Optimization of 3D-printed wing spars via multi-material and graded infill additive manufacturing: An experimental study

Hamza Qayyum, Borhen Louhichi, Malik Hassan, Babar Ashfaq, Muhammad Sulaiman, Muhammad Bilal Khan, Nashmi H. Alrasheedi, Ghulam Hussain

Vol. 19., No.11., Pages 1173-1187, 2025

DOI: 10.3144/expresspolymlett.2025.86

DOI: 10.3144/expresspolymlett.2025.86

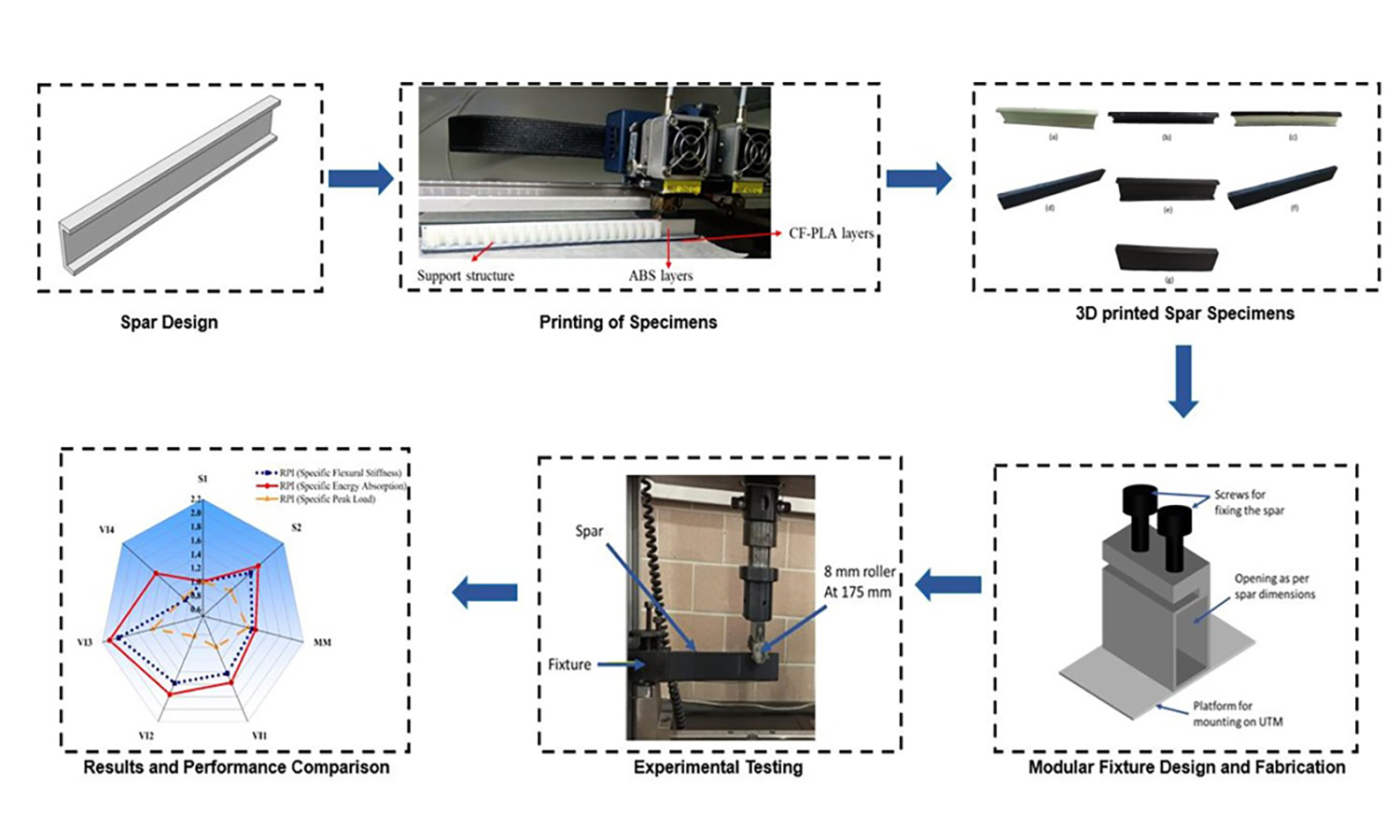

GRAPHICAL ABSTRACT

ABSTRACT

To reduce fuel consumption and extend flight time, the aerospace industry has focused on lightweight design. Achieving this without compromising structural integrity has been challenging. However, innovative additive manufacturing offers new opportunities for practical solutions. This study presents two methods: multi-material additive manufacturing (MMAM) and variable infill density additive manufacturing (VIDAM), aimed at reducing structural weight while maintaining mechanical