The rise of interdisciplinarity: A new era in polymer research?

Vol. 18., No.10., Pages 962-963, 2024

DOI: 10.3144/expresspolymlett.2024.73

DOI: 10.3144/expresspolymlett.2024.73

GRAPHICAL ABSTRACT

RELATED ARTICLES

Sarahí Bautista Reberte, Esmeralda Zuñiga Aguilar, Solange Ivette Rivera Manrique, Carlos Alberto Martínez-Pérez

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

Vol. 19., No.3., Pages 326-338, 2025

DOI: 10.3144/expresspolymlett.2025.23

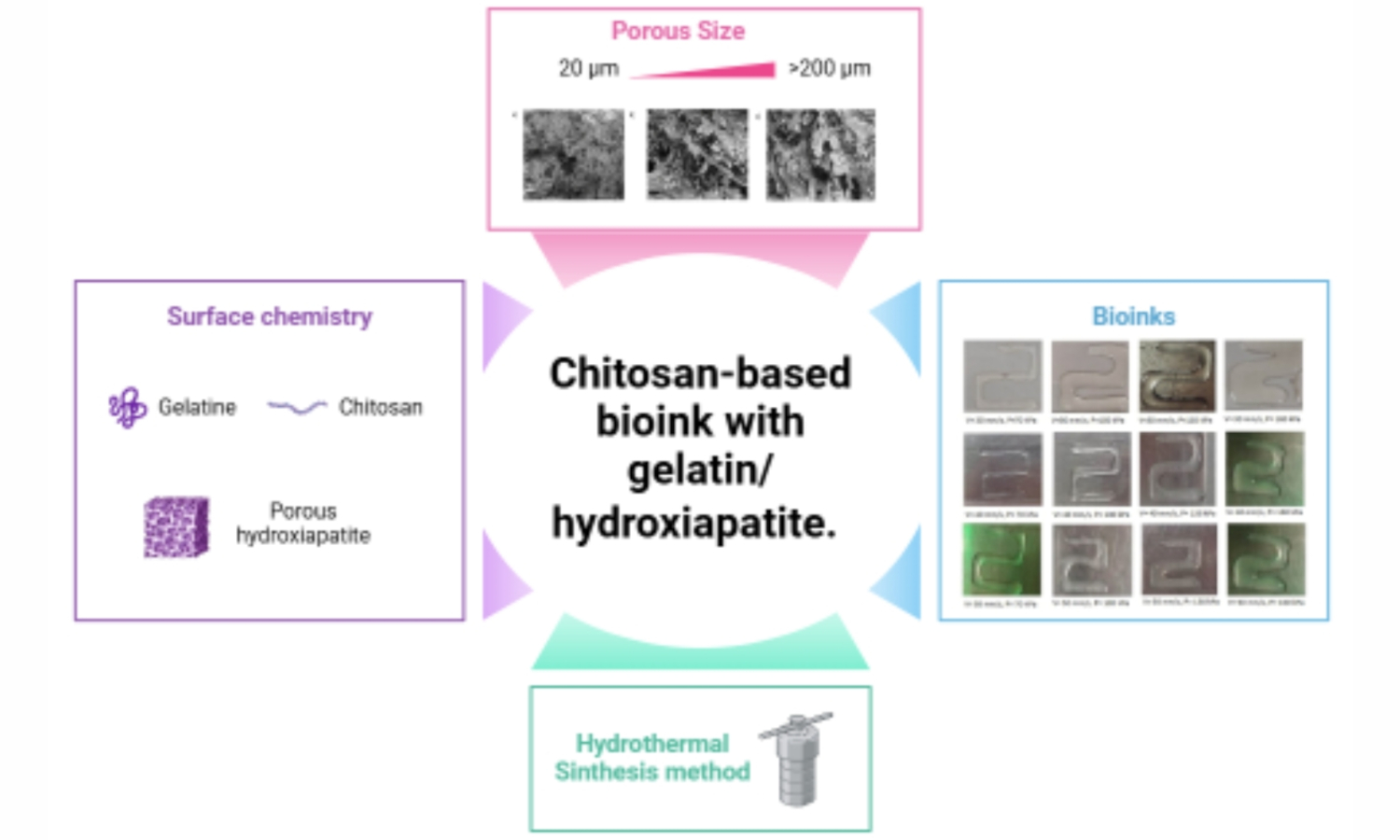

Three-dimensional (3D) bioprinting is a technique currently used for creating tissue engineering scaffolds, using bioinks as the building blocks. These bioinks are composed of biomaterials that provide structural integrity and are synthesized from organic polymers to enhance biocompatibility with the printed constructs. In this study, a series of eleven chitosan-based bioinks were synthesized using the sol-gel technique, employing chitosan of low and medium molecular weight. Three bioink formulations were selected based on their viscosity characteristics and further enriched with gelatin and hydroxyapatite (HA) to enhance their mechanical properties. Characterization tests included Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), and rheological assessments. Viscoelastic materials were obtained, and an experimental model was developed to optimize printing parameters, focusing on pressure and printing speed. Our findings indicate that a bioink formulation comprising a blend of medium and high molecular weight chitosan, supplemented with gelatin and hydroxyapatite, was found to be a promising approach for fabricating scaffolds for bone tissue repair.

