Effect of maleic anhydride concentration on the properties of polyoxymethylene and recycled polyvinyl butyral blends

Emiliano González-Rodríguez, Grecia Michelle Ramírez-Paredes, Ulises Figueroa-López , Elvia Patricia Sánchez-Rodríguez

, Elvia Patricia Sánchez-Rodríguez , Andrea Guevara-Morales

, Andrea Guevara-Morales

, Elvia Patricia Sánchez-Rodríguez

, Elvia Patricia Sánchez-Rodríguez , Andrea Guevara-Morales

, Andrea Guevara-Morales

Vol. 19., No.11., Pages 1144-1160, 2025

DOI: 10.3144/expresspolymlett.2025.84

DOI: 10.3144/expresspolymlett.2025.84

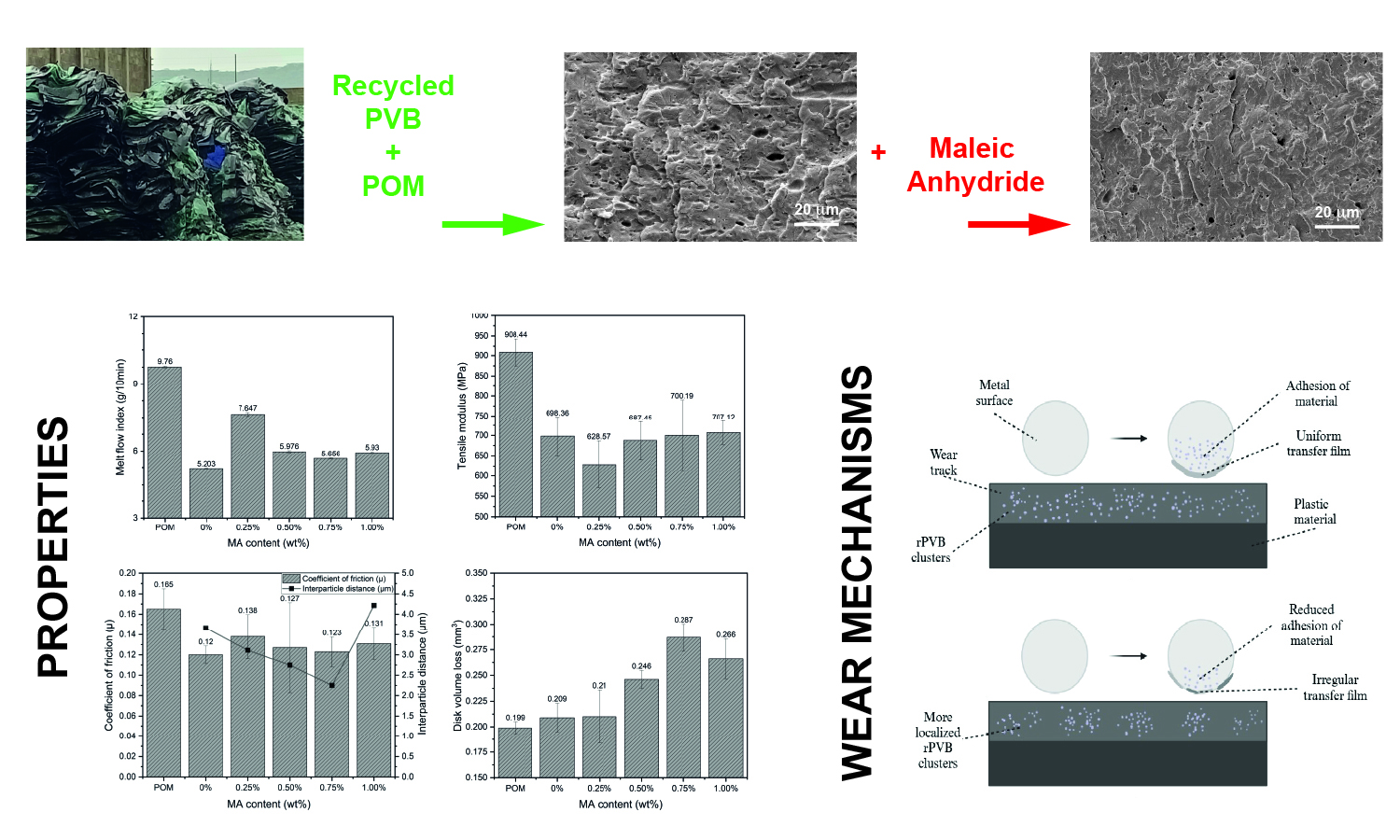

GRAPHICAL ABSTRACT

ABSTRACT

Maleic anhydride (MA) is widely used to modify plastics and as a compatibilizer in recycling. This study examines the effect of varying MA concentrations on blends of polyoxymethylene (POM) and recycled polyvinyl butyral (rPVB) from automotive windshields. Morphological analysis showed that MA contents between 0.25 and 0.75 wt% led to smaller, more closely dispersed rPVB particles, indicating enhanced phase miscibility. Rheological and thermal analyses revealed up to a 47% increase in melt flow index at lower MA concentrations, and improved interfacial interactions and crystallinity at higher levels. The tensile modulus dropped by 10% at 0.25 wt% MA but increased with further additions; tensile strength and Shore D hardness remained unaffected. Impact strength improved by up to 65% with MA addition, mainly due to increased ductility and a morphology characterized by larger rPVB domains and shorter interparticle distances at low MA contents. The coefficient of friction decreased with rPVB but increased with MA, along with higher volume loss. Microscopic wear analysis confirmed that rPVB dispersion, influenced by MA, was key to transfer film formation and surface lubrication. Thus, MA optimization enables tailored mechanical and tribological properties in POM/rPVB blends.