performance. These methods were applied to a wing spar, a test geometry based on stress distribution principles from laminated beam mechanics. The structures produced with these new approaches showed improved mechanical responses compared to those made with traditional additive manufacturing techniques. A maximum increase of 91% in load-carrying capacity and a 34.8% increase in specific energy absorption were observed. scanning electron microscopy analysis revealed that layer bonding and material diffusion greatly influenced the mechanical performance. Although the study was conducted on small-scale models, the design concepts can be adapted to large-scale industrial applications that benefit from lightweight structures, such as the aerospace and automotive.

RELATED ARTICLES

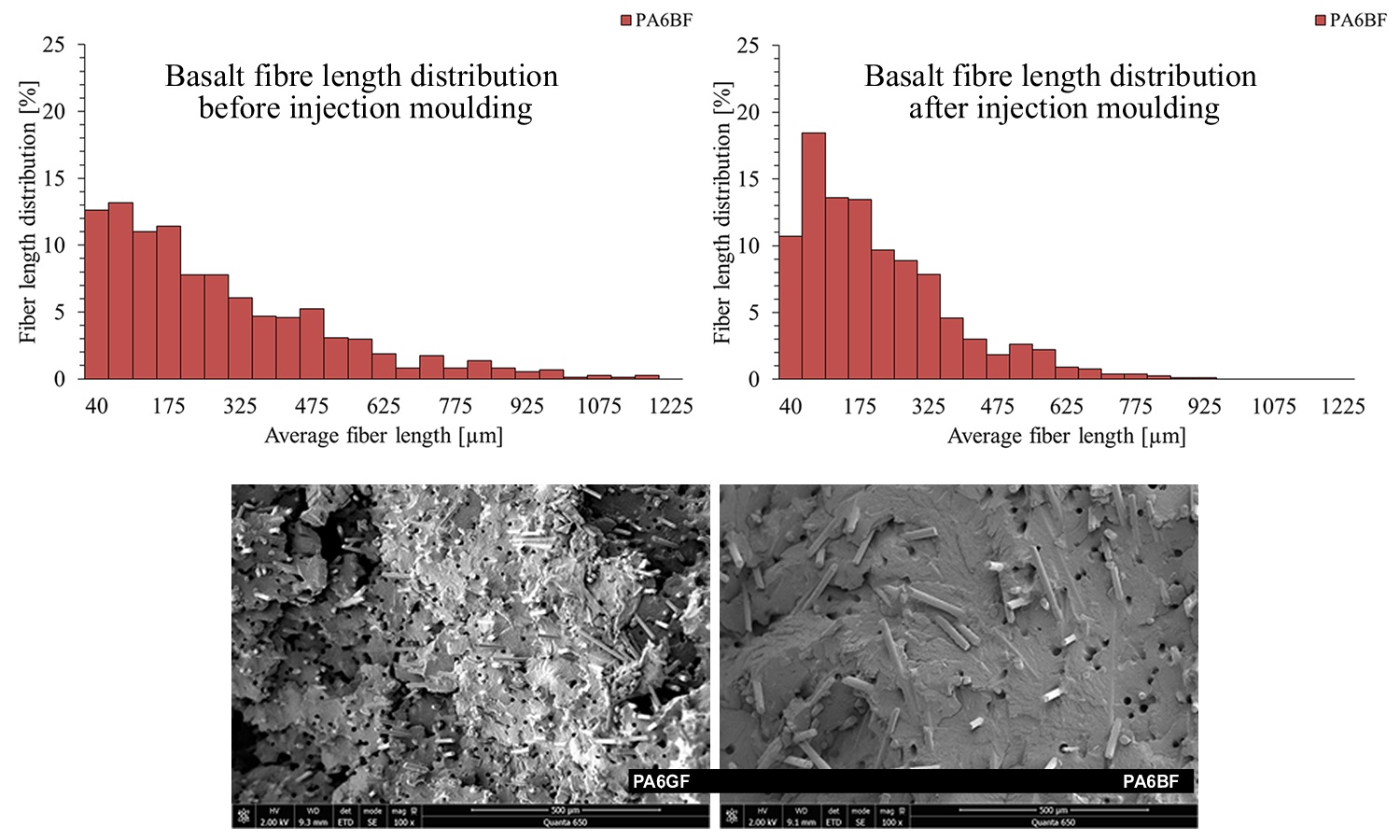

Rebeka Lorber, József Gábor Kovács, Andreas Hausberger, Polona Umek, Miroslav Huskić, Aleš Hančič

