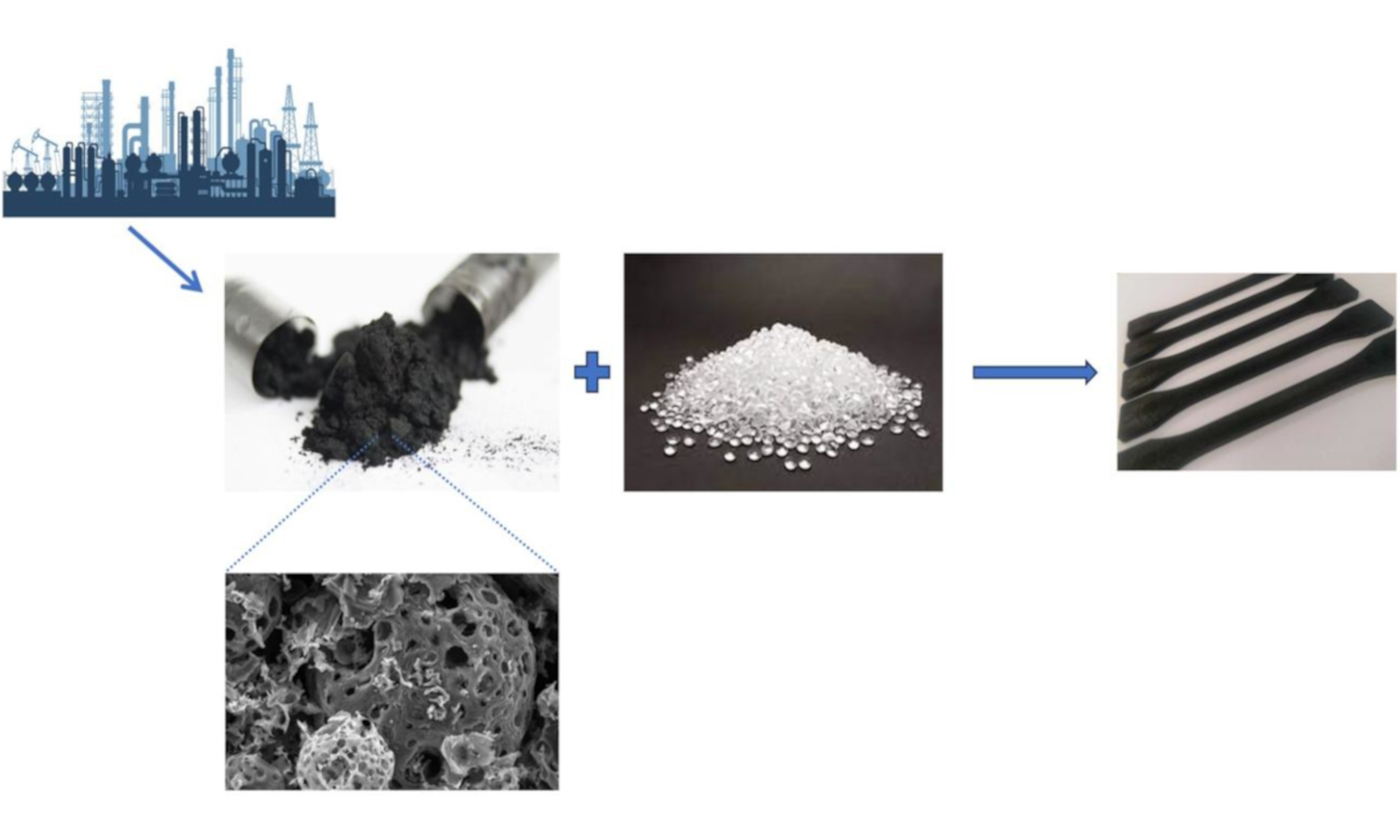

Crude oil, a natural hydrocarbon mixture, is a key energy source and the petrochemical industry’s primary feedstock. Its large-scale processing produces heavy oil fly ash (HOFA), a solid waste that demands effective management. This study explores HOFA’s valorization as a low-cost, carbon-based filler in isotactic polypropylene (iPP) composites. Composites containing 1–20 wt% HOFA were prepared by extrusion and injection molding, then subjected to tensile, impact, and structural analyses (differential scanning calorimetry (DSC), wide angle X-ray scattering (WAXS), microscopy). Mechanical testing revealed that even small HOFA additions raised Young’s modulus proportionately to filler content, consistent with typical filled-polymer behavior. Impact strength increased by roughly 25% at both 1 and 20 wt% loadings, while tensile strength and elongation at break remained comparable to neat iPP. DSC and WAXS demonstrated that HOFA acts as a nucleating agent, promoting the β-crystalline phase, known to enhance toughness, without significantly altering the melting or crystallization temperatures.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

Lumirca Del Valle Espinoza León, Viviane Alves Escócio, Leila Lea Yuan Visconte, Ana Maria Furtado de Sousa, Ana Lúcia Nazareth da Silva, Elen Beatriz Acordi Vasques Pacheco

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

Vol. 19., No.1., Pages 76-93, 2025

DOI: 10.3144/expresspolymlett.2025.6

This study uses a rotomolding procedure to produce hollow cubes made of linear low-density polyethylene (LLDPE) and coconut fibers (CF). The purpose is to investigate the effect of different CF content (0, 5, 12.5, and 20 wt%) and size (100 and 50 mesh) on composite properties. As the CF content rises, the density of all composites decreases due to an increase in material porosity, a result of poor adhesion between the fiber and LLDPE. Impact strength reduced as the content of CF increased, except for the composite with 5 wt% of CF and 50 mesh size. The ineffective adhesion between coir fibers and LLDPE, along with the presence of voids in the matrix, caused the mechanical properties to deteriorate as the CF content increased. The flammability test revealed that all samples dripped. The neat LLDPE sample deformed, whereas the LLDPE/CF composites maintained their shape. This behavior suggests that CF plays a structural role in burning composites. Maleic anhydride-grafted polyethylene (MAPE), calcium stearate, and magnesium stearate additives did not contribute to reducing the composite’s porosity. MAPE was the only additive that did not reduce the elastic modulus of composites.