Fibers and safety in fire retarded polymer systems: Are we just at the beginning of the road?

György Marosi, Katalin Bocz

Vol. 18., No.2., Pages 116-117, 2024

DOI: 10.3144/expresspolymlett.2024.9

DOI: 10.3144/expresspolymlett.2024.9

GRAPHICAL ABSTRACT

RELATED ARTICLES

Yashpal Singh, Raj Kumar, Nikhil Chauhan, Tejas Pramod Naik, Inderdeep Singh

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

Vol. 20., No.1., Pages 97-111, 2026

DOI: 10.3144/expresspolymlett.2026.8

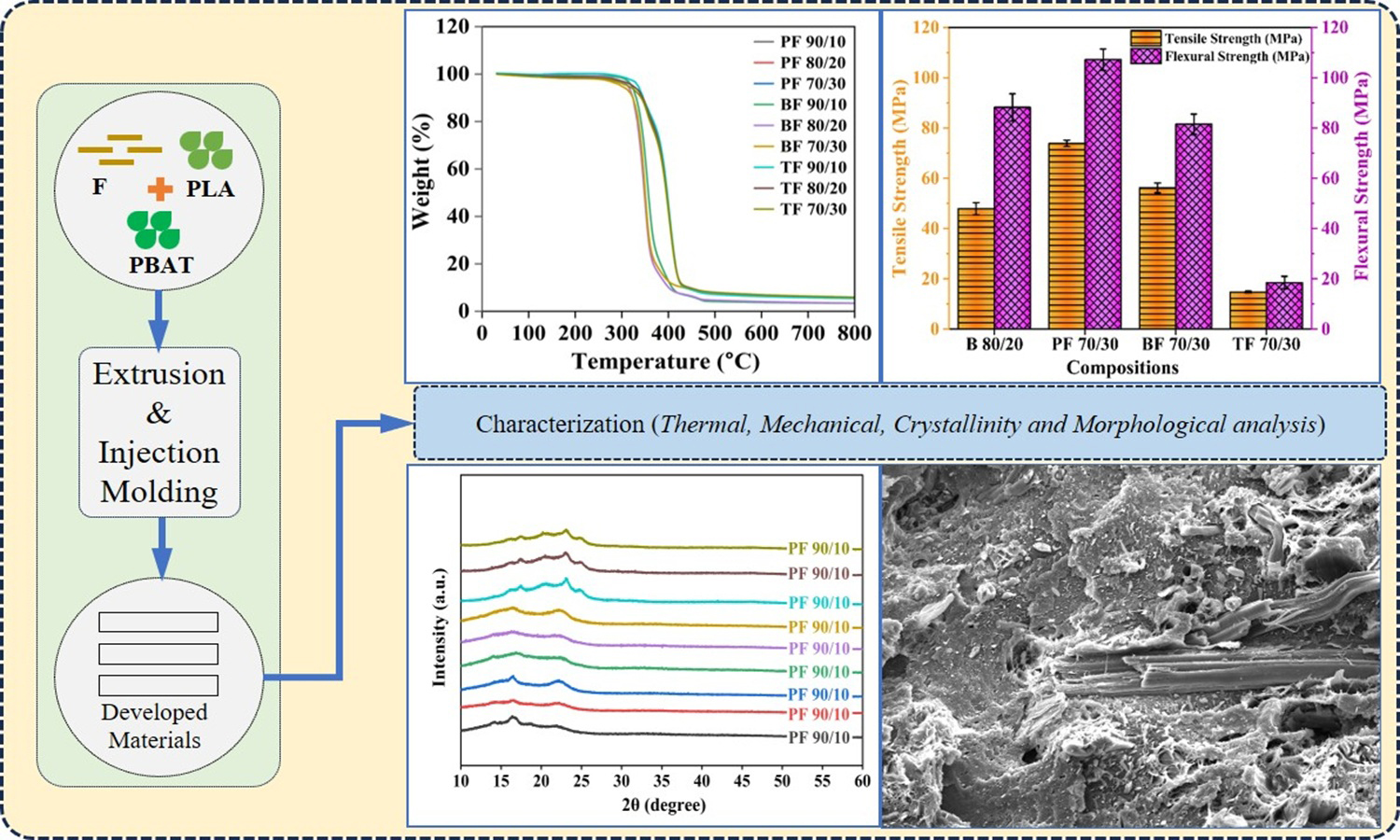

The current experimental investigation presents a comparative evaluation of selected biodegradable polymer blends and their composites, focusing on their material properties. Two biopolymers, polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), along with pineapple fibers (F), as bio-reinforcement were taken for the analysis, which was conducted in two stages: During first stage, PBAT was melt-blended with PLA in varying weight fractions (10, 20, 30, 40, and 50 wt%) to produce PLA/PBAT blend (B) and in second stage, PLA, PBAT, B 80/20 blend were reinforced with pineapple fiber (10, 20, and 30 wt%). The samples were fabricated using extrusion-injection molding. The samples were characterized for density, thermal degradation, crystallinity, and mechanical behaviour. Among the blends, the optimal B 80/20 combination exhibited tensile strength, flexural strength, and elongation at break of 47.9±2.4, 88.2±5.4 MPa, and 330.6±10.47%, respectively. Results indicate that the PLA-based composites (PF) exhibit significantly better density, tensile strength, and flexural strength as compared to neat polymers, blends, blend-based composites (BF), and PBAT-based composites (TF). Among the PF composites, the PF 70/30 composite demonstrated superior performance, with maximum tensile and flexural strength values of 73.9±1.3 and 107.1±4.3 MPa, respectively.

