Manufacture of a chitosan-based bioink with gelatin and hydroxyapatite and its potential application in 3D bioprinting

Sarahí Bautista Reberte, Esmeralda Zuñiga Aguilar , Solange Ivette Rivera Manrique

, Solange Ivette Rivera Manrique , Carlos Alberto Martínez-Pérez

, Carlos Alberto Martínez-Pérez

, Solange Ivette Rivera Manrique

, Solange Ivette Rivera Manrique , Carlos Alberto Martínez-Pérez

, Carlos Alberto Martínez-Pérez

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

DOI: 10.3144/expresspolymlett.2025.23

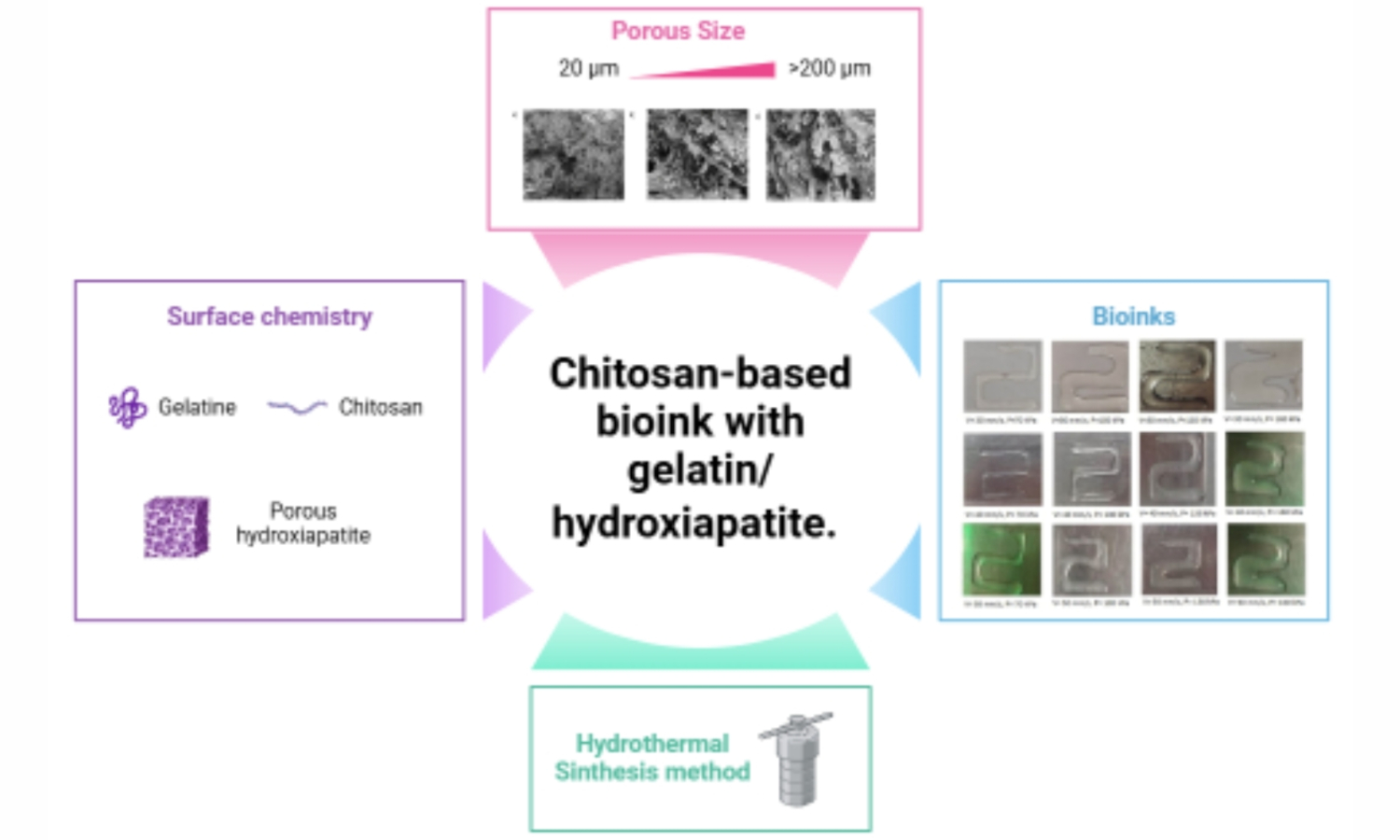

GRAPHICAL ABSTRACT

ABSTRACT

Three-dimensional (3D) bioprinting is a technique currently used for creating tissue engineering scaffolds, using bioinks as the building blocks. These bioinks are composed of biomaterials that provide structural integrity and are synthesized from organic polymers to enhance biocompatibility with the printed constructs. In this study, a series of eleven chitosan-based bioinks were synthesized using the sol-gel technique, employing chitosan of low and medium molecular weight. Three bioink formulations were selected based on their viscosity characteristics and further enriched with gelatin and hydroxyapatite (HA) to enhance their mechanical properties. Characterization tests included Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and rheological assessments. Viscoelastic materials were obtained, and an experimental model was developed to optimize printing parameters, focusing on pressure and printing speed. Our findings indicate that a bioink formulation comprising a blend of medium and high molecular weight chitosan, supplemented with gelatin and hydroxyapatite, was found to be a promising approach for fabricating scaffolds for bone tissue repair.