Karol Tutek, Anna Masek

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

Vol. 19., No.1., Pages 107-121, 2025

DOI: 10.3144/expresspolymlett.2025.8

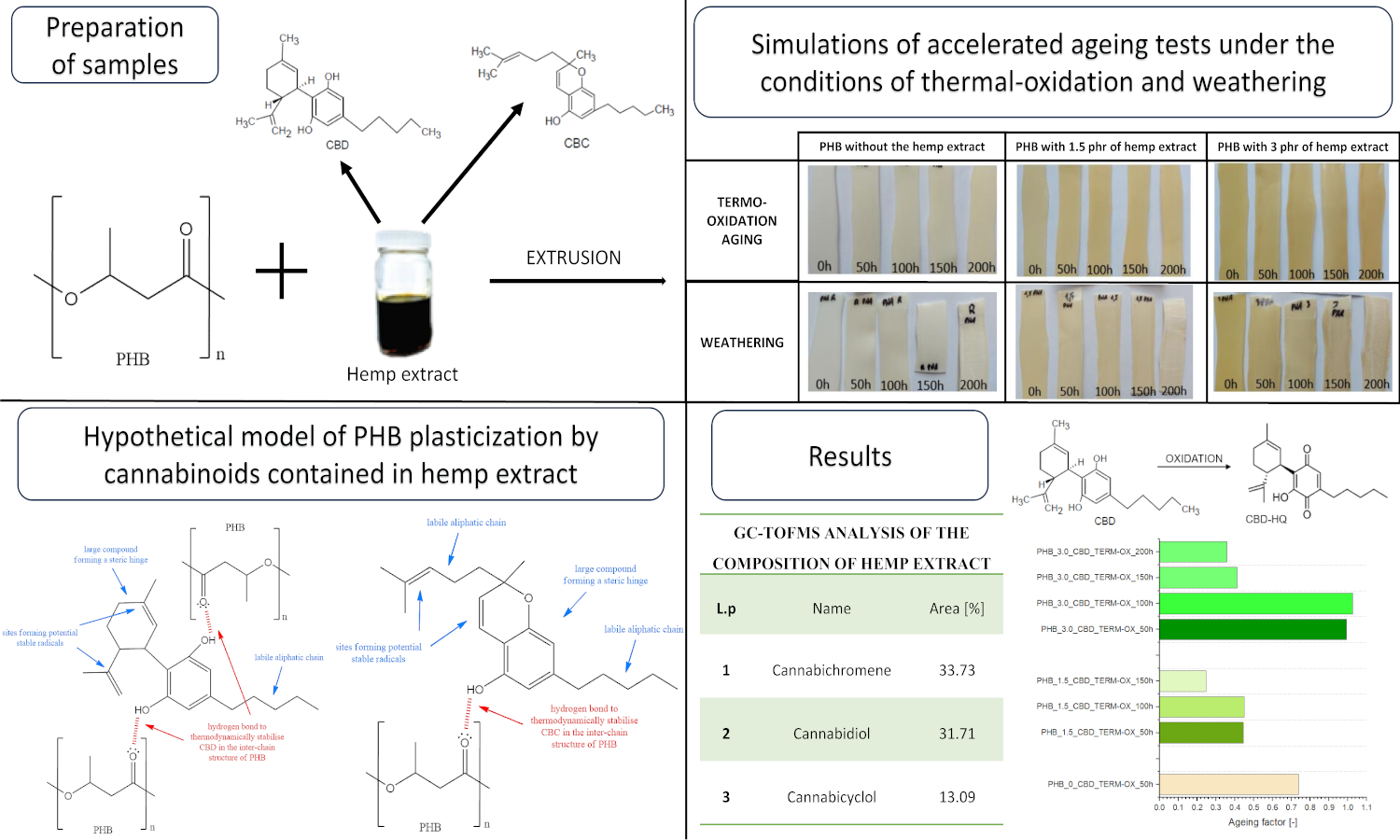

Biodegradable biopolymers like polyhydroxybutyrate (PHB) hold promise for sustainable packaging, but their inherent degradability reduces material stability. Synthetic stabilizers, though effective, raise environmental and potential toxicity concerns. This study explores a multifunctional natural anti-aging agent: a hemp extract rich in cannabidiol (CBD) and cannabichromene (CBC). PHB composites with varying hemp extract concentrations were prepared and subjected to thermooxidative and weathering aging. Characterization employed FTIR-ATR, carbonyl index, and spectrophotometry. Static mechanical properties, DSC, and surface free energy (SFE) were also assessed. Notably, the hemp extract exhibited stability under ambient conditions but showed migration with time and aging. The results suggest a plasticizing effect on PHB and highlight the contrasting roles of the extract: inhibiting thermooxidative aging while potentially accelerating aging under atmospheric conditions. This opens avenues for tailoring material durability, further evaluated by life cycle analysis (LCA). This work represents one of the first investigations into hemp extract as an anti-aging agent for eco-friendly polymers, expanding the knowledge base of natural multifunctional additives.

