Modified poly(ε-caprolactone) with larvae protein environmentally friendly nanofiber: Assessment of interface properties and characterization

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

DOI: 10.3144/expresspolymlett.2024.62

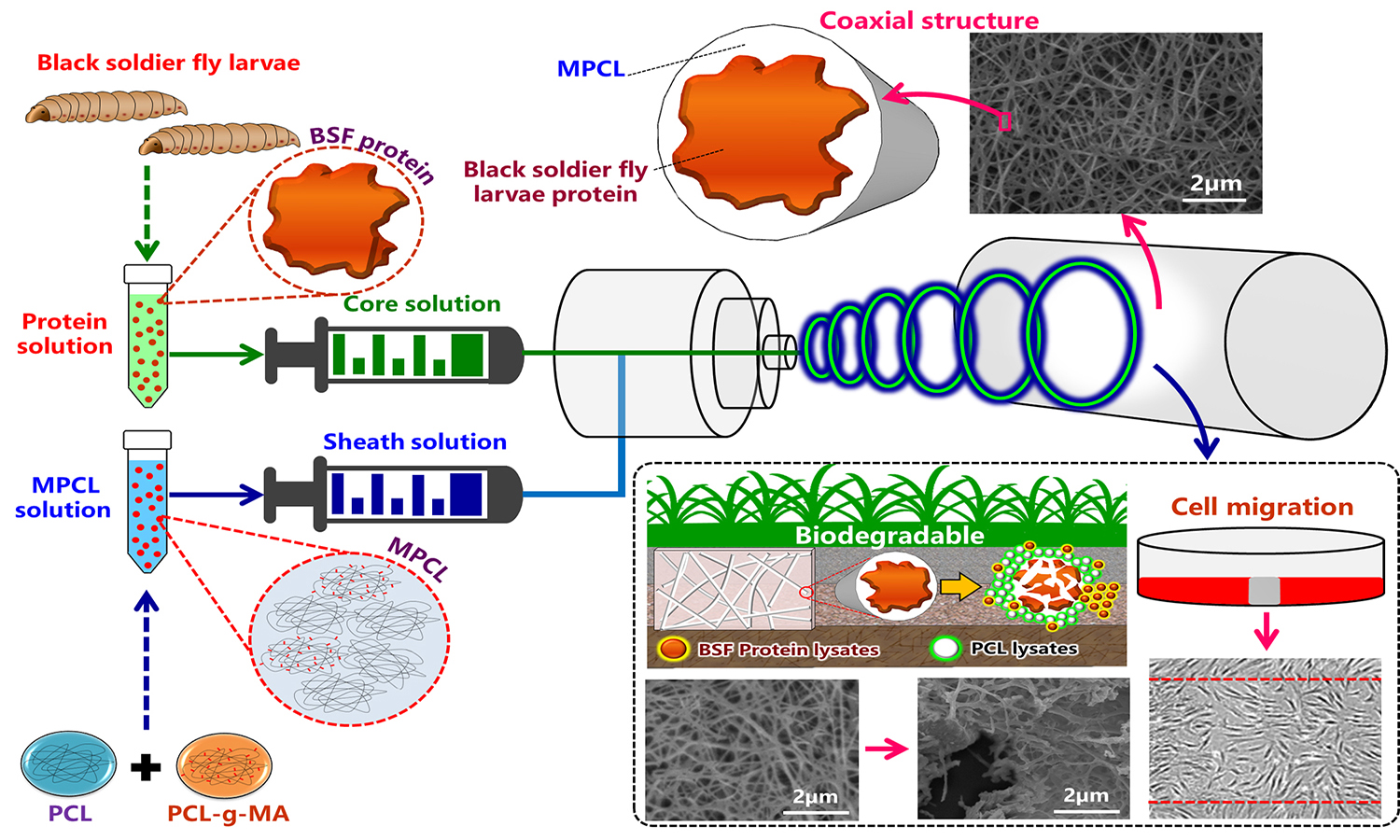

GRAPHICAL ABSTRACT

ABSTRACT

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.