RELATED ARTICLES

Paulina Wiśniewska, Natalia A. Wójcik, Józef Haponiuk, Jacek Ryl, Henri Vahabi, Krzysztof Formela, Mohammad Reza Saeb

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

Vol. 19., No.9., Pages 878-892, 2025

DOI: 10.3144/expresspolymlett.2025.67

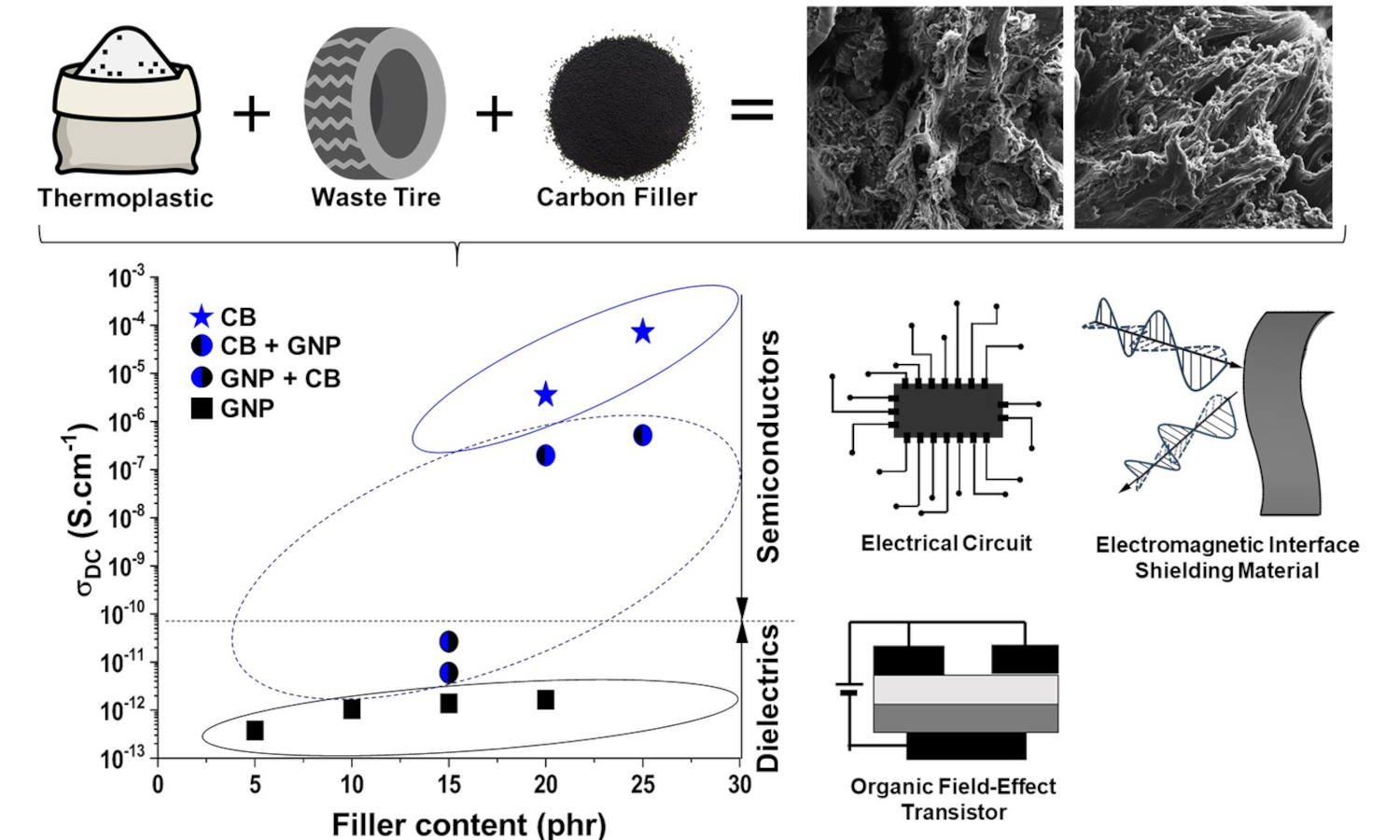

Waste rubber management through developing blends of thermoplastics with ground tire rubber (GTR) has gained significant attention for creating sustainable, high-performance materials with enhanced properties. In this work, we developed customized graphene/polymer nanocomposites applying GTR, ethylene-vinyl acetate copolymer (EVA), and graphene nanoplatelets (GNPs), taking carbon black (CB) as the reference additive. A wide range of electrical conductivity from 10–12 S/cm (dielectric) to 10–5 S/cm (semiconductor) was obtained for optimized composites containing GNPs and CB, respectively. Thermal, mechanical, and flame-retardant properties looked promising for additive manufacturing, while electrical conductivity was tailored for soft electronics. In view of processability, mechanical