Ju Li, Lize Yang, Shuo Chen, Guotao Sun

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

Vol. 19., No.1., Pages 47-59, 2025

DOI: 10.3144/expresspolymlett.2025.4

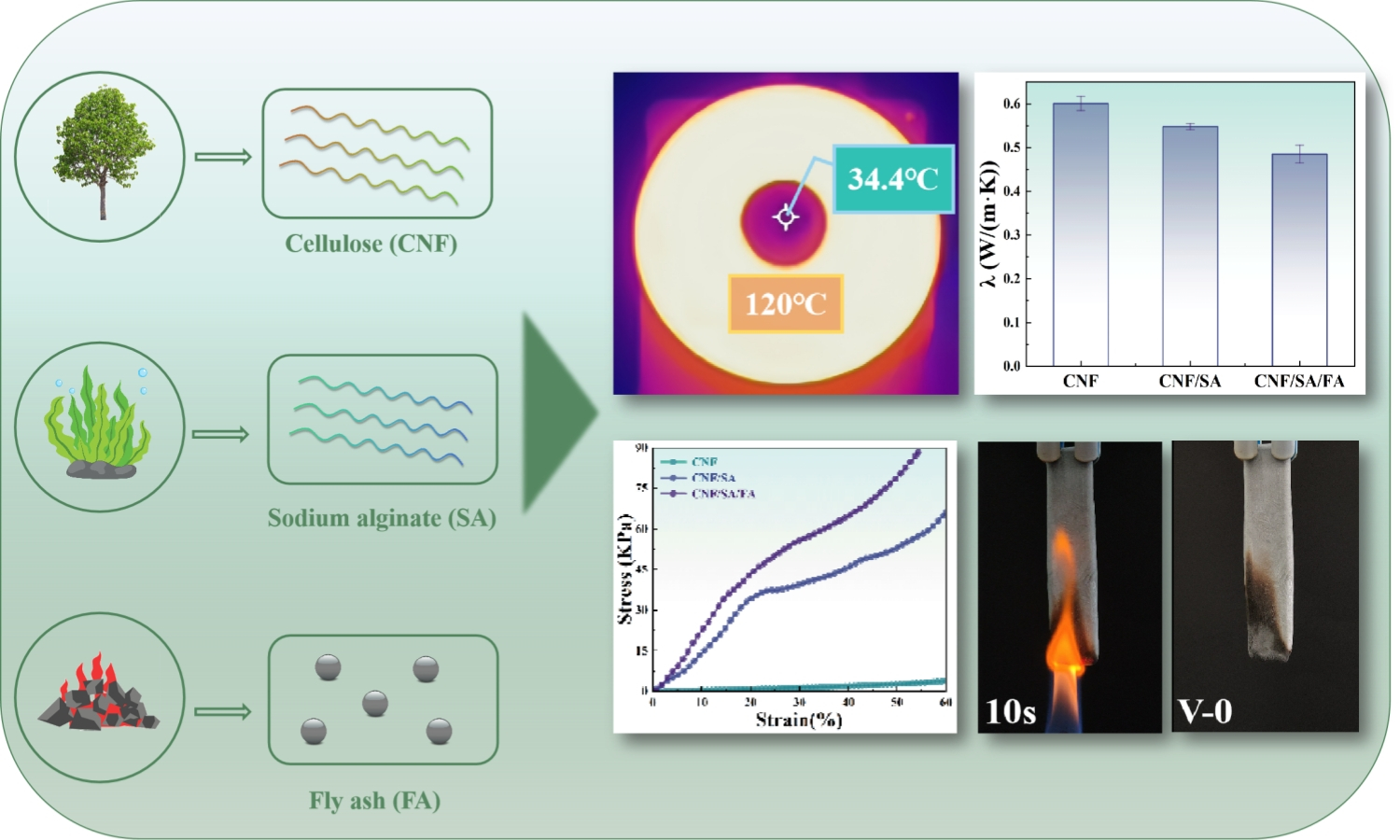

The widespread use of cellulose nanofiber (CNF)-based aerogels is hindered by their limited flame retardancy and mechanical properties. This study addresses these challenges by developing cellulose nanofiber/sodium alginate/fly ash (CNF/SA/FA) aerogel through a one-pot method, utilizing industrial waste fly ash (FA) as a reinforcing material. Various characterization and analytical techniques were employed to evaluate the properties of the CNF/SA/FA aerogel. The findings have revealed that resulting aerogel exhibited excellent thermal insulation performance, with a thermal conductivity of 0.485 W/(m·K), along with an impressive compressive strength of 88.4 kPa and favorable shape processability. Vertical combustion tests demonstrated a V-0 rating, indicating superior flame retardancy, and the aerogel achieved a remarkable 79.16% residual carbon, confirming their effective heat shielding capabilities. Notably, the incorporation of FA significantly enhanced both the thermal and mechanical properties of the composite aerogel, presenting a sustainable and effective solution to optimizing the properties of aerogel for thermal insulation.

Nguyen Hoc Thang, Nguyen Van Phuc, Tran Thi Tu Nhi, Dang Xuan Cuong, Do Quang Minh

Vol. 18., No.2., Pages 160-192, 2024

DOI: 10.3144/expresspolymlett.2024.13

Vol. 18., No.2., Pages 160-192, 2024