RELATED ARTICLES

Khmais Zdiri, Aurélie Cayla, Christine Campagne

Vol. 20., No.4., Pages 383-394, 2026

DOI: 10.3144/expresspolymlett.2026.30

Vol. 20., No.4., Pages 383-394, 2026

DOI: 10.3144/expresspolymlett.2026.30

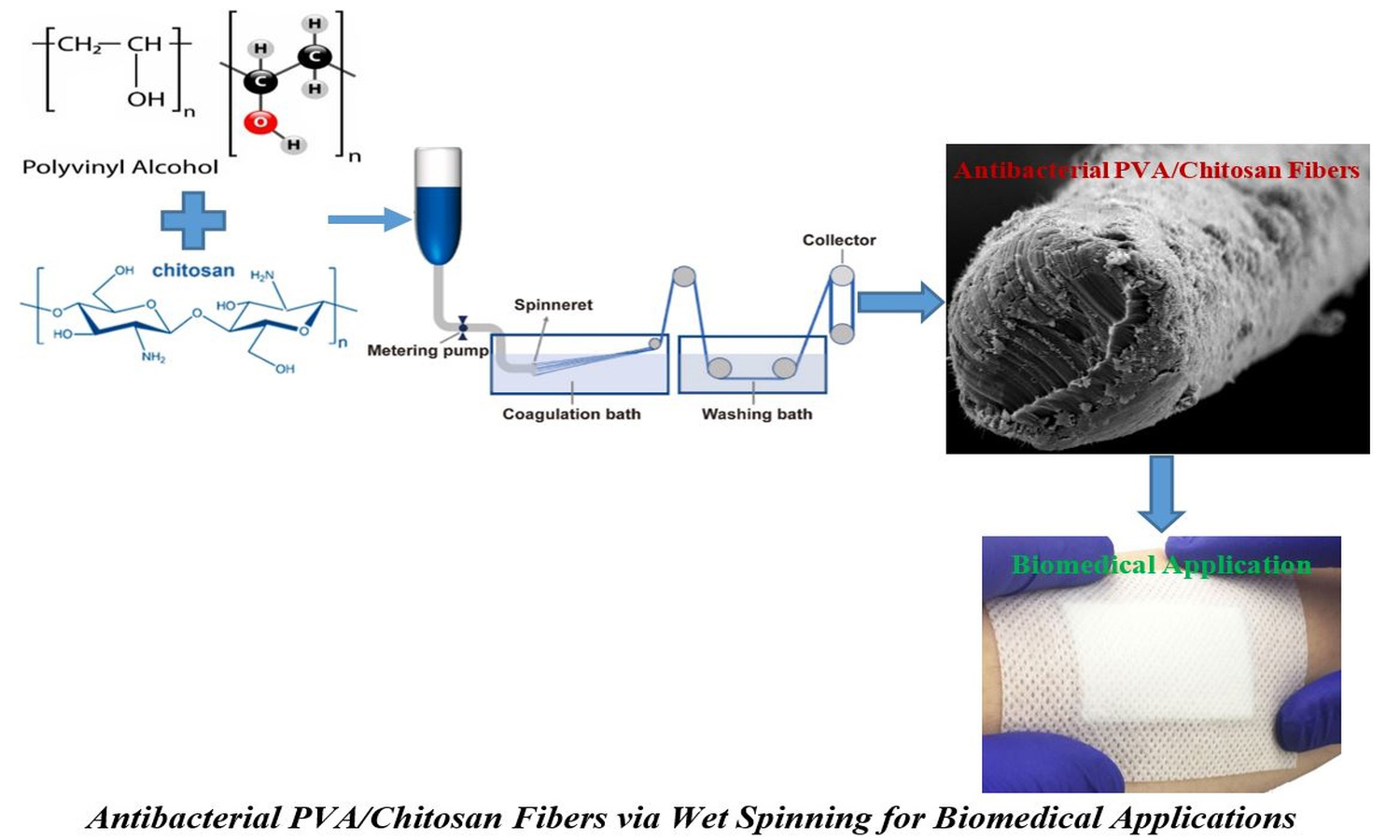

Growing interest in natural and eco-friendly materials has driven the search for sustainable alternatives to synthetic antimicrobial agents. This study aims to develop antibacterial fibers based on poly(vinyl alcohol) (PVA) reinforced with chitosan (CTS) using an environmentally friendly wet-spinning process. Morphological analysis revealed surface irregularities that increased with CTS content, confirming its effect on fiber microstructure. Thermal analyses by differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) showed that CTS incorporation decreased the melting temperature while improving thermal stability. Mechanical testing demonstrated enhanced tensile strength (σs) and Young’s modulus (E) due to strong intermolecular interactions between CTS and the PVA matrix. The highest σs (1045 MPa) was obtained at 3 wt% CTS, while E reached 7.1 GPa at 5 wt%. Antibacterial tests against Staphylococcus aureus and Escherichia coli confirmed strong activity attributed to –NH2 groups of CTS disrupting bacterial membranes. These results highlight the potential of PVA/CTS fibers for biomedical applications such as wound dressing and antibacterial materials.