Vol. 19., No.11., Pages 1133-1143, 2025

DOI: 10.3144/expresspolymlett.2025.83

Vol. 19., No.11., Pages 1133-1143, 2025

DOI: 10.3144/expresspolymlett.2025.83

With the increasing use of e-mobility, the demand for high-quality materials to produce polymer gears is growing. Due to the tendency towards using natural materials and reducing carbon footprint, basalt fibers (BF) are tested as a substitute for glass fibers (GF). For this purpose, composites of polyamide 6 (PA6) with GF and BF, with and without compatibilizer and polytetrafluoroethylene (PTFE) are produced, tested, and properties compared. The mechanical, thermomechanical, thermal, and tribological properties of the composites, as well as the size of the fibers after the production of the composites and after injection molding, are determined. The compatibilizer improves the impact strength, while the glass fibers have a better reinforcing effect. The fibers increase crystallinity, but the effect is minimal. The thermal conductivity increases approximately the same for both fibers and is highest at composites that, in addition to 30% fibers, also contain PTFE. The tribological properties are comparable but slightly better for glass fibers. The fiber length is greatly reduced during the production of the composites and is around 200–300 μm in both cases. SEM imaging and mapping analysis show good dispersion of the fibers in the polymer and relatively poor compatibility with PA6.

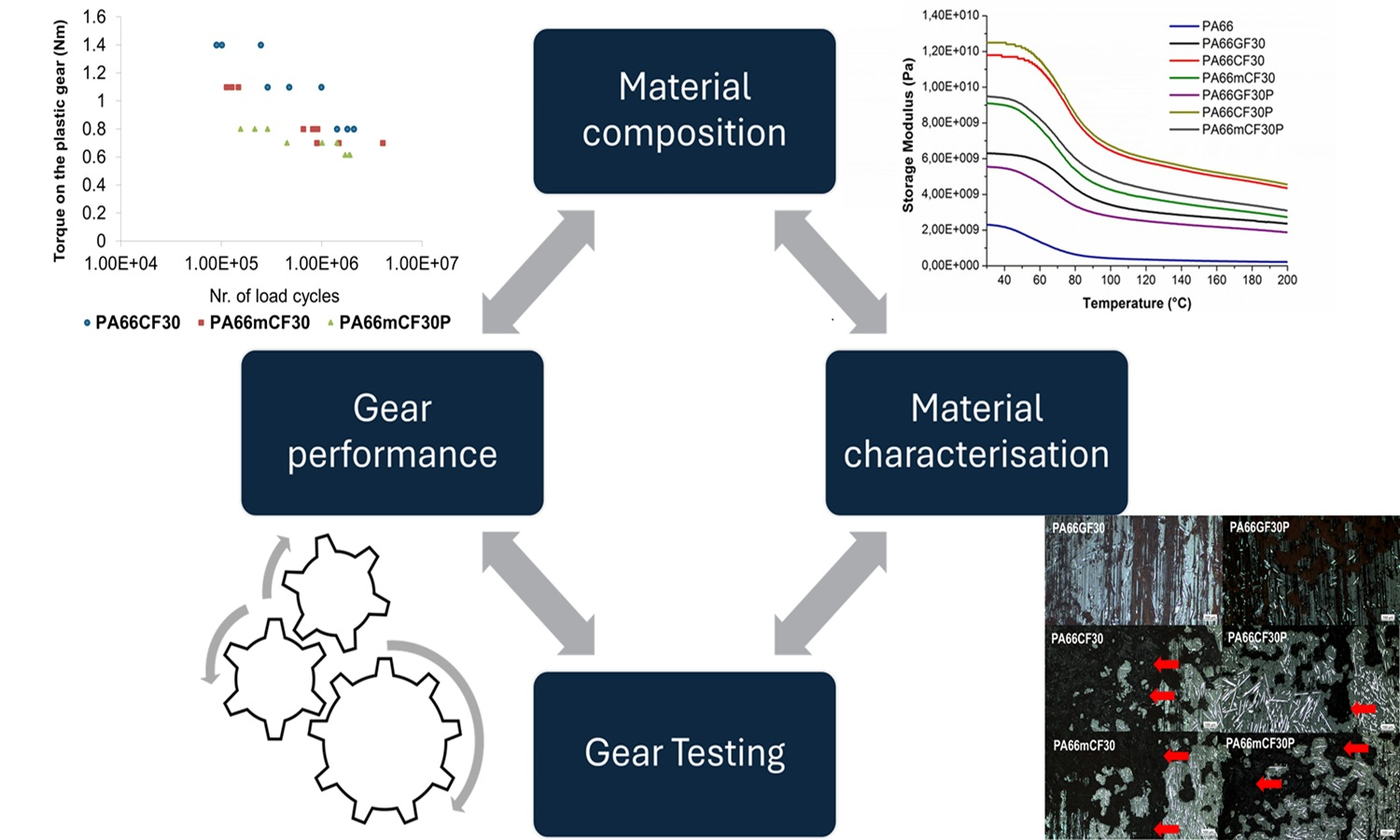

Rebeka Lorber, Janez Slapnik, Borut Černe, Andreas Hausberger, Jan Sumfleth

