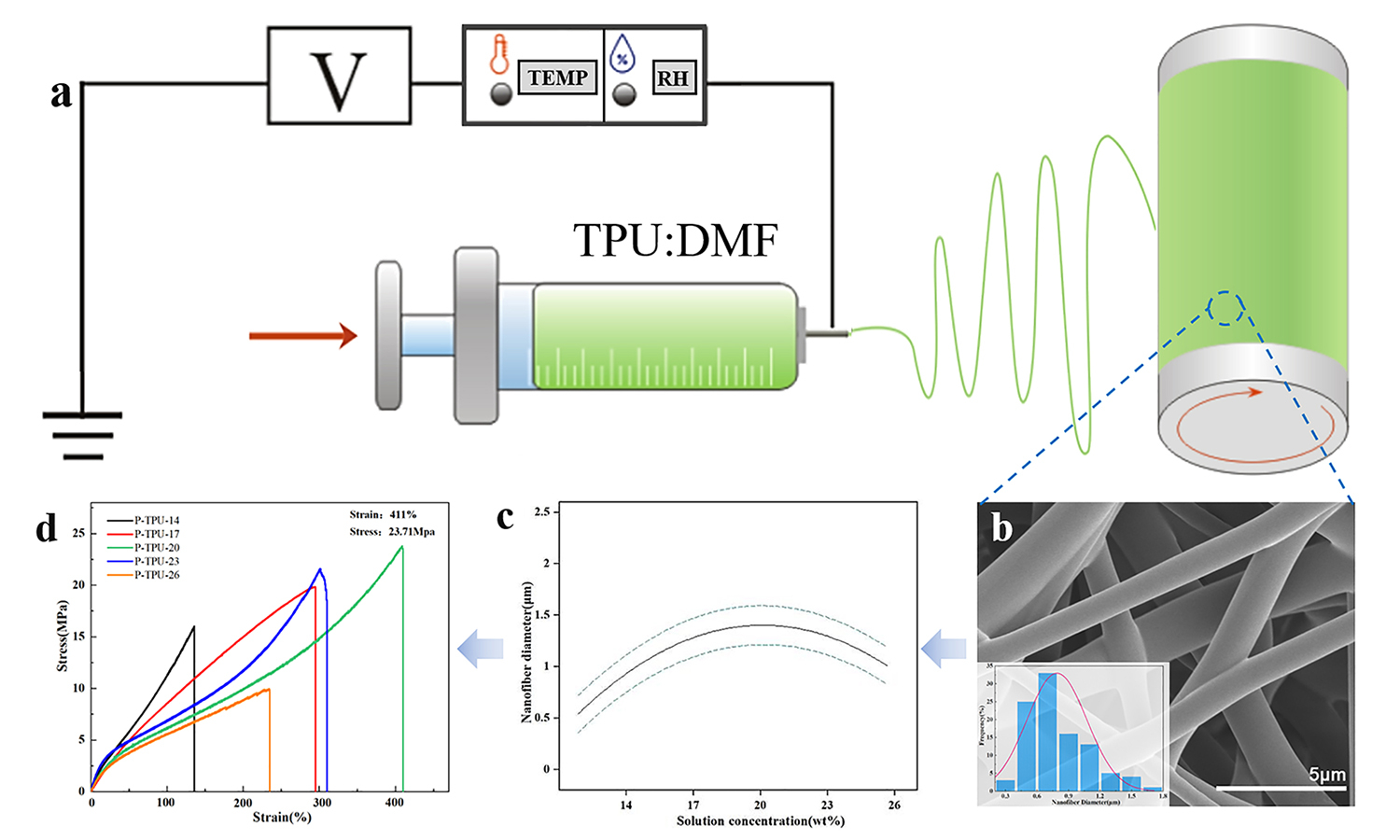

Analysis and optimization of electrospinning parameters for fabricating thermoplastic polyurethanes (TPU) nanofibers by response surface methodology