strength, and elasticity, GNPs-incorporated EVA/GTR composites showed an edge over their CB-aided counterparts. For example, tensile strength and elongation at break of EVA/GTR blends reinforced with 20 phr GNPs were 4.8 MPa and 681%, respectively, compared to 4.0 MPa and 651% for the composite comprising an identical amount of CB. Interestingly, combining GNPs and CB enhanced the thermal stability and flame retardancy of EVA/GTR compared to only GNPs or CB. These results were promising from both sustainability and advanced functional materials perspectives.

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

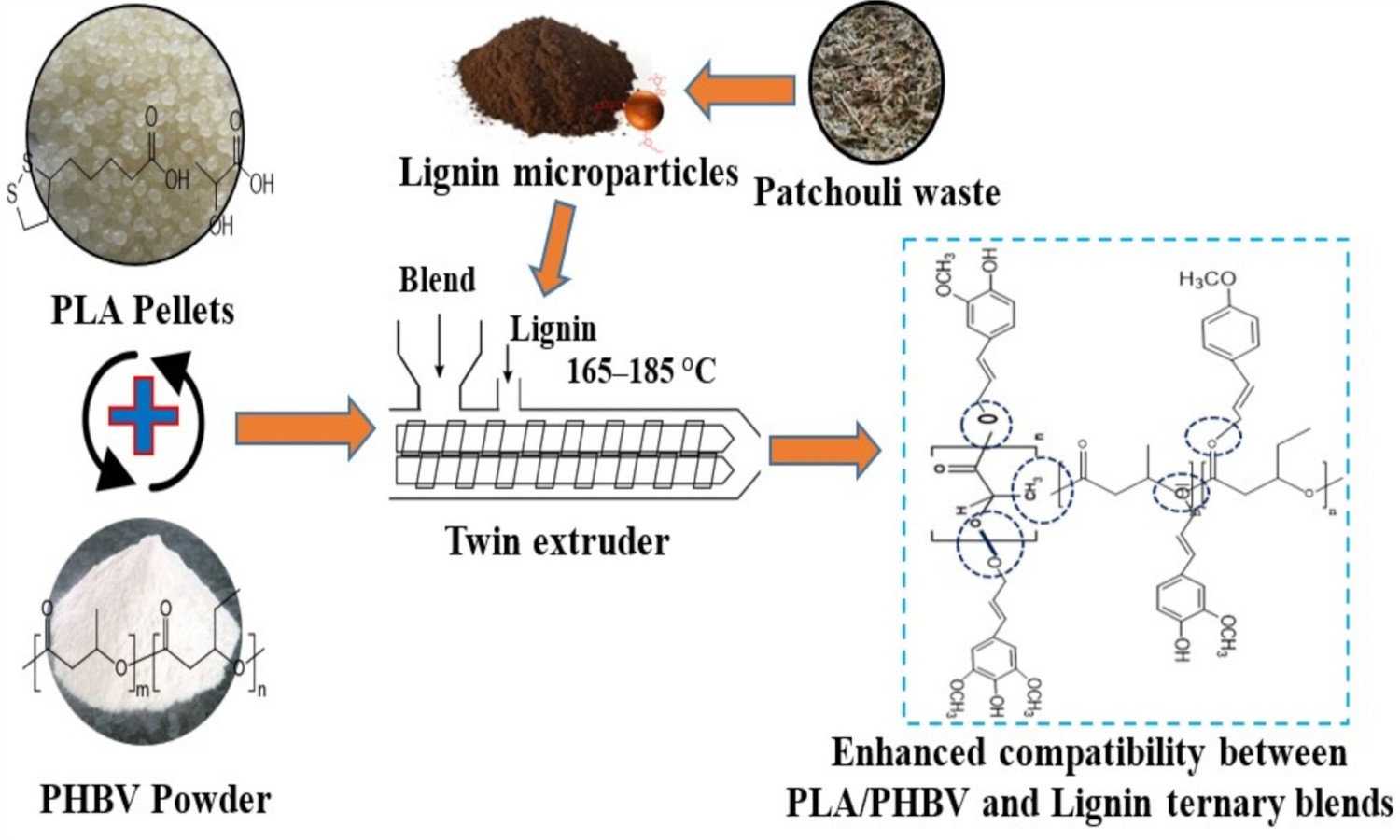

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

Ming Qiu Zhang

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

This is an editorial article. It has no abstract.

Csenge Tóth, Ábris Dávid Virág, László Mészáros

Vol. 18., No.4., Pages 348-348, 2024

DOI: 10.3144/expresspolymlett.2024.25

Vol. 18., No.4., Pages 348-348, 2024

DOI: 10.3144/expresspolymlett.2024.25

This is an editorial article. It has no abstract.