Poly-flex-antennas: Application of polymer substrates in flexible antennas

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

DOI: 10.3144/expresspolymlett.2024.28

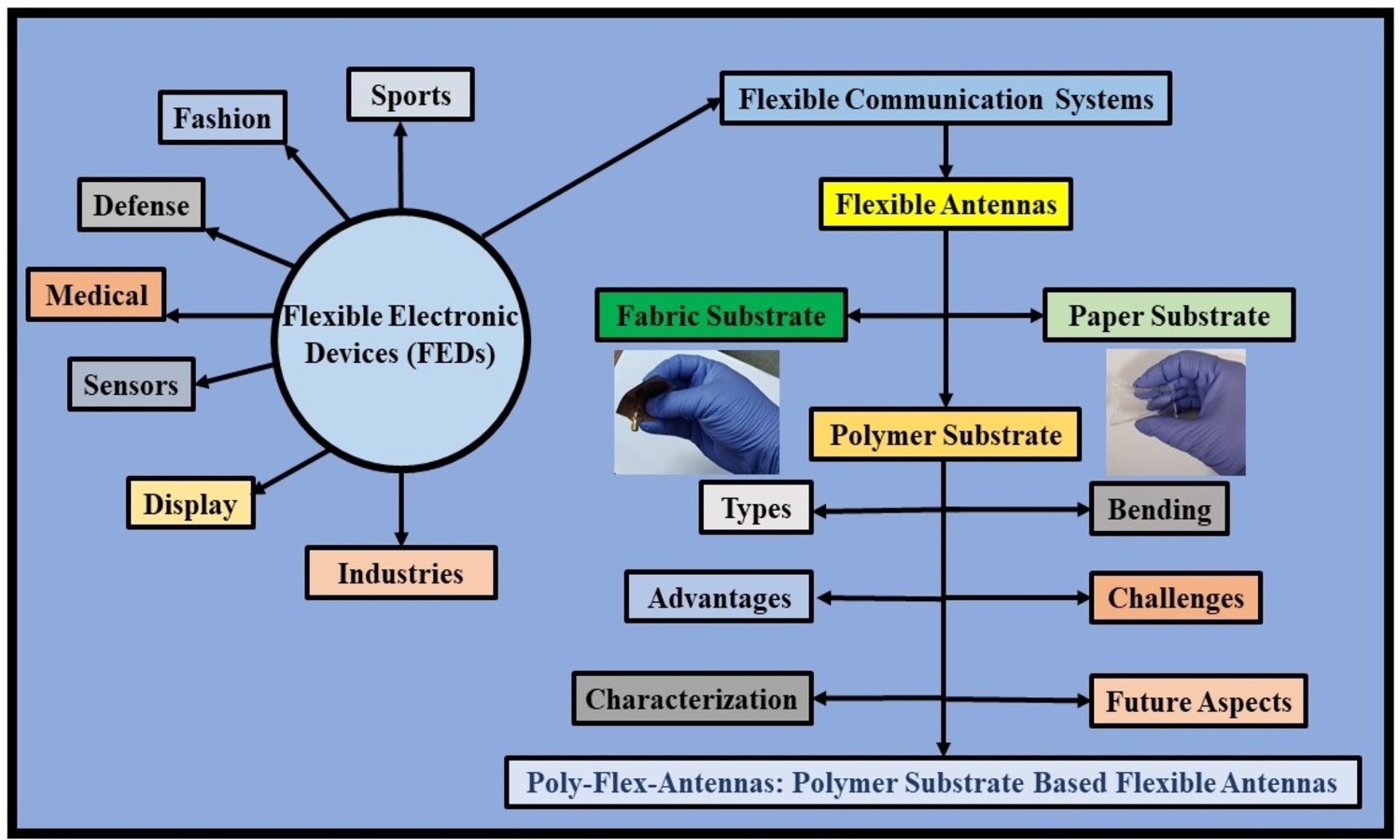

GRAPHICAL ABSTRACT

ABSTRACT

The

proliferation of flexible electronics has entirely transformed the field of

antenna design and paved the door for cutting-edge uses in communication,

sensing, and other areas. The present research lends a succinct overview of the

intriguing advancements in flexible antenna technology, with specific emphasis

on the implementation of polymer substrates. As we refer to poly-flex antennas in

