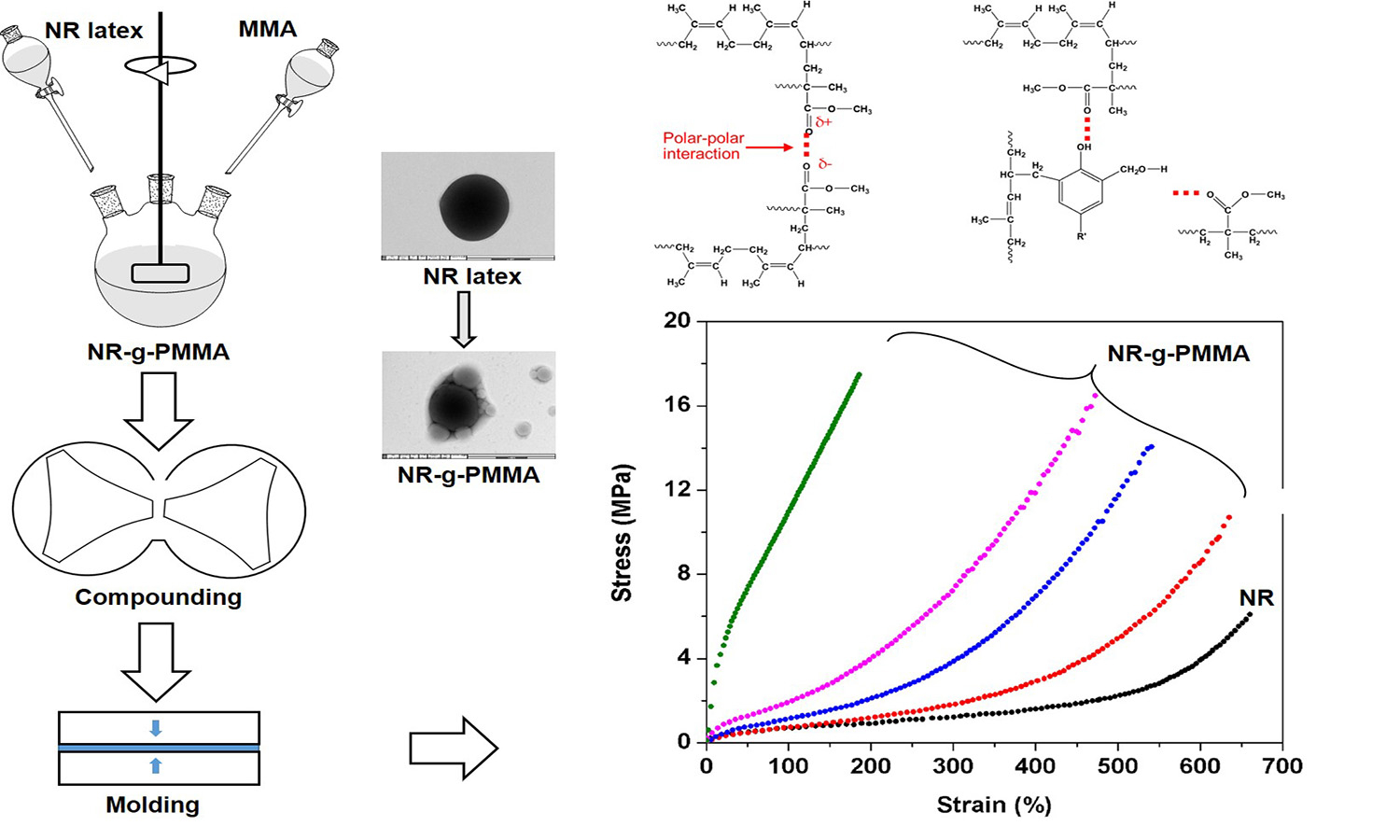

Structure and properties of resole resin crosslinked vulcanizates of natural rubber grafted with polymethylmethacrylate