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

Vol. 19., No.10., Pages 1073-1089, 2025

DOI: 10.3144/expresspolymlett.2025.80

The study investigates the use of repurposed milled carbon fibre (mCF) as reinforcement for polyamide 66 (PA66) in gear applications, addressing environmental and cost concerns of virgin carbon fibres. Neat PA66 and PA66 composites reinforced with mCF, glass fibres (GF), and carbon fibres (CF), with and without polytetrafluoroethylene (PTFE), were injection moulded and evaluated for microstructure (fibre length), thermal, mechanical, surface, and tribological properties, as well as gear performance under VDI 2736 guidelines. CF reinforced composites showed the highest modulus and tensile strength, followed by mCF and GF. PTFE reduced modulus and strength in binary composites. All reinforced composites significantly lowered the coefficient of friction (COF) and wear rate compared to neat PA66, with mCF showing the most notable improvements. PTFE slightly improved tribological performance only for GF (wear) and CF (COF) composites. In gear testing, binary composites outperformed neat PA66, with CF performing best, followed by mCF and GF. Ternary composites had slightly lower performance than their binary equivalents. Correlation analysis showed that gear performance is closely linked to structural integrity. Failure analysis revealed higher crack susceptibility in mCF reinforced gears due to shorter fibre length. The findings highlight mCF reinforced PA66 as a sustainable, cost-effective material for durable polymer gears.

