Investigating the combined effects of devulcanization level and carbon black grade on the SBR/GTR composites

Vol. 18., No.12., Pages 1191-1208, 2024

DOI: 10.3144/expresspolymlett.2024.91

DOI: 10.3144/expresspolymlett.2024.91

GRAPHICAL ABSTRACT

ABSTRACT

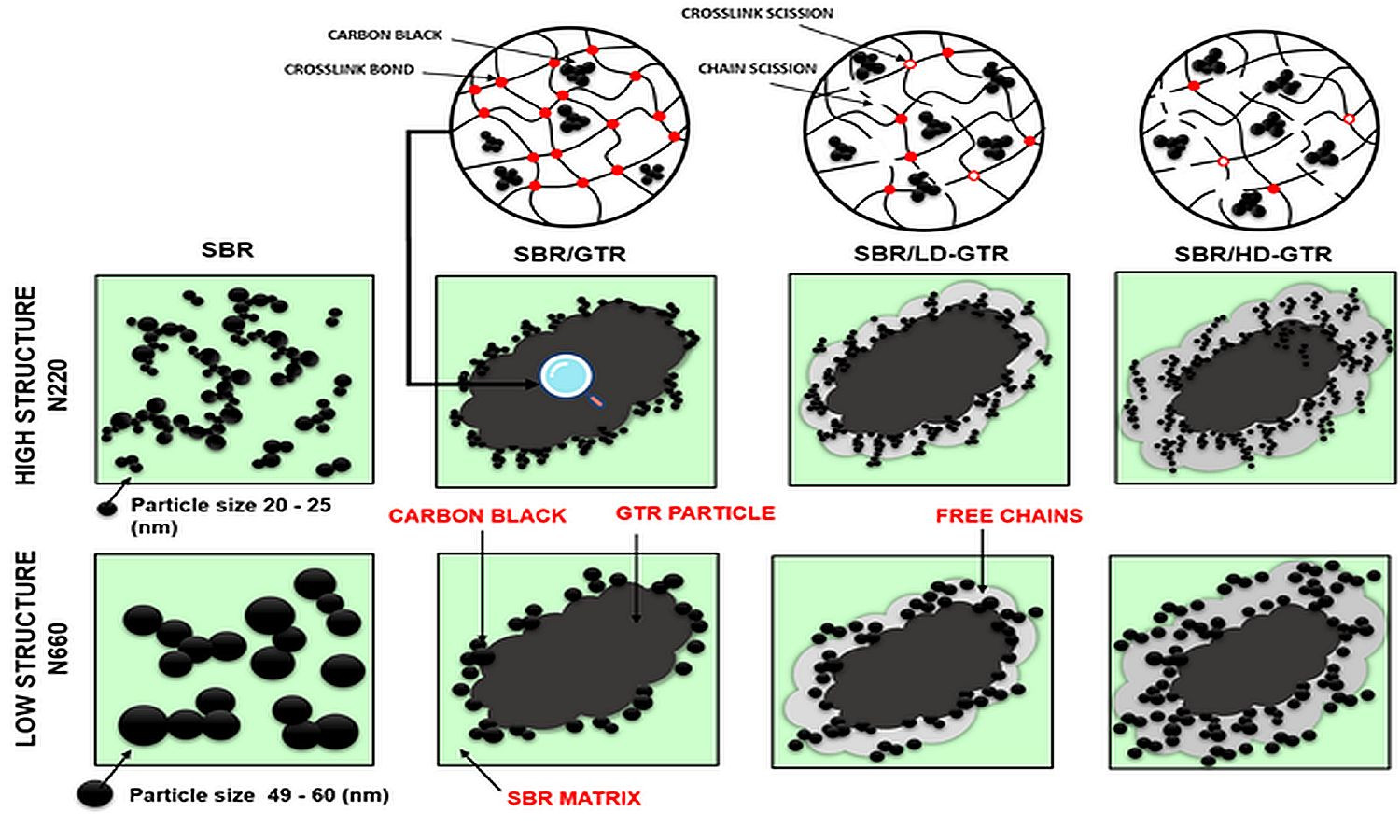

Carbon black migration between ground tire rubber (GTR) and rubber matrix is essential in developing high-performance rubber/GTR composites. In this work, carbon black N220 (surface area: 107.1 m2/g, particle size: 20–25 nm) and N660 (surface area: 33.1 m2/g, particle size: 49–60 nm) were used as the reinforcement fillers for styrene-butadiene rubber (SBR) blended with reclaimed GTR. The combined effects of GTR devulcanization level and carbon black grade on the properties of SBR/GTR composites were investigated considering curing characteristics, thermal stability, physico-mechanical properties, dynamic mechanical properties, swelling behavior, and morphology. The results showed that, regardless of GTR devulcanization level and carbon black grade, application of GTR resulted in deterioration of mechanical properties compared to a reference sample without GTR. It was observed the reinforcement effect of carbon black in SBR/GTR composites was more visible with higher devulcanization level of GTR and lower particle sizes of carbon black fillers. SBR/GTR composites reinforced with carbon black N220 were characterized by tensile strength in the range of 15.3–16.3 MPa and abrasion resistance in the range of 120–123 mm3, which justify their potential application in the manufacturing of technical rubber goods or footwear.

RELATED ARTICLES

Reinforcing effect of thermo-oxidative reclaimed rubber on NR/SBR blends for tire tread applications