Vol. 18., No.5., Pages 546-558, 2024

DOI: 10.3144/expresspolymlett.2024.40

DOI: 10.3144/expresspolymlett.2024.40

GRAPHICAL ABSTRACT

ABSTRACT

The structure and property relationships of graft copolymers from natural rubber (NR) and polymethyl methacrylate (PMMA) crosslinked with a phenolic resin were investigated. The NR grafted with PMMA (NR-g-PMMA) having different grafting levels was initially prepared by emulsion polymerization before compounding and vulcanization. Then, proton nuclear magnetic resonance and transmission electron microscopy were used to verify the resultant NR-g-PMMAs. The graft copolymers crosslinked with phenolic resin exhibited improvements in various properties. Tensile modulus and tensile strength increased at least 18 and 95%, respectively, over the un-grafted counterpart and further improved with grafting percentage, while the elongation at break decreased accordingly. Storage modulus in rubbery plateau increased while tanδ peak height decreased with PMMA content. Moreover, the thermal stability of the graft copolymers was also improved over that of the plain NR at least 23 °C, depending on MMA contents. These improvements are tentatively attributed to the strong adhesion between NR and PMMA phases, based on interactions between the functional groups of PMMA and hydrogen bonding between phenolic resin crosslinker and PMMA. The results clearly suggest that the phenolic resin could be an effective crosslinker for NR-g-PMMA.