Vol. 18., No.8., Pages 807-818, 2024

DOI: 10.3144/expresspolymlett.2024.60

DOI: 10.3144/expresspolymlett.2024.60

GRAPHICAL ABSTRACT

ABSTRACT

Thermoplastic polyurethanes (TPU) have attracted increasing attention due to their excellent flexibility, chemical stability, processability and greenness. The traditional processes generally limit them to civil and industrial applications, but electrospun TPU nanofibers with high porosity, high specific surface area and superior mechanical properties are promising in emerging fields. TPU nanofibers’ properties are affected by various electrospinning parameters, such as solution concentration, applied voltage, flow rate and rotational speed. Thus, 29 sets of experiments were designed here by the efficient and low-cost response surface methodology (RSM). The analysis of variance (ANOVA) revealed that the model agrees well with experimental results, and solution concentration is the most crucial parameter affecting nanofibers’ morphology and diameter. Based on it, the impacts of solution concentration and orientation on the mechanical properties of the TPU nanofiber membrane were investigated. Benefiting from the stress transfer and network deformation, the TPU nanofiber membranes parallel to the collection direction possessed the highest stress strength (23.71 MPa), while the nanofiber membranes vertical showed the widest strain range (485%). This study provides useful guidance for the preparation of high-performance TPU nanofibers, contributing to expanding its applicability in emerging fields such as biomedical, filtration and separation, and flexible sensing.