Yunhui Xu, Zaheer ul Haq, Junrong Li, Hui Tu, Zaixue Wang, Houluo Cong

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

Vol. 20., No.2., Pages 142-153, 2026

DOI: 10.3144/expresspolymlett.2026.12

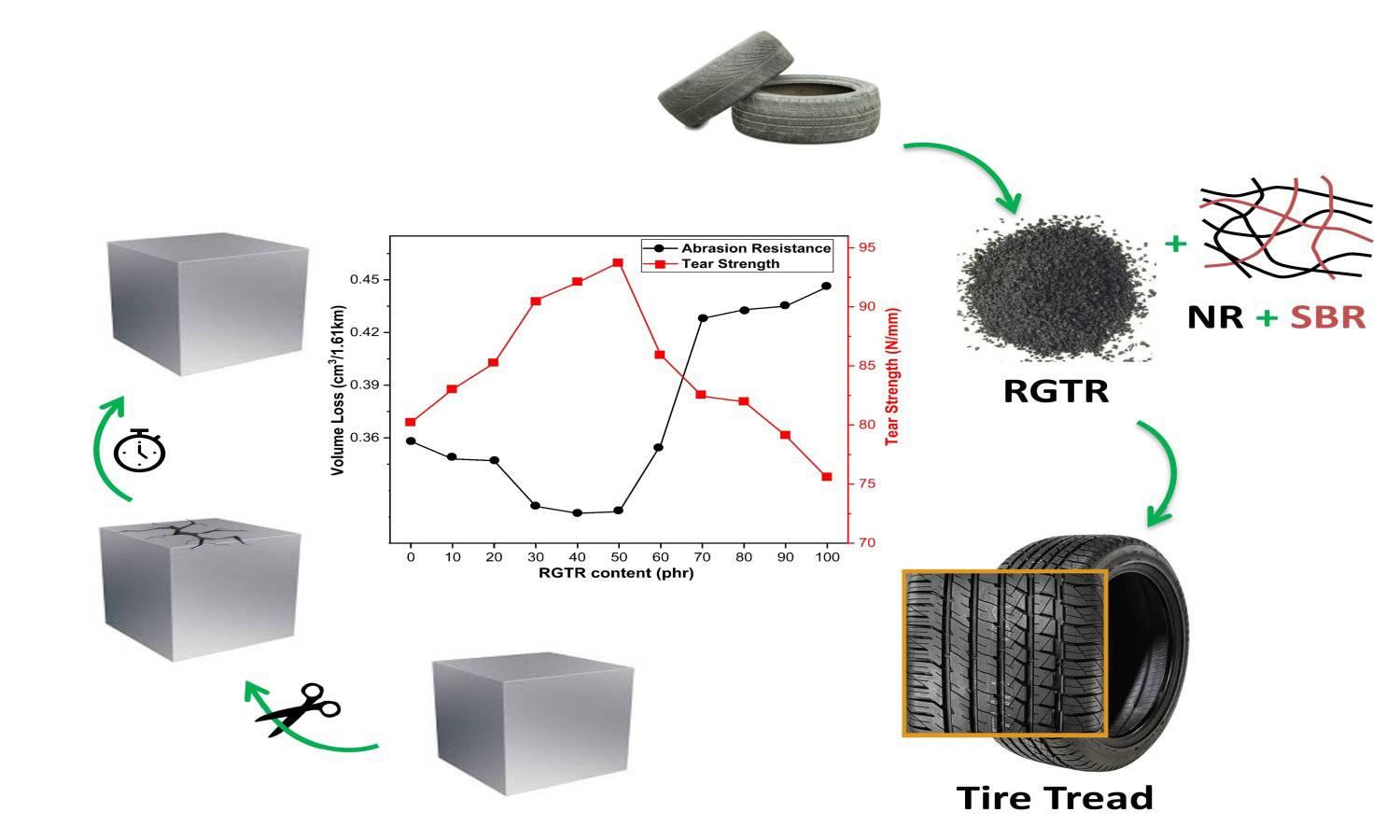

This study explores the application of thermo-oxidative reclaimed ground tire rubber (RGTR) in natural rubber (NR)/styrene butadiene rubber (SBR) composite, focusing on its impact on morphology, mechanical properties, rheological behavior, vulcanization characteristics, aging resistance, tear strength and abrasion resistance. The findings revealed that RGTR enhances the tear strength and abrasion resistance of NR/SBR composites while maintaining comparable tensile strength, elongation at break, and modulus. The incorporation of RGTR reduced Mooney viscosity of the NR/SBR composites and improved flowability. It also shortened the vulcanization time and enhanced vulcanization efficiency. The NR/SBR composites with RGTR loadings below 60 phr exhibited optimal performance, achieved a maximum tear strength of 93.77 N/mm and improved abrasion resistance. However, higher RGTR content led to increased agglomeration, as evidenced by scanning electron microscopy (SEM), which showed finer dispersion at lower RGTR contents and larger aggregates at higher loadings. These findings demonstrate the potential of RGTR as a sustainable additive for enhancing specific properties in NR/SBR composites, contributing to both performance optimization and waste tire management.

Dibyendu Dey, Sharmistha Dhar, Barkat Aziz, Sambhu Bhadra, Sujith Nair, Kinsuk Naskar

