Becoming the symbol of recycling instead of consumption – 50 years of PET bottles

Ferenc Ronkay

Vol. 17., No.12., Pages 1180-1181, 2023

DOI: 10.3144/expresspolymlett.2023.89

DOI: 10.3144/expresspolymlett.2023.89

GRAPHICAL ABSTRACT

RELATED ARTICLES

Zaheer ul Haq, Teng Ren, Xinyan Yue, Krzysztof Formela, Denis Rodrigue, Xavier Colom Fajula, Tony McNally, Dong Dawei, Yong Zhang, Shifeng Wang

Vol. 19., No.3., Pages 258-293, 2025

DOI: 10.3144/expresspolymlett.2025.20

Vol. 19., No.3., Pages 258-293, 2025

DOI: 10.3144/expresspolymlett.2025.20

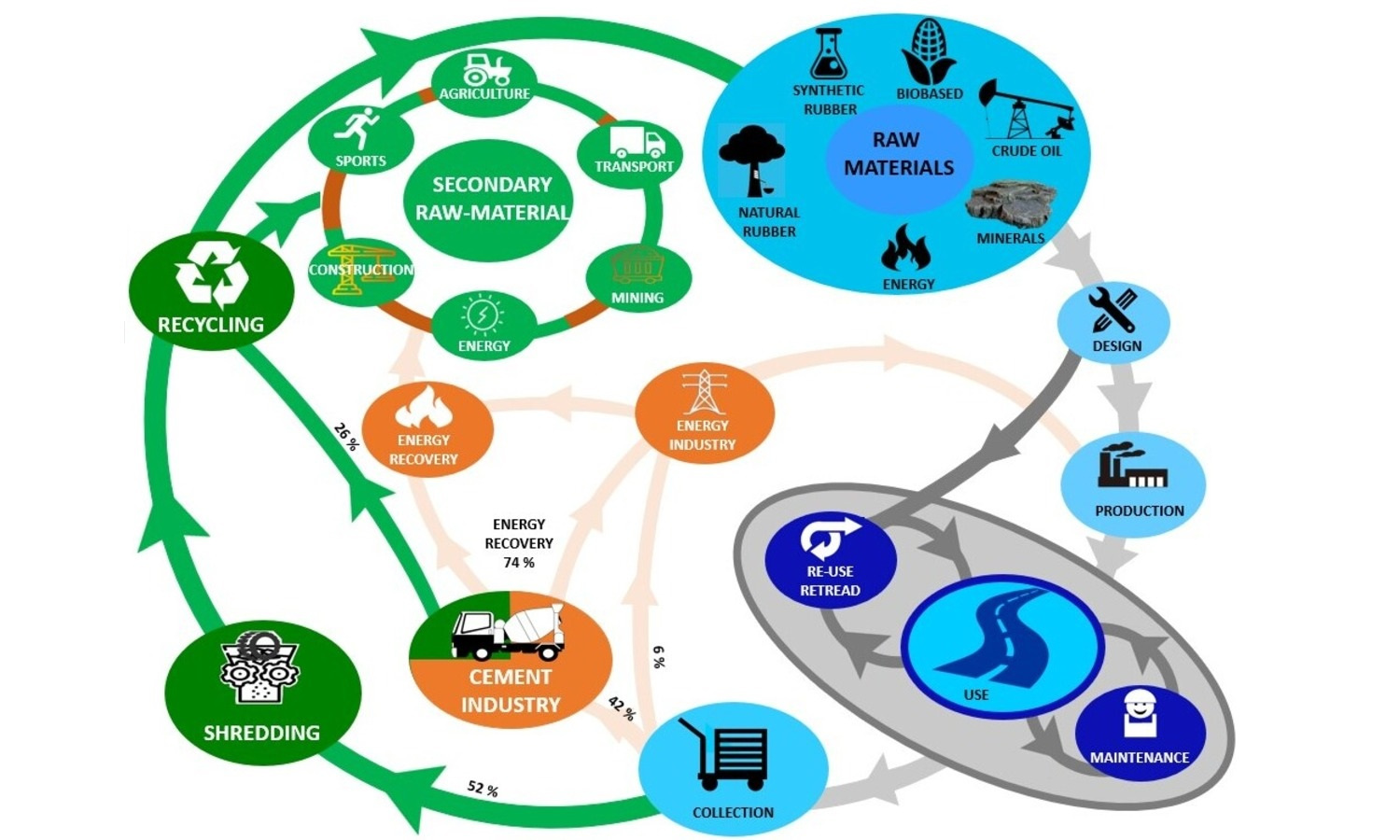

As a complex composite material, tire rubber has always presented significant environmental and waste management concerns due to its non-biodegradability and accumulation in landfills. The devulcanization of tire rubber has emerged as a historical challenge in the field of sustainable rubber engineering since Goodyear invented cross-linking in 1839. This review provides a comprehensive analysis of waste tire recycling processes, focusing on the sources, legislation, management strategies, and utilization across different regions. It explores the multifaceted challenges of devulcanizing rubber, with a specific focus on transitioning from ground tire rubber to the concept of multi-decrosslinking: sulfur bridge breakage, rubber chain depolymerization and micro-nano sized core-shell carbon black. Ideal devulcanization has restricted the release of reinforcing fillers, resulting in devulcanized rubber mainly containing dozens of micron particles, which hinder the wide usage of devulcanized rubber. This review comprehensively assesses the current state-of-the-art techniques for tire rubber devulcanization, including physical, chemical and biological methods. It explores the intricacies of ground tire rubber as a starting material, structural evolution of ground tire rubber during the devulcanization process and the associated challenges in achieving efficient devulcanization while retaining desirable mechanical properties. Furthermore, through an in-depth analysis of recent advancements, limitations and prospects, this paper offers a complete understanding of the challenges faced in tire rubber devulcanization. Considering the technical and environmental aspects of these processes, this work contributes to multi-decrosslinking, the ongoing discourse on sustainable materials development and circular economy initiatives, which pave the way for future innovations in the field of rubber recycling.

Wenxin Gan, Hanyu Xue, Hongyi Lin, Renjin Gao, Yuchi Zhang, Liwei Wang, Jiuping Rao

