General trends in highly cited articles in Express Polymer Letters

Vol. 18., No.1., Pages 1-1, 2024

DOI: 10.3144/expresspolymlett.2024.1

DOI: 10.3144/expresspolymlett.2024.1

GRAPHICAL ABSTRACT

RELATED ARTICLES

Konrad Stefaniak, Anna Masek

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

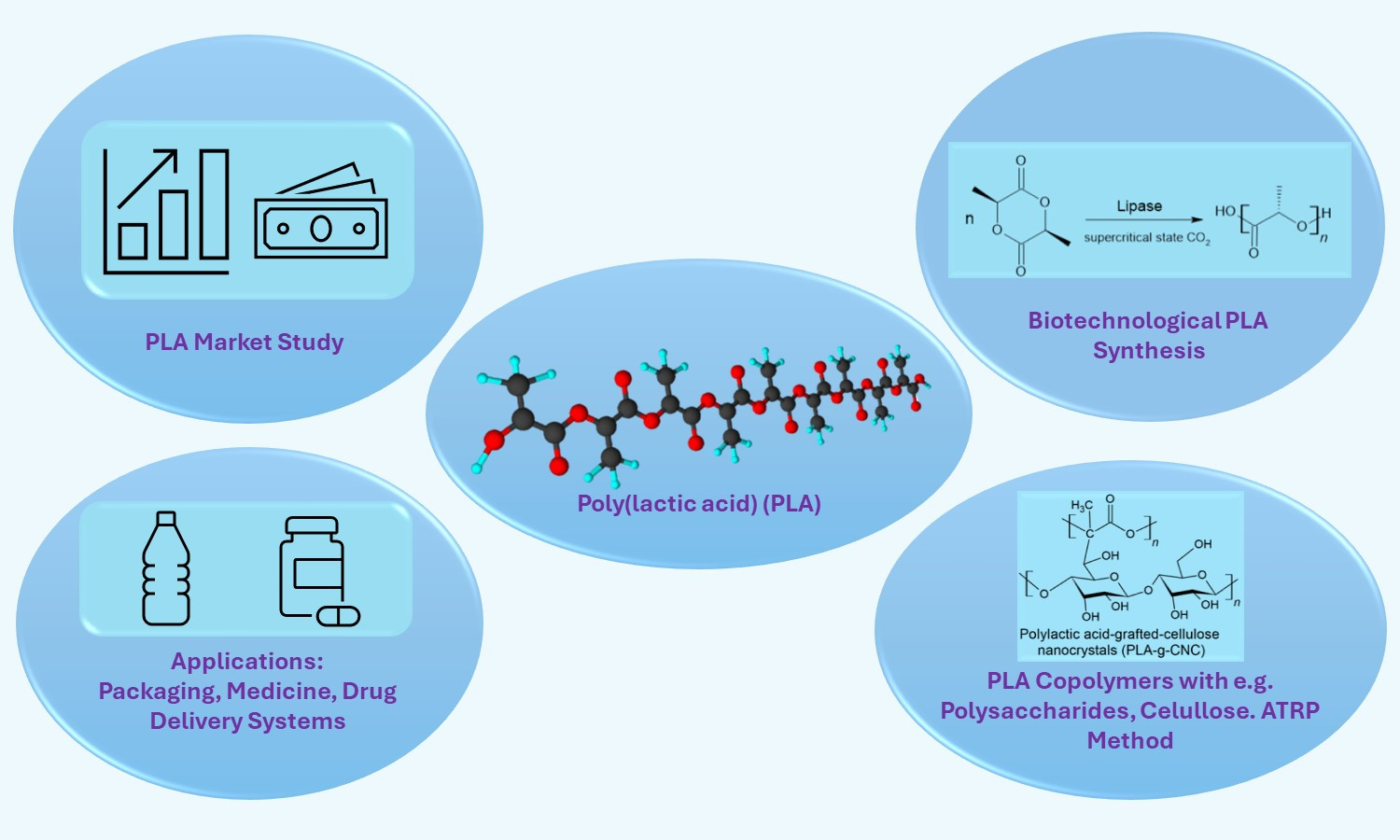

This review is focused on recent achievements in poly(lactic acid) (PLA) synthesis and copolymerization with special regard to biotechnological routes of PLA synthesis, which use bacteria/enzymes (e.g., enzymatic ring opening polymerization (eROP)). Besides PLA, also lactic acid (LA) synthesis is described and an emphasis is put on the biotechnological methods. Having regard to PLA copolymerization, this paper attempts to describe different types of PLA copolymers (such as block copolymers, PLA copolymers with polysaccharides, PLA-cellulose copolymer composites, and PLA polymer brushes). A detailed overview of the recent accomplishments in the field of PLA copolymers is presented. Various enhanced properties and applications of presented PLA copolymers are discussed. The attention is placed mainly on applications in the field of tissue engineering, drug delivery systems, and the packaging sector. Furthermore, a PLA market study and its economic forecast are presented. Eventually possible directions for future research in the field of PLA synthesis and copolymerization are indicated.

