UV curable PVA-based hydrogel systems: Properties, applications and future directions

Muhammad Akmal, Hafiza Mehtab, Rimsha Amjad, Fauzia Iqbal , Ahmad Irfan, Robina Begum

, Ahmad Irfan, Robina Begum , Zahoor H. Farooqi

, Zahoor H. Farooqi

, Ahmad Irfan, Robina Begum

, Ahmad Irfan, Robina Begum , Zahoor H. Farooqi

, Zahoor H. Farooqi

Vol. 18., No.11., Pages 1109-1134, 2024

DOI: 10.3144/expresspolymlett.2024.85

DOI: 10.3144/expresspolymlett.2024.85

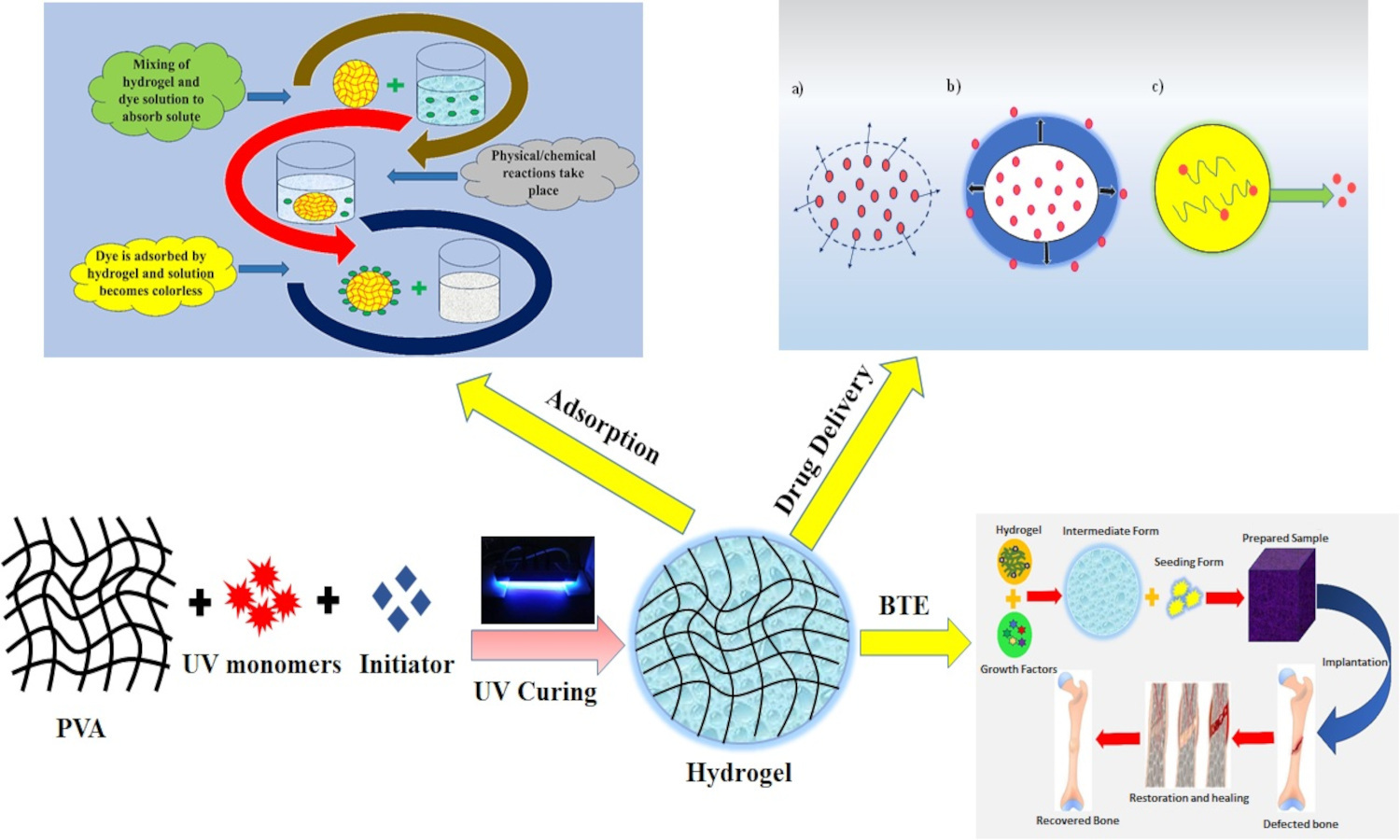

GRAPHICAL ABSTRACT

ABSTRACT

Poly(vinyl alcohol) (PVA) based hydrogels have gained more interest in the field of biomaterials because of their many biomedical uses (i.e., wound healing, drug delivery, and tissue engineering) and intrinsic physicochemical and biological characteristics. They can be made using a variety of synthetic techniques, but all of them are very time-consuming. Among them, photopolymerization also referred to as light-induced polymerization, has drawn a lot of attention because of its benefits, which include not requiring the use of solvents, easy and quick network formation, energy efficiency, quick processing, control over both space and time and reliability of crosslinking density and matrix strength. Ultraviolet (UV)-curable hydrogels containing PVA as a main component are gaining interest because of their excellent properties, including biodegradability, biocompatibility, less cytotoxicity and remarkable mechanical strength. This review highlights the significance of UV curable systems and their components, types, advantages and disadvantages of photoinitiators (PIs), UV curable monomers and their structures, properties of UV-cured PVA hybrid hydrogels, and their characterizations and applications in different fields. The photopolymerization mechanisms, tunable properties, and unique advantages of these hydrogels have been explored in detail. Furthermore, it sheds light on recent advancements in PVA-based hydrogels research and future exploration in this domain.

RELATED ARTICLES

Sarahí Bautista Reberte, Esmeralda Zuñiga Aguilar, Solange Ivette Rivera Manrique, Carlos Alberto Martínez-Pérez