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

Vol. 20., No.2., Pages 127-141, 2026

DOI: 10.3144/expresspolymlett.2026.11

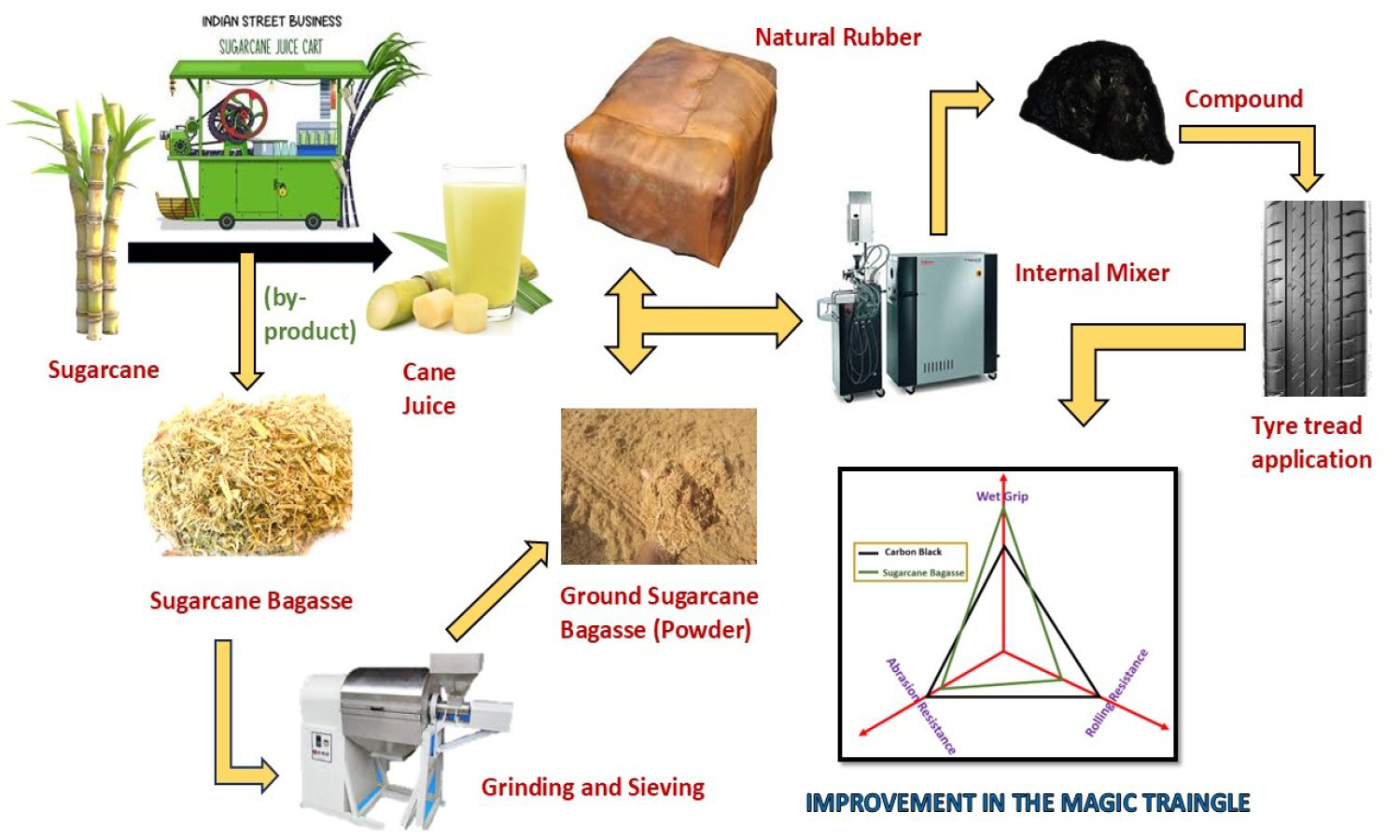

Ground sugarcane bagasse (GSB), an agro-waste rich in lignocellulosic components, was studied as a sustainable bio-filler in natural rubber (NR) tread compounds to lessen reliance on petroleum-derived carbon black (CB). A control formulation with 45 phr CB was compared to hybrid formulations with 40, 35, and 30 phr CB mixed with 5, 10, and 15 phr GSB. Tensile strength 13.1 MPa, elongation at break 700%, and hardness 67 Shore A were all optimally balanced by the compound containing 10 phr GSB (S2), while also exhibiting good cure behavior and thermal stability. Improved tire performance characteristics were confirmed by a dynamic mechanical study, which showed that tan δ at 60 °C decreased by 8.0% (resulting in lower rolling resistance) and increased by 3.9% (improving wet traction) at 0°C. The Payne effect showed improved filler dispersion as a result of GSB partially replacing CB. The results show that appropriately dispersed GSB can partially reinforce NR, enhancing energy efficiency and sustainability. However, larger GSB loadings decrease modulus, tear strength, and abrasion resistance due to lower interfacial adhesion and the presence of micro-voids. According to this study, pulverized sugarcane bagasse shows promise as an environmentally friendly filler for green tire applications, promoting the circular economy and lowering the carbon footprint of rubber compounding.