Ju Li, Lize Yang, Shuo Chen, Guotao Sun

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

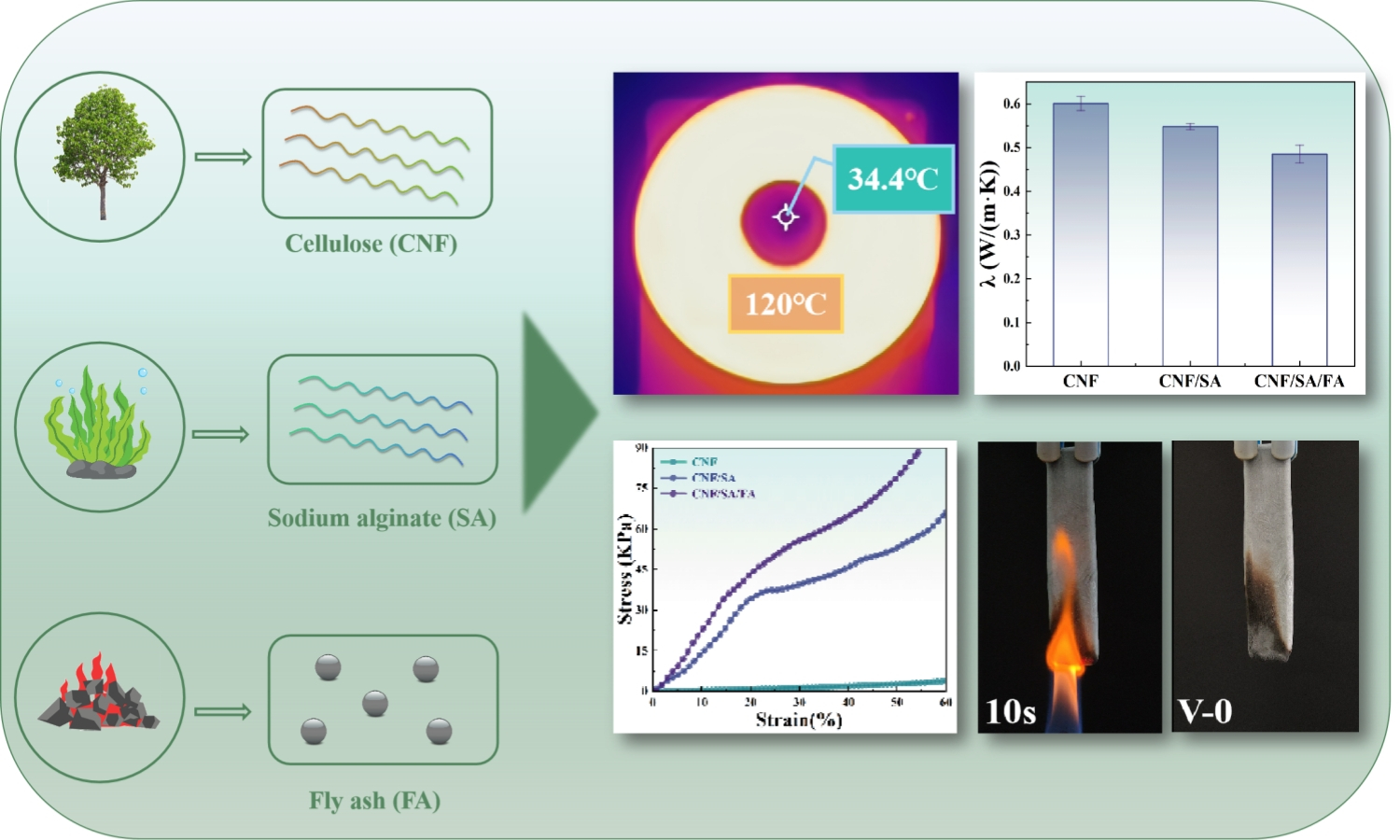

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

