Content

All issues / Volume 17 (2023) / Issue 10 (October)

László József Varga, Tamás Bárány

Vol. 17., No.10., Pages 991-991, 2023

DOI: 10.3144/expresspolymlett.2023.73

Vol. 17., No.10., Pages 991-991, 2023

DOI: 10.3144/expresspolymlett.2023.73

This is an editorial article. It has no abstract.

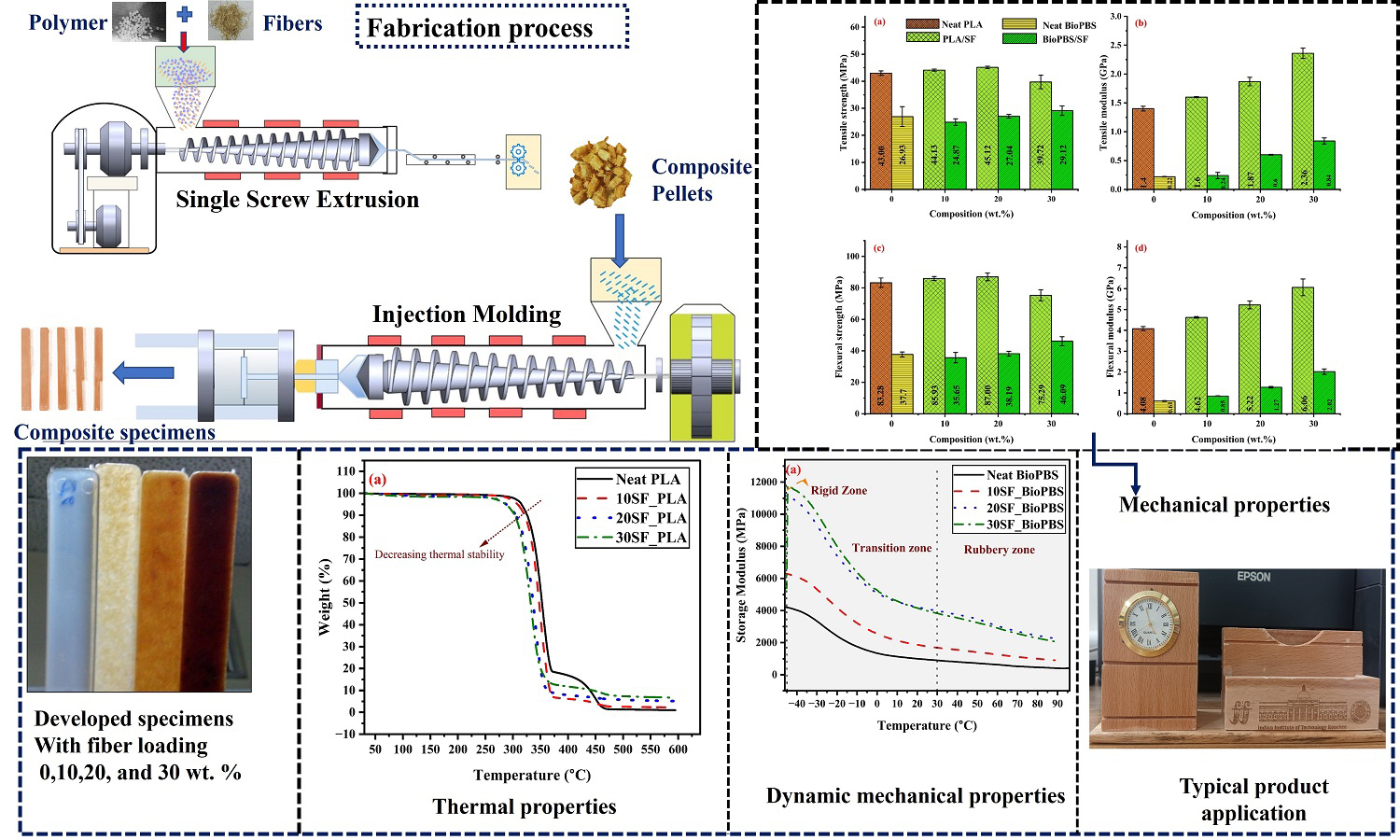

Karri Santosh Kumar, Sandeep Gairola, Inderdeep Singh

Vol. 17., No.10., Pages 992-1006, 2023

DOI: 10.3144/expresspolymlett.2023.74

Vol. 17., No.10., Pages 992-1006, 2023

DOI: 10.3144/expresspolymlett.2023.74

In the global pursuit of using sustainable constituents for developing composite materials, the current investigation has paid particular attention to the most promising biopolymers, such as poly(lactic acid) (PLA) and bio-based poly(butylene succinate) (bio PBS). The research endeavor emphasizes a comparative assessment of short sisal fiber (SF) reinforced (10,20, and 30 wt%) PLA and bio PBS biocomposites. The analysis and discussion have been reported for the thermal, mechanical,crystallinity, and dynamic mechanical behavior of developed composite materials. Based on mechanical properties, the optimal fiber loading for SF/PLA and SF/bio PBS biocomposites was 20 and 30 wt%, respectively. The developed composites have shown a considerable improvement in crystallinity of 17.88 and 41.13% at 20 and 30 wt% of fiber loading in SF/PLA and SF/bio PBS, respectively. The maximum storage modulus values of 14.23 GPa (20SF/PLA) and 11.74 GPa (30SF/bio