this article, they stand for the incorporation of polymer substrates in antenna

design. Polymer substrates are the optimum candidate for flexible antenna

applications as they have specific advantages, including being lightweight,

conformable, and inexpensive. The main features of poly-flex antennas, such as

their design concepts, fabrication processes, and performance characteristics,

are being explored in this proposed article. We delve into the wide variety of

polymer substrates that are appropriate for antennas, taking into account their

dielectric characteristics, flexibility, and environmental resistance. Their

dielectric characterization, bending effects, challenges, and future prospects

of this burgeoning field are also addressed. We conclude by emphasizing the

immense potential of poly-flex-antennas to shape the future of wireless

communication and sensing systems, and how the adoption of polymer substrates

is driving innovation in antenna engineering.

RELATED ARTICLES

Ha Ngoc Giang, Thanh Thai Nguyen, Thu Thi Trang Luu, Anh Thi Ngoc Pham, Tuan Nguyen Anh Huynh

Vol. 19., No.5., Pages 519-530, 2025

DOI: 10.3144/expresspolymlett.2025.38

Vol. 19., No.5., Pages 519-530, 2025

DOI: 10.3144/expresspolymlett.2025.38

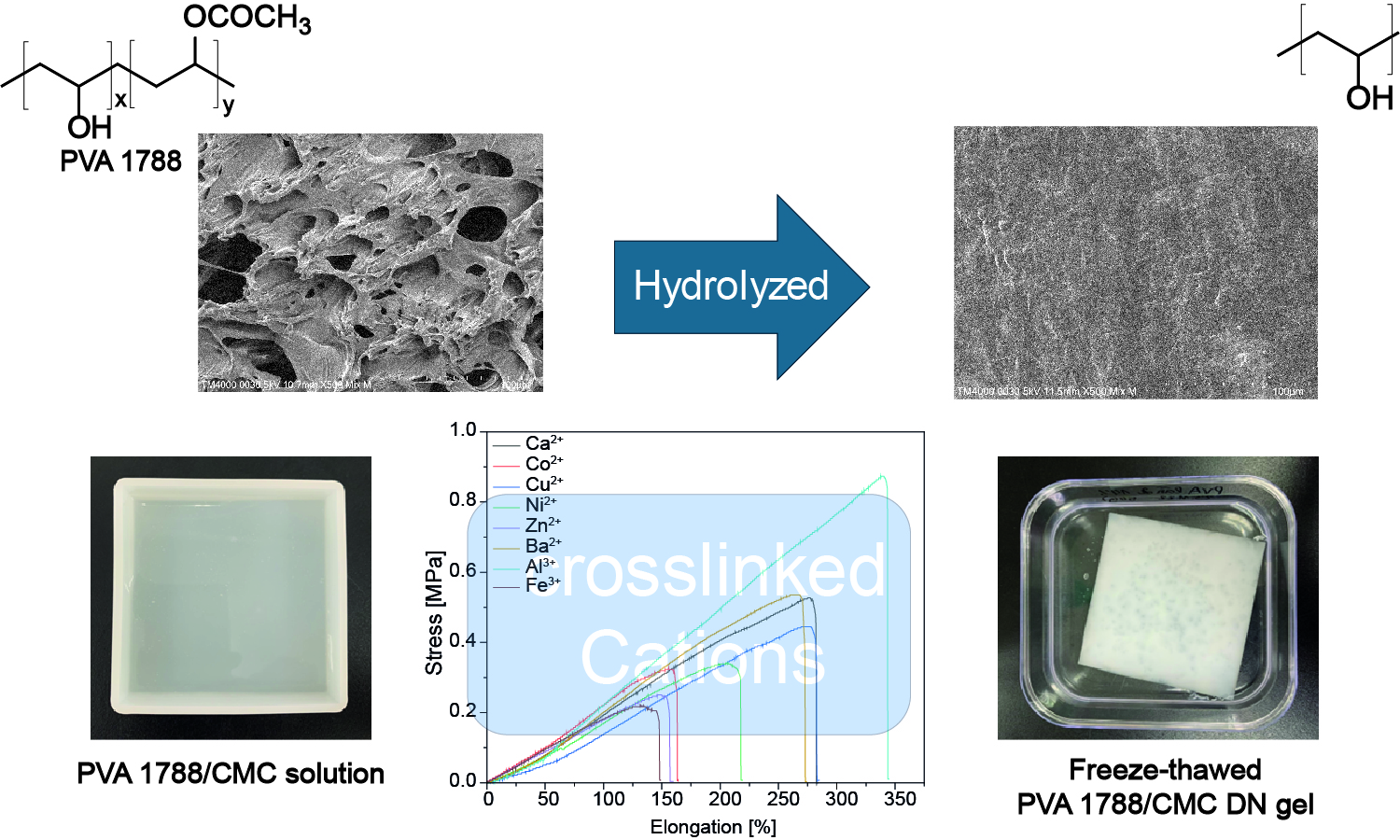

