Preparation and characterization of novel nanofibrous composites prepared by electrospinning as potential nerve guidance conduits (NGCs)

Aleksandra Sierakowska-Byczek , Julia Radwan-Pragłowska

, Julia Radwan-Pragłowska , Łukasz Janus, Tomasz Galek

, Łukasz Janus, Tomasz Galek , Karol Łysiak, Mirosław Tupaj

, Karol Łysiak, Mirosław Tupaj , Dariusz Bogdał

, Dariusz Bogdał

, Julia Radwan-Pragłowska

, Julia Radwan-Pragłowska , Łukasz Janus, Tomasz Galek

, Łukasz Janus, Tomasz Galek , Karol Łysiak, Mirosław Tupaj

, Karol Łysiak, Mirosław Tupaj , Dariusz Bogdał

, Dariusz Bogdał

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

DOI: 10.3144/expresspolymlett.2024.61

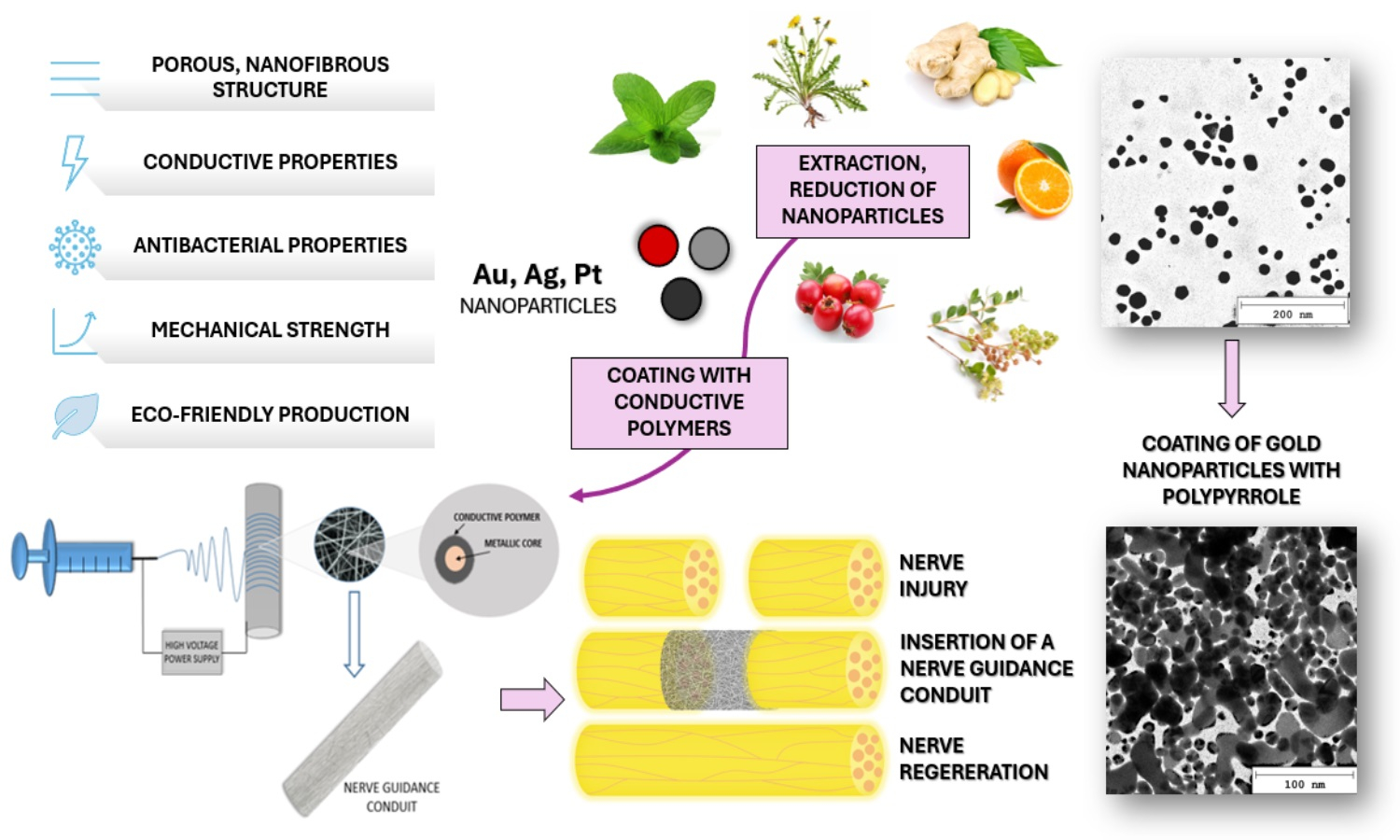

GRAPHICAL ABSTRACT

ABSTRACT

Appropriate protection and guiding are crucial during peripheral nerves repair. New generation nerve guidance conduits (NGCs) should not only provide mechanical support for the damaged nerve but also support healing processes. One of the most promising tissue regeneration applications is fibrous biomaterials since they are characterized by high porosity, flexibility, and strength. Additionally, they enable cell adhesion and proliferation. In this study, novel fibrous nanocomposites were obtained by applying the electrospinning technique, using polylactic acid (PLA) as a polymeric matrix which was further modified with metallic nanoparticles coated with conductive polymers. Such an approach resulted in the obtainment of biomaterials with a potential ability to conduct nerve impulses. The chemical structure of the obtained composites, as well as the morphology of ready products and separate nanocomponents, were investigated using Fourier-transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscope (SEM) techniques. Furthermore, conductive and swelling properties in various media were determined. Finally, biomaterials were confirmed to be non-cytotoxic to L929 mouse fibroblasts and 1321N1 human glial cells. Based on the presented results, it can be concluded that nanofibrous nerve guidance conduits have all the key properties in the process of peripheral nerve regeneration and may constitute an important step in novel NGCs development.

RELATED ARTICLES

Soni Thakur, Amal M. Sindi, Rahul Dev Bairwan, Rasha A. Mahmoud, Eman Alfayez, Nurul Fazita Mohammad Rawi, Kanchan Jha, H.P.S. Abdul Khalil