Chin-San Wu, Shan-Shue Wang, Dung-Yi Wu, Wanwen Gu

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

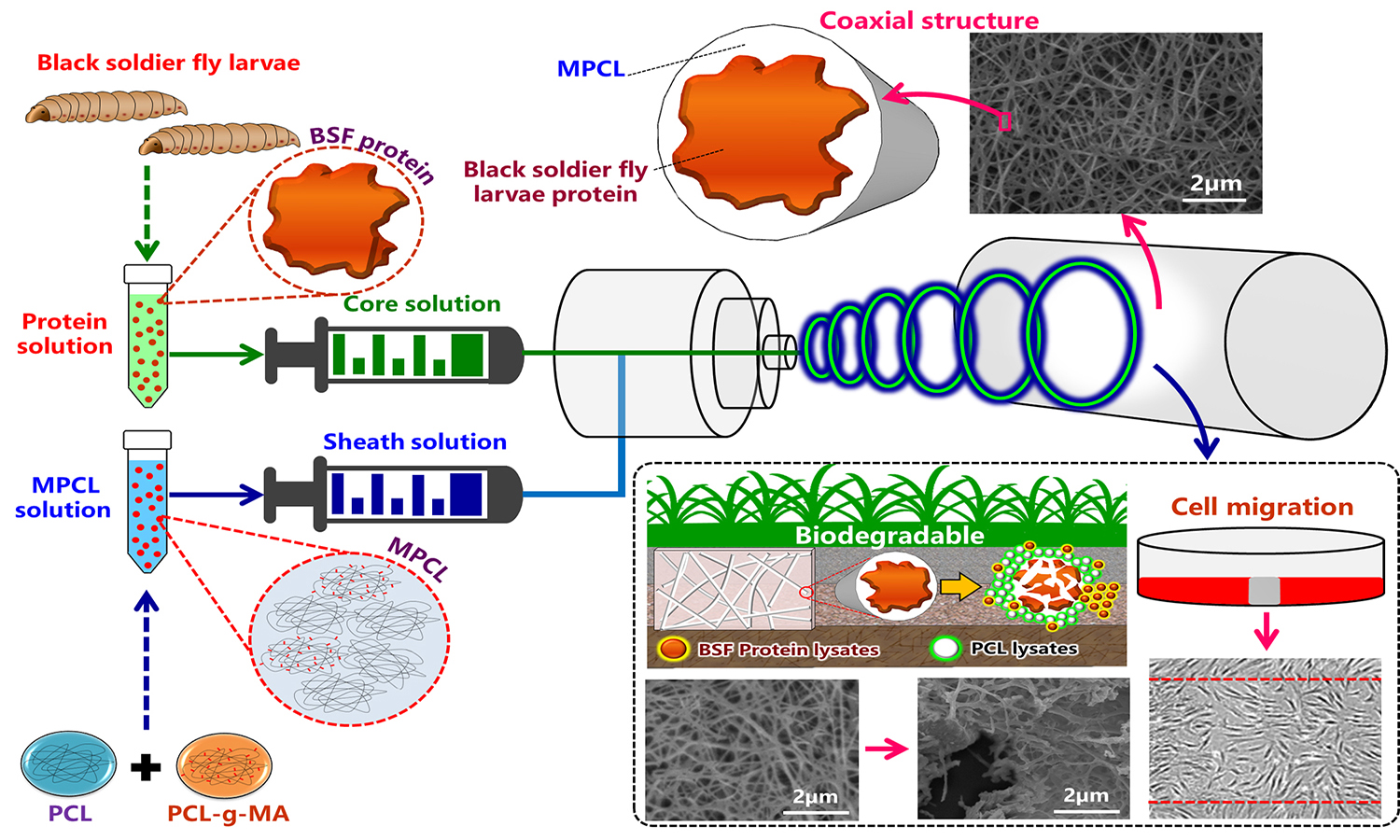

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.

