Mechanical and electrical properties of self-healable rubber blends under influence of imidazole mixture and selective wetting of hybrid filler

Le Hong Hai , Hoang Xuan Tung, Yashwanth Sai Anjaneya Varma Kosuri, Subhradeep Mandal, Kedar Nath Dhakal

, Hoang Xuan Tung, Yashwanth Sai Anjaneya Varma Kosuri, Subhradeep Mandal, Kedar Nath Dhakal , Rameshwar Adhikari

, Rameshwar Adhikari , Beate Langer, Sven Wiessner

, Beate Langer, Sven Wiessner

, Hoang Xuan Tung, Yashwanth Sai Anjaneya Varma Kosuri, Subhradeep Mandal, Kedar Nath Dhakal

, Hoang Xuan Tung, Yashwanth Sai Anjaneya Varma Kosuri, Subhradeep Mandal, Kedar Nath Dhakal , Rameshwar Adhikari

, Rameshwar Adhikari , Beate Langer, Sven Wiessner

, Beate Langer, Sven Wiessner

Vol. 18., No.4., Pages 420-440, 2024

DOI: 10.3144/expresspolymlett.2024.31

DOI: 10.3144/expresspolymlett.2024.31

GRAPHICAL ABSTRACT

ABSTRACT

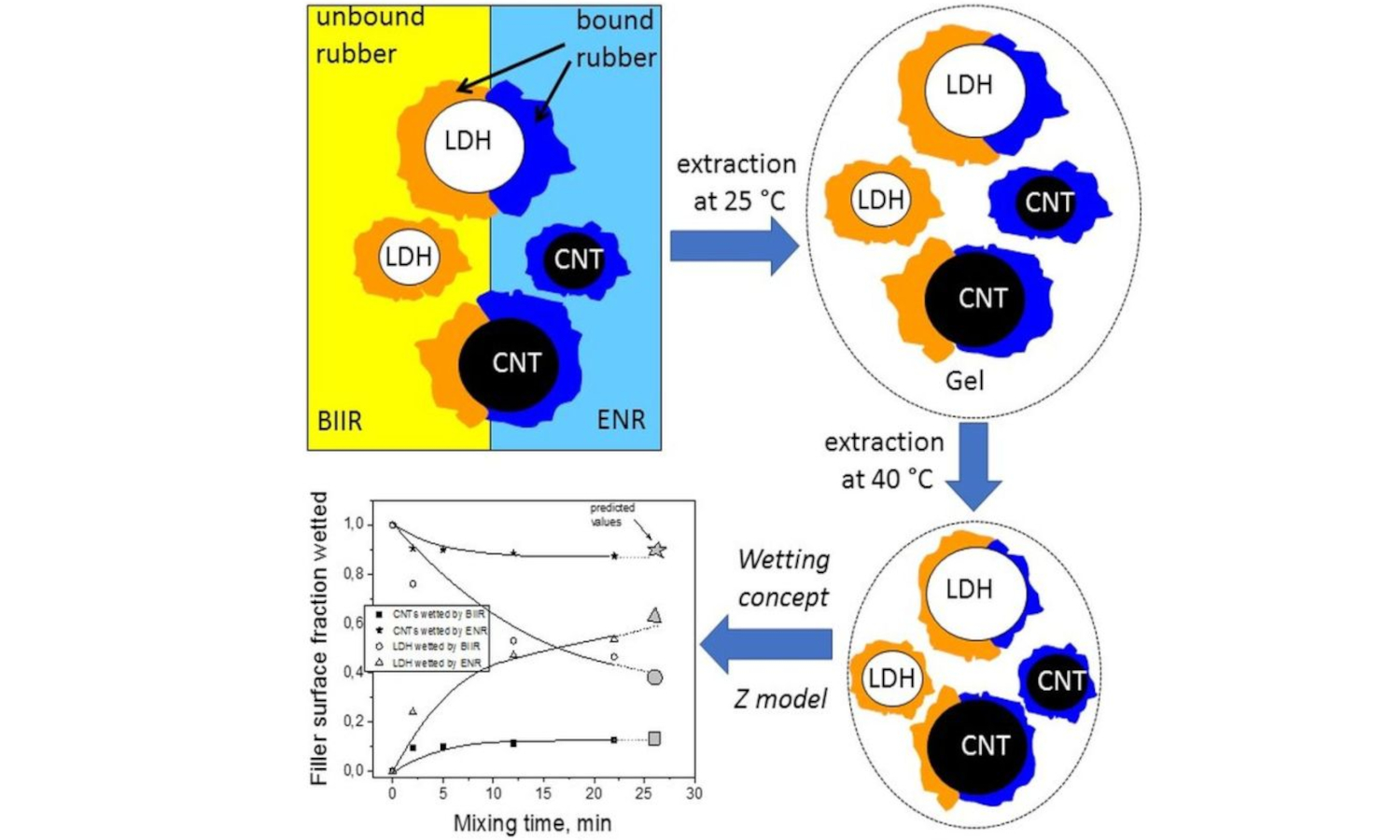

Flexible rubber composites based on blends of bromobutyl rubber (BIIR)/epoxidized natural rubber (ENR) filled with a hybrid filler of layered double hydroxides (LDH)/carbon nanotubes (CNT) were prepared, which may be of interest for use in tires and inner liner. An imidazole mixture of butyl-imidazole and 1H-imidazole was proposed to achieve reversible non-covalent networks consisting of ionic clusters and hydrogen bonding that led to the self-healing properties of each blend phase. The objective of the present work was to characterize the effects of selective modification of the rubber blends by imidazole and selective wetting of the hybrid filler on the mechanical and electrical properties and the self-healing effectivity. The wetting concept used to characterize the selective wetting of a single filler in a rubber blend was further developed for a hybrid filler in BIIR/ENR blends. During the one-step mixing and the masterbatch mixing process, re-localization of the hybrid filler between the blend phases under thermodynamic driving forces was observed. Within the specified mixing time, the thermodynamic equilibrium state of filler localization could not be reached. The nearly uniform distribution of LDH in both blend phases and the preferential localization of CNTs in the ENR matrix were found to be essential in giving the BIIR/ENR blends the best combination of self-healing properties and electrical conductivity. The high electrical conductivity of the composites can be exploited to generate a high temperature locally at the damage site inside the rubber samples when an electrical voltage is applied, resulting in an acceleration of the self-healing process.

RELATED ARTICLES

Nabil Hayeemasae, Sitisaiyidah Saiwari, Siriwat Soontaranon, Mohamad Irfan Fathurrohman, Abdulhakim Masa