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

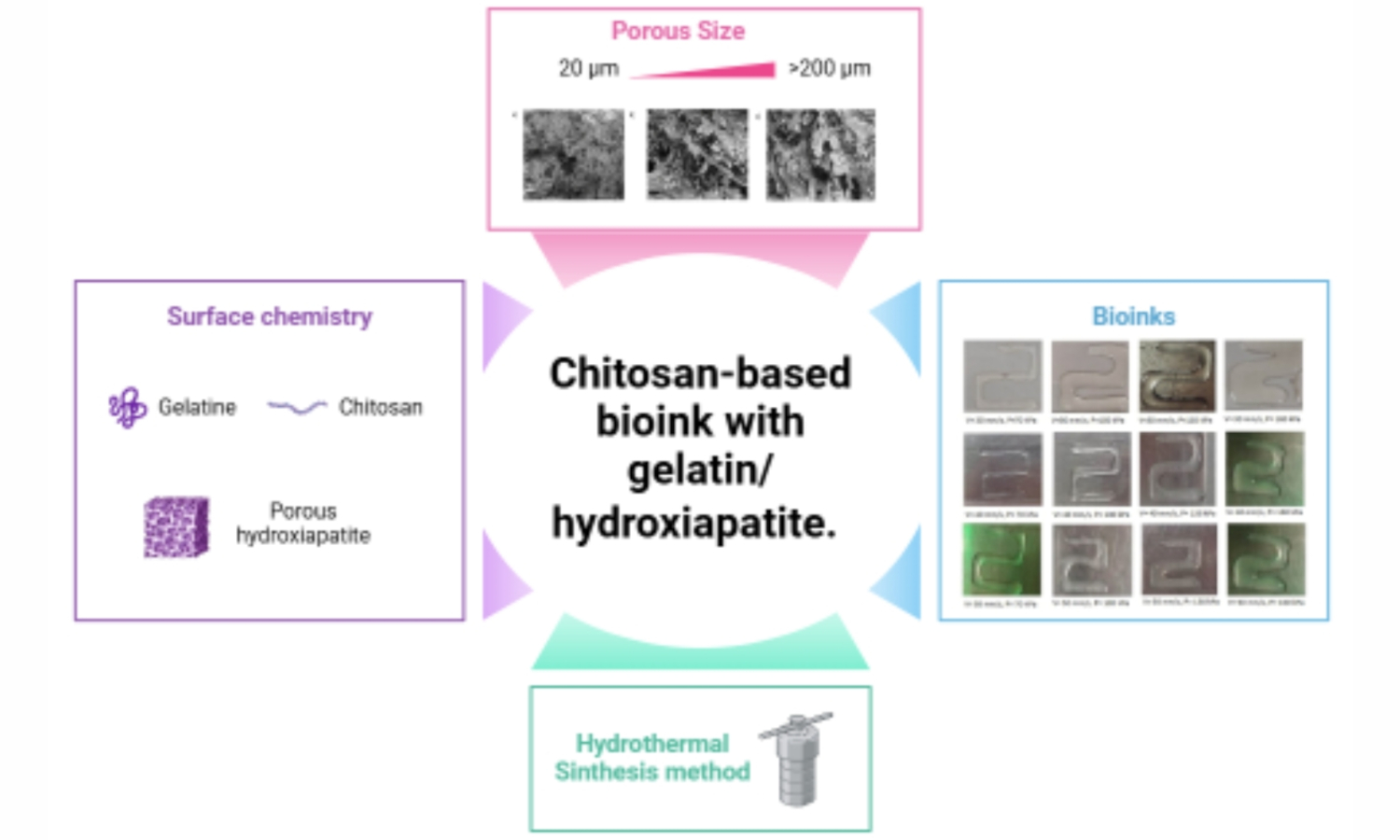

Three-dimensional (3D) bioprinting is a technique currently used for creating tissue engineering scaffolds, using bioinks as the building blocks. These bioinks are composed of biomaterials that provide structural integrity and are synthesized from organic polymers to enhance biocompatibility with the printed constructs. In this study, a series of eleven chitosan-based bioinks were synthesized using the sol-gel technique, employing chitosan of low and medium molecular weight. Three bioink formulations were selected based on their viscosity characteristics and further enriched with gelatin and hydroxyapatite (HA) to enhance their mechanical properties. Characterization tests included Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and rheological assessments. Viscoelastic materials were obtained, and an experimental model was developed to optimize printing parameters, focusing on pressure and printing speed. Our findings indicate that a bioink formulation comprising a blend of medium and high molecular weight chitosan, supplemented with gelatin and hydroxyapatite, was found to be a promising approach for fabricating scaffolds for bone tissue repair.