RELATED ARTICLES

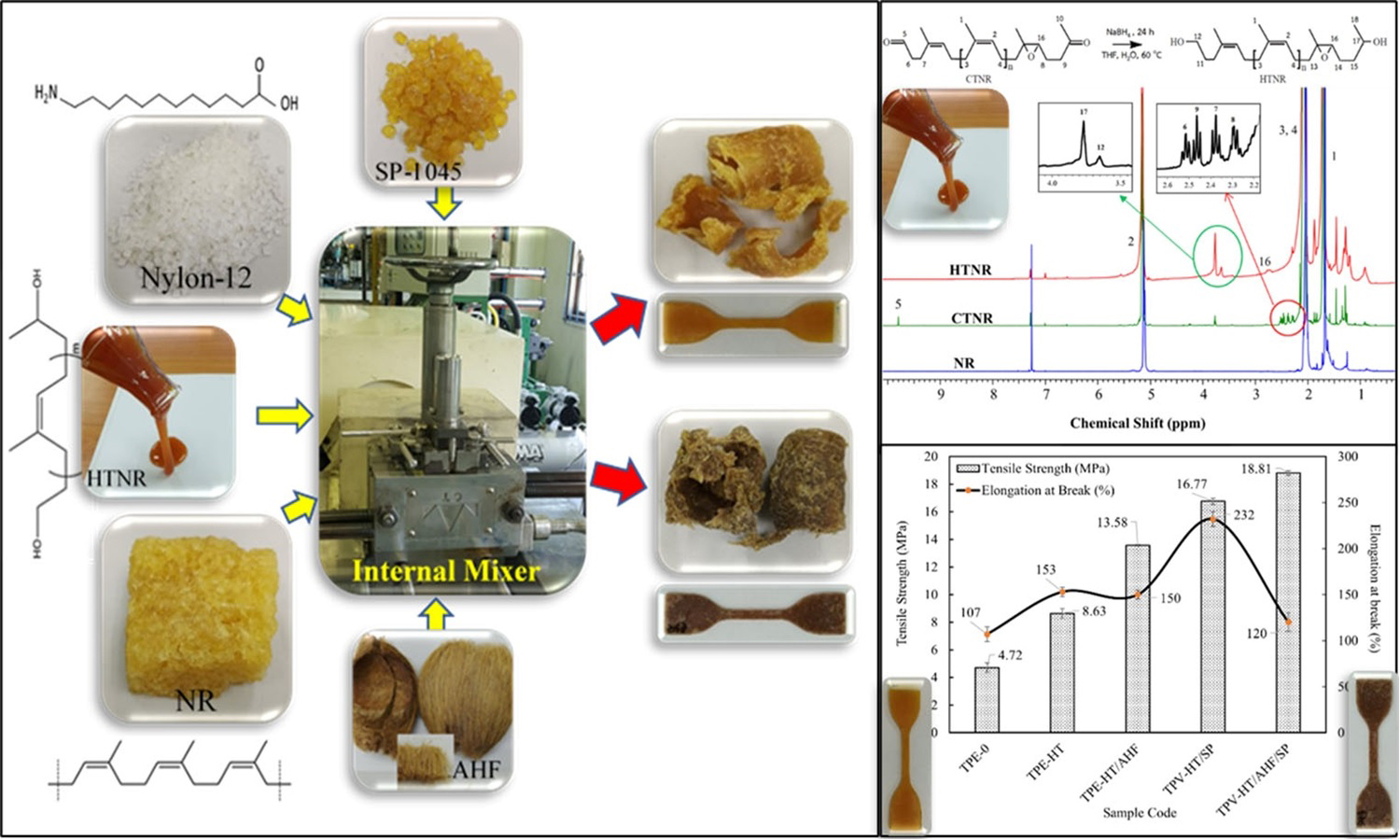

Jutatip Makmanee Treitler, Diew Saijun, Kritsada Phatcharasit, Suwat Rattanapan

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

Vol. 19., No.12., Pages 1310-1319, 2025

DOI: 10.3144/expresspolymlett.2025.96

This work introduces an innovative method to enhance the compatibility of nylon-12/natural rubber thermoplastic elastomers by utilizing hydroxyl telechelic natural rubber as a reactive compatibilizer and natural fibers as reinforcement. Hydroxyl telechelic natural rubber was synthesized from natural rubber via oxidative cleavage to carbonyl telechelic natural rubber, followed by reduction with sodium borohydride. Proton nuclear magnetic resonance (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) verified the structure. Incorporating hydroxyl telechelic natural rubber into nylon-12/natural rubber (40/60 wt%) blends significantly enhanced interfacial adhesion, improving tensile strength and elongation at break compared to the uncompatibilized mix. Dynamic vulcanization using phenolic resin achieved an optimal balance of strength and ductility. The incorporation of areca husk fiber enhanced tensile strength, hardness, and solvent resistance, with a slight decrease in ductility and tear strength. Rheological analysis indicated that hydroxyl telechelic natural rubber increased melt viscosity due to improved phase interactions, while dynamic vulcanization reduced the melt flow index through network formation. Solvent uptake experiments confirmed that hydroxyl telechelic natural rubber, areca husk fiber, and SP-1045 vulcanizing agent minimized swelling in isooctane, toluene, and diesel oil.