Vol. 19., No.3., Pages 339-349, 2025

DOI: 10.3144/expresspolymlett.2025.24

Vol. 19., No.3., Pages 339-349, 2025

DOI: 10.3144/expresspolymlett.2025.24

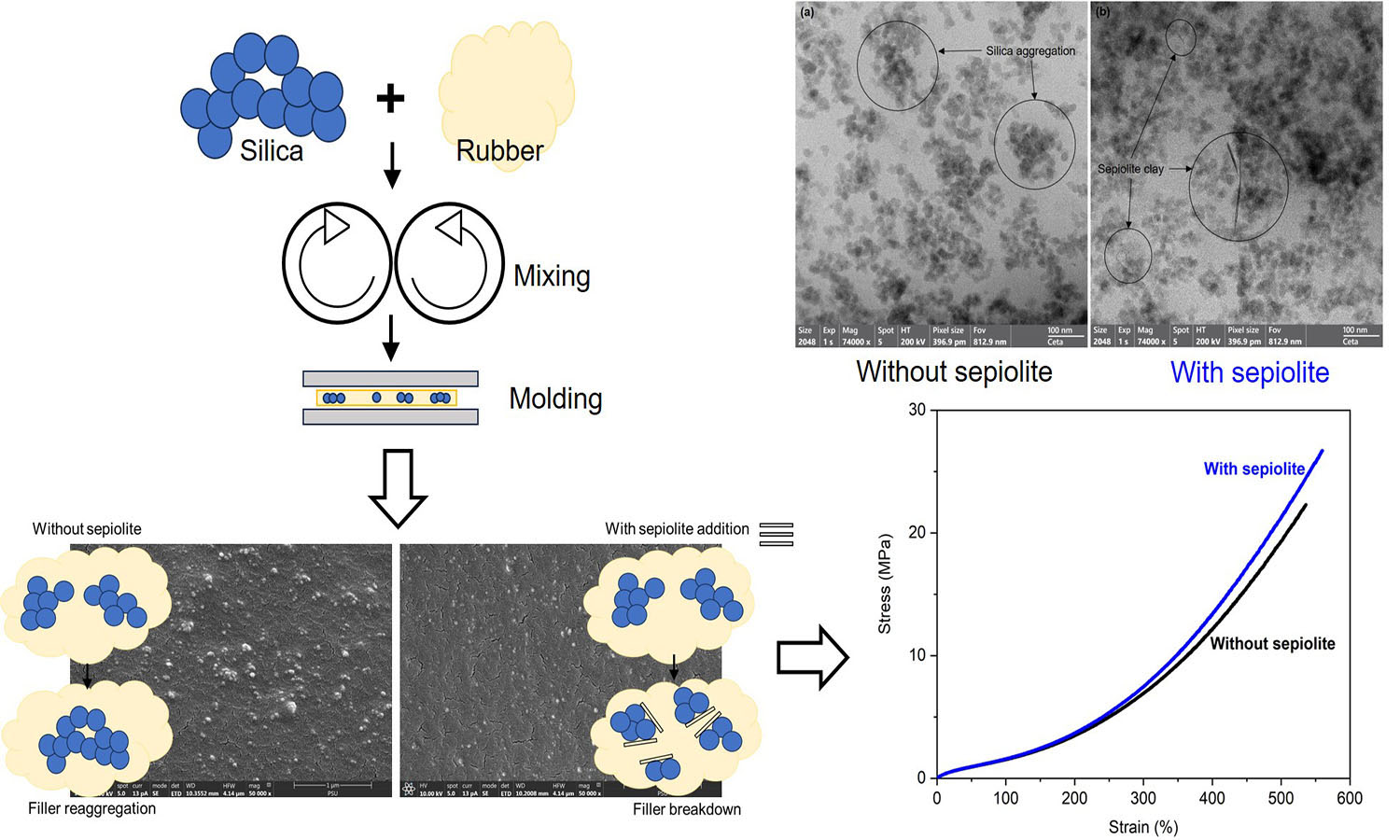

Natural rubber (NR) composites filled with silica and crosslinked with phenolic resin were prepared in this study. The influence of a small sepiolite addition (1–5 part(s) per hundred parts of rubber, phr) on the properties of NR composites was studied. It was found that sepiolite reduced silica aggregate size, allowing improved dispersion in the NR matrix. Sepiolite facilitates silica dispersion by locating at the silica surfaces and acting as a barrier that prevents agglomeration of silica filler. The swelling resistance, crosslink density, tensile strength, and strain-induced crystallization were all strengthened by incorporating sepiolite because of the improved silica dispersion. The greatest tensile strength was achieved at a 2 phr sepiolite addition level. The improvement was about 18% over the reference composite due to the greatest filler-rubber interactions and the finest filler dispersion. The results clearly indicate that sepiolite clay can be applied as a dispersing agent in silica-containing rubber composites.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