Rattanawadee Hedthong, Thorsak Kittikorn, Suding Kadea, Phuthanet Bamrungsiri

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

Vol. 19., No.4., Pages 423-440, 2025

DOI: 10.3144/expresspolymlett.2025.31

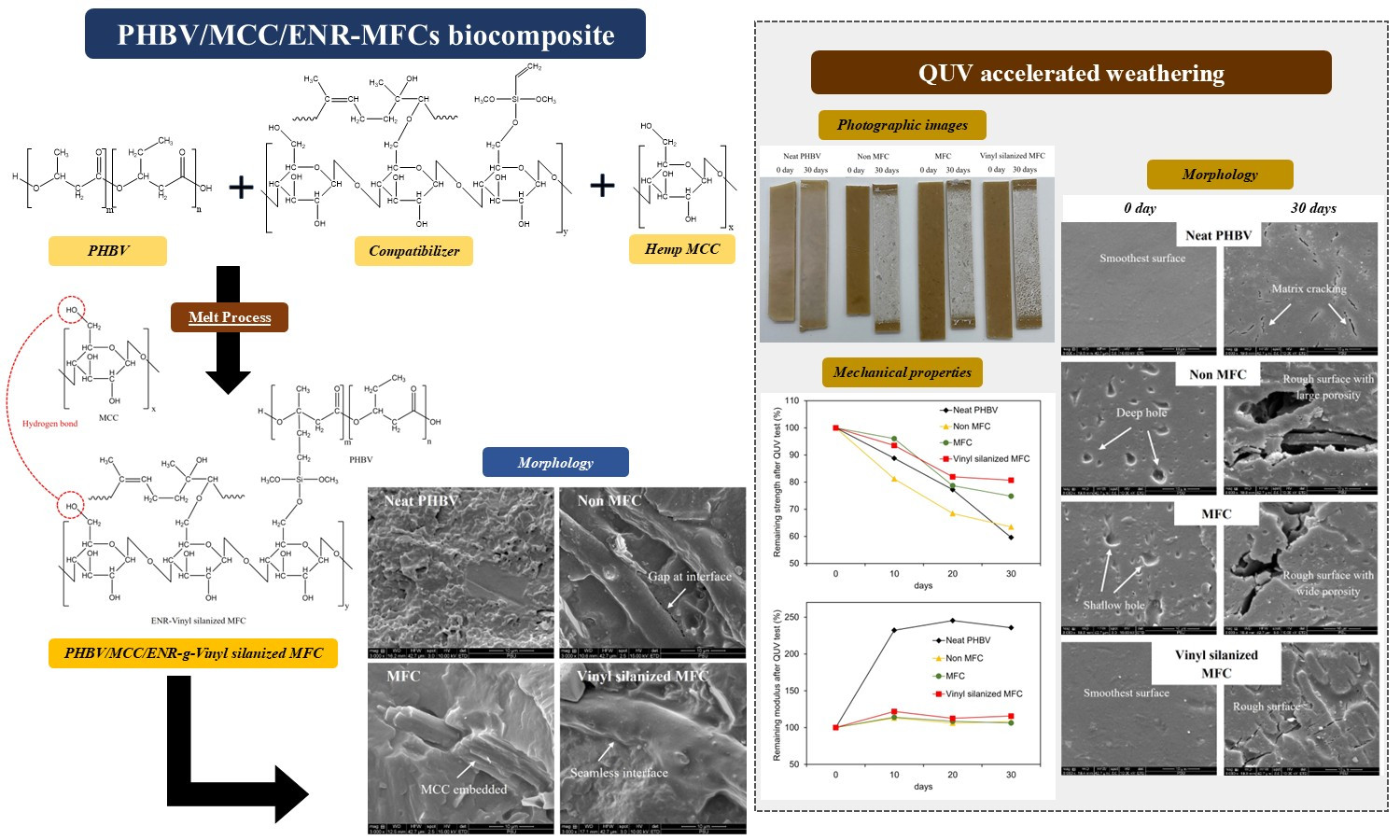

This research aimed to enhance the properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) biocomposites by incorporating hemp microcrystalline cellulose (MCC). Additionally, to improve interfacial adhesion between PHBV and MCC phases, a compatibilizer consisting of epoxidized natural rubber (ENR) grafted with microfibrillated cellulose (MFC) modified by vinyltrimethoxysilane (ENR-vinyl silanized MFC) was introduced. The addition of 5 wt% MCC increases the flexural modulus by approximately 65%. The use of ENR-vinyl silanized MFC as a compatibilizer demonstrated improved compatibility, as observed in scanning electron microscope (SEM) images. After 30 days of accelerated weathering (QUV) exposure, the flexural strength of the PHBV-based biocomposite with ENR-vinyl silanized MFC and MCC (vinyl silanized MFC biocomposite) was superior to that of the other samples. The remaining flexural strength can be sequentially categorized as follows: vinyl silanized MFC > MFC > non-MFC > PHBV. The Tg of PHBV-based biocomposites showed no significant change. Interestingly, the crystallinity of the vinyl silanized MFC biocomposite was the highest among all materials and demonstrated higher hydrophobicity. This makes the vinyl silanized MFC biocomposite a suitable material for construction, furniture, and both exterior and interior decoration.