Freeze-thaw (F-T) poly(vinyl alcohol) (PVA) as a soft network and ionic-crosslinked sodium carboxymethyl cellulose (CMC) as a hard network were applied to fabricate a double network (DN) gel using a one-step process. Mechanical properties of the DN gel using a high degree of hydrolysis PVA (PVA-CMC of 60-1) were significantly improved compared to that of a single network gel of PVA. The tensile strength of ~0.55 MPa and elongation at break of 179% could be achieved. The mechanical properties of PVA-poly(acrylic acid) DN gel were lower than that of PVA-CMC samples. Fourier-transformed infrared (FTIR) spectroscopy results showed less compatibility between polyacrylic acid (PAA) and PVA compared to that of CMC. The solution made from the lower hydrolysis degree PVA (PVA1788) could form a strong gel after being treated with NaOH 1 M. The FTIR result showed the disappearance of acetate groups. A large melting peak in differential scanning calorimetry (DSC) results showed high crystallinity of the hydrolyzed-PVA1788. The effect of various multivalent cations on the mechanical properties of PVA1788-CMC DN gel was performed. The properties of the samples followed the order: Fe3+<Co2+<Ni2+<Cu2+<Zn2+<Ca2+~Ba2+<Al3+. The tensile strength of DN gel fabricated using AlCl3 solution could reach 0.87 MPa, and the elongation at break was 330%.

Sarahí Bautista Reberte, Esmeralda Zuñiga Aguilar, Solange Ivette Rivera Manrique, Carlos Alberto Martínez-Pérez