RELATED ARTICLES

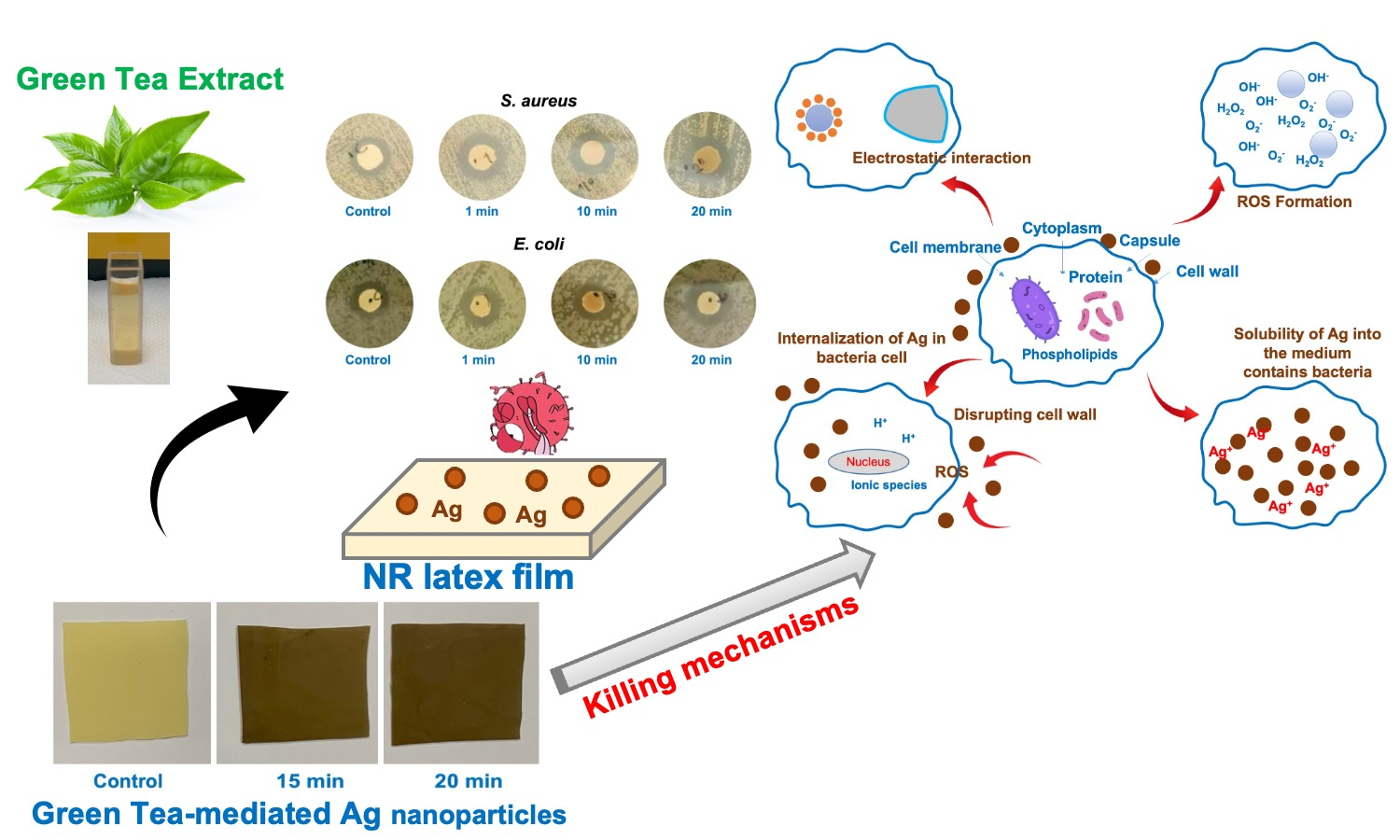

Abdulhakim Masa, Nureeyah Jehsoh, Sawitree Dueramae, Nabil Hayeemasae

Vol. 19., No.7., Pages 653-669, 2025

DOI: 10.3144/expresspolymlett.2025.50

Vol. 19., No.7., Pages 653-669, 2025

DOI: 10.3144/expresspolymlett.2025.50

An antibacterial natural rubber (NR) latex film was successfully prepared in this study. This was done by coating silver (Ag) nanoparticles onto the surface of the NR latex film. The Ag nanoparticles were synthesized using green tea (GT) extract as a bio-reducing agent. The corresponding Ag nanoparticles were then deposited onto the NR latex film. Before synthesis, the phenolic compounds were identified using high-performance liquid chromatography (HPLC). The Ag nanoparticles were found to be smaller than 25 nm in size. Subsequently, an experimental evaluation was conducted to determine the influence of deposition time, namely 1 to 20 min, on the film’s overall performance. Scanning electron microscopy (SEM) with energy dispersive X-ray spectroscopy (SEM-EDX) confirmed that the Ag content was higher over the deposition time. The surface roughness of the samples was also screened by atomic force microscopy (AFM), where the films became rougher over the deposition time, confirming that Ag nanoparticles dispersed over the surface. As for the antibacterial activities, both qualitative and quantitative tests showed significant outputs. The clear zones of S. aureus and E. coli increased over the deposition time, and a shorter contact time was used to kill the bacteria. This study offers a scientific foundation that supports the development of future rubber products utilizing these findings.