Chin-San Wu, Shan-Shue Wang, Dung-Yi Wu, Wanwen Gu

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

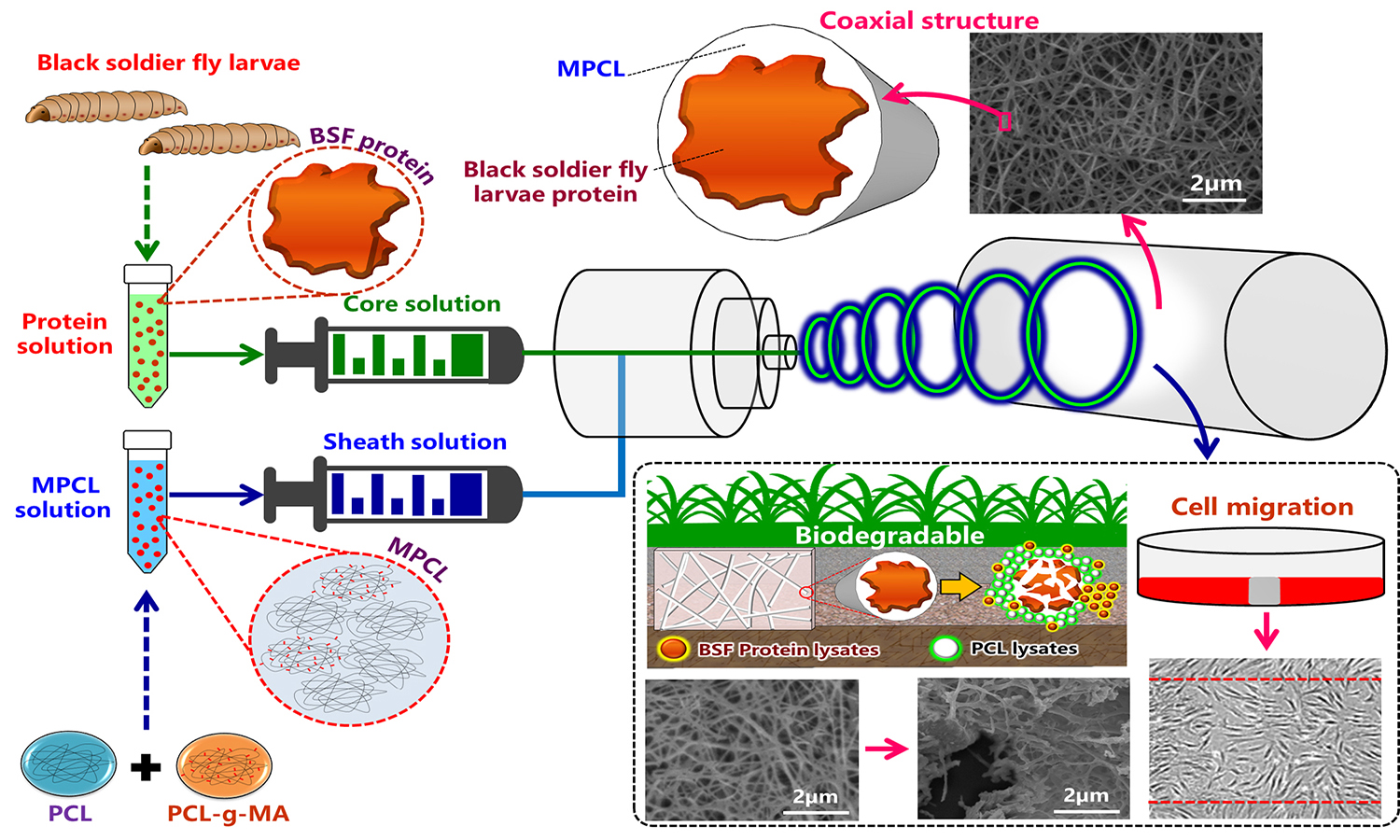

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.