Fatma Nur Parın, Hatice Dinç, Uğur Parın, Elife Kıldalı, Gökçe Taner

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

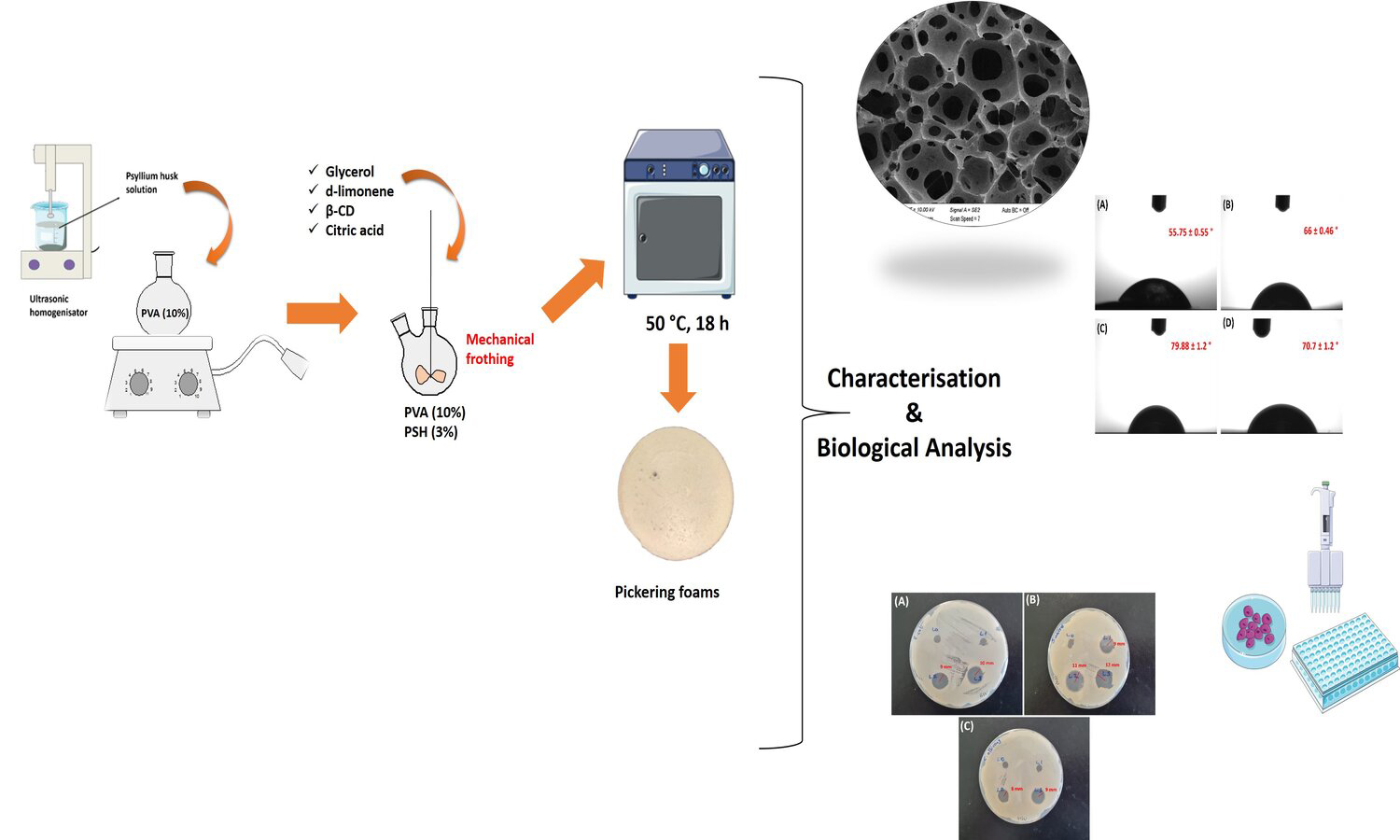

In this study, Pickering foamed emulsions have been prepared using β-cyclodextrin (β-CD), and d-limonene as a surfactant and an oil phase, respectively. The incorporation of β-CD/d-limonene inclusion complexes (ICs) in specific proportions (1:1, 1:3, and 1:5) to water phase, which is a polymer matrix composed of a mixture of polyvinyl alcohol (PVA) and psyllium husk (PSH) by mechanical frothing at high speed, and air bubbles have been formed in oil in water (o/w) emulsions. Ecofriendly bio-based foams have been developed in this method. Scanning Electron Microscope (SEM) analysis showed PVA/PSH Pickering foams usually open porous morphologies and the addition of d-limonene increases the amount of porosity from 43 to 49%. Although the resulting foams indicated similar thermal degradation profile, the presence of d-limonene in foams increased thermal stability. The surfaces of foams have a hydrophilic property with contact angles values lower than 80°. The tensile strength of foams decreased from 170 to 100 kPa due to the increased porosity. All foams indicated antibacterial activity to Staphylococcus aureus (S. aureus) with 9–12 mm zone inhibition. The incorporation of d-limonene into foams surprisingly decreased the cell viability. In brief, our findings show that the Pickering foams can be beneficial for wound healing applications.