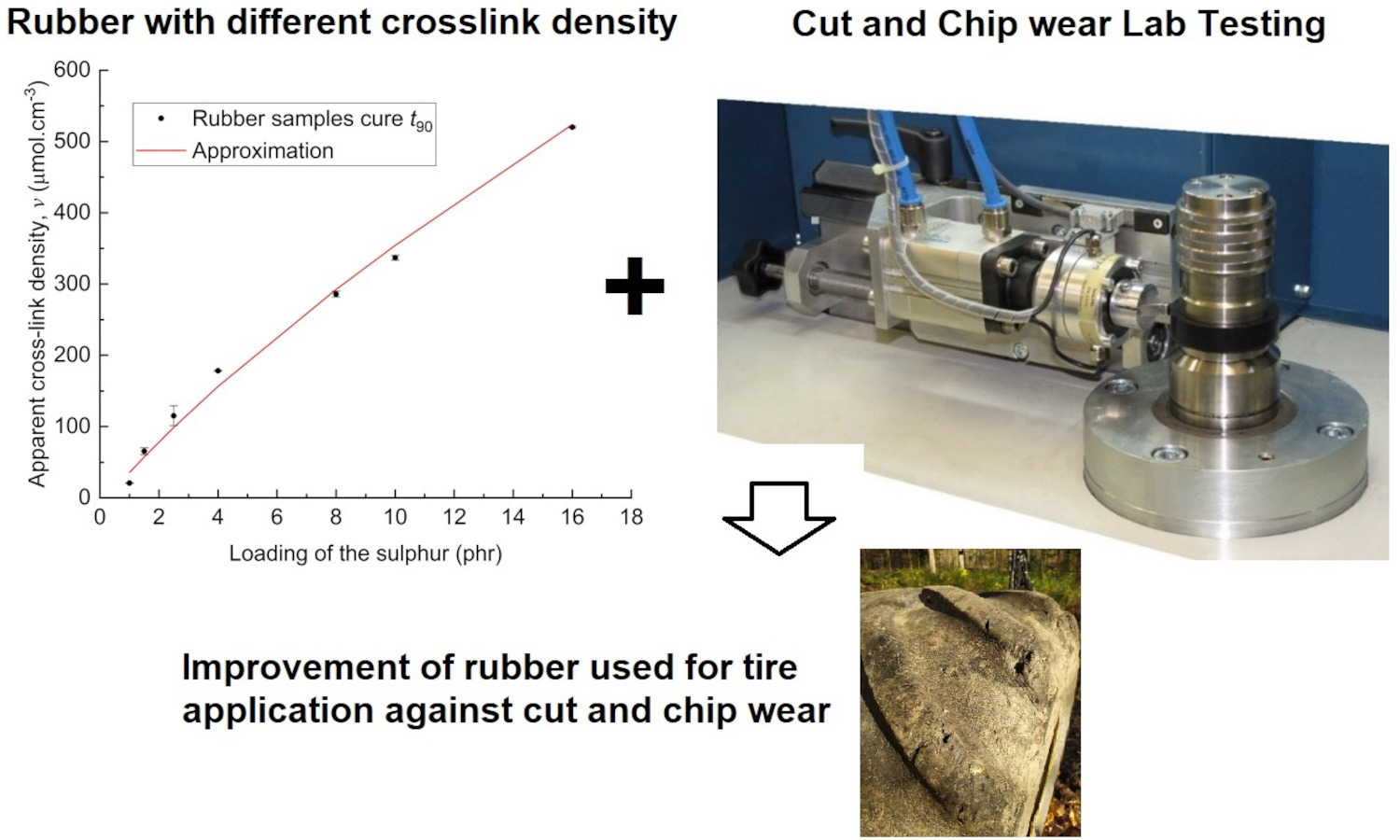

Marek Pöschl, Radek Stoček, Petr Zádrapa, Martin Stěnička, Gert Heinrich

Vol. 18., No.12., Pages 1178-1190, 2024

DOI: 10.3144/expresspolymlett.2024.90

Vol. 18., No.12., Pages 1178-1190, 2024

DOI: 10.3144/expresspolymlett.2024.90

This paper extends previous studies by the authors that aimed to describe the effect of apparent cross-link density (CLD) of the rubber polymer networks on the fracture mechanism caused by cut and chip (CC) wear of natural rubber (NR), demonstrating the positive effect of conventional vulcanization (CV). This work is focused on the determination of the effect of CLD while keeping constant the accelerator-to-sulfur ratio A/S = 0.2, typical for CV systems. For this ratio, different sulfur quantities were chosen, and the concentration of the accelerator N-tert-butyl-benzothiazole sulphonamide (TBBS) was calculated to achieve CLDs in a range from 35 to 524 μmol・cm–3. Standard analyses such as tensile tests, hardness, rebound resilience and DIN abrasion were performed. From these analyses, the optimum physical properties of the NR-based rubber were estimated to be in the CLD range of approximately 60 to 160 μmol・cm–3. A CC wear analysis was performed with an Instrumented cut and chip analyzer (ICCA) and it was found that the highest CC wear resistance of the NR is in the CLD range of 35 to 100 μmol・cm–3. Furthermore, the effect of straininduced crystallization (SIC) of NR on CC wear and its dependence on the CLD region was discussed. For the first time, we determine a CLD range for a CV system in which the material achieves both optimal mechanical properties and CC wear resistance.