Hatay Cöcen, Nilgün Kızılcan

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

Vol. 20., No.1., Pages 82-96, 2026

DOI: 10.3144/expresspolymlett.2026.7

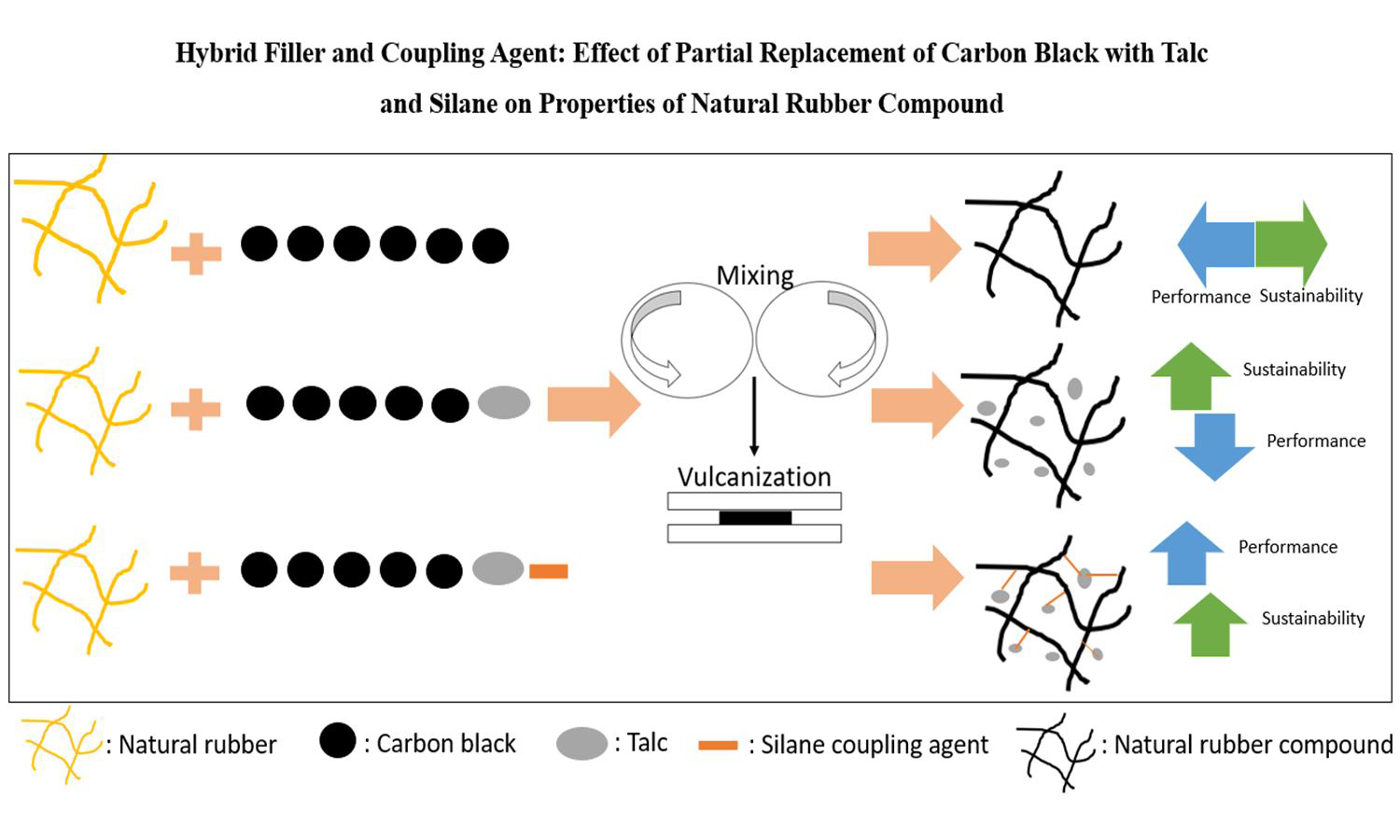

This study investigates a sustainable hybrid-filler strategy for natural rubber (NR) compound by partially replacing petroleum-based carbon black (CB) with talc and introducing a silane coupling agent to mitigate interfacial incompatibility. Compounds containing CB, CB+talc and CB+talc+increasing silane were produced via two-stage mixing and characterized for morphology (dispersion/mapping), curing and flow behavior (differential scanning calorimetry DSC/moving die rheometer, MDR/Mooney), crosslink density (Flory–Rehner), physical–mechanical properties, dynamic performance (Payne effect/heat build-up/tension–fatigue), and thermal stability (aging/thermogravimetric analysis,TGA). Talc reduced the compound viscosity, offering processing benefits. The swelling test indicated that talc decreased crosslink density, but silane recovered it, forming covalent linkages. Tensile strength and elongation at break were improved without altering hardness. Dynamically, talc increased heat build-up, whereas silane inverted the trend and reduced the temperature rise gradually from 41.5 to 29.4°C at 2 phr. Fatigue life was improved with talc (~10%), and further with silane (up to 36% at 2 phr), highlighting a favorable stiffness–fatigue balance with compatibilization. Overall, partial CB replacement by talc, in combination with silane, delivers meaningful sustainability gains with improved dynamic performance while preserving key mechanical properties of NR compounds.

Cristian Valdés, Valentina Guzmán, Camila Ponce, Maribel Mamani, Juan Guevara, Claudia Vergara, Rodrigo Andler