RELATED ARTICLES

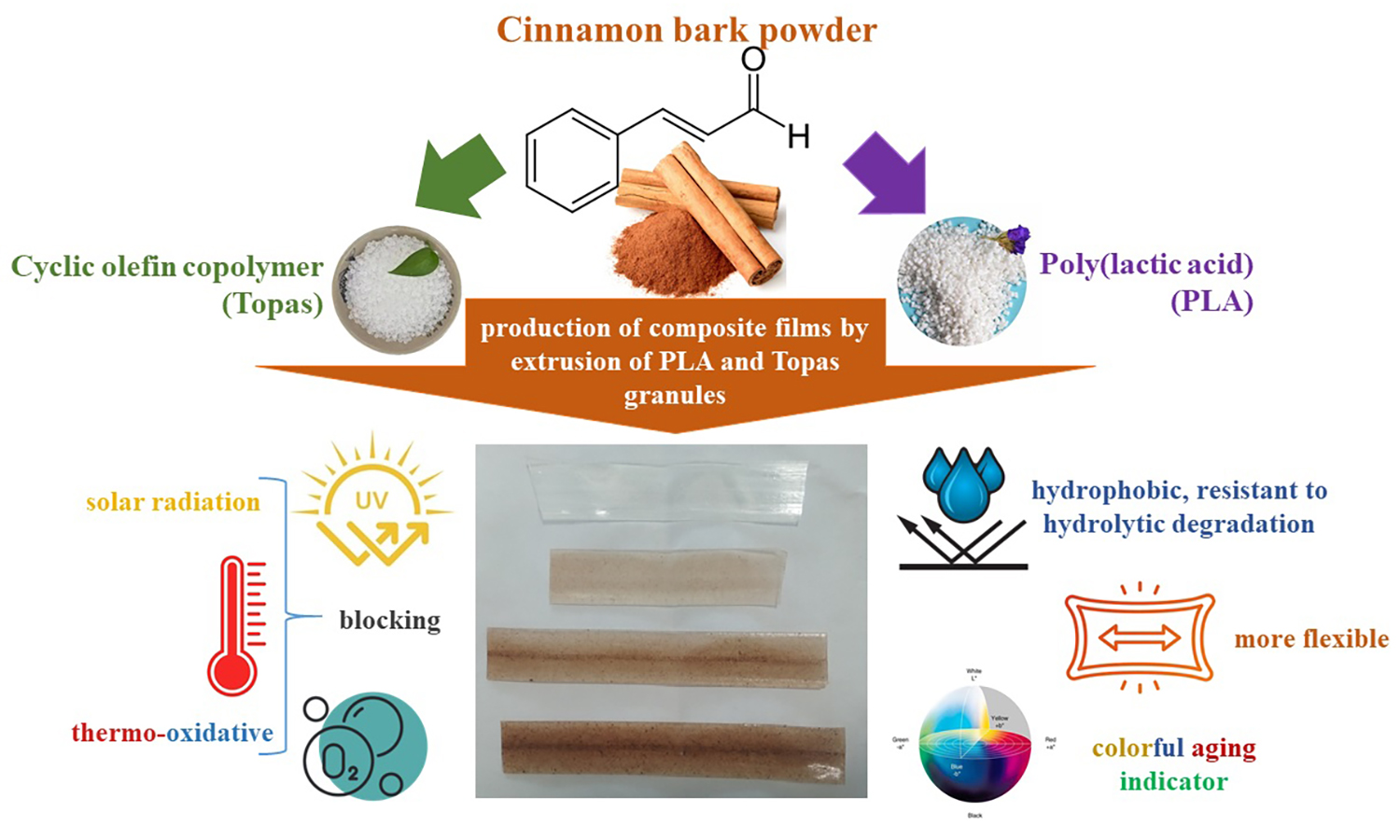

Effect of natural cinnamon extract on the stabilizing properties of biodegradable packaging polymers