Ju Li, Lize Yang, Shuo Chen, Guotao Sun

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

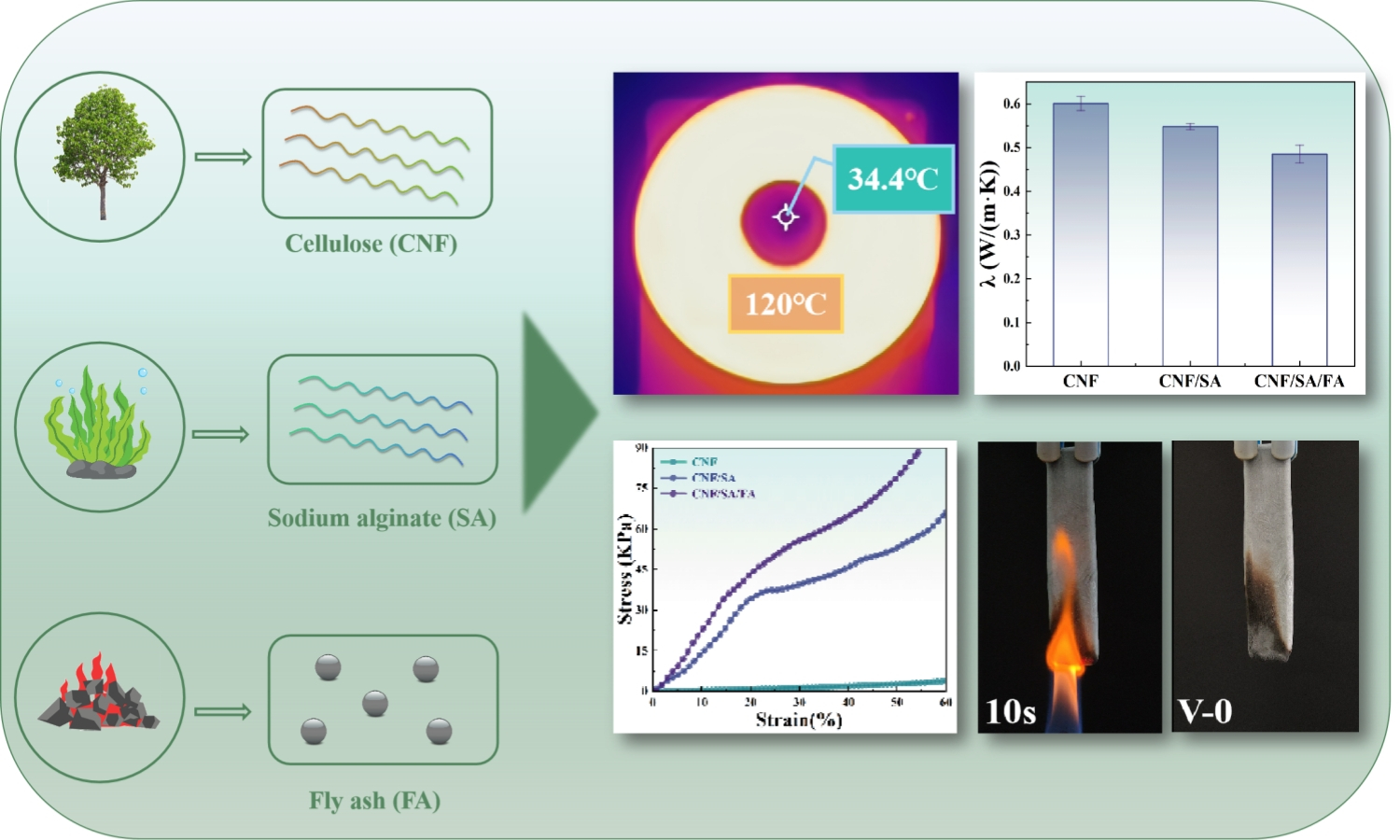

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

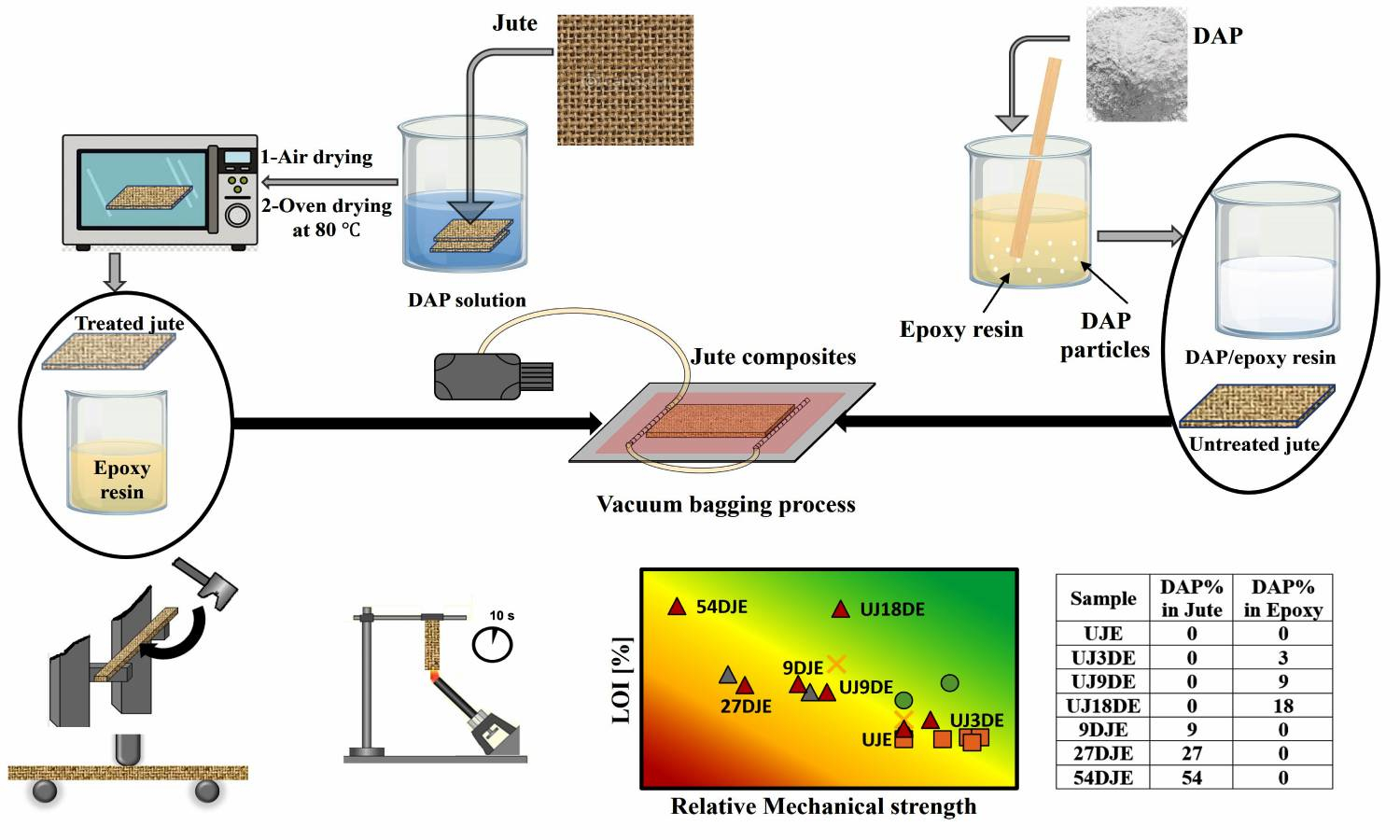

Noha Ramadan, Mohamed Taha, Ahmed Elsabbagh

Vol. 18., No.8., Pages 779-795, 2024

DOI: 10.3144/expresspolymlett.2024.58

Vol. 18., No.8., Pages 779-795, 2024

DOI: 10.3144/expresspolymlett.2024.58

Natural fibre-reinforced polymer composite (NFRPC) has been introduced as one of the solutions to overcome the ecological and environmental problems accompanying the widespread usage of polymeric materials in every facet of life. However, the organic nature of both natural fibres (NFs) and polymers increases their flammability behaviour, and this, in turn, limits their application. In this regard, this work concentrates on studying the effect of adding flame retardants (FR) to jute-reinforced epoxy composites (JRECs), either by treating the jute fabric with diammonium phosphate (DAP) or adding DAP powder to the epoxy resin matrix on the flame retardancy performance as well as the mechanical properties. The results showed that the effect of the incorporation method of DAP either to jute fabric or to resin matrix has a significant difference on the flammability test results at low concentrations; however, at higher concentrations, the flame retardancy performance is not affected by the technique of adding FR to the composite system. On the other hand, the mechanical properties are significantly affected by the method of incorporating FR to JRECs at all concentrations. Moreover, the results obtained from JRECs with FR systems were evaluated and compared with the literature by constructing selection charts that relate the flame retardancy level to mechanical properties.