Vol. 19., No.6., Pages 594-609, 2025

DOI: 10.3144/expresspolymlett.2025.45

Vol. 19., No.6., Pages 594-609, 2025

DOI: 10.3144/expresspolymlett.2025.45

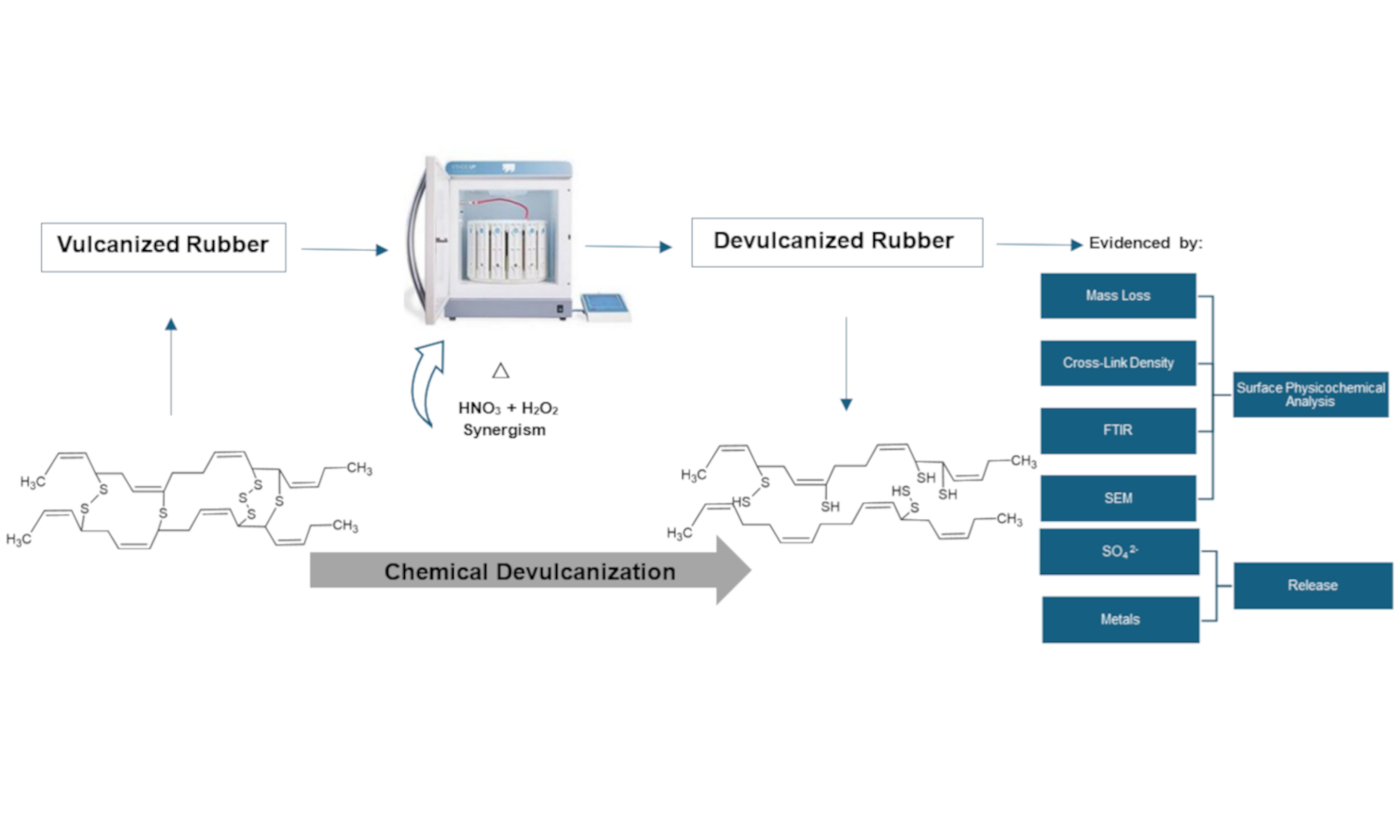

Waste rubber disposal causes considerable negative environmental impacts due to its increase worldwide, mainly in the automotive industry. Therefore, the search for technological solutions for rubber waste is a priority, and the first step in this material degradation is devulcanization due to its difficult degradation. This study evaluated rubber devulcanization using a closed vessel microwave digestion system with nitric acid (HNO3) and hydrogen peroxide (H2O2) through chemical characterization, aiming at verifying the synergistic effect between these oxidizing agents. Microwave irradiation was applied as a heating method to facilitate the chemical reactions, focusing on the synergism between HNO3 and H2O2. Results showed that 5 M H2O2 in combination with 1% HNO3, presented better results. A greater decrease in cross-link density was demonstrated as the concentration of H2O2 increased (3.96·10–5±1.99·10–6 mol/cm3), likewise, higher sulfates released (926.8±53.4 mg/L), increased mass loss (12.184±1.06%), rubber surface fragmentation, and important variations in the C–S, C=O bands, showing better results when devulcanization is carried out in synergism between HNO3 and H2O2.