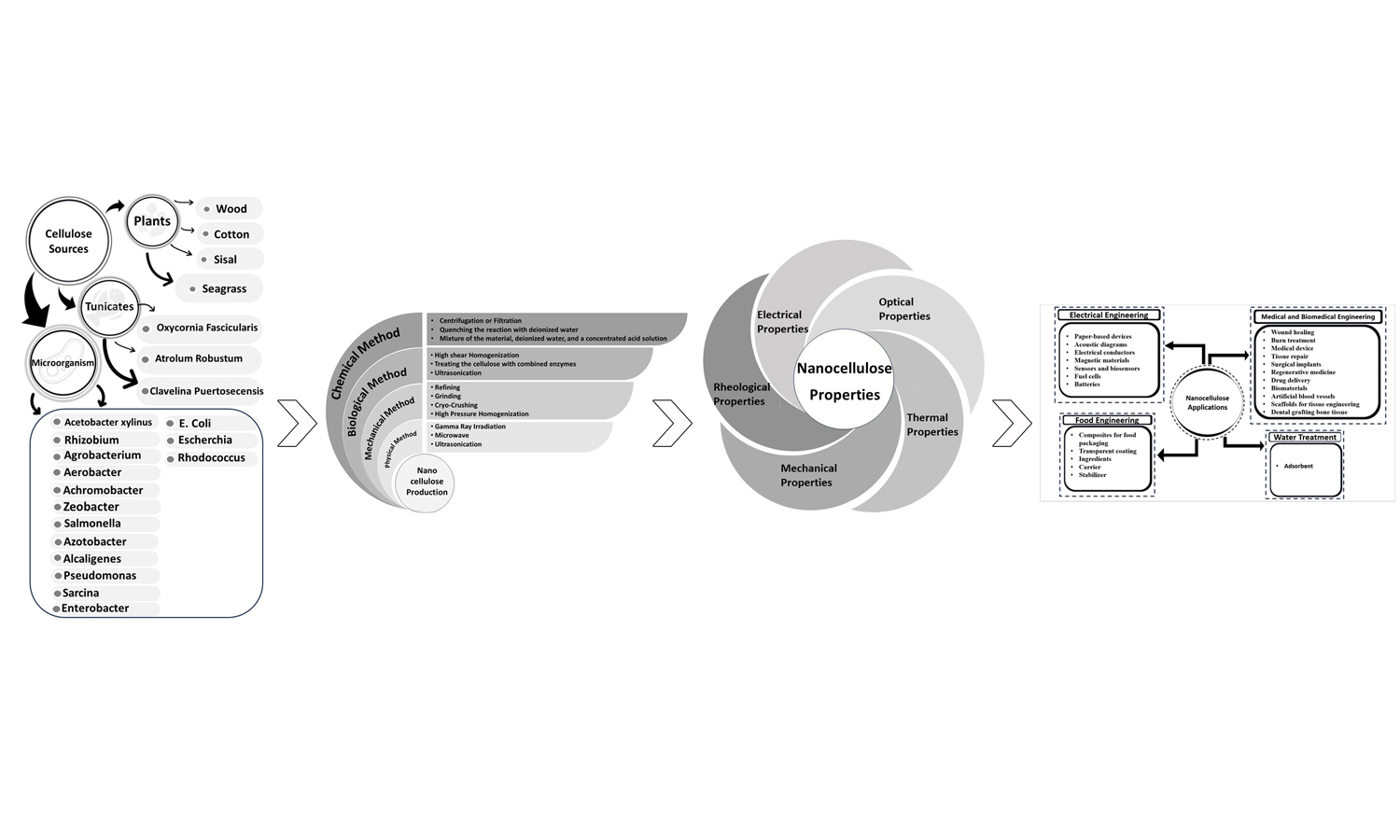

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Phakawat Thongnuanchan, Pornsuwan Buangam