DOI: 10.3144/expresspolymlett.2024.13

Polymer-based hydrogels are hydrophilic polymer networks with a remarkable capacity to absorb substantial amounts of water and biological fluids, rendering them highly attractive for drug delivery applications. The COVID-19 pandemic has acted as a catalyst for research and innovation in the realm of polymer-based hydrogels for drug delivery, with a particular emphasis on antiviral therapeutics, vaccines, diagnostics, and precision delivery to the respiratory system. The distinctive attributes of hydrogels, such as their biocompatibility, customizable drug release profiles, and ease of functionalization, establish them as versatile platforms for the development of advanced drug delivery systems to combat not only COVID-19 but also a spectrum of other infectious diseases. This study is dedicated to scruti-nizing and evaluating the characteristics of polymer-based hydrogels employed in drug delivery for the treatment of diseases associated with the SARS-CoV-2 virus. Furthermore, the investigation introduces a novel classification system for polymer-based hydrogels deployed in drug delivery for SARS-CoV-2-related diseases. Additionally, the paper provides an up-to-date evaluation of the latest developed hydrogels utilized in drug delivery for the treatment of dis-eases linked to the SARS-CoV-2 virus, based on research conducted through the recent months of 2023.

Alejandro Lerma-Canto, Ivan Dominguez-Candela, Jaume Gomez-Caturla, Vicent Fombuena, Daniel Garcia-Garcia