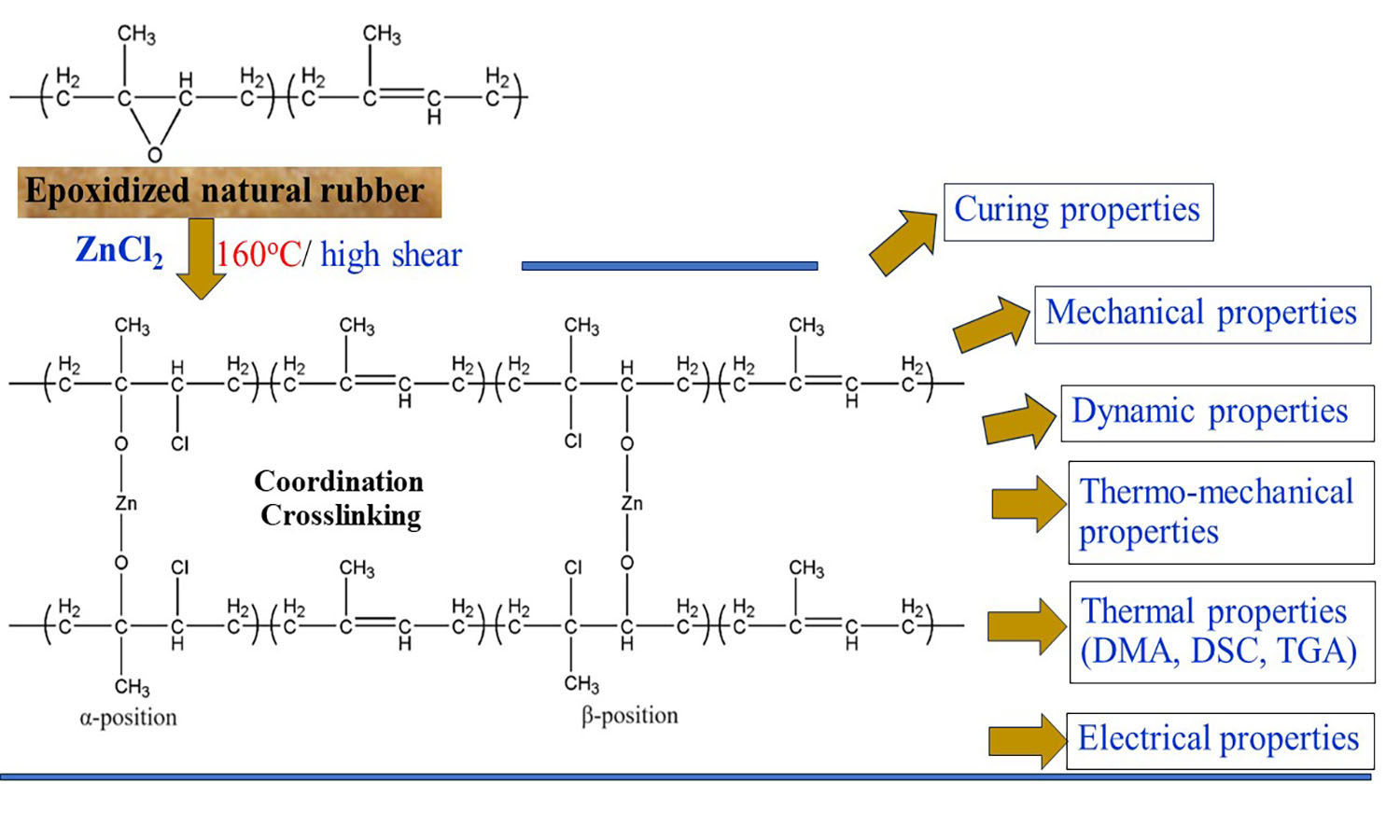

Kamonthip Rittimas, Skulrat Pichaiyut, Charoen Nakason

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

Epoxidized natural rubber with 50 mol% epoxide (ENR-50) was compounded with zinc chloride (ZnCl2) and subjected to torque response analysis using a moving die rheometer. It was found that different ZnCl2 concentrations (3, 5, 7, 9, and 12 millimoles (mmol)) mixed in ENR-50 exhibited positive torque responses, prompting further molecular characterization using Fourier transform infrared spectroscopy. The results indicated distinct absorption peaks at wavenumbers of 442 and 809 cm–1, which signify the presence of –O–Zn–O– coordination linkages. The curing characteristics of ENR and ZnCl2 compounds showed that increasing ZnCl2 content resulted in higher minimum and maximum torque values, but also led to a decrease in scorch time and cure rate index (CRI). Moreover, higher ZnCl2 concentrations enhanced the strength properties (tensile strength, moduli, stiffness, toughness, and hardness), crosslink densities, dynamic shear moduli, initial modulus during relaxation experiments, and thermal resistance, as evidenced by temperature scanning stress relaxation (TSSR), thermogravimetric analysis, and dynamic mechanical analysis. However, an increase in ZnCl2 content led to a reduction in elongation at break due to the higher crosslink density within the coordination networks in the ENR matrix, which resulted in the movement constraint of the rubber vulcanizate.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Phakawat Thongnuanchan, Pornsuwan Buangam