Dam Xuan Thang, Tong Khanh Linh

Vol. 20., No.3., Pages 246-263, 2026

DOI: 10.3144/expresspolymlett.2026.20

Vol. 20., No.3., Pages 246-263, 2026

DOI: 10.3144/expresspolymlett.2026.20

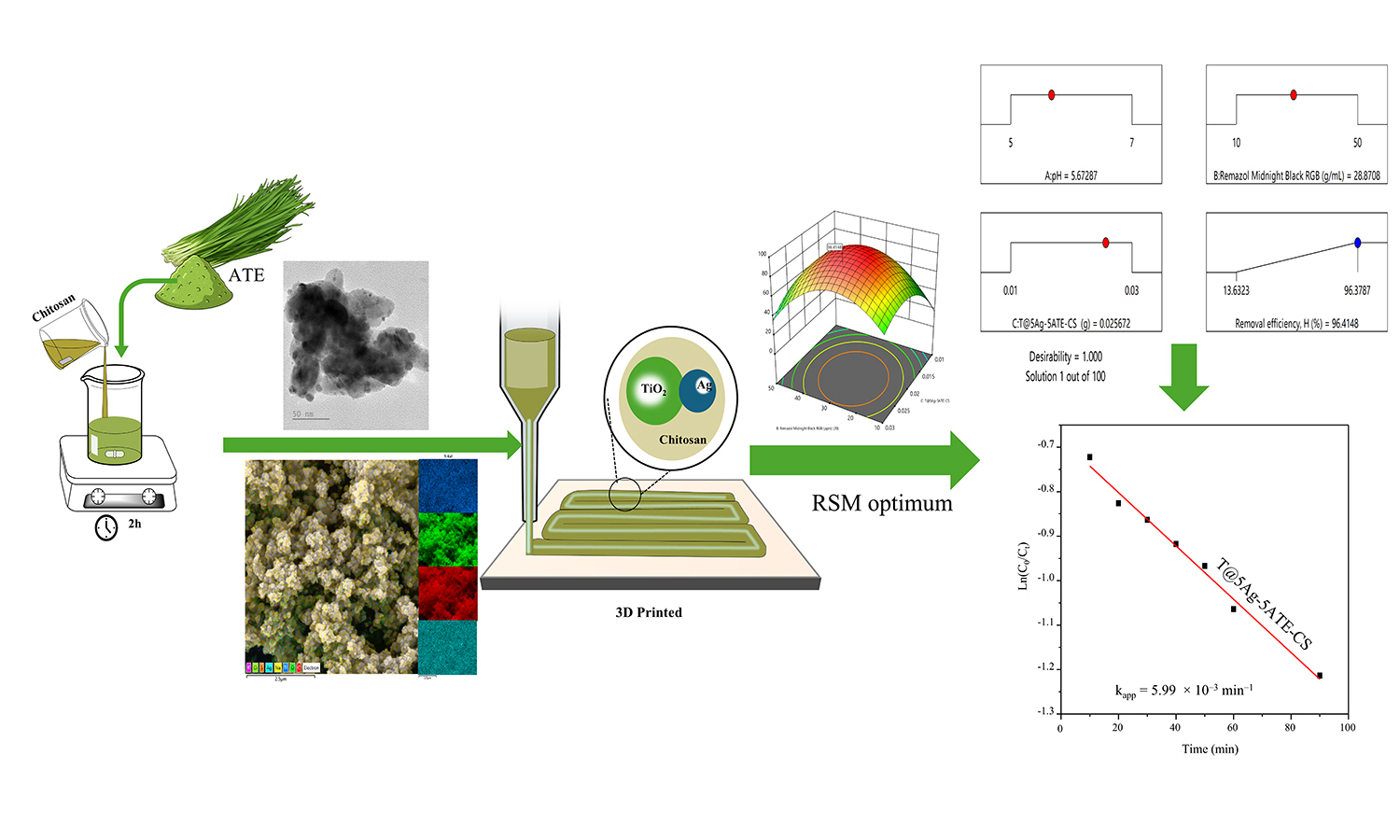

We report a green route to Ag–TiO2 nanocomposites using an Allium tuberosum extract, rich in organosulfur and polyphenolic constituents, as a dual-function biogenic reducer and stabilizer, enabling efficient Ag+→Ag0 conversion and capping of Ag–TiO2 without the use of harsh reagents. The nanocomposites are formulated into chitosan-based inks for direct ink writing (DIW) of porous, mechanically robust, reusable membranes (optimal formulation T@5Ag–5ATE–CS) with a homogeneous Ag dispersion. Multiscale characterization (SEM/TEM, XRD, FTIR, UV–vis DRS, EDS mapping) confirms metallic Ag0 uniformly decorating TiO2 and an extended visible-light response attributable to strong localized surface plasmon resonance. Under near-UV/visible irradiation, the membranes decolorize Remazol Midnight Black RGB dye with pseudo-first-order kinetics, yielding kapp up to 5.99·10–3 min–1 with R2 ≈ 0.99 and outperforming pristine TiO2. Response surface methodology identifies an optimum at pH 5.67, 28.87 mg·L–1 dye, and 0.0257 g catalyst, delivering a predicted 96.41% versus experimental 95.07% removal (validation error 1.39%) with excellent model statistics (R2 ≈ 0.995). The combined effects of Allium-tuberosum-assisted Ag plasmonics, TiO2 photocatalysis, and chitosan-enhanced adsorption underpin the high photocatalytic activity and reusability, highlighting a scalable, eco-friendly pathway to printable photocatalytic/antimicrobial membranes for wastewater treatment.

Cláudia Andréa Batista dos Santos, Bartłomiej Kryszak, Rafał Malinowski, Aleksandra Ujćič, Konrad Szustakiewicz