Vol. 19., No.3., Pages 311-325, 2025

DOI: 10.3144/expresspolymlett.2025.22

Vol. 19., No.3., Pages 311-325, 2025

DOI: 10.3144/expresspolymlett.2025.22

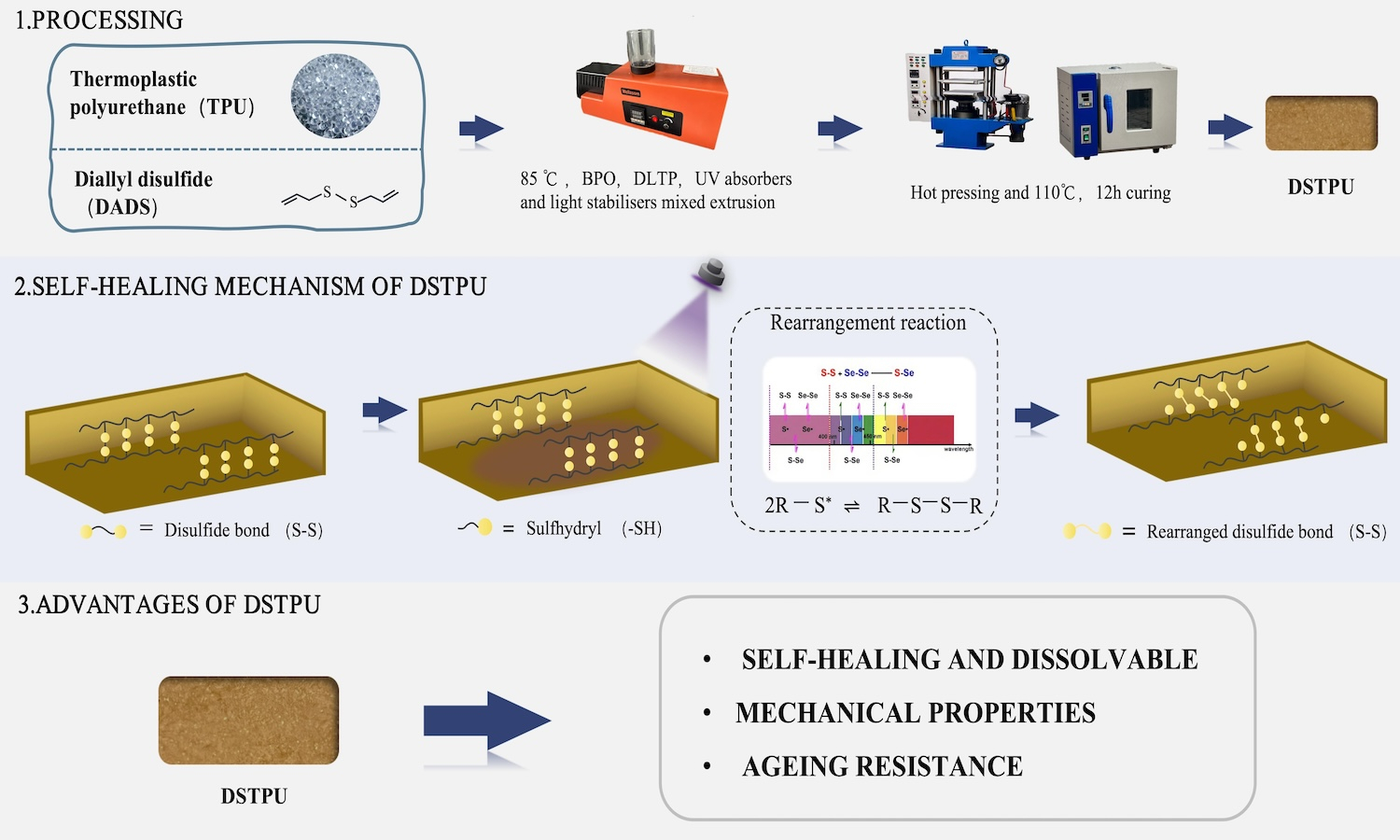

Cross-linking frequently enhanced the mechanical properties of linear polymeric materials; however, it also resulted in the transition from thermoplastic to thermosetting materials, which posed issues from an environmental perspective. Thermoplastic polyurethane (TPU) elastomers were extensively applied across various industries. To improve the mechanical properties of TPU while preserving its environmental benefits, this study integrated radical copolymerization technology to develop a reversible crosslinked TPU. Specifically, the linear polyurethane molecular chains were crosslinked using diallyl disulfide (DADS) as a functional cross-linking monomer. Through radical copolymerization reactions, reversible crosslinks formed from disulfide bonds were created between the linear polyurethane molecular chains, yielding a self-healing reversible crosslinked thermoplastic polyurethane (DSTPU). The study showed that DSTPU could self-heal and dissolve under UV light and alkaline N,N-dimethylformamide (DMF) conditions, achieving 82.2% self-healing efficiency at 3 phr DADS. It dissolved into fine particles in alkaline DMF. Disulfide bonds in DSTPU enhanced cross-linking, boosting 19% oxygen permeability, thermal conductivity (0.218 W/(m·K)), and mechanical properties like tensile stress (11.18 MPa), force (134.13 N), and elongation (548%). These bonds also enhanced aging resistance, cutting ΔYI to 6.0%.