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

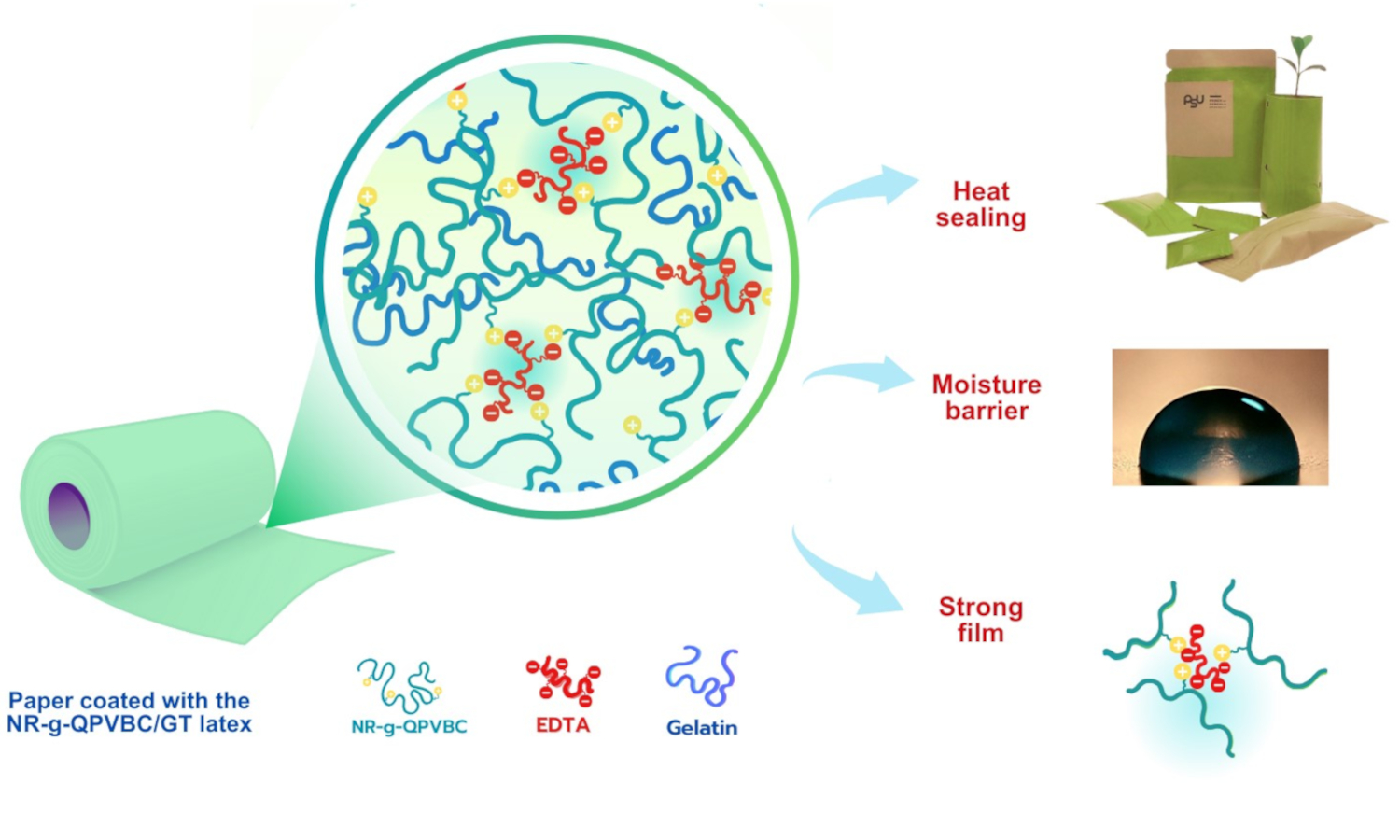

Research into sustainable packaging materials has gained increasing importance due to the pressing environmental concerns related to plastic waste. The present study focused on developing a sustainable paper coating based on modified natural rubber (NR) latex filled with gelatin (GT). The graft copolymer latex of NR and poly(vinylbenzyl chloride) bearing quaternary ammonium groups, abbreviated as NR-g-QPVBC, was first synthesized. GT was then incorporated into the latex, and the combination of these materials resulted in a heat-sealable film with good tensile properties and a water barrier. The ionic crosslinking of the latex film was achieved by the reaction with ethylenediaminetetraacetic acid (EDTA). Heat-sealing studies of the NR-g-QPVBC latex film filled with GT (NR-g-QPVBC/GT) revealed its heat-sealability at 160 °C. Scanning electron microscope (SEM) analysis further confirmed the diffusion of the chains across the interface during heat sealing. Dip coating was a method for depositing latex film on kraft paper. The paper coated with the NR-g-QPVBC/GT latex showed a significant increase in dry and wet-tensile strength compared to the uncoated paper. The sealing process was optimized to achieve a heat-seal strength of 755.31 N/m at a dwell time of 3 s and a temperature of 160 °C. The research's practical application was demonstrated by transforming the coated paper into various heat-sealable bags using a handheld bag sealer.