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

Vol. 20., No.2., Pages 197-214, 2026

DOI: 10.3144/expresspolymlett.2026.16

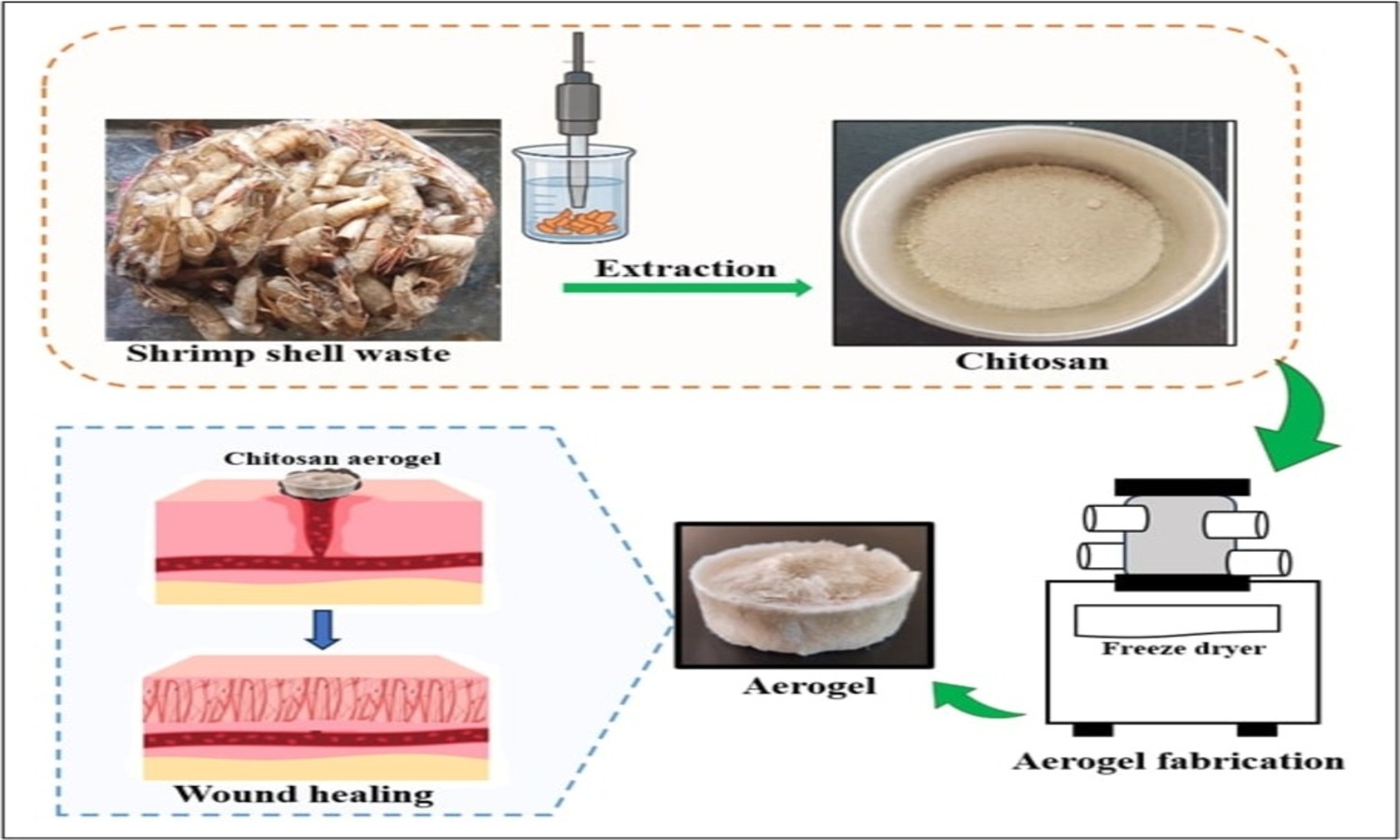

This research presents an eco-friendly approach for extracting chitosan from shrimp shell waste through ultrasound-assisted extraction (UAE) to prepare biocompatible aerogel scaffolds for biomedical applications. The study investigates the influence of various ultrasonic treatment times (10, 20, 30, 40 min) on the yield and structural and physicochemical properties of the extracted chitosan via characterization using Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA). Among the tested conditions, the 30 min UAE-treated chitosan aerogels showed optimal porosity and structural integrity. Biocompatibility of the aerogels was evaluated, and the results confirmed their non-cytotoxic nature. The bioactivity of the chitosan aerogels was evaluated in terms of their in vitro wound closure ability and antibacterial properties. The aerogels demonstrated a wound closure rate of around 51% after 72 h, significantly higher than the untreated control (37%). In addition, they exhibited clear antibacterial activity against Escherichia coli and Staphylococcus aureus. This sustainable extraction and fabrication method not only adds value to marine waste but also produces functional biomaterials with potential applications in wound healing, tissue engineering, and regenerative medicine, supporting global efforts toward sustainability and circular bioeconomy.

Eva Kuželová Košťáková

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

This is an editorial article. It has no abstract.

Jordi Puiggalí

Vol. 19., No.12., Pages 1214-1215, 2025

DOI: 10.3144/expresspolymlett.2025.89

Vol. 19., No.12., Pages 1214-1215, 2025

DOI: 10.3144/expresspolymlett.2025.89

This is an editorial article. It has no abstract.

Mark Shneider, Xiaomeng Sui, Iddo Pinkas, Ulyana Shimanovich, Israel Greenfeld, Daniel Wagner