Tuğba Erol, Eren Yıldırım, Işıl Acar

Vol. 18., No.12., Pages 1224-1264, 2024

DOI: 10.3144/expresspolymlett.2024.93

Vol. 18., No.12., Pages 1224-1264, 2024

DOI: 10.3144/expresspolymlett.2024.93

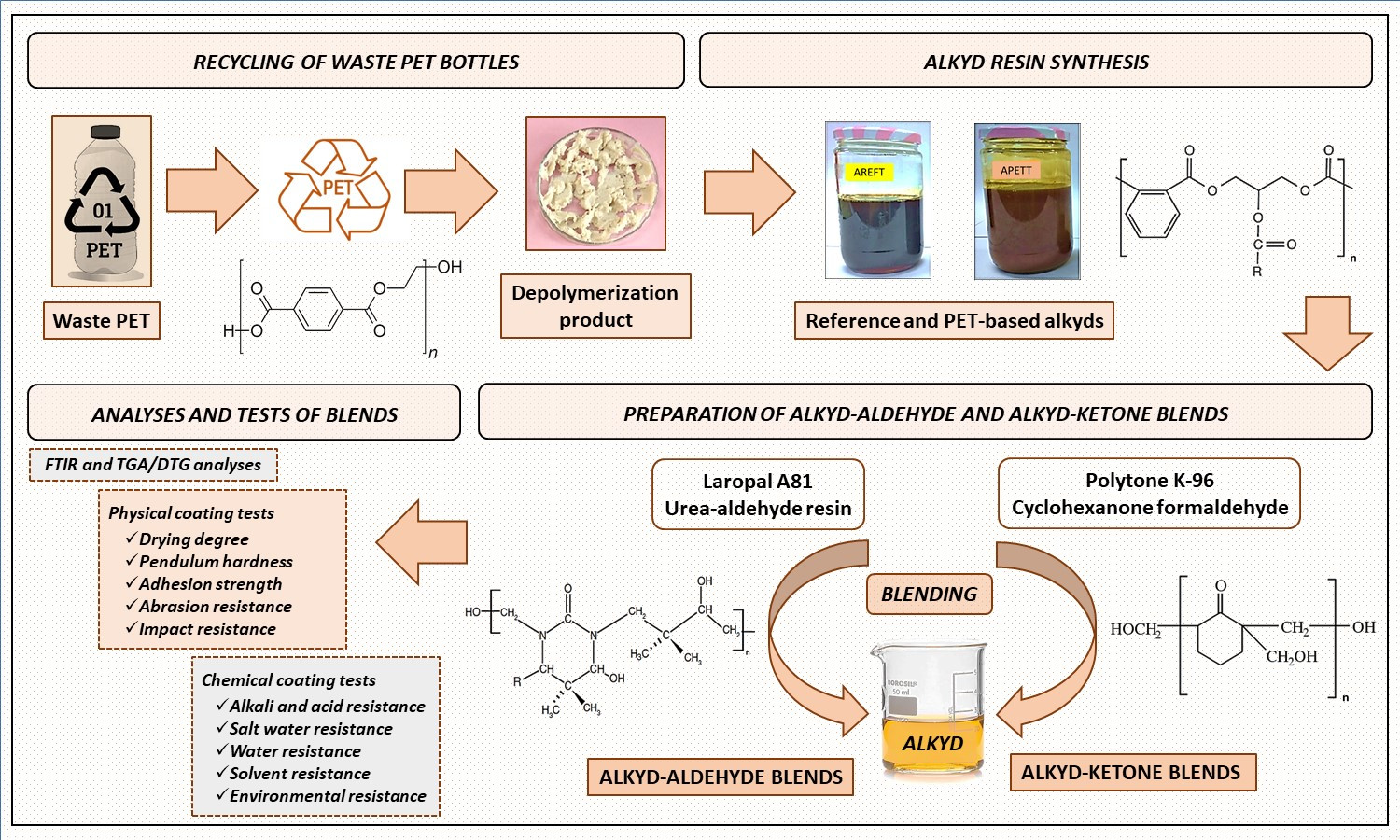

This study aims to develop alkyd-aldehyde and alkyd-ketone blends by modification of waste poly(ethylene terephthalate) (PET) based alkyd resin with urea-aldehyde (UA) and cyclohexanone formaldehyde (CHF) resins for use in coating applications. PET flakes were depolymerized by simultaneous hydrolysis-glycolysis reaction, and depolymerization product (DP) was used completely instead of the diol in the alkyd synthesis. For comparison, reference alkyds without PET were also synthesized. The effect of modifier resin at different ratios and the presence of DP on the coating and thermal properties of blend films were investigated. Medium-hard/hard and gloss/high gloss films with excellent adhesion and impact resistance were obtained from both blends. These films also demonstrated superior chemical and environmental resistance. Blends with CHF resin had better alkali resistance than those with UA resin. In PET-based blends, thermal resistance significantly increased with the addition of the CHF resin to the alkyd resin. Notably, the use of DP did not show a negative effect on the properties of alkyd resin and blend films. On the contrary, much better results were obtained than the alkyd resin alone. Overall, the modification with UA and CHF modifiers and using DP improved the coating properties of the blends. These blends are expected to be considered a sustainable and environmentally friendly alternative for designing versatile coatings for various applications.

Ming Qiu Zhang

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

Vol. 18., No.6., Pages 559-560, 2024

DOI: 10.3144/expresspolymlett.2024.41

This is an editorial article. It has no abstract.

Janka Bobek-Nagy, Róbert Kurdi, András Kovács, Lilla Simon-Stőger, Márton Szigeti, Csilla Varga