Anna Kosmalska-Olańska, Anna Masek

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

Vol. 20., No.1., Pages 52-71, 2026

DOI: 10.3144/expresspolymlett.2026.5

The growing focus on sustainability, eco-friendly technologies, decarbonization, and reducing carbon footprints shapes current industry challenges. This article reviews the potential of cinnamon as a bio-additive for polymer stabilization in packaging. Samples were prepared from ethylene-norbornene copolymer (Topas), a cyclic olefin copolymer known for purity, transparency, and low gas permeability, and poly(lactic acid) (PLA), a bio-based alternative to petroleum plastics. Cinnamon powder was added in 0.5, 1.0, and 1.5 wt%. After solar and thermo-oxidative aging, hydrophobicity, chemical composition, mechanical, and color properties were analyzed. Results showed higher hydrophobicity and resistance to hydrolytic degradation due to reduced water penetration. PLA, normally brittle, became more flexible, with 0.5 wt% cinnamon showing optimal performance after 100 h of solar aging, similar to Topas composites. Overall, PLA and cyclic olefin copolymer (COC) films with cinnamon improved durability, extended food shelf life, and acted as natural color indicators of material aging.

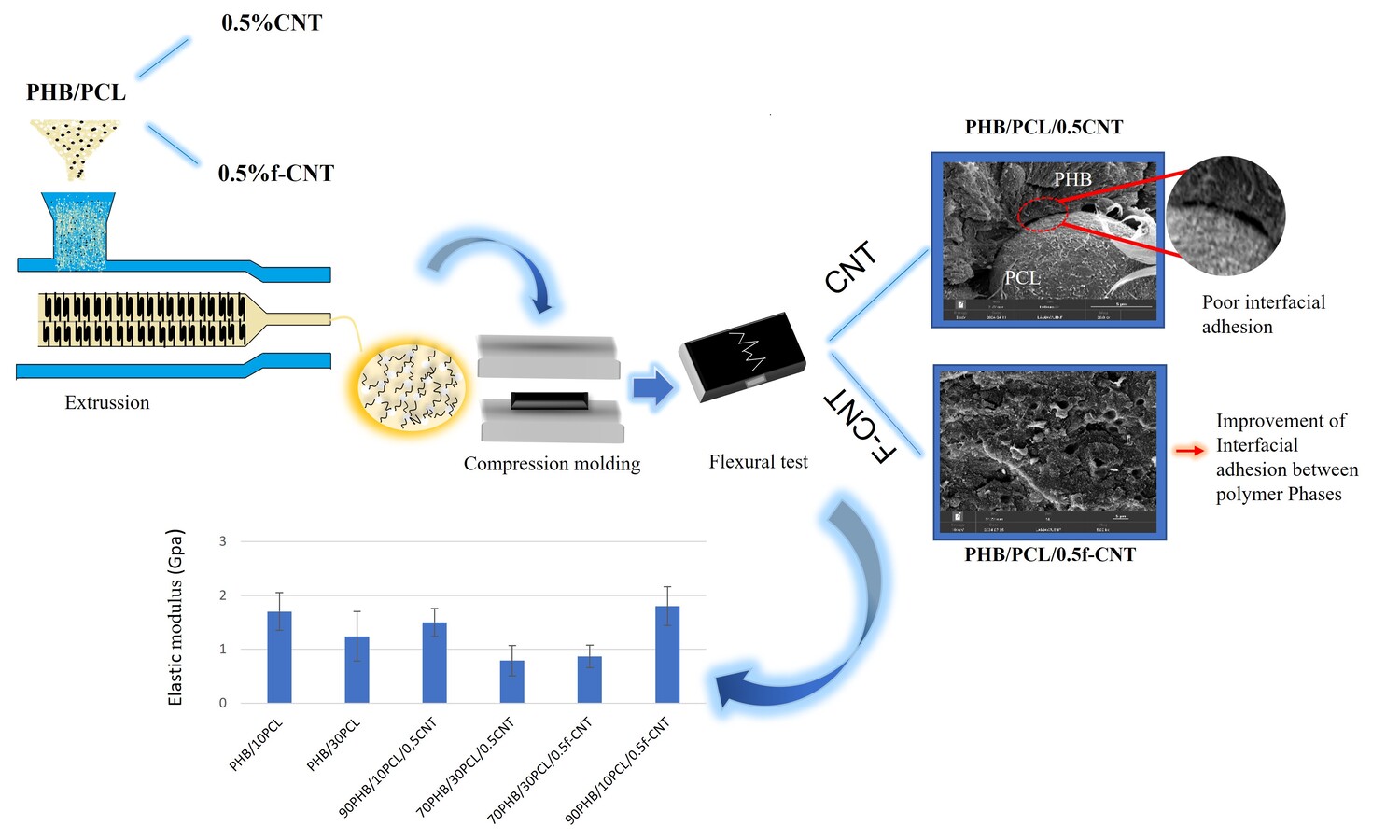

Alexandra Maria Cardona Loaiza, Maria Eduarda Araújo Ribeiro, Ruben J. Sanchez Rodriguez