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

Vol. 20., No.3., Pages 264-278, 2026

DOI: 10.3144/expresspolymlett.2026.21

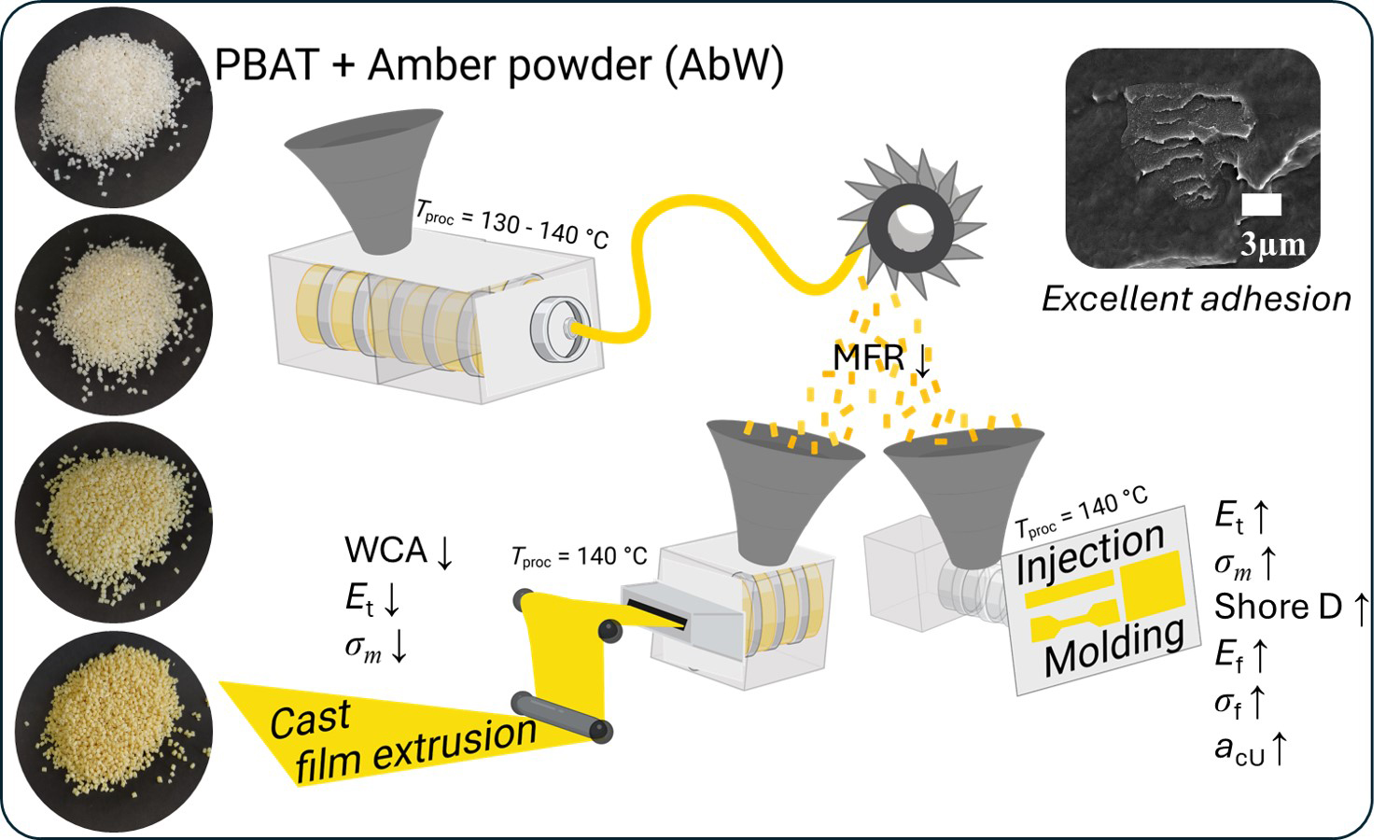

This study investigates the interaction between poly(butylene adipate-co-terephthalate) (PBAT) and amber powdered waste (AbW) from jewelry at different filler concentrations (0, 1, 2.5, and 5 wt%) obtained via melt mixing in a corotating twin screw extruder. The resulting materials were pelletized and processed using two techniques: 1) cast film extrusion and 2) injection molding. The shaped specimens exhibited excellent interfacial adhesion. Thermal behavior, as assessed by Vicat softening temperature (VST), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA), showed minimal variation among the composites. Despite similar melt flow rate (MFR) values among the samples, the incorporation of AbW affected the behavior of the polymer during cast film extrusion. Consequently, the composite films exhibited lower tensile mechanical parameters (tensile strength, Young’s modulus, stress and strain at break) compared to the neat PBAT film. In turn, the injection molded composites showed improved tensile, flexural, and impact parameters compared to their neat counterpart. Additionally, a slight decrease in water contact angle (WCA) suggested increased surface hydrophilicity of the extruded films. These findings demonstrate the potential of AbW as an additive for biopolymer composites with enhanced mechanical performance. The increased surface hydrophilicity is particularly relevant for applications targeting biocompatibility and biodegradability.