PBS) were observed. The loss modulus of the SF/PLA and SF/bio PBS composites was around 74 and 89% higher than the loss modulus of the PLA and the bio PBS matrix, respectively. Overall, composites fabricated with bio PBS (SF/bio PBS) have shown better crystallinity, thermal stability, and ease of processing than SF/PLA composites.

Hosein Pouriman, Kevin Graham, Krishnan Jayaraman

Vol. 17., No.10., Pages 1007-1018, 2023

DOI: 10.3144/expresspolymlett.2023.75

Vol. 17., No.10., Pages 1007-1018, 2023

DOI: 10.3144/expresspolymlett.2023.75

Four out of twelve different formulations consisting of poly(lactic acid) (PLA), poly(3-hydroxybutyrate-co-hydroxyvalerate) (PHBV), triethyl citrate (TC), and epoxy-functionalized styrene acrylate (ESA) components were selected based on their superior elongation at break, rheological properties, and composition range from other batches. Each batch was made into a monolayer thin film via a blown film extrusion process. The films’ mechanical, oxygen gas, and moisture barrier and aesthetic properties were measured. The findings paved the understanding for developing biodegradable packaging to extend the shelf life of oxygen and moisture-sensitive food products. The results proved the significance of systematic analysis of the interacting effects of components’ mixing ratios on different properties of the blend. The produced films’ oxygen gas and moisture barrier properties showed significant improvement compared to neat PLA; however, still more than neat PHBV.