Vol. 19., No.9., Pages 862-877, 2025

DOI: 10.3144/expresspolymlett.2025.66

Vol. 19., No.9., Pages 862-877, 2025

DOI: 10.3144/expresspolymlett.2025.66

Polyhydroxybutyrate (PHB) is a polymer with great application potential; however, its brittleness and low mechanical strength restrict its use in many fields. This study investigated a strategy to overcome the mechanical limitations of PHB by blending it with polycaprolactone (PCL) and producing nanocomposites with non-functionalized carbon nanotubes (CNT) and functionalized ones (f-CNT). The effect of blend composition and the addition of f-CNT were studied in hotpressed specimens. In PHB/30PCL blends, a reduction in the overall crystallinity degree was observed, while in PHB/10PCL the crystallinity maintained close to neat PHB. In PHB/10PCL nanocomposites, no significant change was registered, but in PHB/30PCL with f-CNT, the crystallinity degree increased and achieved values comparable to PHB. Differential scanning calorimetry suggested that f-CNT had a higher impact in PCL crystallinity in formulations of PHB/30PCL. Scanning electron microscopy showed that in these formulations, f-CNT were preferably located at the interface of PHB/PCL, while in PHB/10PCL the particles were mainly located in PHB. In general, the blends suffered with a reduction in elastic modulus and strength, especially for PHB/30PCL formulation.