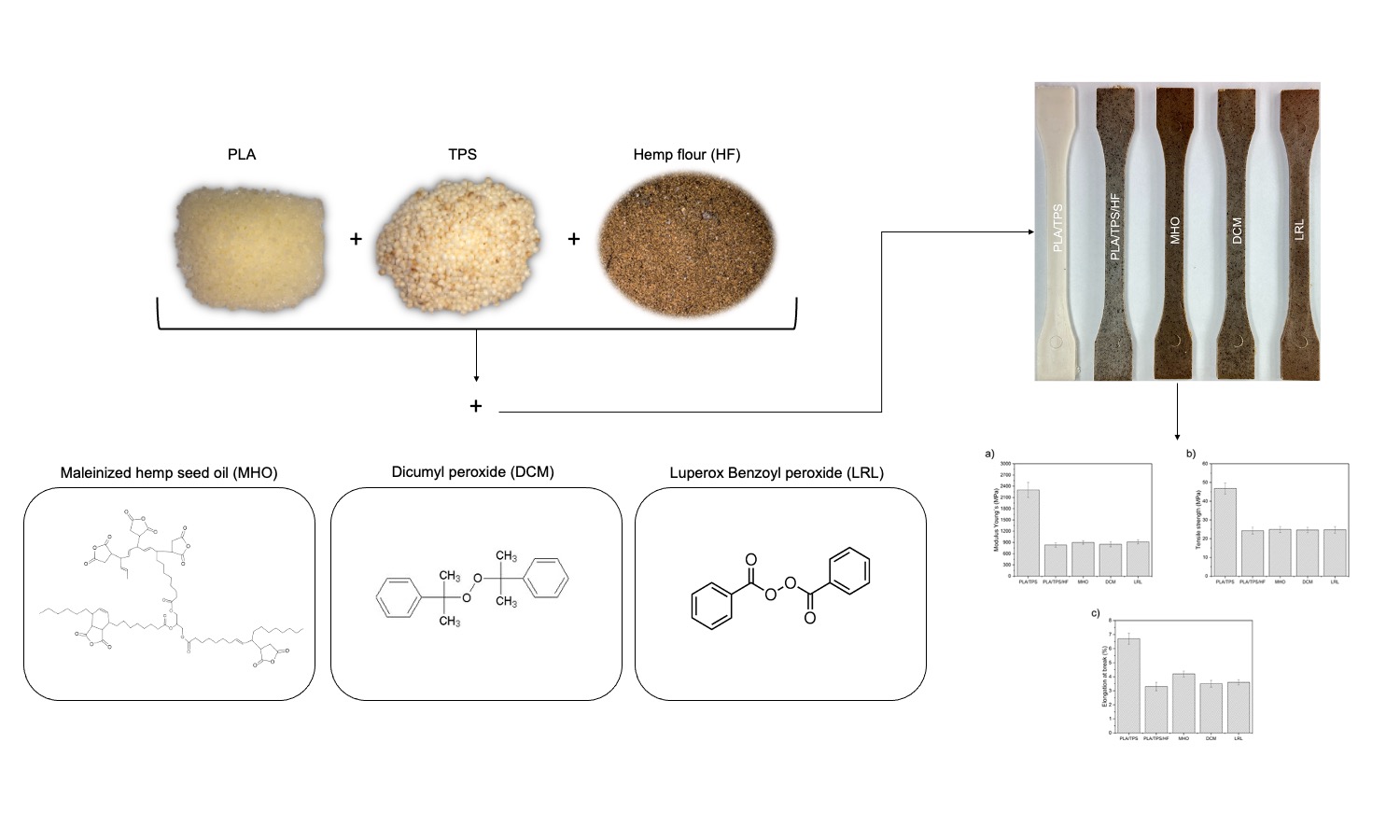

Alejandro Lerma-Canto, Ivan Dominguez-Candela, Jaume Gomez-Caturla, Vicent Fombuena, Daniel Garcia-Garcia

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

In a blend of poly(lactic acid) (PLA) and thermoplastic starch (TPS), a 15% load of hemp seed lignocellulosic filler (HF) was incorporated. Additionally, separate petrochemical-based compatibilizers, such as dicumyl peroxide (DCM) and benzoyl peroxide (LRL), as well as a bio-based compatibilizer, maleinized hemp seed oil (MHO), were introduced. Adding HF to the PLA/TPS blend reduced tensile mechanical properties due to the stress concentration phenomenon arising from the lack of interaction between components, yielding a more brittle material. This issue was mitigated by adding compatibilizers, notably the incorporation of MHO into the PLA/TPS/HF blend this increased elongation at break by enhancing compatibility among the blend components and providing a plasticizing effect. Moreover, regarding thermal properties, it was observed that the inclusion of HF led to a decrease in the glass transition temperature (Tg), cold crystallization temperature (Tcc), and melting temperature (Tm). Conversely, adding MHO to this blend increased all these values compared to the PLA/TPS/HF mixture, attributed to the plasticizing effect imparted by the modified oil. Additionally, following fracture in Charpy impact testing, the samples were subjected to field emission scanning electron microscopy (FESEM) analysis to examine the fractured surface of the various samples.