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

Vol. 18., No.2., Pages 214-228, 2024

DOI: 10.3144/expresspolymlett.2024.15

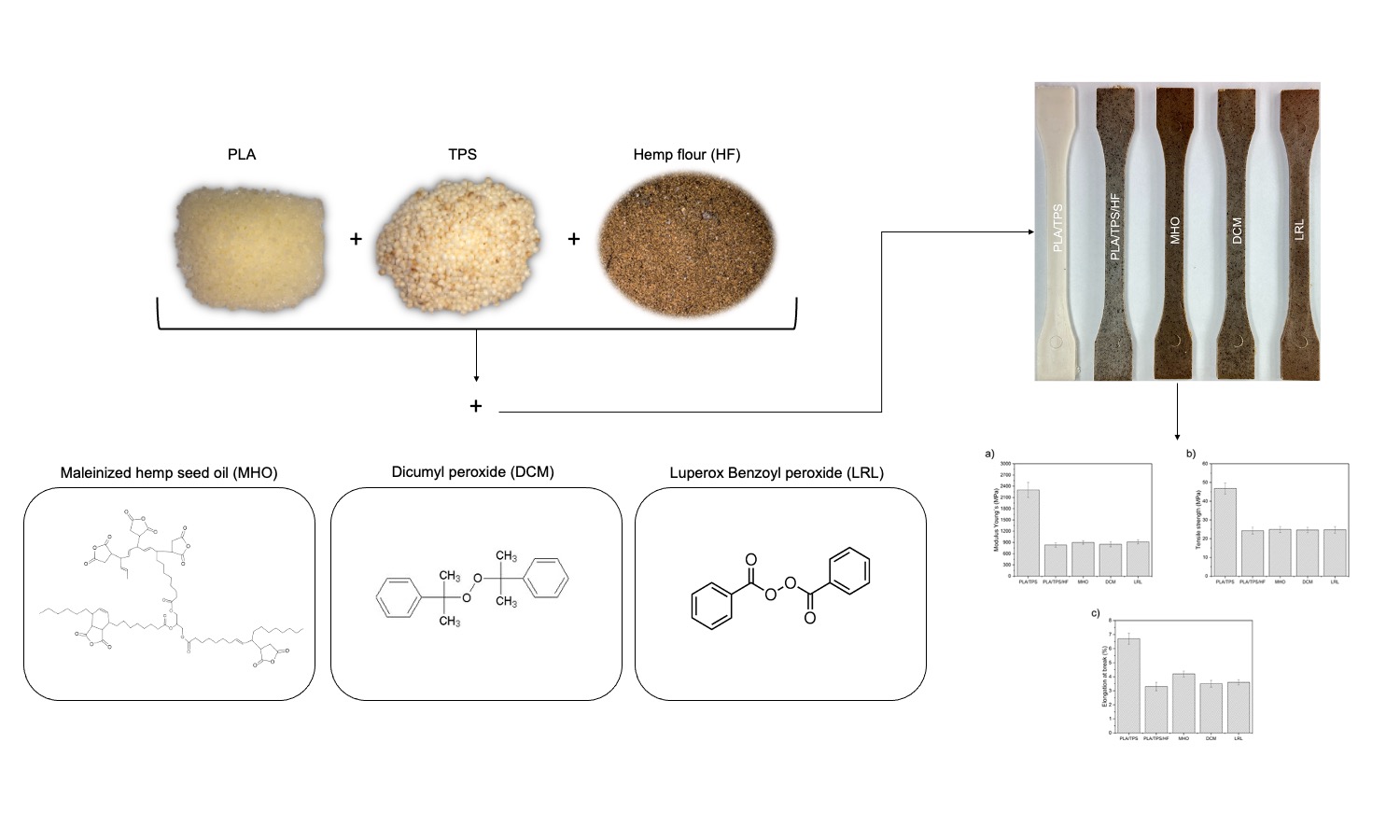

In a blend of poly(lactic acid) (PLA) and thermoplastic starch (TPS), a 15% load of hemp seed lignocellulosic filler (HF) was incorporated. Additionally, separate petrochemical-based compatibilizers, such as dicumyl peroxide (DCM) and benzoyl peroxide (LRL), as well as a bio-based compatibilizer, maleinized hemp seed oil (MHO), were introduced. Adding HF to the PLA/TPS blend reduced tensile mechanical properties due to the stress concentration phenomenon arising from the lack of interaction between components, yielding a more brittle material. This issue was mitigated by adding compatibilizers, notably the incorporation of MHO into the PLA/TPS/HF blend this increased elongation at break by enhancing compatibility among the blend components and providing a plasticizing effect. Moreover, regarding thermal properties, it was observed that the inclusion of HF led to a decrease in the glass transition temperature (Tg), cold crystallization temperature (Tcc), and melting temperature (Tm). Conversely, adding MHO to this blend increased all these values compared to the PLA/TPS/HF mixture, attributed to the plasticizing effect imparted by the modified oil. Additionally, following fracture in Charpy impact testing, the samples were subjected to field emission scanning electron microscopy (FESEM) analysis to examine the fractured surface of the various samples.