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

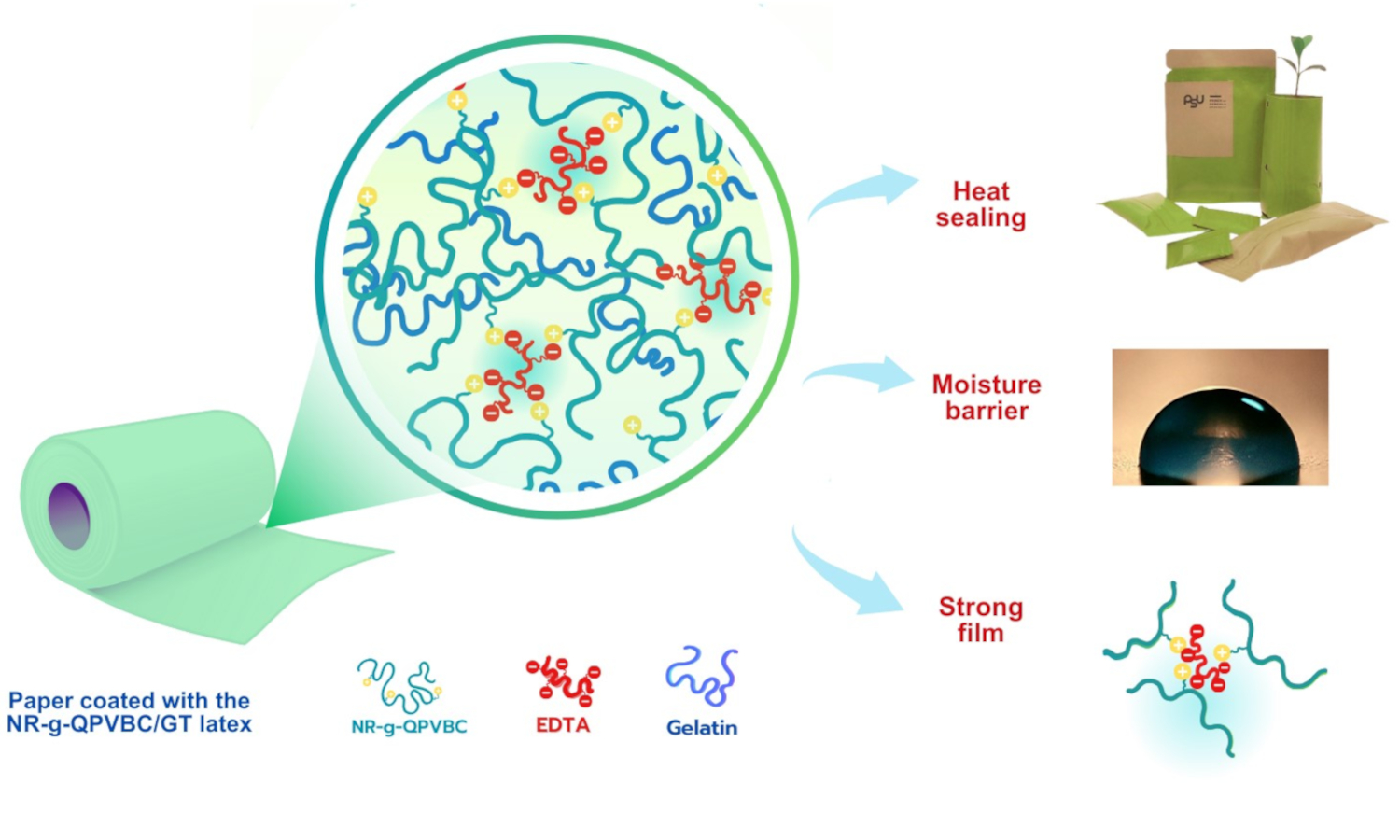

Research into sustainable packaging materials has gained increasing importance due to the pressing environmental concerns related to plastic waste. The present study focused on developing a sustainable paper coating based on modified natural rubber (NR) latex filled with gelatin (GT). The graft copolymer latex of NR and poly(vinylbenzyl chloride) bearing quaternary ammonium groups, abbreviated as NR-g-QPVBC, was first synthesized. GT was then incorporated into the latex, and the combination of these materials resulted in a heat-sealable film with good tensile properties and a water barrier. The ionic crosslinking of the latex film was achieved by the reaction with ethylenediaminetetraacetic acid (EDTA). Heat-sealing studies of the NR-g-QPVBC latex film filled with GT (NR-g-QPVBC/GT) revealed its heat-sealability at 160 °C. Scanning electron microscope (SEM) analysis further confirmed the diffusion of the chains across the interface during heat sealing. Dip coating was a method for depositing latex film on kraft paper. The paper coated with the NR-g-QPVBC/GT latex showed a significant increase in dry and wet-tensile strength compared to the uncoated paper. The sealing process was optimized to achieve a heat-seal strength of 755.31 N/m at a dwell time of 3 s and a temperature of 160 °C. The research's practical application was demonstrated by transforming the coated paper into various heat-sealable bags using a handheld bag sealer.

Sreethu Thiyyanthiruthy Kumbalaparambil, Ajay Haridas Chandaparambil, Kinsuk Naskar