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

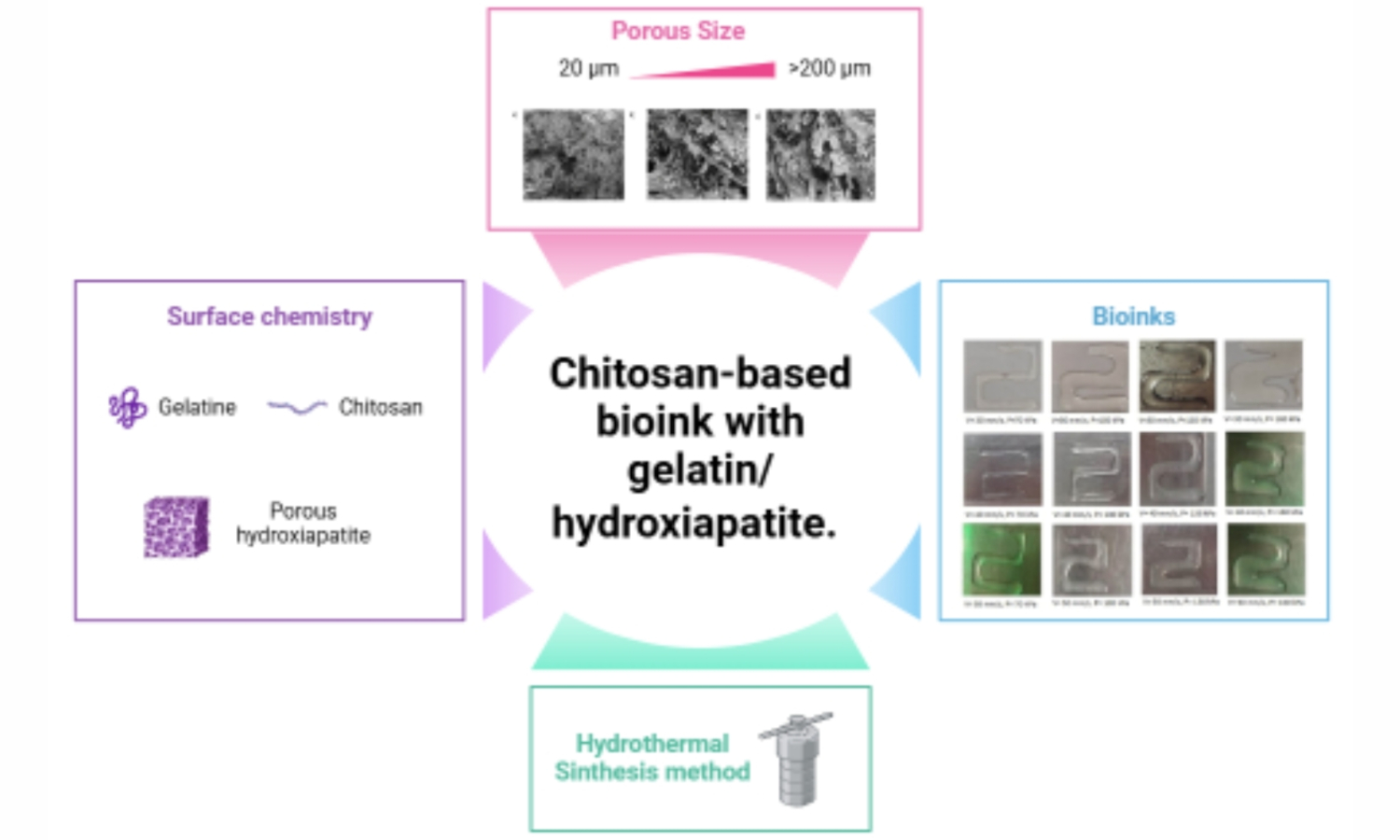

Three-dimensional (3D) bioprinting is a technique currently used for creating tissue engineering scaffolds, using bioinks as the building blocks. These bioinks are composed of biomaterials that provide structural integrity and are synthesized from organic polymers to enhance biocompatibility with the printed constructs. In this study, a series of eleven chitosan-based bioinks were synthesized using the sol-gel technique, employing chitosan of low and medium molecular weight. Three bioink formulations were selected based on their viscosity characteristics and further enriched with gelatin and hydroxyapatite (HA) to enhance their mechanical properties. Characterization tests included Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and rheological assessments. Viscoelastic materials were obtained, and an experimental model was developed to optimize printing parameters, focusing on pressure and printing speed. Our findings indicate that a bioink formulation comprising a blend of medium and high molecular weight chitosan, supplemented with gelatin and hydroxyapatite, was found to be a promising approach for fabricating scaffolds for bone tissue repair.

Waleed Y. Rizg, Amerh Aiad Alahmadi, Mohammed Baradwan, Rahul Dev Bairwan, Marwan M, Ahmed K. Mohamed, Sherif El Saadany, CK Abdullah, H.P.S. Abdul Khalil

