Engineering highly aligned continuous nanofibers via electrospinning: A comprehensive study on collector design, electrode geometry, and collector speed

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

DOI: 10.3144/expresspolymlett.2024.63

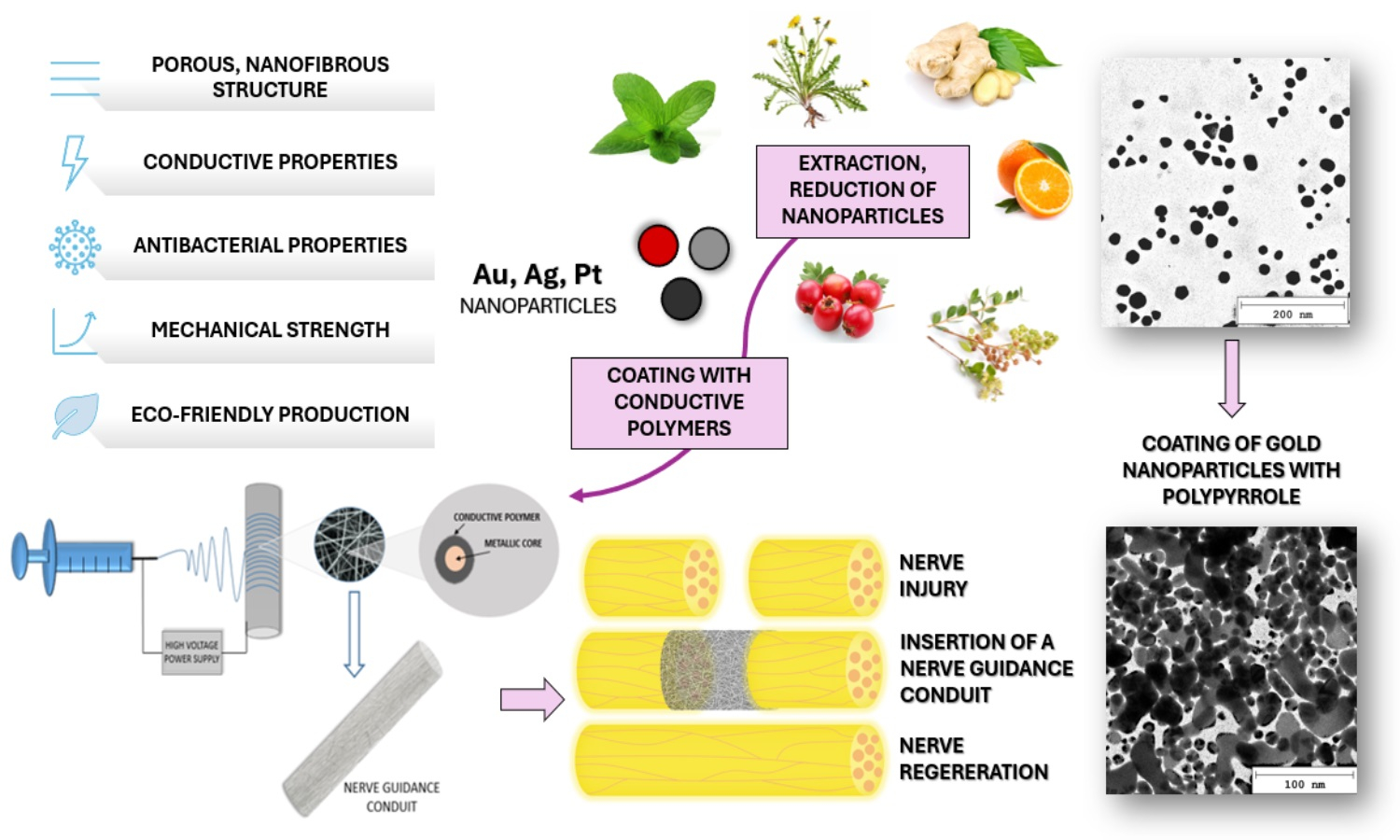

GRAPHICAL ABSTRACT

ABSTRACT

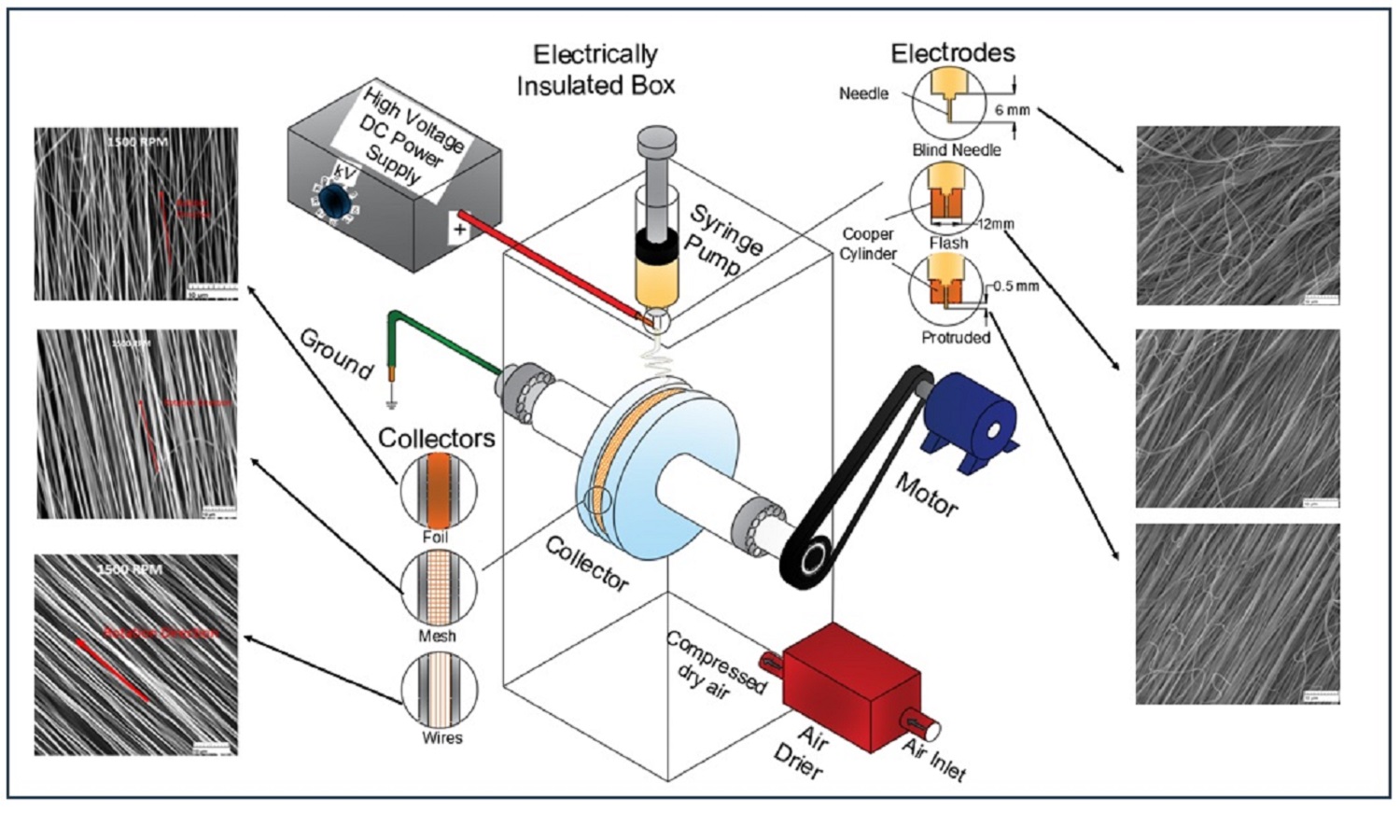

Nanomaterials, particularly nanofibers produced through electrospinning, have garnered significant attention due to their unique properties and diverse applications. This research explores the influence of collector design, electrode geometry, and collector speed on the properties of electrospun polyacrylonitrile (PAN) nanofibers. Finite element analysis (FEA) was employed to simulate electric fields, revealing the impact of collector geometry on field intensity. The experimental setup, enclosed in an isolated chamber, employed various collector types and electrode configurations. Scanning electron microscope (SEM) analysis showcased the effect of collector speed on fiber alignment and diameter. Furthermore, FEA simulations elucidated the role of electrode geometry and voltage in shaping the electric field, impacting fiber properties. The study introduces a novel, in-house method for producing highly aligned nanofibers and provides insights into optimizing electrospinning parameters for enhanced fiber properties. A testing protocol is devised to minimize surface damage when conducting mechanical tests on nanofiber films, employing a dynamic mechanical analyzer (DMA). Mechanical testing demonstrated the correlation between alignment and tensile strength. Overall, this research contributes valuable insights for tailoring electrospinning processes for tissue engineering and energy storage.