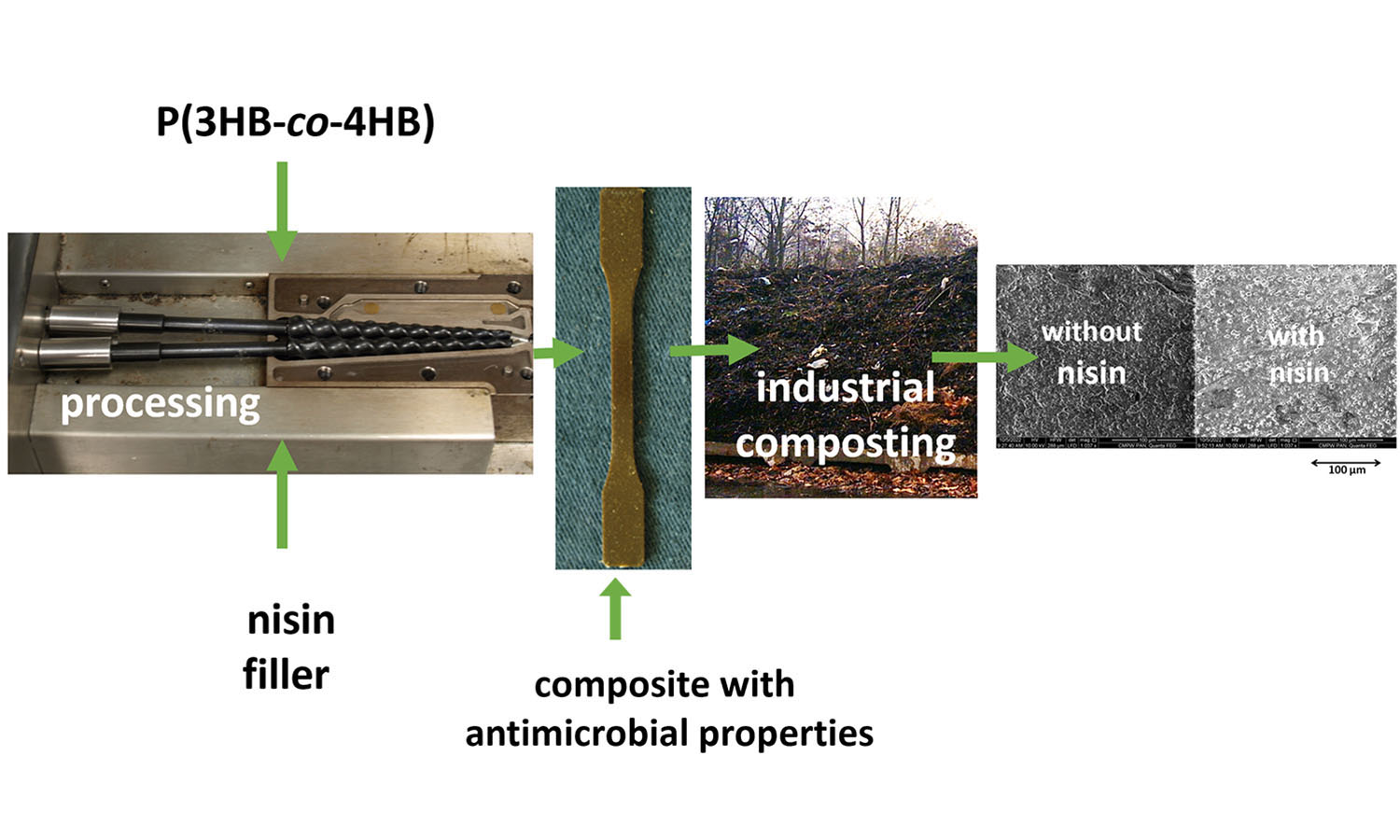

Marta Musioł, Michał Sobota, Henryk Janeczek, Anna Smola -Dmochowska, Brian Johnston, Iza Radecka

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

Vol. 19., No.8., Pages 773-782, 2025

DOI: 10.3144/expresspolymlett.2025.59

This study focused on developing compostable packaging materials possessing beneficial microbiological characteristics and evaluating their degradation process. We explore the use of nisin as a versatile antimicrobial additive in biodegradable materials. Our findings demonstrate nisin’s significant influence on the processing and degradation of composites. Nisin’s amphiphilic structure, characterized by both hydrophobic and hydrophilic components, enhances its interaction with the polymer matrix. This interaction affects smaller molar mass reduction during processing and leads to variations in degradation dynamics. The results suggest that nisin has minimal impact on the thermal stability of the matrix during processing, with less than a one-degree increase observed. Thermal stability improved for all materials during degradation, but nisin’s presence slowed this increase. Nisin’s influence on the matrix of jute fiber composites, was more pronounced, affecting the material during processing and subsequent degradation. The results indicate that samples containing nisin inhibit the growth of the gram-positive bacterium Staphylococcus aureus (S. aureus) after 24 h of incubation. The inclusion of fillers in composites elevates the microbiological activity by filler ‘antibacterial promotion’ effects in samples containing nisin. Connection with previous studies highlights the significance of polymer chain length on the composite’s antimicrobial properties.