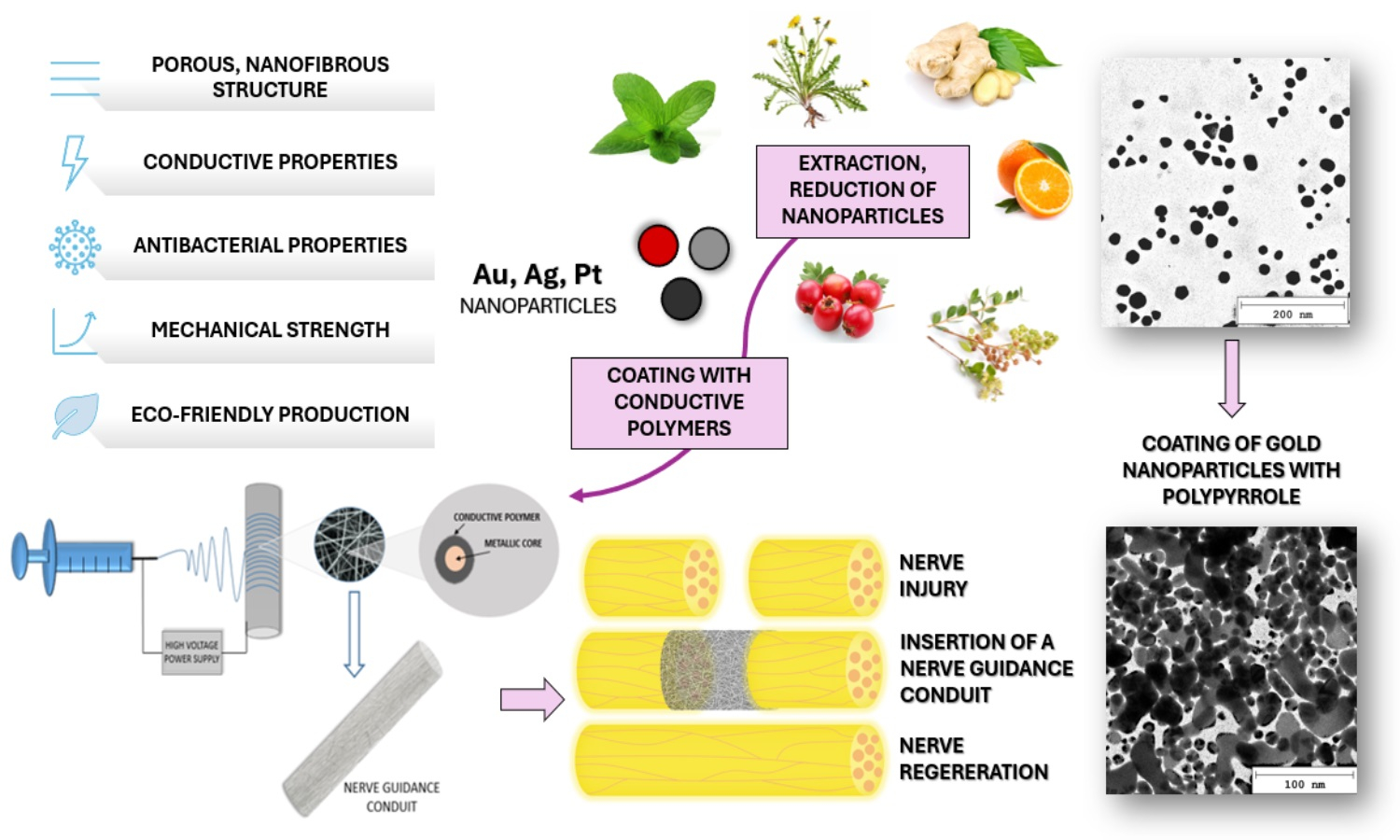

Aleksandra Sierakowska-Byczek, Julia Radwan-Pragłowska, Łukasz Janus, Tomasz Galek, Karol Łysiak, Mirosław Tupaj, Dariusz Bogdał

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Appropriate protection and guiding are crucial during peripheral nerves repair. New generation nerve guidance conduits (NGCs) should not only provide mechanical support for the damaged nerve but also support healing processes. One of the most promising tissue regeneration applications is fibrous biomaterials since they are characterized by high porosity, flexibility, and strength. Additionally, they enable cell adhesion and proliferation. In this study, novel fibrous nanocomposites were obtained by applying the electrospinning technique, using polylactic acid (PLA) as a polymeric matrix which was further modified with metallic nanoparticles coated with conductive polymers. Such an approach resulted in the obtainment of biomaterials with a potential ability to conduct nerve impulses. The chemical structure of the obtained composites, as well as the morphology of ready products and separate nanocomponents, were investigated using Fourier-transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscope (SEM) techniques. Furthermore, conductive and swelling properties in various media were determined. Finally, biomaterials were confirmed to be non-cytotoxic to L929 mouse fibroblasts and 1321N1 human glial cells. Based on the presented results, it can be concluded that nanofibrous nerve guidance conduits have all the key properties in the process of peripheral nerve regeneration and may constitute an important step in novel NGCs development.