Nabil Hayeemasae, Siriwat Soontaranon, Abdulhakim Masa

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

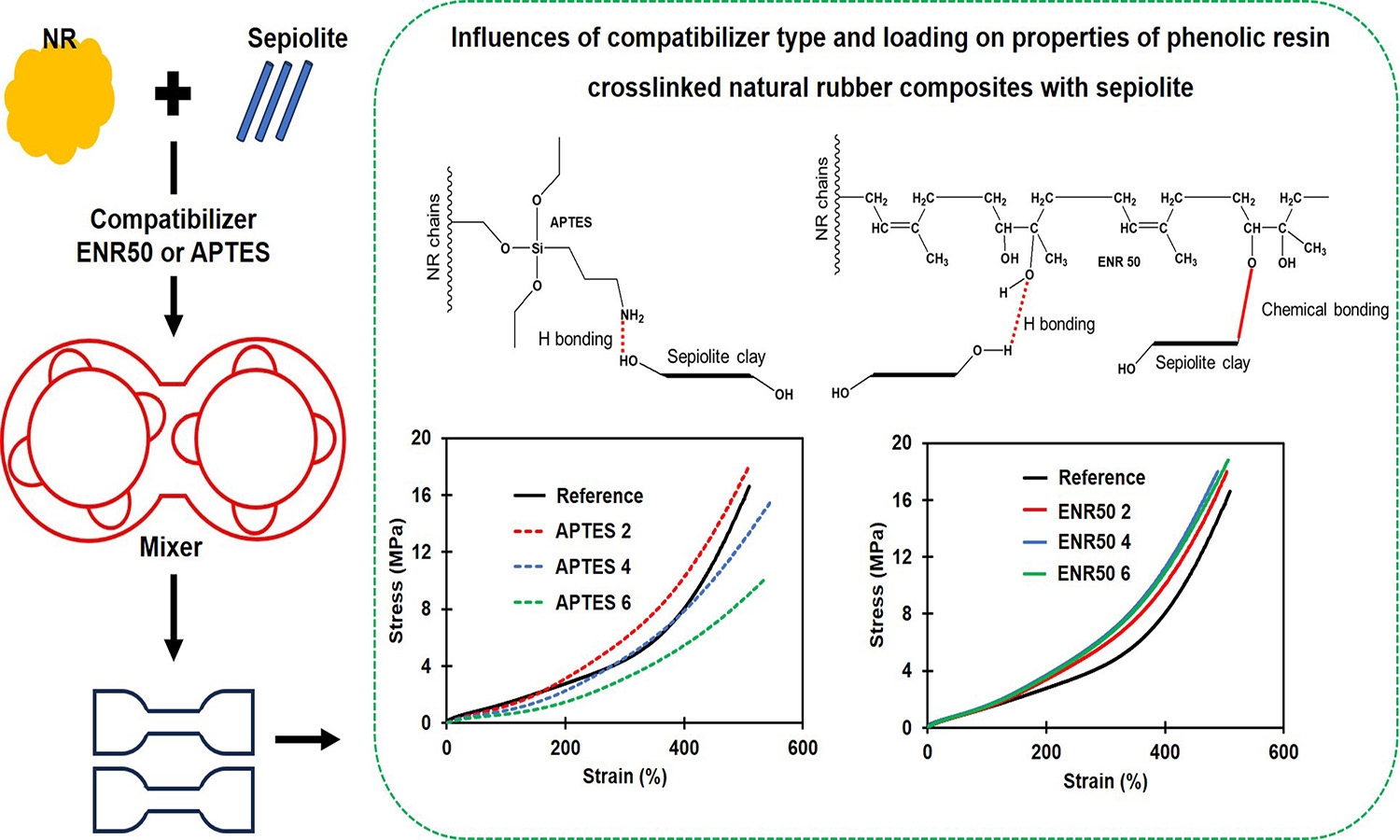

Natural rubber (NR) composites reinforced with sepiolite and crosslinked with phenolic resin were prepared. Effects of compatibilizer types and contents, namely 3-aminopropyl triethoxysilane (APTES) or epoxidized NR (ENR50), on curing, tensile, strain-induced crystallization, and stress relaxation were investigated. Compared to APTES, ENR50 provided a greater compatibilizing effect in the NR composites. The ENR50 introduced strong physical and chemical interactions between sepiolite and NR, while only physical interaction was present in the APTES compatibilized composites. Stronger interaction between rubber and sepiolite improved filler dispersion, swelling resistance, and tensile strength; and delayed stress relaxation of the composite. Increased addition of ENR50 improved the modulus and tensile strength, and the greatest tensile strength was achieved at 2 phr ENR50 with a 15% improvement over composite without compatibilizer. In the case of APTES, 2 phr level enhanced tensile strength, but a further increase in APTES content degraded tensile, swelling resistance, and stress relaxation responses, due to its plasticizing effect. Moreover, ENR50 enhanced the strain-induced crystallization and delayed stress relaxation of the composites more than APTES. Weaker interaction between rubber and filler in APTES filled composites was due to having only hydrogen bonds formed between rubber and filler, in addition to crosslinks.