Konrad Stefaniak, Anna Masek

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

Vol. 19., No.4., Pages 386-408, 2025

DOI: 10.3144/expresspolymlett.2025.29

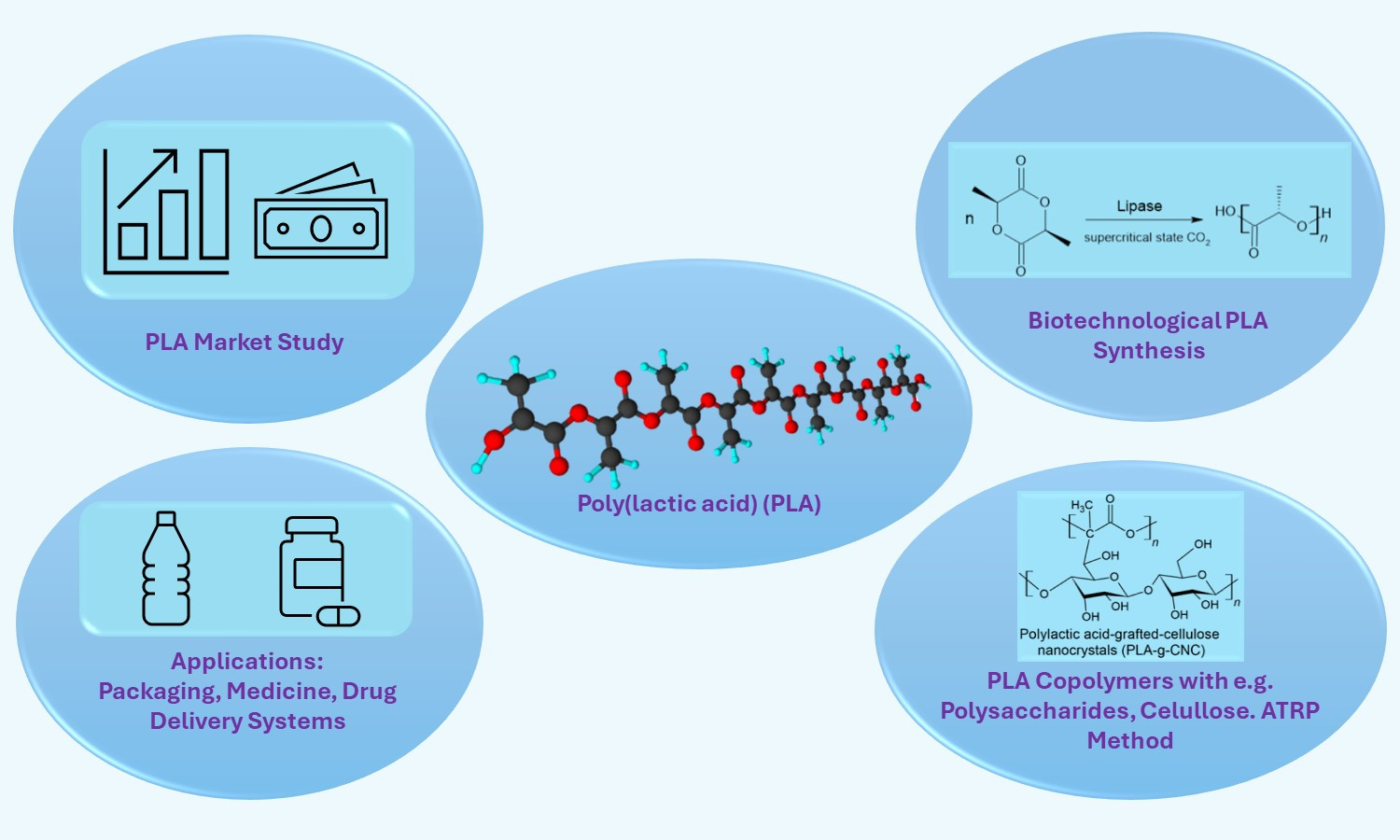

This review is focused on recent achievements in poly(lactic acid) (PLA) synthesis and copolymerization with special regard to biotechnological routes of PLA synthesis, which use bacteria/enzymes (e.g., enzymatic ring opening polymerization (eROP)). Besides PLA, also lactic acid (LA) synthesis is described and an emphasis is put on the biotechnological methods. Having regard to PLA copolymerization, this paper attempts to describe different types of PLA copolymers (such as block copolymers, PLA copolymers with polysaccharides, PLA-cellulose copolymer composites, and PLA polymer brushes). A detailed overview of the recent accomplishments in the field of PLA copolymers is presented. Various enhanced properties and applications of presented PLA copolymers are discussed. The attention is placed mainly on applications in the field of tissue engineering, drug delivery systems, and the packaging sector. Furthermore, a PLA market study and its economic forecast are presented. Eventually possible directions for future research in the field of PLA synthesis and copolymerization are indicated.