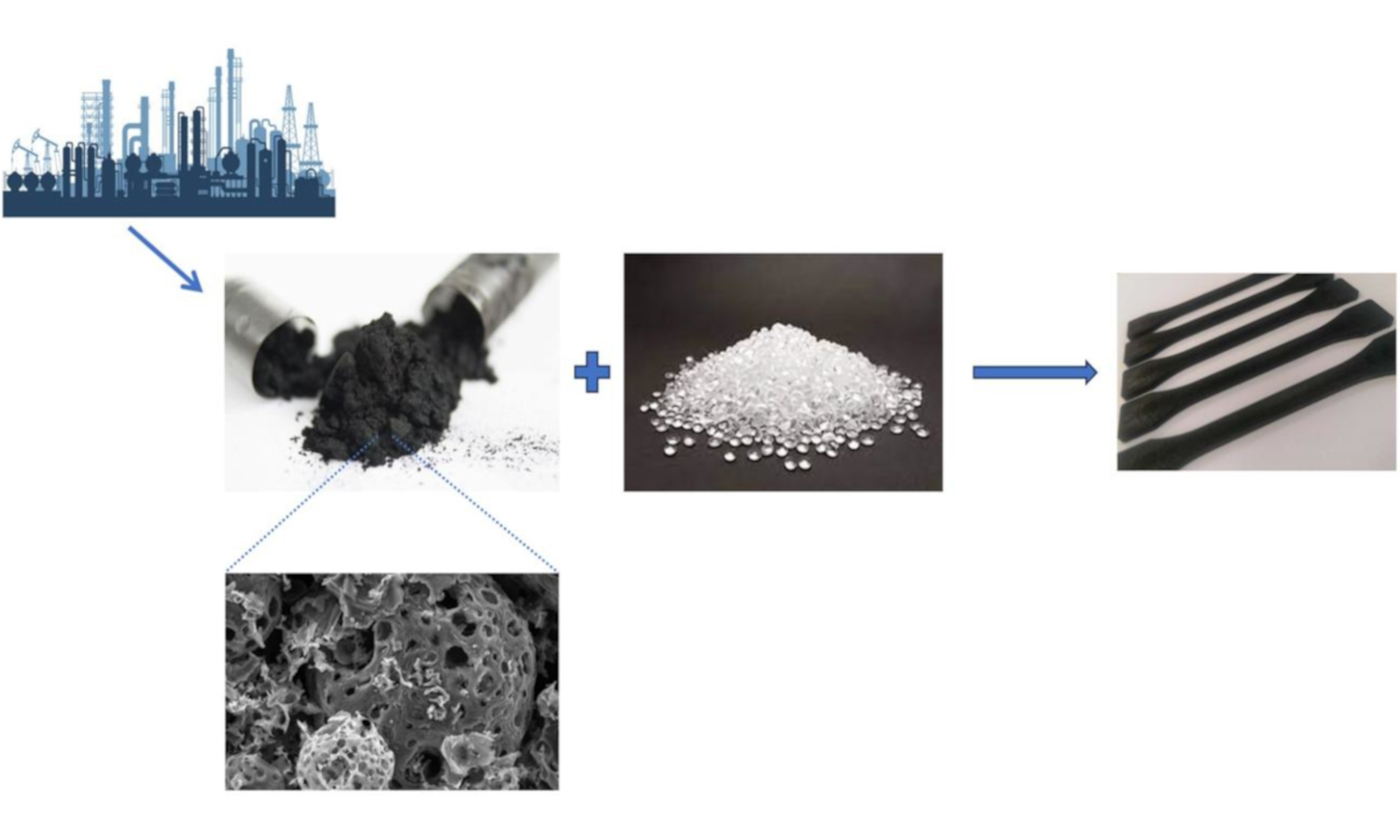

Joanna Szymańska, Wojciech H. Bednarek, Włodzimierz Urbaniak, Paweł Brzęk, Dominik Paukszta

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

Vol. 19., No.9., Pages 946-958, 2025

DOI: 10.3144/expresspolymlett.2025.71

Crude oil, a natural hydrocarbon mixture, is a key energy source and the petrochemical industry’s primary feedstock. Its large-scale processing produces heavy oil fly ash (HOFA), a solid waste that demands effective management. This study explores HOFA’s valorization as a low-cost, carbon-based filler in isotactic polypropylene (iPP) composites. Composites containing 1–20 wt% HOFA were prepared by extrusion and injection molding, then subjected to tensile, impact, and structural analyses (differential scanning calorimetry (DSC), wide angle X-ray scattering (WAXS), microscopy). Mechanical testing revealed that even small HOFA additions raised Young’s modulus proportionately to filler content, consistent with typical filled-polymer behavior. Impact strength increased by roughly 25% at both 1 and 20 wt% loadings, while tensile strength and elongation at break remained comparable to neat iPP. DSC and WAXS demonstrated that HOFA acts as a nucleating agent, promoting the β-crystalline phase, known to enhance toughness, without significantly altering the melting or crystallization temperatures.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

These findings confirm that HOFA, a waste by-product, can be an effective filler for iPP, improving stiffness and impact resistance without compromising other key properties. Its use offers both economic advantages, through reduced material costs, and environmental benefits by diverting industrial waste from disposal. This approach holds promise for developing sustainable, high-performance polymer composites.