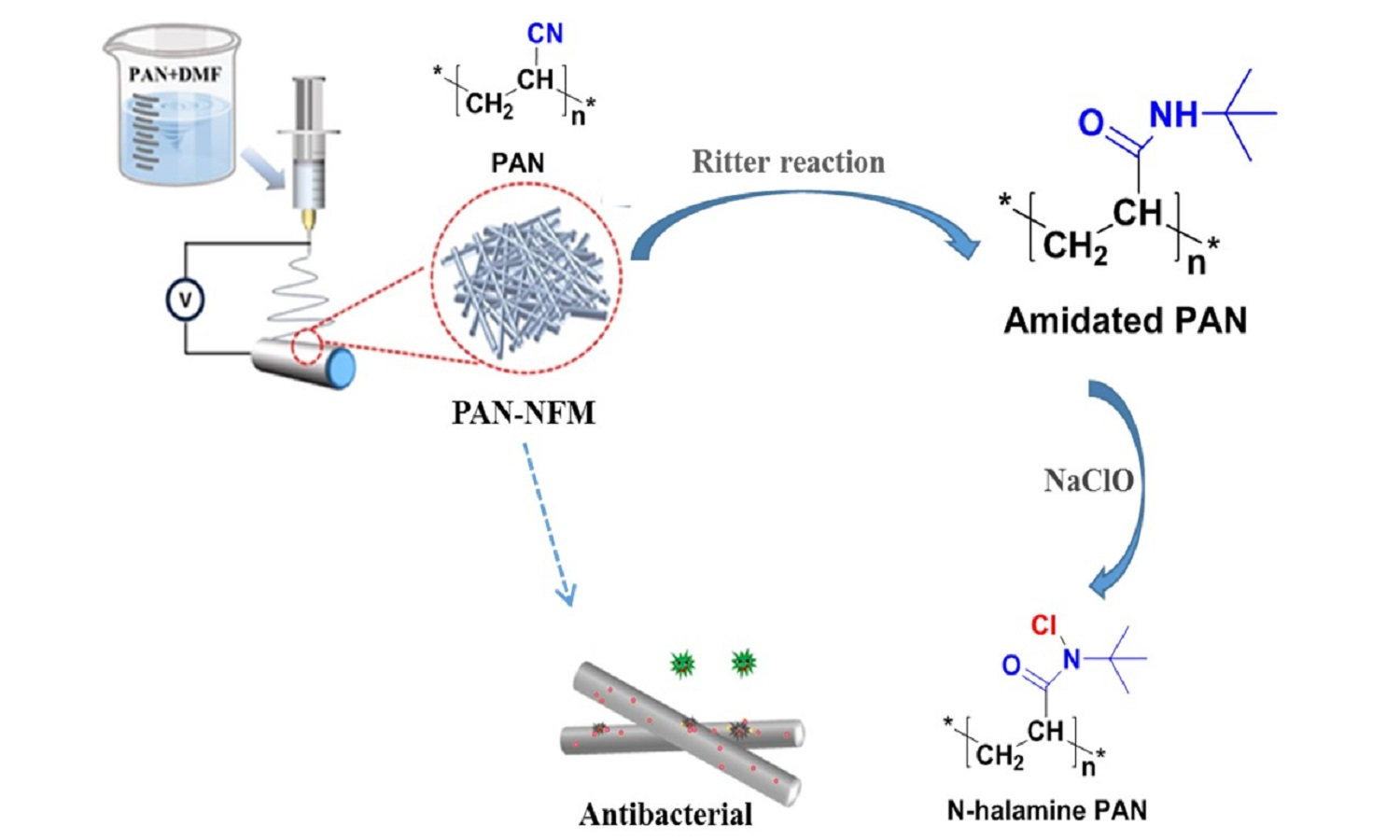

Jiadong Hu, Huiling Chen, Junpeng Zhong, Changming Li, Ronggui Li, Rong Zhou, Hongwei He

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

Vol. 19., No.4., Pages 351-360, 2025

DOI: 10.3144/expresspolymlett.2025.26

Electrospun (e-spun) nanofiber materials have emerged as a prominent research focus owing to their extensive and promising potential applications across biomedical, energy, and environmental domains. Polyacrylonitrile (PAN) is a commonly used polymer for electrospinning (e-spinning). Due to insufficient hydrophilic properties of nitrile groups of PAN, its e-spun nonwoven membranes had low water absorption and moisture absorption, which limited application in medical and health fields. In this study, it was investigated that the hydrophilic modification of e-spun PAN nanofiber membrane (NFM) was conducted via Ritter reaction to convert nitrile groups into hydrophilic amide ones, thereby improving the hydrophilicity of PAN NFMs. The surface morphologies and structure of the modified e-spun fibers were characterized and verified by SEM, FTIR and XPS. After 60–90 min of Ritter reaction, the fiber diameter of the PAN NFM became thicker, transforming from a hydrophobic membrane to a hydrophilic one, and the water contact angle decreased from 124.2 to 40.7°. The amidated PAN obtained membrane was post-treatment with sodium hypochlorite to make some amide groups change to N-halamine, which took the PAN NFM antibacterial activity or bacteriostasis. This work suggested a strategy that the espun PAN NFMs modified would have a promising application in medical dressings, air filtration, etc.