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

Vol. 19., No.10., Pages 1012-1026, 2025

DOI: 10.3144/expresspolymlett.2025.76

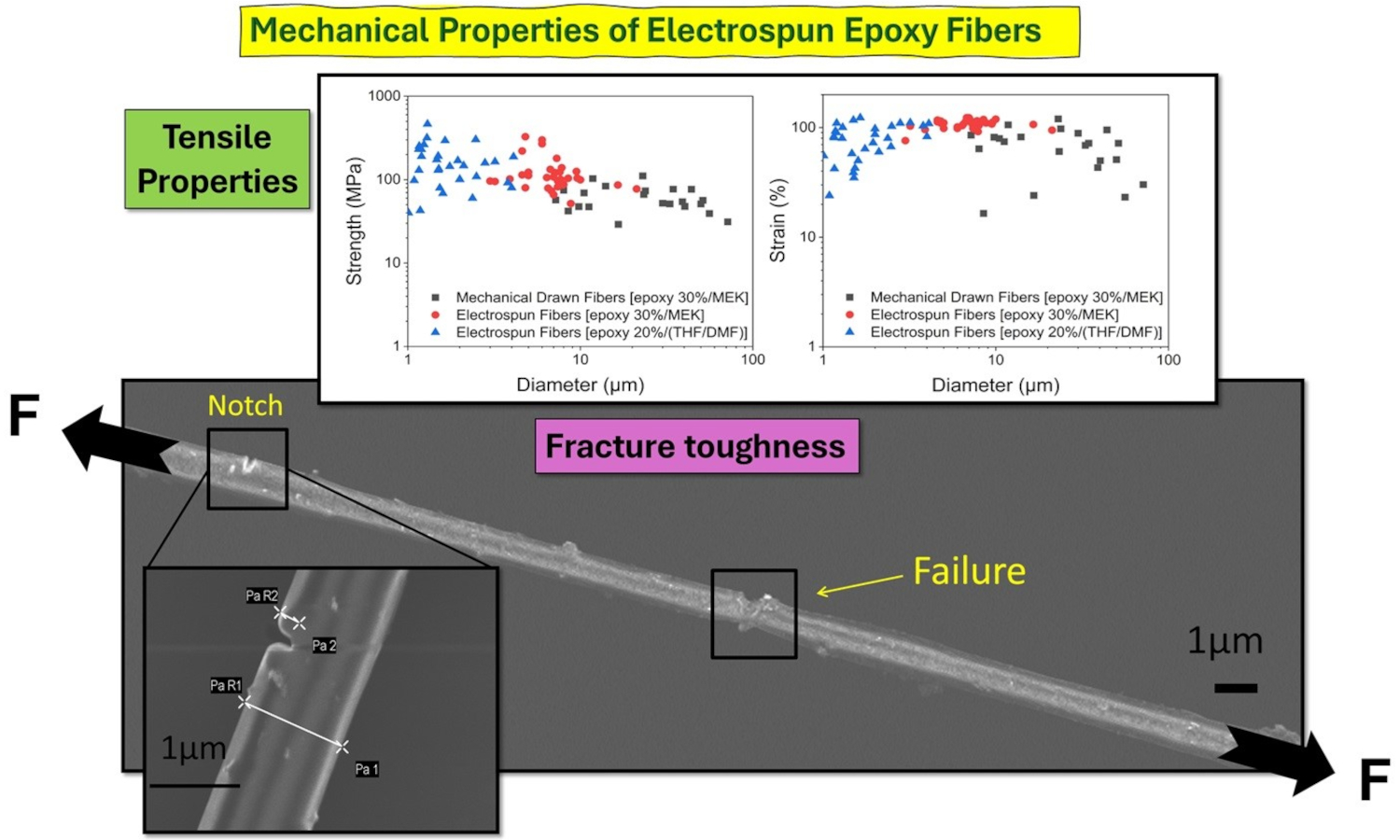

Electrospinning is a widely used technique for manufacturing nanofibers from polymers. The formation of continuous fibers during the drawing of a viscous solution typically depends on entanglements between polymer chains, making thermoplastics the preferred choice. In this study, we have shown that thermosetting polymers such as epoxy, which have crosslinked covalent bonds, can also be electrospun. The resulting fibers have diameters ranging from 150 nm to 6 μm. Tensile mechanical properties of fibers with diameters varying between 410 nm and 4 μm are compared with those of molded epoxy bulk. The electrospun fibers exhibit approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to the equivalent properties of bulk epoxy. When compared with brittle molded bulk, these fibers showed ductile properties. We also observed a correlation between the fiber diameter and the mechanical properties. The molecular morphology of the fibers was monitored and analyzed using polarized micro-Raman spectroscopy to detect molecular orientation. A comparison with epoxy fibers of different diameters from previous studies was conducted to better understand the size effect. This study shows, explains and models the evolution of epoxy molecular morphology from the solution (soft matter) to fiber (solid-state), explaining the transition from brittle to ductile in epoxy fibers, and clarifying the molecular mechanisms that lead to improved mechanical properties.