Fatma Nur Parın, Hatice Dinç, Uğur Parın, Elife Kıldalı, Gökçe Taner

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

Vol. 18., No.3., Pages 282-295, 2024

DOI: 10.3144/expresspolymlett.2024.20

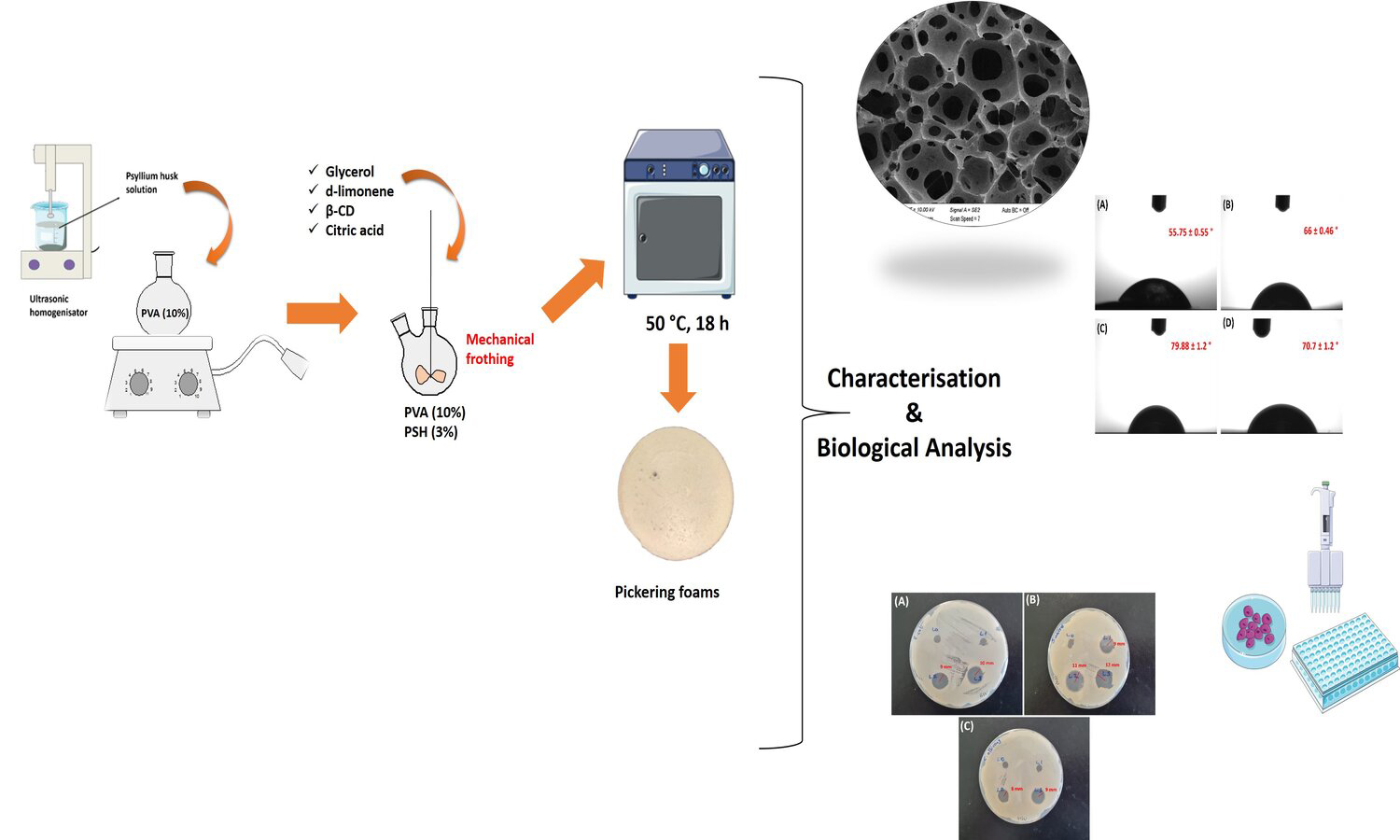

In this study, Pickering foamed emulsions have been prepared using β-cyclodextrin (β-CD), and d-limonene as a surfactant and an oil phase, respectively. The incorporation of β-CD/d-limonene inclusion complexes (ICs) in specific proportions (1:1, 1:3, and 1:5) to water phase, which is a polymer matrix composed of a mixture of polyvinyl alcohol (PVA) and psyllium husk (PSH) by mechanical frothing at high speed, and air bubbles have been formed in oil in water (o/w) emulsions. Ecofriendly bio-based foams have been developed in this method. Scanning Electron Microscope (SEM) analysis showed PVA/PSH Pickering foams usually open porous morphologies and the addition of d-limonene increases the amount of porosity from 43 to 49%. Although the resulting foams indicated similar thermal degradation profile, the presence of d-limonene in foams increased thermal stability. The surfaces of foams have a hydrophilic property with contact angles values lower than 80°. The tensile strength of foams decreased from 170 to 100 kPa due to the increased porosity. All foams indicated antibacterial activity to Staphylococcus aureus (S. aureus) with 9–12 mm zone inhibition. The incorporation of d-limonene into foams surprisingly decreased the cell viability. In brief, our findings show that the Pickering foams can be beneficial for wound healing applications.