Vol. 18., No.10., Pages 991-1007, 2024

DOI: 10.3144/expresspolymlett.2024.76

Vol. 18., No.10., Pages 991-1007, 2024

DOI: 10.3144/expresspolymlett.2024.76

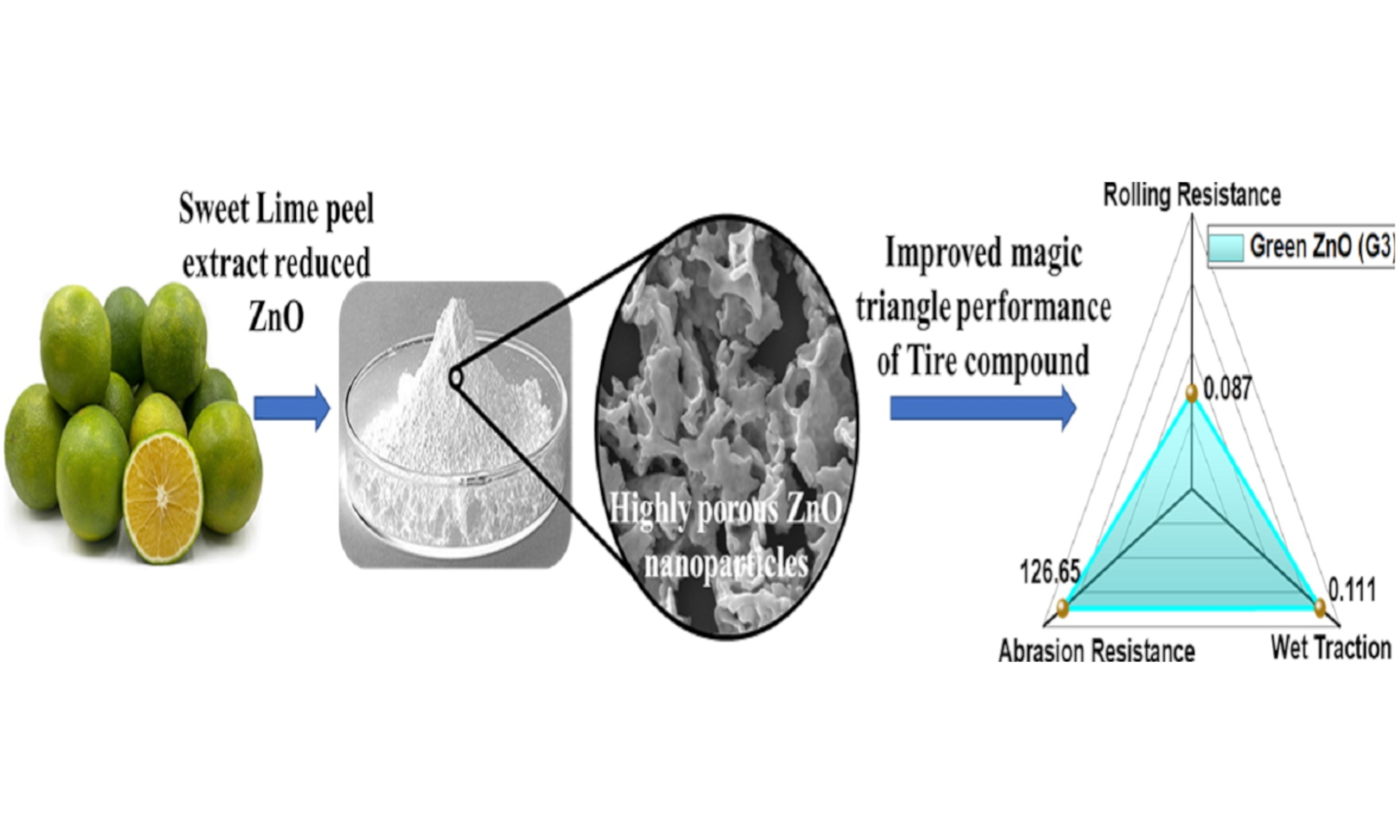

This study addresses the increasing demand for eco-friendly rubber compounding additives by exploring greensynthesized zinc oxide (ZnO) nanoparticles. The green synthesis of ZnO nanoparticles is gaining attention due to its ecofriendly approach and potential applications. This study investigates the synthesis of ZnO nanoparticles using sweet lime peel extract as a green method, comparing it with chemical synthesis. The obtained nanoparticles are characterized and evaluated for suitability as activators in natural rubber composites for tire applications. Furthermore, the cytotoxicity of the prepared ZnO nanoparticles on mice cells is assessed, revealing lower toxicity for green-synthesized ZnO compared to chemically synthesized ZnO. Payne effect analysis on the composites demonstrates improved polymer-filler interaction and mechanical properties for the green-synthesized ZnO-loaded composites. Notably, the incorporation of green-synthesized ZnO leads to significant enhancements in tensile strength due to its higher surface area. It achieves desirable magic triangle tire properties, including low rolling resistance, high wet traction, and high abrasion resistance. These findings highlight the promising potential of green ZnO as an environmentally friendly alternative to chemical ZnO in rubber compounding.