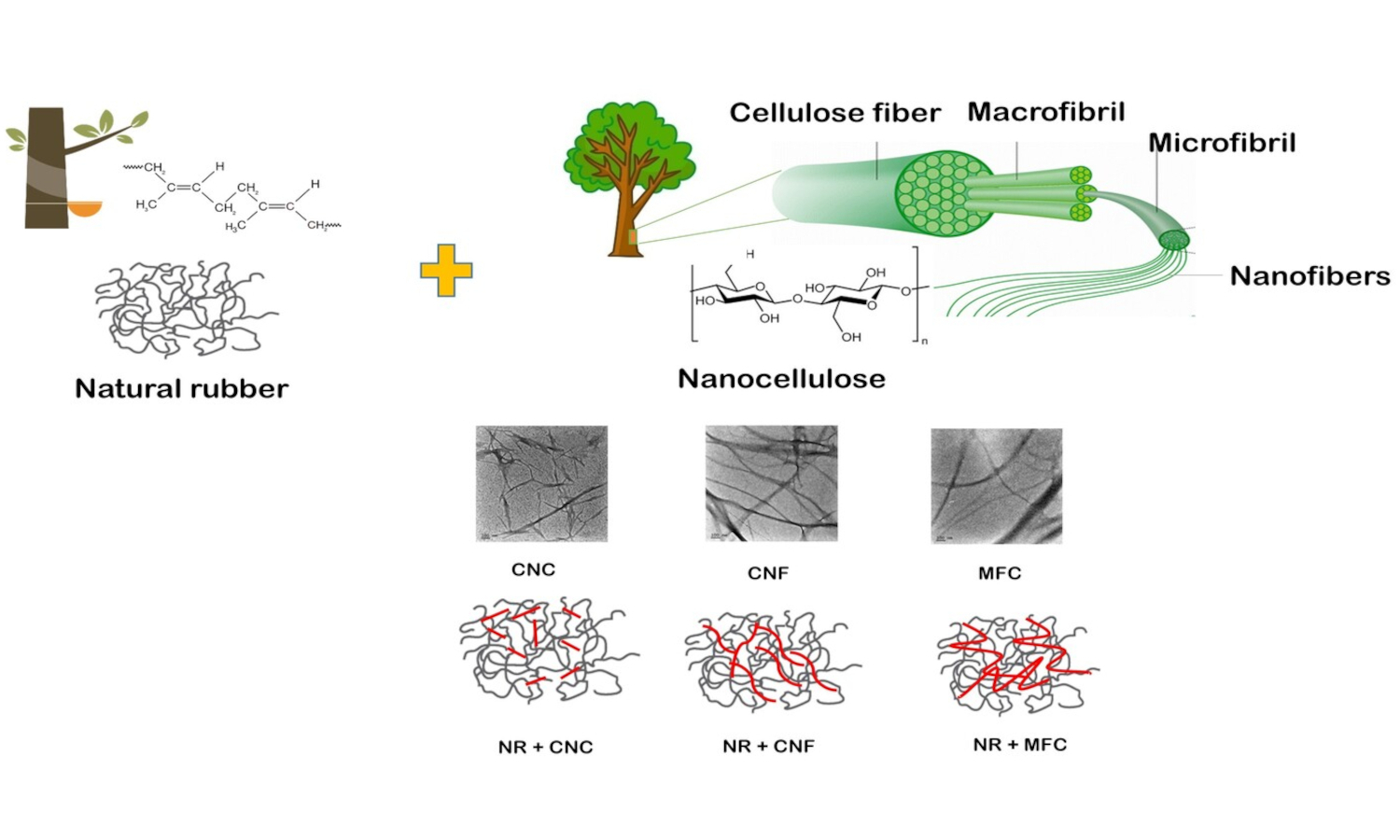

Milanta Tom, Sabu Thomas, Bastien Seantier, Yves Grohens, Mohamed Pulikaparambil Kochaidrew, Ramakrishnan Subramanian, Tapas Ranjan Mohanty, Henri Vahabi, Hanna Joseph Maria, Jibin Keloth Paduvilan, Martin George Thomas

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

Vol. 18., No.6., Pages 638-655, 2024

DOI: 10.3144/expresspolymlett.2024.47

The augmented demand for

sustainable nanocomposites has paved the way to explore naturally derived

materials. Nanocellulose, with its bountiful sources and inherent properties,

ranks top in the list of biofillers with a perspective of reducing the carbon

footprint. A systematic study is required to understand the reinforcing effect

of various types of nanocellulose. In the present work, we selected three types

of nanocellulose, i.e.,

cellulose nanocrystal (CNC), cellulose nanofiber (CNF) and microfibrillated

cellulose (MFC), to investigate the effect of geometrical structure on the

properties of unvulcanized natural rubber (NR). Incorporating these fillers

improved the tensile strength and modulus of natural rubber films significantly

through reinforcement via filler network structure. The reinforcing effect of

CNF was found to be higher compared to CNC and MFC, where an increase of 3.85

MPa in tensile strength from the neat sample was obtained. More uniform

dispersion was evident through transmission electron microscopy, atomic force

microscopy and Raman imaging for CNF in the rubber matrix. The structural

properties were determined using Raman spectra and X-ray diffraction. The rheological

studies revealed a good interaction between filler and NR. The work presented

comprehensively compares different types of nanocellulose as reinforcing filler

in NR matrix, which will help the researchers select an ideal type for their

specific application and, thus, the proper usage of renewable resources,

leading to sustainability and a circular economy.

Andrea Kohári, Tamás Bárány

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

This is an editorial article. It has no abstract.