Vol. 17., No.11., Pages 1166-1179, 2023

DOI: 10.3144/expresspolymlett.2023.88

Vol. 17., No.11., Pages 1166-1179, 2023

DOI: 10.3144/expresspolymlett.2023.88

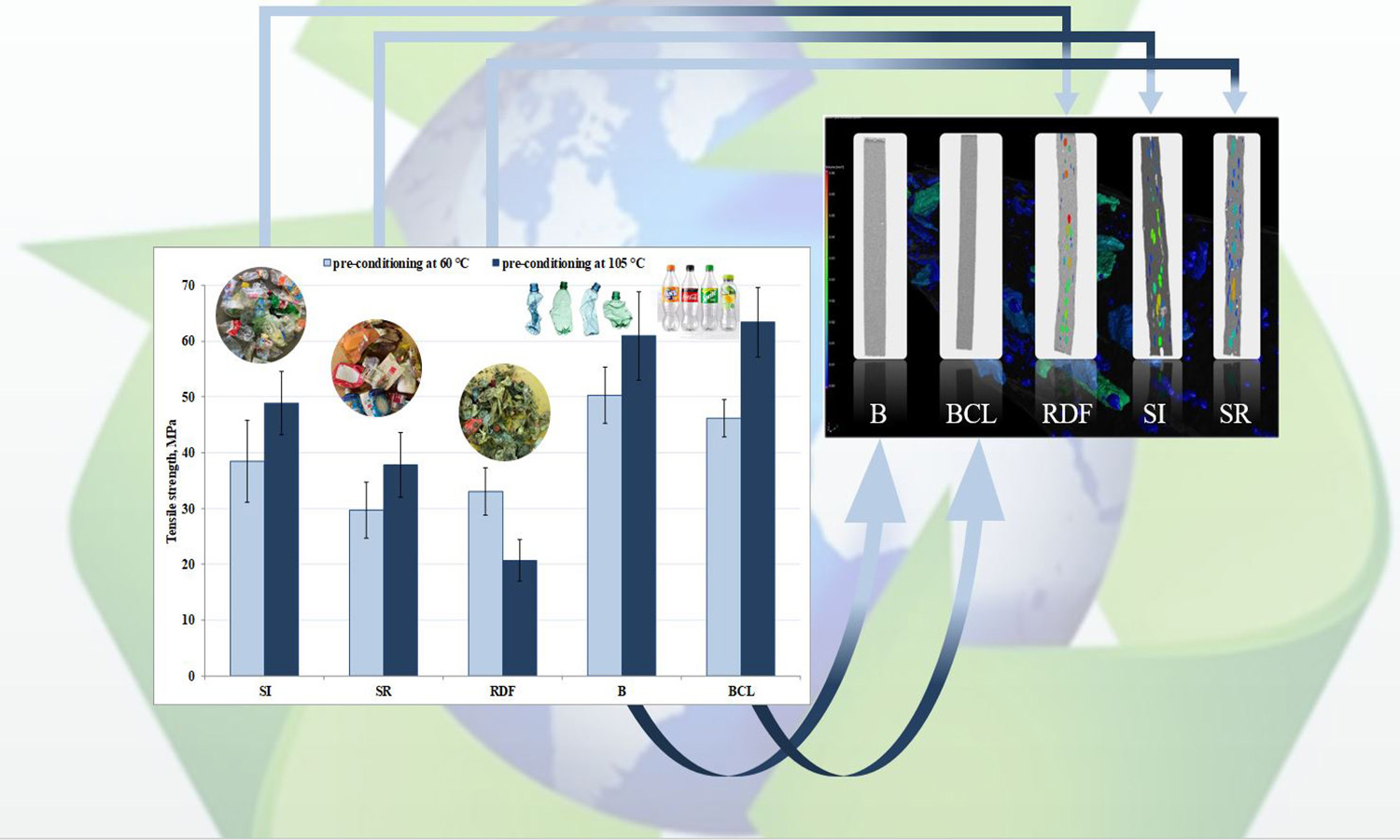

Under

the era of circular economy, the deposit-refund system (DRS) for e.g. polyethylene

terephthalate (PET) is thought to be a good choice to achieve a more structured

plastic recycling. The present research has the aim to make a comprehensive description

and a practical guideline in order to evaluate how collection and separation

system influence the quality and efficiency of mechanical recycling of PET. The

DRS has been symbolized by manually collected bottles with (BCL) and without

(B) caps and labels. Samples have been given from the selective income (SI) and

the sorting residue (SR) of a manual selective waste sorting plant and PET

fraction of refuse derived fuel (RDF). Based on preliminary qualification results

such as melt flow indices (MFI), PET bottles are worth selecting into the main

colours like water clear, blue, and all the others together, referred to as

PET-A, PET-B, and PET-D fractions of the sorting plant. The SR seemed to be a beneficial

raw material for PET recycling as both mechanical and rheological properties

were proper enough. PET separated from the Mechanical Biological Treatment

(MBT) plant as RDF showed the worst processing and mechanical properties, but

both can be improved with deeper precleaning. X-ray tomography (CT) scans have

shown a correlation between the source of waste and the gas void structure

which influence the macroscopic mechanical properties.