Rattanawadee Hedthong, Thorsak Kittikorn, Suding Kadea, Phuthanet Bamrungsiri

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

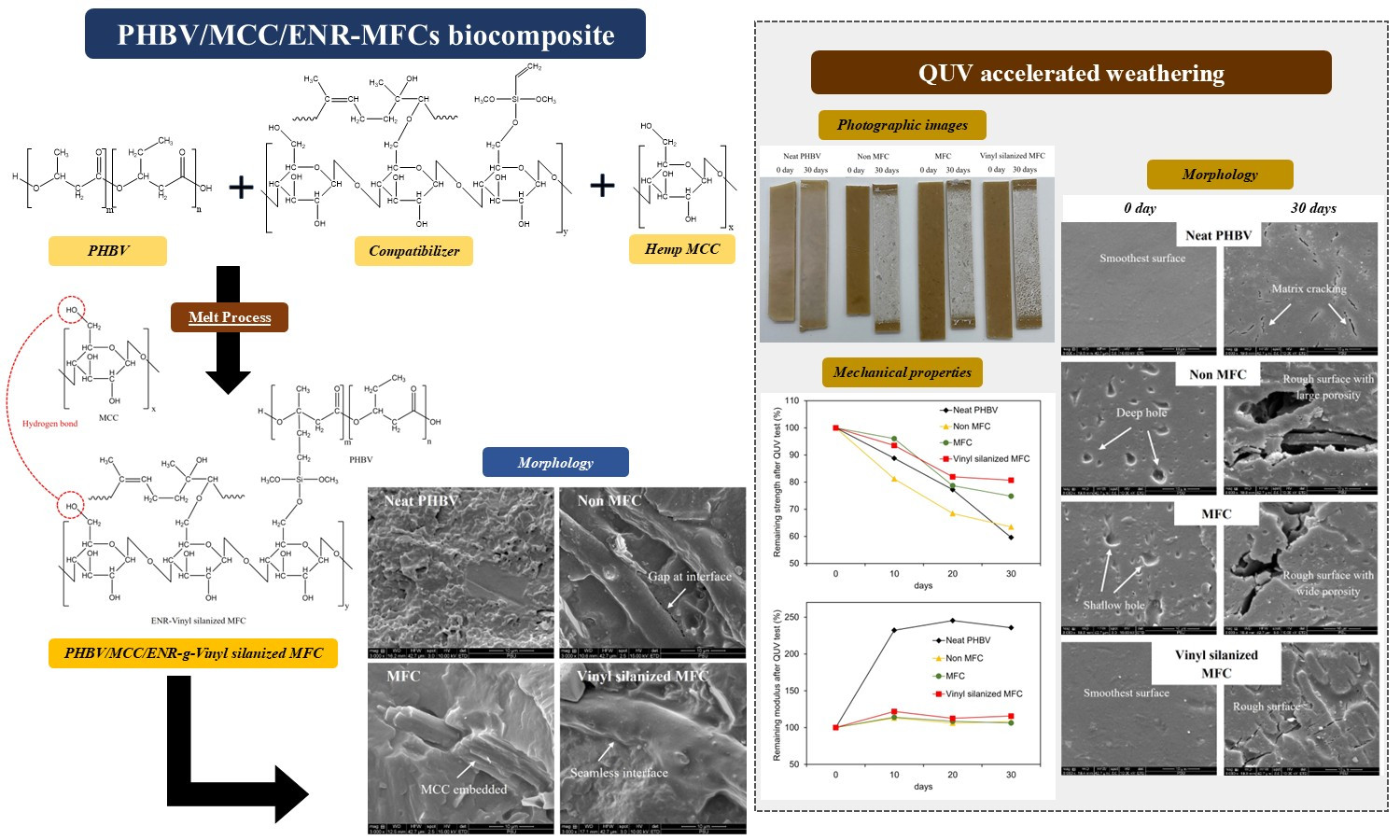

This research aimed to enhance the properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) biocomposites by incorporating hemp microcrystalline cellulose (MCC). Additionally, to improve interfacial adhesion between PHBV and MCC phases, a compatibilizer consisting of epoxidized natural rubber (ENR) grafted with microfibrillated cellulose (MFC) modified by vinyltrimethoxysilane (ENR-vinyl silanized MFC) was introduced. The addition of 5 wt% MCC increases the flexural modulus by approximately 65%. The use of ENR-vinyl silanized MFC as a compatibilizer demonstrated improved compatibility, as observed in scanning electron microscope (SEM) images. After 30 days of accelerated weathering (QUV) exposure, the flexural strength of the PHBV-based biocomposite with ENR-vinyl silanized MFC and MCC (vinyl silanized MFC biocomposite) was superior to that of the other samples. The remaining flexural strength can be sequentially categorized as follows: vinyl silanized MFC > MFC > non-MFC > PHBV. The Tg of PHBV-based biocomposites showed no significant change. Interestingly, the crystallinity of the vinyl silanized MFC biocomposite was the highest among all materials and demonstrated higher hydrophobicity. This makes the vinyl silanized MFC biocomposite a suitable material for construction, furniture, and both exterior and interior decoration.