RELATED ARTICLES

Timothy K. Mulenga, Sanjay Mavinkere Rangappa, Suchart Siengchin

Vol. 19., No.5., Pages 470-493, 2025

DOI: 10.3144/expresspolymlett.2025.35

Vol. 19., No.5., Pages 470-493, 2025

DOI: 10.3144/expresspolymlett.2025.35

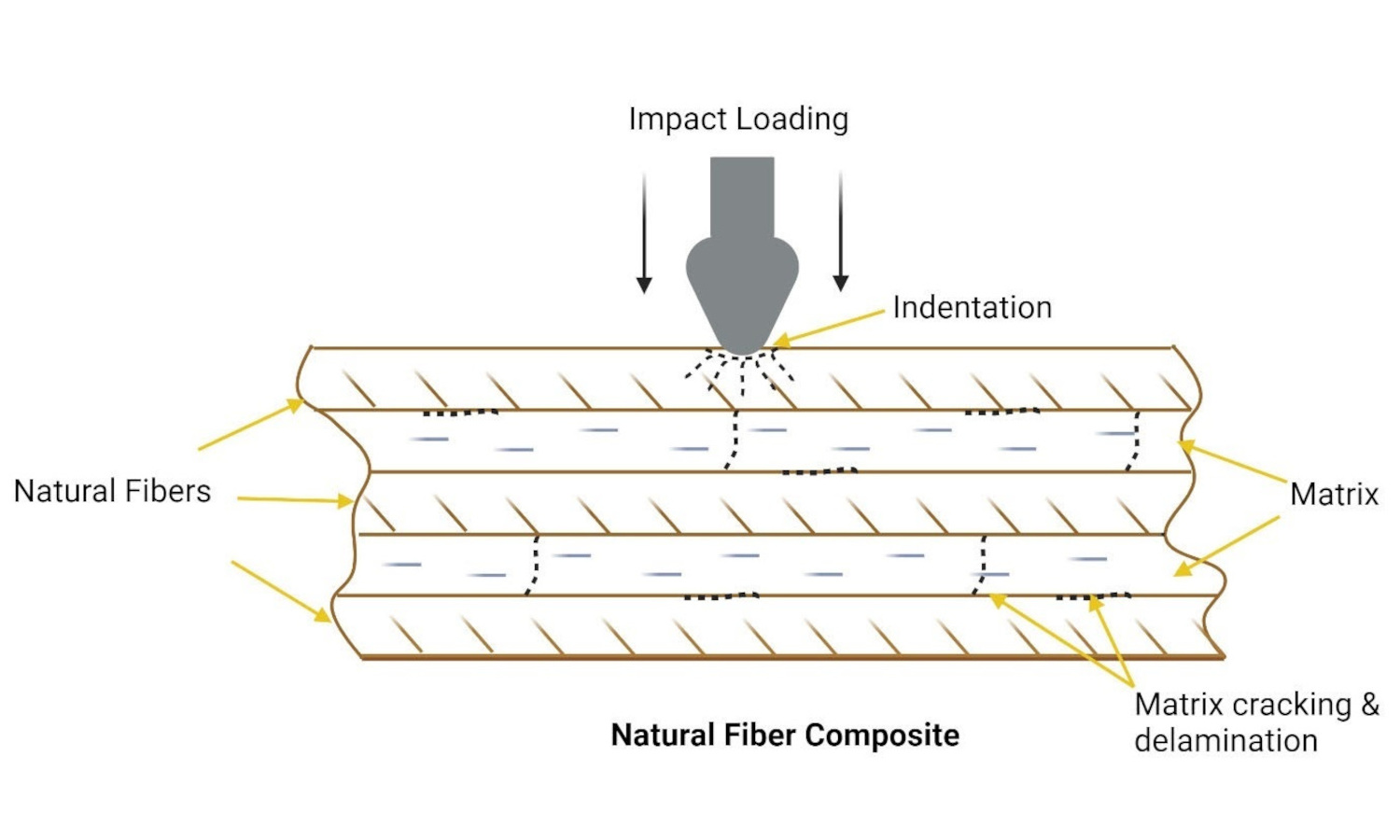

Natural fiber composites (NFC) have emerged as promising sustainable alternatives to conventional synthetic materials due to the increasing environmental concerns and unsustainable reliance on depleting petroleum resources. NFCs offer various advantages, such as reduced costs, low density, biodegradability, and good specific mechanical properties. However, their impact resistance remains a crucial factor that greatly influences their suitability for sectors like automotive, construction, and aerospace, where impact loading is prevalent. This review comprehensively analyzes the impact resistance of NFCs, aiming to elucidate the factors governing their behavior under varying impact loading conditions. The study delves into the influence of key parameters such as fiber type, matrix properties, and fiber-matrix adhesion on the impact response of NFCs. Different impact loading methods, including low-velocity impact and high-velocity impact, are examined, highlighting their distinct effects on NFC failure mechanisms. Furthermore, the review investigates the effectiveness of various methods employed to enhance the impact strength of NFCs. Finally, it identifies current challenges and limitations associated with impact-resistant NFCs and outlines potential future research directions to overcome these obstacles and unlock the full potential of these sustainable materials.