Evangelia Balla, Panagiotis Klonos, Apostolos Kyritsis, Dimitrios Bikiaris

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

Vol. 20., No.2., Pages 154-167, 2026

DOI: 10.3144/expresspolymlett.2026.13

In recent decades, numerous efforts have been dedicated to the investigation of eco-friendly non-isocyanate polyurethanes (NIPUs) as alternatives to conventional polyurethanes (PUs). Since isocyanates are classified by the EU as hazardous and toxic compounds, NIPUs offer a promising route to mitigate isocyanate-related health risks as well as other environmental concerns associated with traditional PU synthesis. In the present study, we report the synthesis as well as the detailed structural and thermal characterization of a new series of fully biobased non-isocyanate polyurethanes (NIPUs) based on aliphatic dicarboxylic acids of different chain lengths. The NIPUs were prepared via a two-step polyaddition reaction involving glycerol carbonate and diamine. Their synthesis enables a sustainable pathway to tailor NIPUs’ physicochemical properties via diacid structure control. Studies of their structure, thermal behavior and trends, morphological, and hydrolytic findings confirmed strong diacid chain length dependence on glass transition temperature (Tg ~13, 0, ‒5 and –23 °C), molecular weight, surface wettability, and enzymatic degradability. Short-chain diacids yielded NIPUs with rapid hydrolytic degradation, while their longer-chain analogs were hydrophobic and thermally stable. Contact angle measurements (~75–85°) also confirm these trends. The tunable properties position these materials among strong candidates for biomedical applications.