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

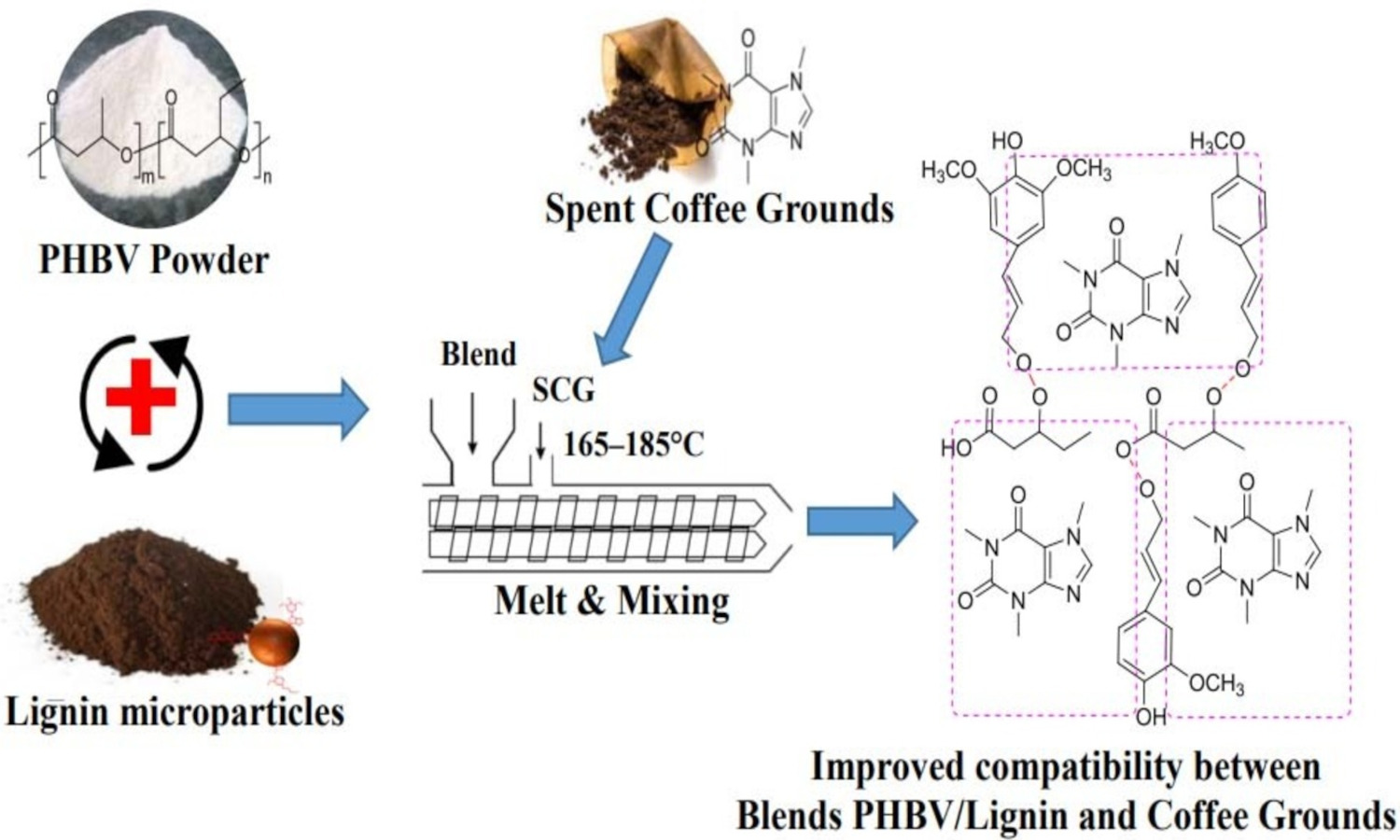

This study investigated the development of thermoplastic composites by incorporating crude lignin extracted from coir fiber waste, into poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a biodegradable polymer. The extracted crude lignin was blended with PHBV as a matrix, and spent coffee grounds (SCG) were used as biofillers. SCG were chemically modified through sodium hydroxide (NaOH) treatment and maleic anhydride (MA) grafting to enhance their compatibility with the PHBV/lignin blend. Raw and modified SCG were characterized for their functional, morphological, and thermal properties before being incorporated. Thermoplastic biocomposites were prepared via melt compounding and compression molding and evaluated for water barrier, morphological, mechanical, and thermal properties. Results showed that MA-grafted SCG significantly enhanced PHBV-lignin properties, increasing tensile strength by 23.7% and thermal stability by 11.9% compared to the control matrix. Optimal performance was observed at 5% MA-grafted SCG filler loading. However, higher SCG concentrations (7%) led to filler agglomeration, negatively affecting the material properties. This research demonstrated the potential of utilizing agricultural and food waste to create high-performance thermoplastic composites for future applications in biodegradable packaging, contributing to the advancement of a circular economy and environmental sustainability.