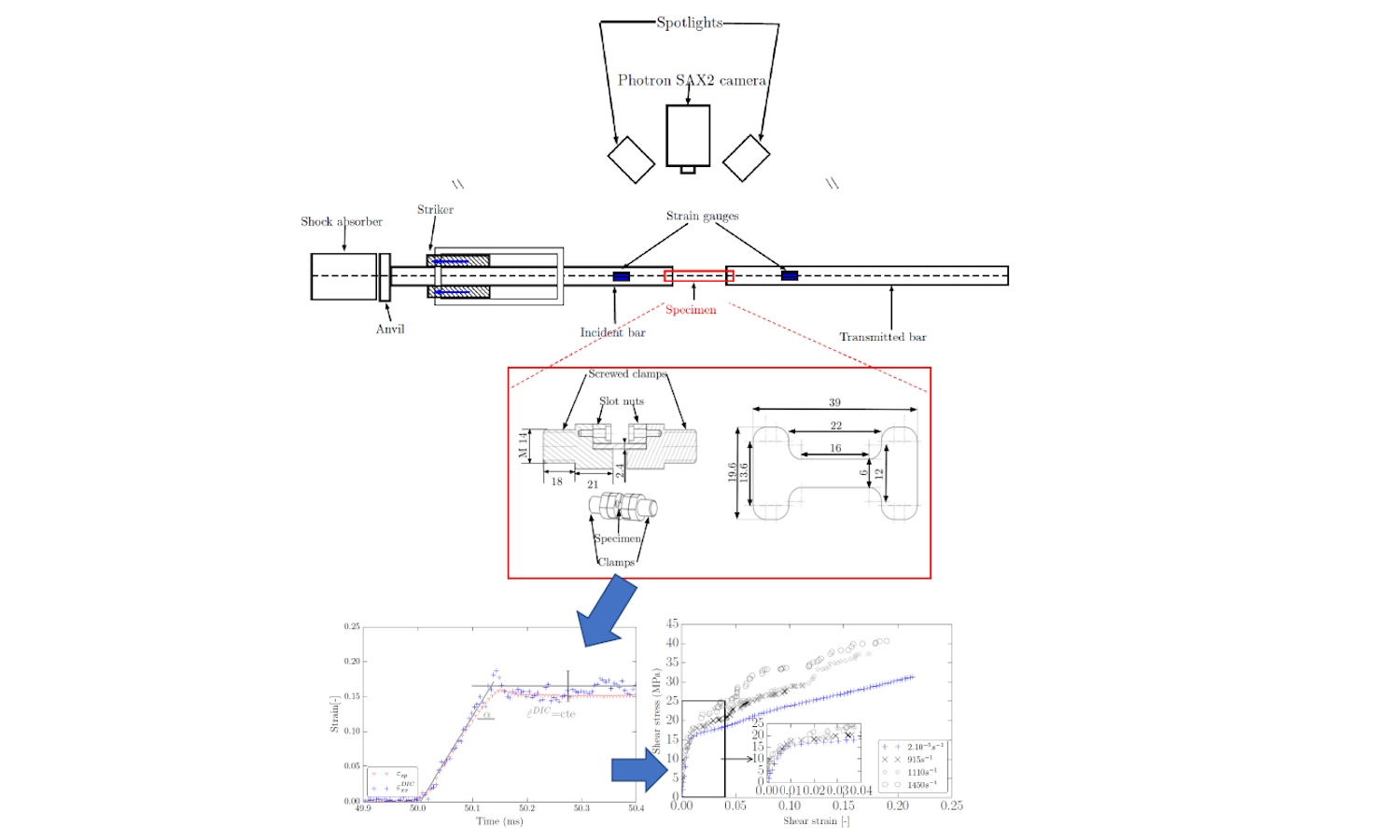

Magali Castres, Aboulghit El Malki Alaoui, Camille Caisso, Martin Monloubou, Michel Arrigoni

Vol. 18., No.10., Pages 1008-1022, 2024

DOI: 10.3144/expresspolymlett.2024.77

Vol. 18., No.10., Pages 1008-1022, 2024

DOI: 10.3144/expresspolymlett.2024.77

Nowadays, ultra high molecular weight polyethylene (UHMWPE), allows the combination of lightweight, high strength and is praised for the design of severely loaded structures. It has become a good option for lightweight armour solutions. It is therefore important to characterise its mechanical behaviour. Up to now, strain rate effects on mechanical behaviour have been poorly explored. In this work, this issue is tackled by studying the strain rate influence on the in-plane deformation, in shear and tension of the Tensylon® HSBD30A, a UHMWPE dedicated to ballistic and blast protection. Two laminates of Tensylon® of respective orientation [0 °/90°]20 and [±45°]20 were subjected to static and split Hopkinson tensile bar (SHTB) tests. A new mounting system was designed, and new specimen shapes were used to match the experimental setup configurations. Digital image correlation (DIC) was used to measure the in-plane strain. A significant strain-rate dependence on the material behaviour.is evidenced. Besides, results exhibit a higher strength for the [0°/90°]20 specimen than for the [±45°]20 one. Despite some limitations, the proposed setup and measurement methods allowed visualisation of strain rate effects on the stress-strain relationship for strain rates ranging from the quasi-static regime to the dynamic one (1500 s–1).