Mehmet Selim Demirtaş, Mrinal C. Saha

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

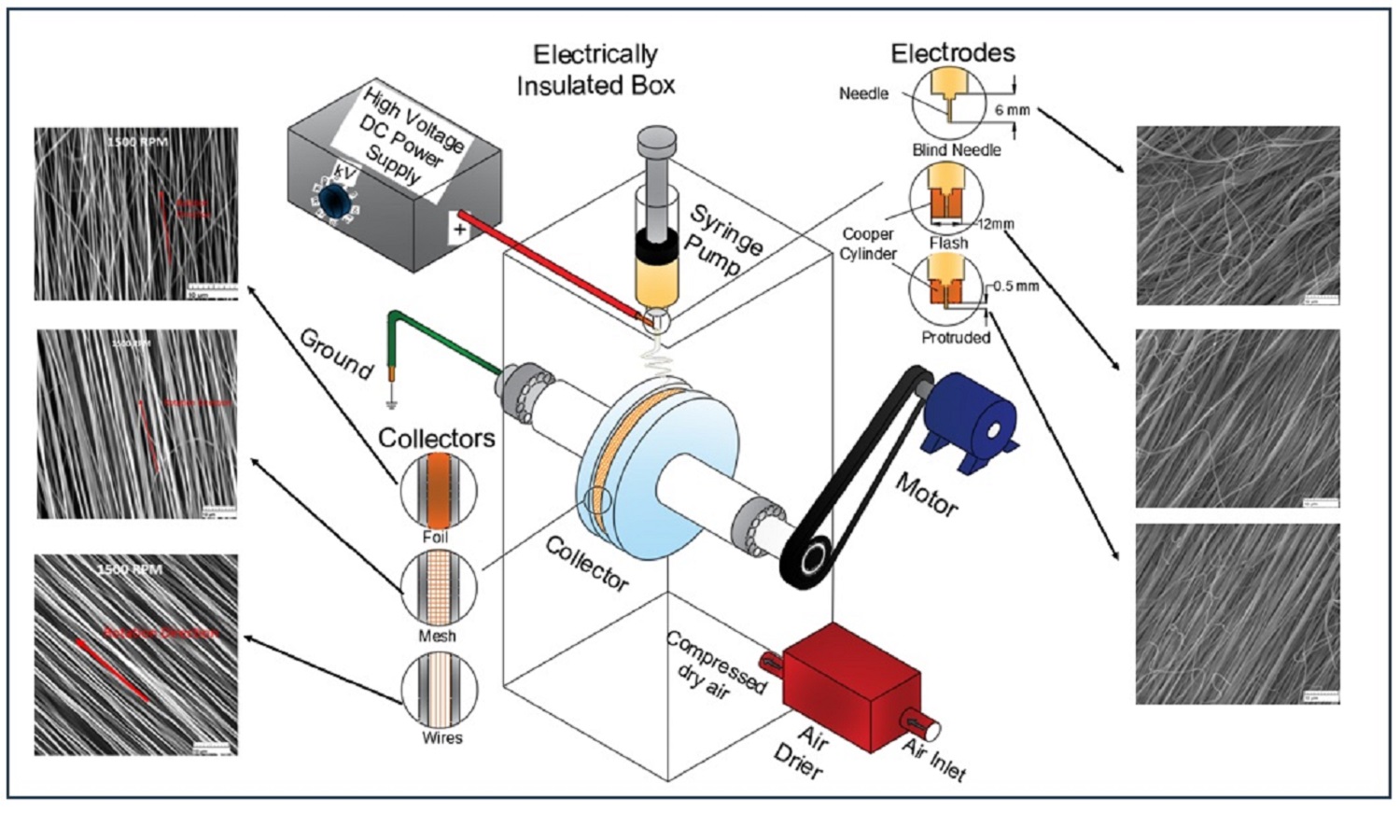

Nanomaterials, particularly nanofibers produced through electrospinning, have garnered significant attention due to their unique properties and diverse applications. This research explores the influence of collector design, electrode geometry, and collector speed on the properties of electrospun polyacrylonitrile (PAN) nanofibers. Finite element analysis (FEA) was employed to simulate electric fields, revealing the impact of collector geometry on field intensity. The experimental setup, enclosed in an isolated chamber, employed various collector types and electrode configurations. Scanning electron microscope (SEM) analysis showcased the effect of collector speed on fiber alignment and diameter. Furthermore, FEA simulations elucidated the role of electrode geometry and voltage in shaping the electric field, impacting fiber properties. The study introduces a novel, in-house method for producing highly aligned nanofibers and provides insights into optimizing electrospinning parameters for enhanced fiber properties. A testing protocol is devised to minimize surface damage when conducting mechanical tests on nanofiber films, employing a dynamic mechanical analyzer (DMA). Mechanical testing demonstrated the correlation between alignment and tensile strength. Overall, this research contributes valuable insights for tailoring electrospinning processes for tissue engineering and energy storage.