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

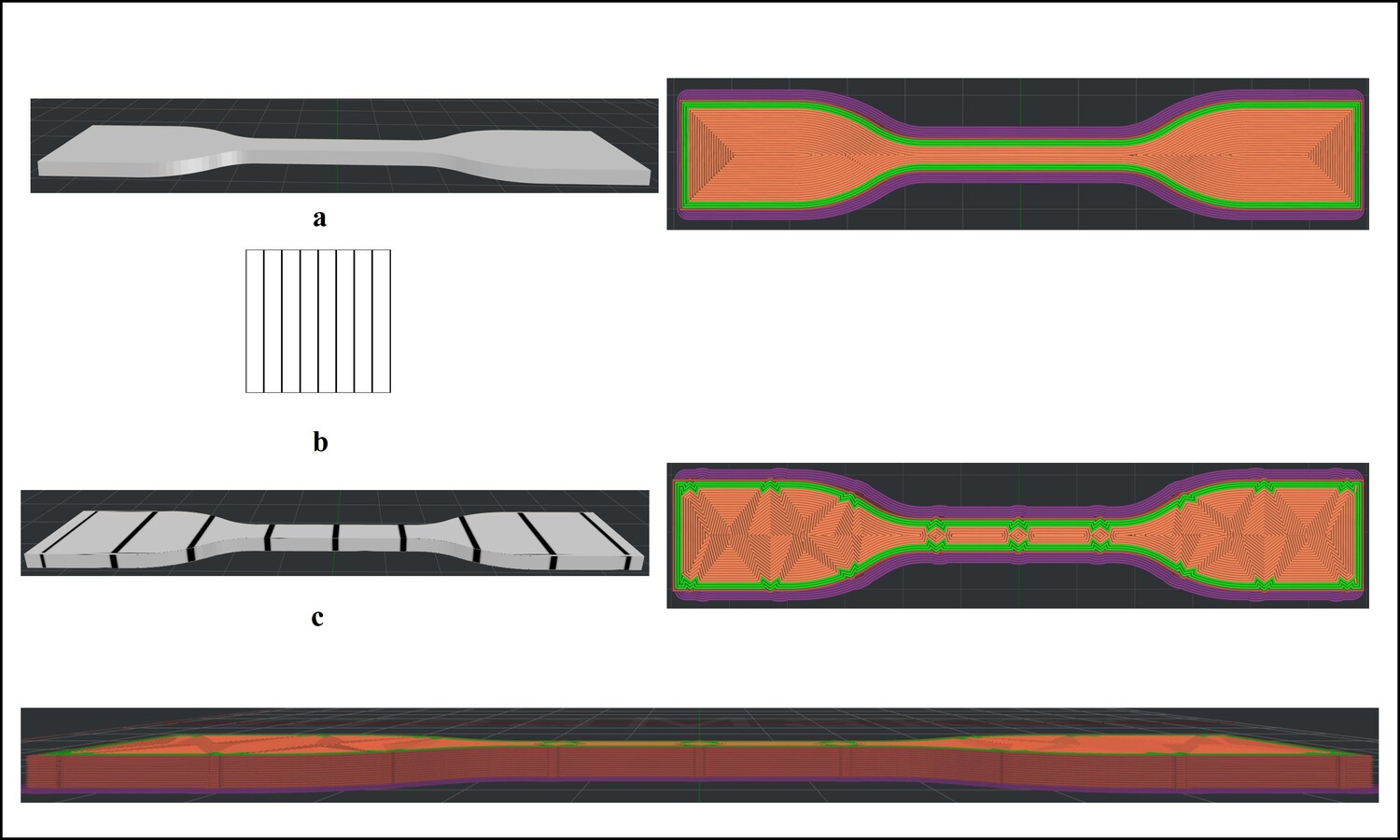

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

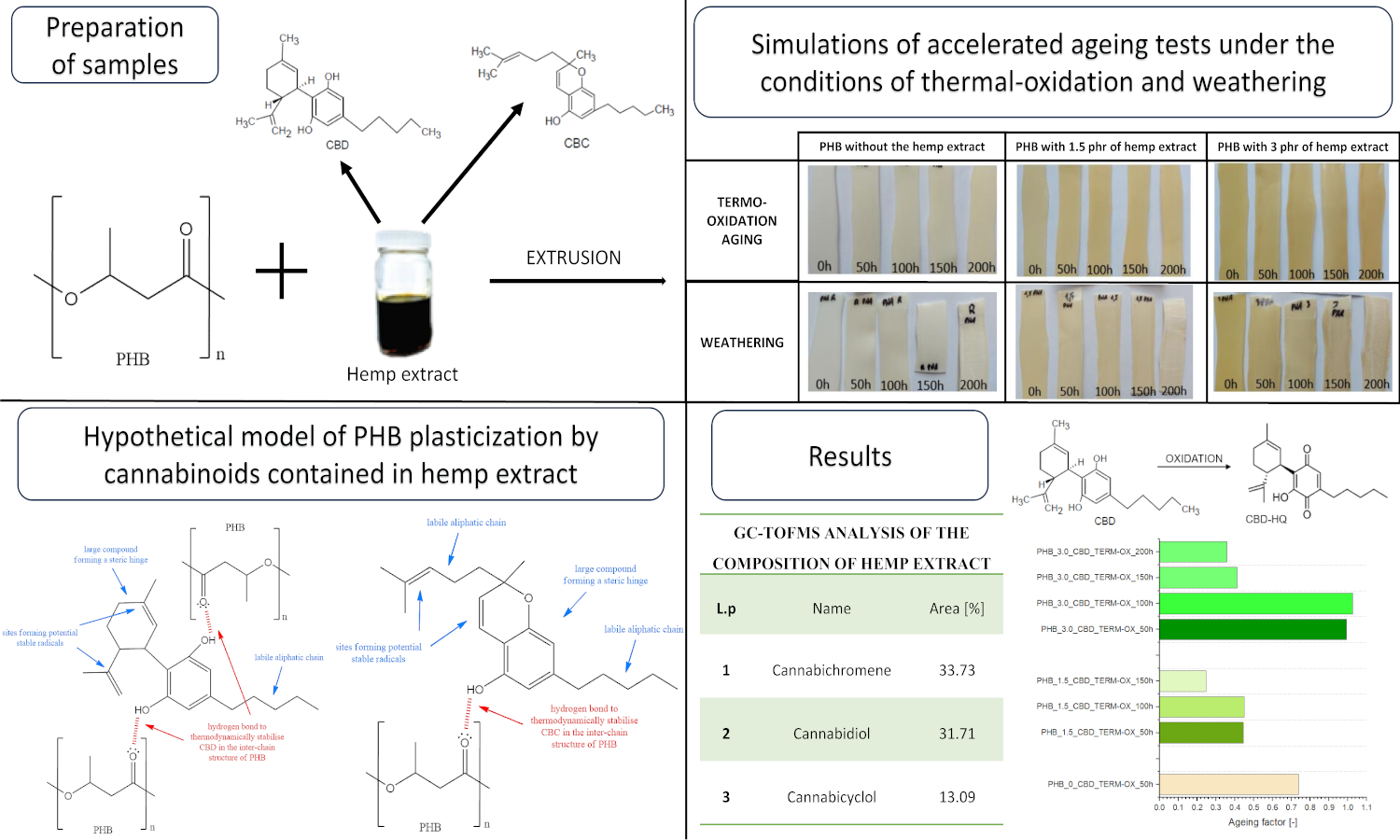

Karol Tutek, Anna Masek

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Biodegradable biopolymers like polyhydroxybutyrate (PHB) hold promise for sustainable packaging, but their inherent degradability reduces material stability. Synthetic stabilizers, though effective, raise environmental and potential toxicity concerns. This study explores a multifunctional natural anti-aging agent: a hemp extract rich in cannabidiol (CBD) and cannabichromene (CBC). PHB composites with varying hemp extract concentrations were prepared and subjected to thermooxidative and weathering aging. Characterization employed FTIR-ATR, carbonyl index, and spectrophotometry. Static mechanical properties, DSC, and surface free energy (SFE) were also assessed. Notably, the hemp extract exhibited stability under ambient conditions but showed migration with time and aging. The results suggest a plasticizing effect on PHB and highlight the contrasting roles of the extract: inhibiting thermooxidative aging while potentially accelerating aging under atmospheric conditions. This opens avenues for tailoring material durability, further evaluated by life cycle analysis (LCA). This work represents one of the first investigations into hemp extract as an anti-aging agent for eco-friendly polymers, expanding the knowledge base of natural multifunctional additives.