Quentin Watel, Aurélie Cayla, Fabien Salaün, François Boussu

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

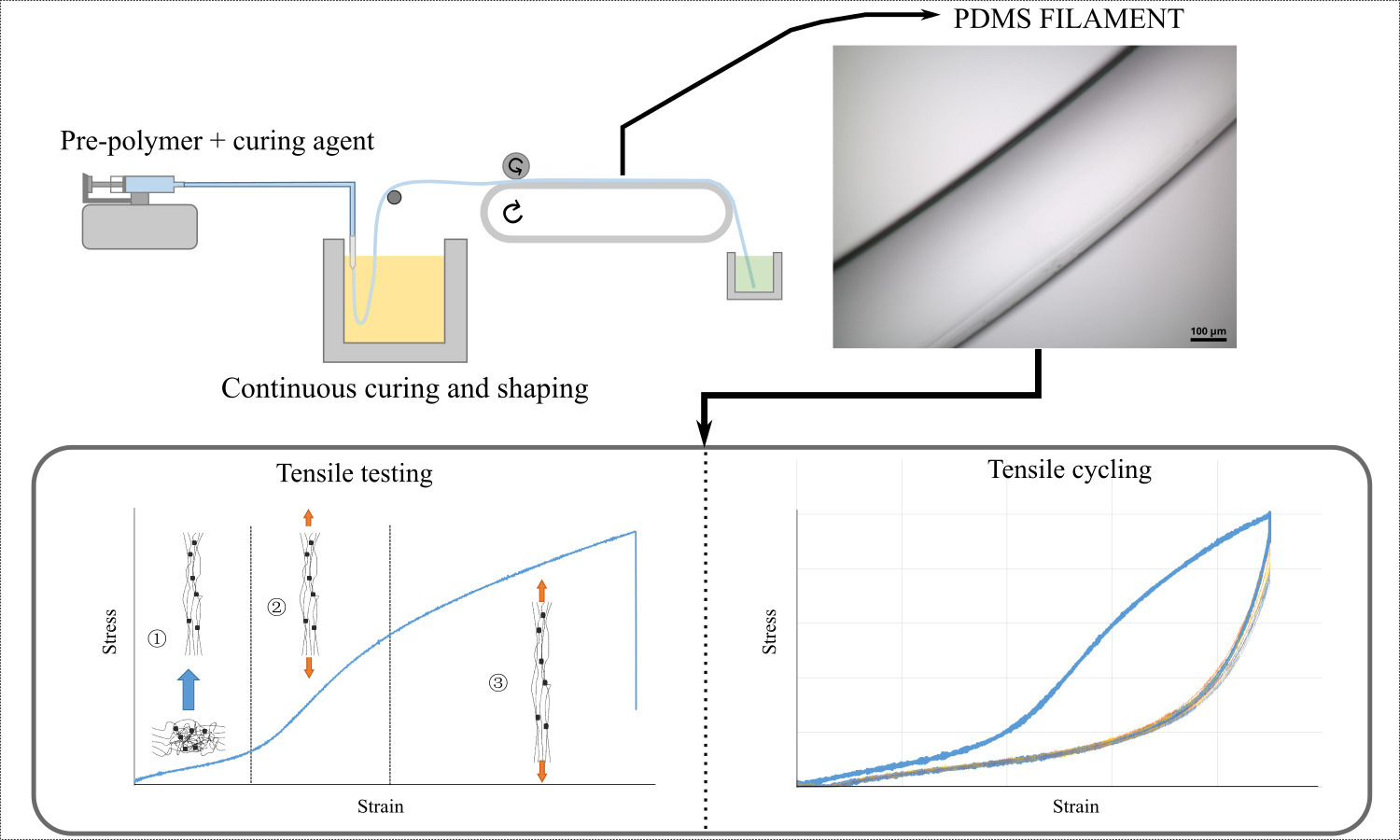

In this work, a PDMS spinning technique is developed and enables the continuous production of a filament with a circular cross-section (~500 μm diameter). The production of continuous silicone polymer filaments can be useful in the textile field to provide new properties in applications such as weaving, knitting or composite reinforcement. The method involves injecting the pre-polymer and curing agent mixture into a heated oil bath (202–215 °C) to simultaneously shape and cure the PDMS. The morphological and mechanical properties of the filament are studied regarding the production parameters (formulation, needle diameter, bath temperature, conveyor belt speed). The most homogeneous filament is produced at the highest temperature (215°C) and conveyor belt speed (13.6 m∙min–1). When subjected to cyclic mechanical stress, the PDMS filament produced exhibits stable mechanical behavior, making it suitable for a wide range of applications.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