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

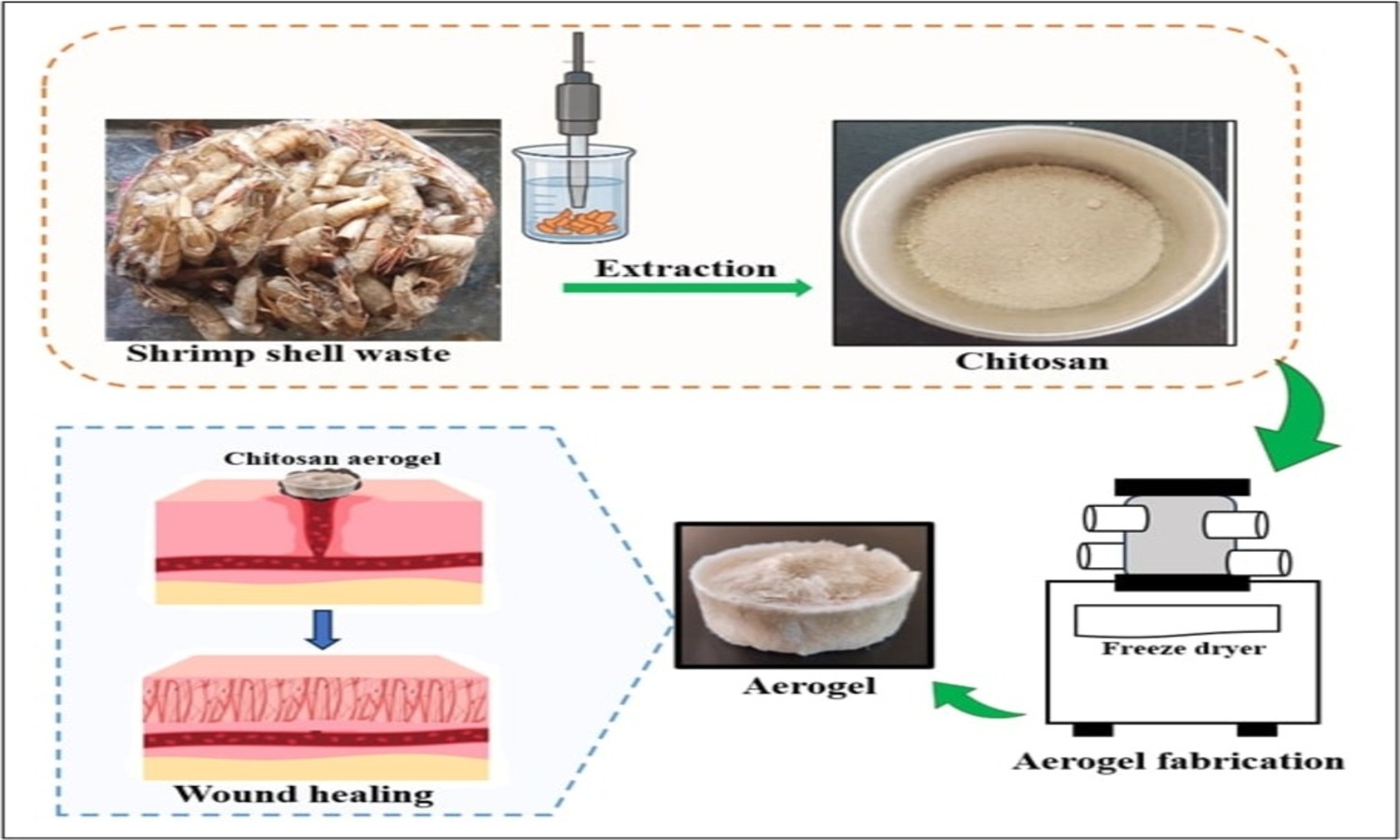

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.