Sanjoy Datta, Ondřej Peter, Evghenii Harea, Radek Stoček, Kinsuk Naskar

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

Vol. 18., No.9., Pages 911-920, 2024

DOI: 10.3144/expresspolymlett.2024.68

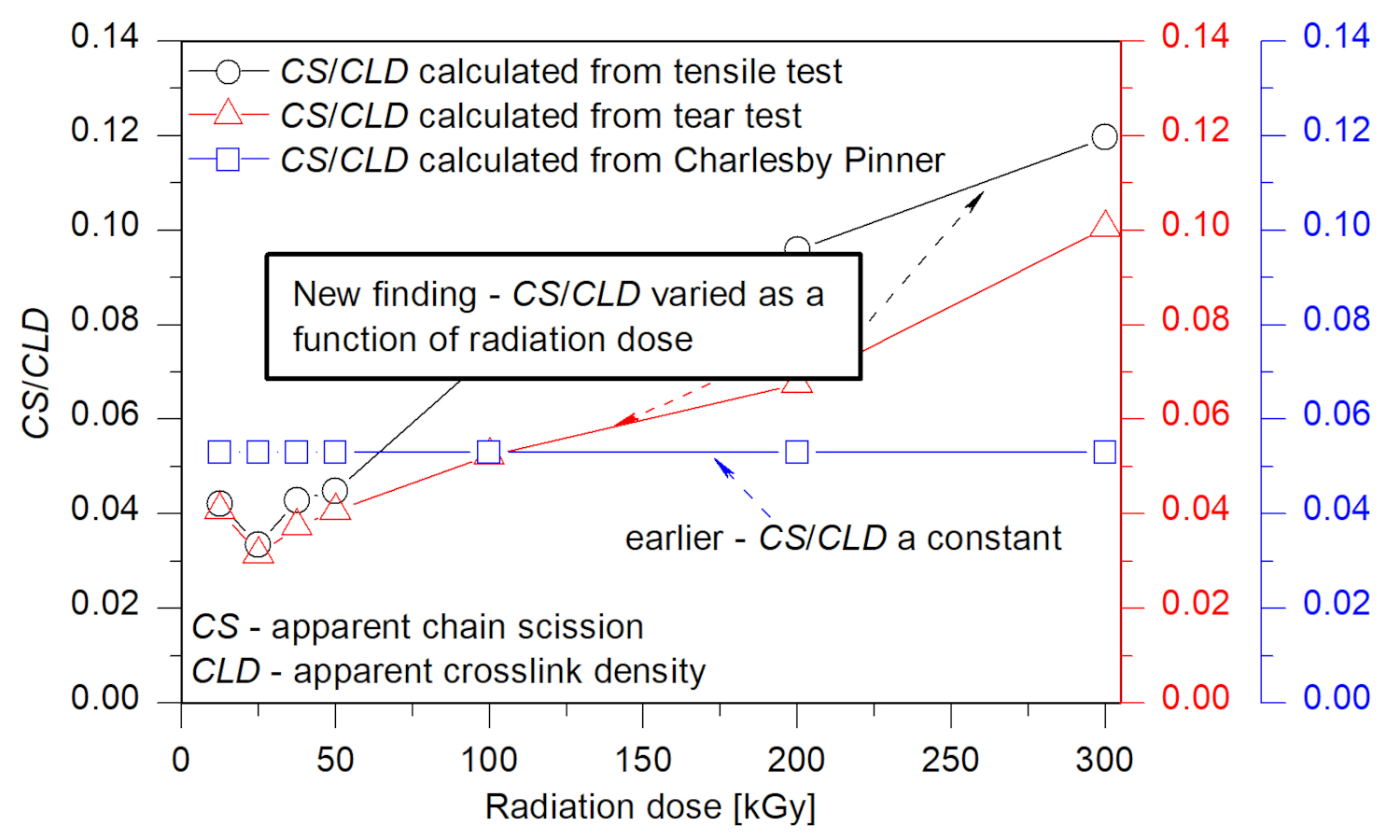

Electron beam (EB) treatment of a high vinyl styrene-butadiene-styrene (SBS) block copolymer was accomplished by exposing the polymer to high-energy electrons generated from an electron accelerator. This resulted in the formation of free radicals of carbon on the polybutadiene units in the backbone of the elastomer and subsequent radical coupling to produce cross-links. In the process, some unavoidable chain scission (CS) also occurred. An attempt was made to mathematically trace the nature of the CS as a function of radiation dose with the aid of the experimentally determined cross-link density (CLD), tensile strength and tear strength, the latter three also obtained as functions of radiation dose. The radiation dose was varied from 12.5 to 300.0 kGy in multiples of 12.5 kGy. The novelty of the work was, in part to create a function that can be used to calculate chain-scission in dependence of EB radiation dose. It was found that a change in the ratio of CS to CLD occurred as a function of radiation dose over the previously calculated constant ratio, using the Charlesby-Pinner equation.