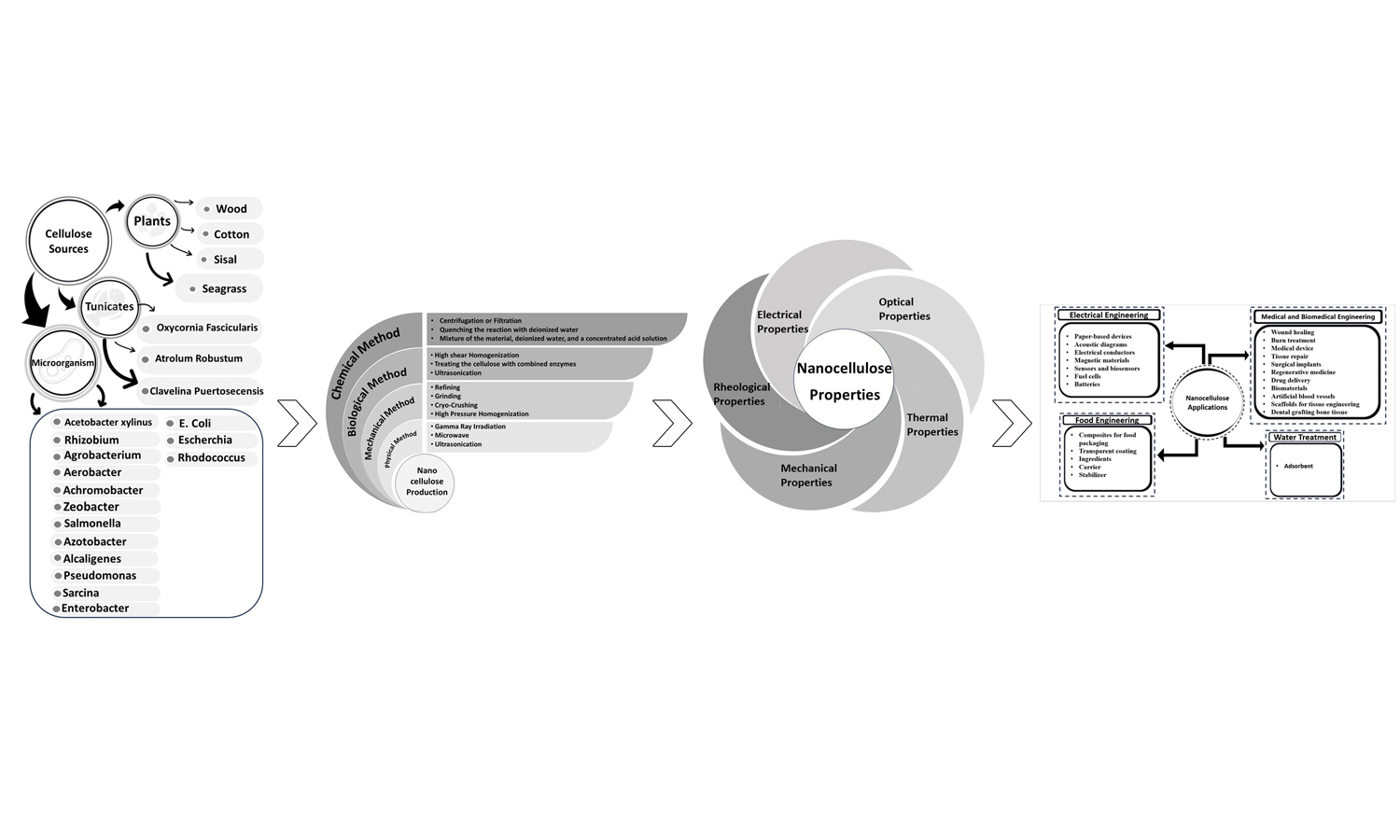

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.

Aleksandra Sierakowska-Byczek, Julia Radwan-Pragłowska, Łukasz Janus, Tomasz Galek, Karol Łysiak, Mirosław Tupaj, Dariusz Bogdał

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Appropriate protection and guiding are crucial during peripheral nerves repair. New generation nerve guidance conduits (NGCs) should not only provide mechanical support for the damaged nerve but also support healing processes. One of the most promising tissue regeneration applications is fibrous biomaterials since they are characterized by high porosity, flexibility, and strength. Additionally, they enable cell adhesion and proliferation. In this study, novel fibrous nanocomposites were obtained by applying the electrospinning technique, using polylactic acid (PLA) as a polymeric matrix which was further modified with metallic nanoparticles coated with conductive polymers. Such an approach resulted in the obtainment of biomaterials with a potential ability to conduct nerve impulses. The chemical structure of the obtained composites, as well as the morphology of ready products and separate nanocomponents, were investigated using Fourier-transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscope (SEM) techniques. Furthermore, conductive and swelling properties in various media were determined. Finally, biomaterials were confirmed to be non-cytotoxic to L929 mouse fibroblasts and 1321N1 human glial cells. Based on the presented results, it can be concluded that nanofibrous nerve guidance conduits have all the key properties in the process of peripheral nerve regeneration and may constitute an important step in novel NGCs development.

Kolos Molnár

Vol. 18., No.3., Pages 243-244, 2024

DOI: 10.3144/expresspolymlett.2024.17

Vol. 18., No.3., Pages 243-244, 2024

DOI: 10.3144/expresspolymlett.2024.17

This is an editorial article. It has no abstract.