Sanjoy Datta, Ondřej Peter, Evghenii Harea, Radek Stoček, Kinsuk Naskar

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

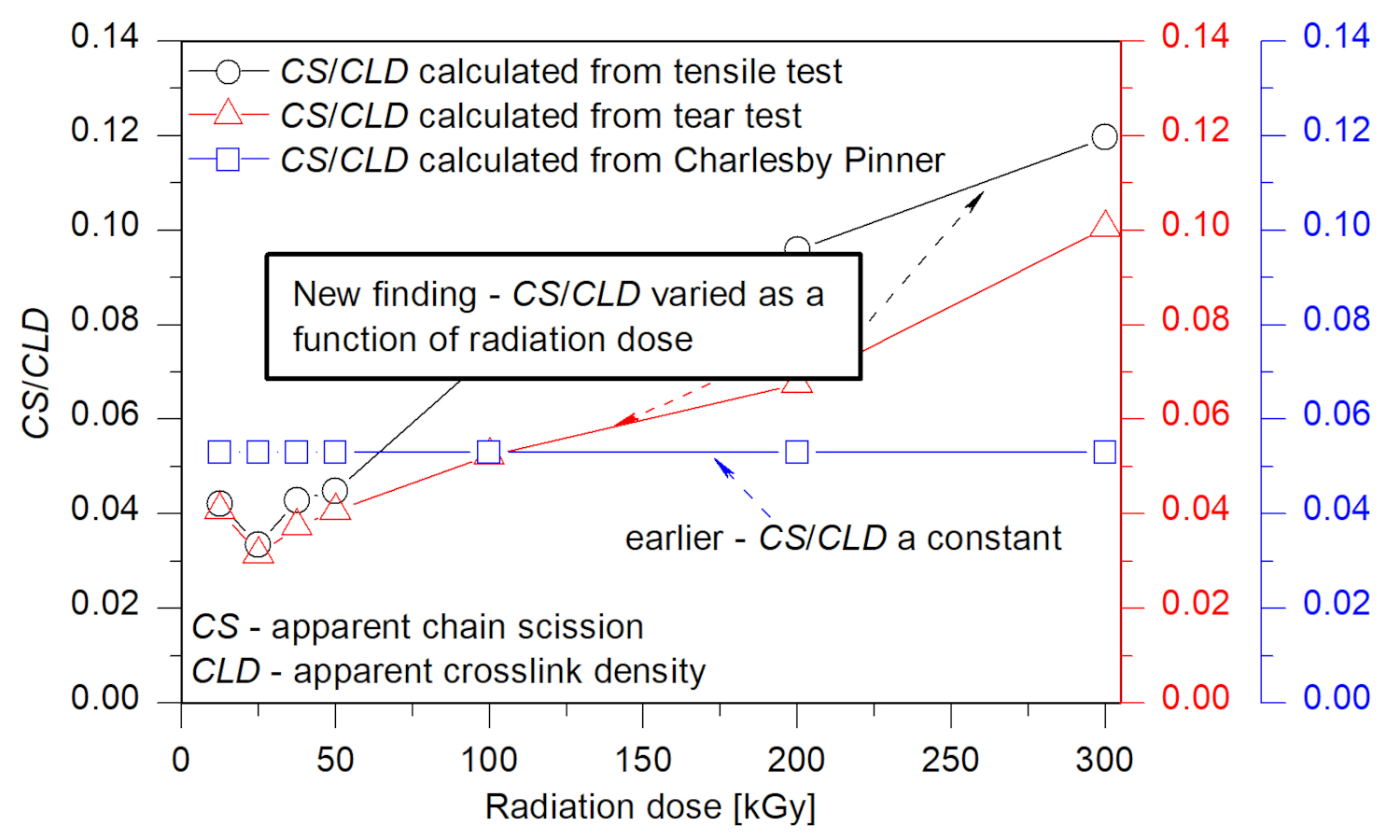

Electron beam (EB) treatment of a high vinyl styrene-butadiene-styrene (SBS) block copolymer was accomplished by exposing the polymer to high-energy electrons generated from an electron accelerator. This resulted in the formation of free radicals of carbon on the polybutadiene units in the backbone of the elastomer and subsequent radical coupling to produce cross-links. In the process, some unavoidable chain scission (CS) also occurred. An attempt was made to mathematically trace the nature of the CS as a function of radiation dose with the aid of the experimentally determined cross-link density (CLD), tensile strength and tear strength, the latter three also obtained as functions of radiation dose. The radiation dose was varied from 12.5 to 300.0 kGy in multiples of 12.5 kGy. The novelty of the work was, in part to create a function that can be used to calculate chain-scission in dependence of EB radiation dose. It was found that a change in the ratio of CS to CLD occurred as a function of radiation dose over the previously calculated constant ratio, using the Charlesby-Pinner equation.