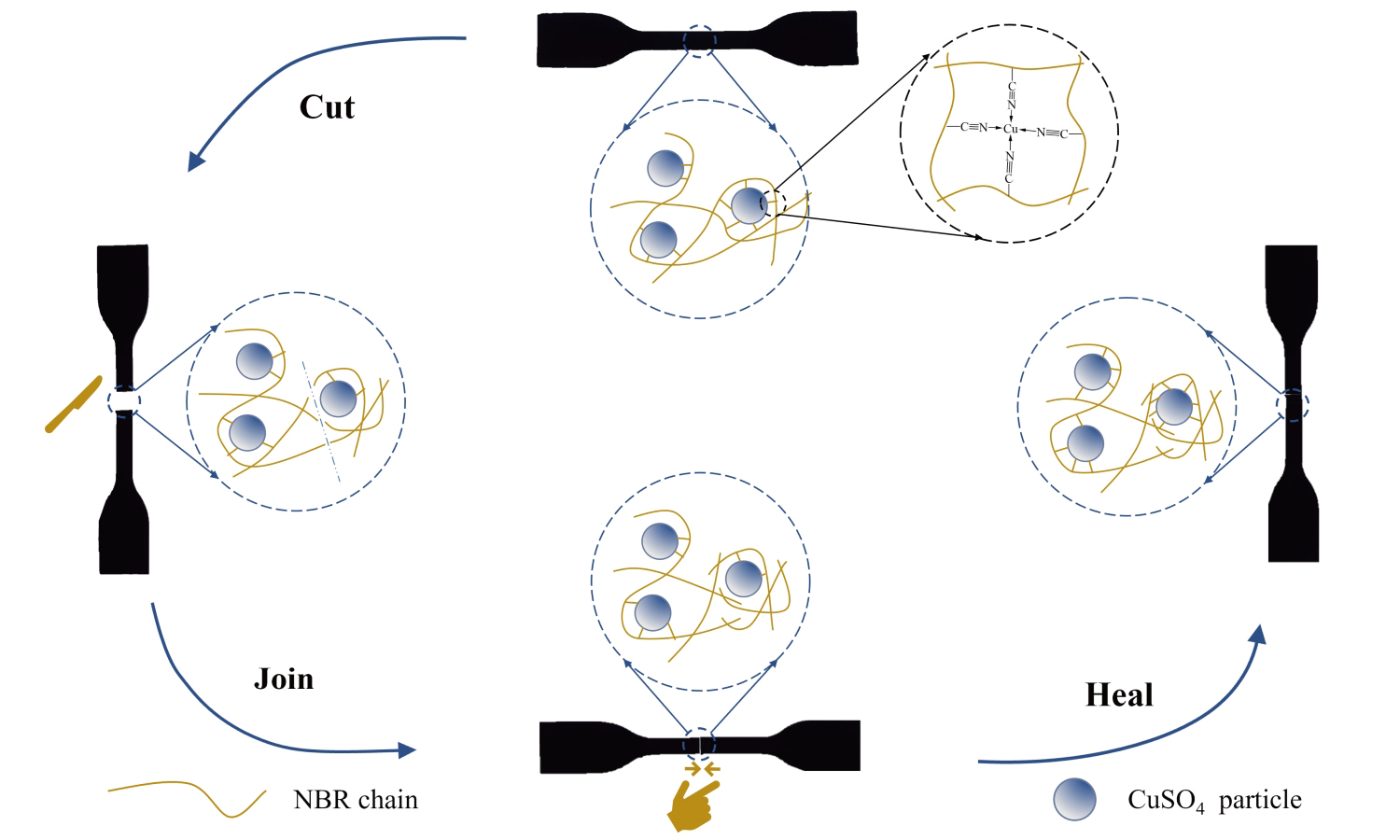

Yuan Gao, Weiran Zhang, Junhao Wang, Zishuo Wang, Zhaobo Wang

Vol. 17., No.10., Pages 1019-1030, 2023

DOI: 10.3144/expresspolymlett.2023.76

Vol. 17., No.10., Pages 1019-1030, 2023

DOI: 10.3144/expresspolymlett.2023.76

In this research, a nitrile-butadiene rubber (NBR) was prepared with excellent mechanical, self-healing and recycling properties by introducing metal-ligand coordination interaction. A coordination crosslinking network based on ligand bonding was successfully introduced in the NBR matrix by mechanical compounding. The dynamic reversibility of the coordination crosslinking network not only provides the vulcanizate with excellent mechanical properties but also confers a remarkable self-healing ability under high temperatures and recyclable property under mechanical shear, respectively. The sample, which was subjected to the complete cut, could be capable of restoring its original tensile strength after self-healing treatment. The self-healing efficiency of NBR vulcanizate is significantly dependent on the self-healing temperature and time, which can surprisingly reach 97% of the original tensile strength after self-healing treatment at 180 °C for 60 min. After the mechanical shear, the coordination crosslinking network is reversibly transformed. The tensile strength of the NBR vulcanizates after mechanical shearing recycling and re-vulcanization was similar to that of the original NBR vulcanizates. This research presents a novel approach to enhance the durability of rubber used in commercial applications, endowing it with reshaping and recycling capabilities and mitigating environmental issues associated with waste rubber.

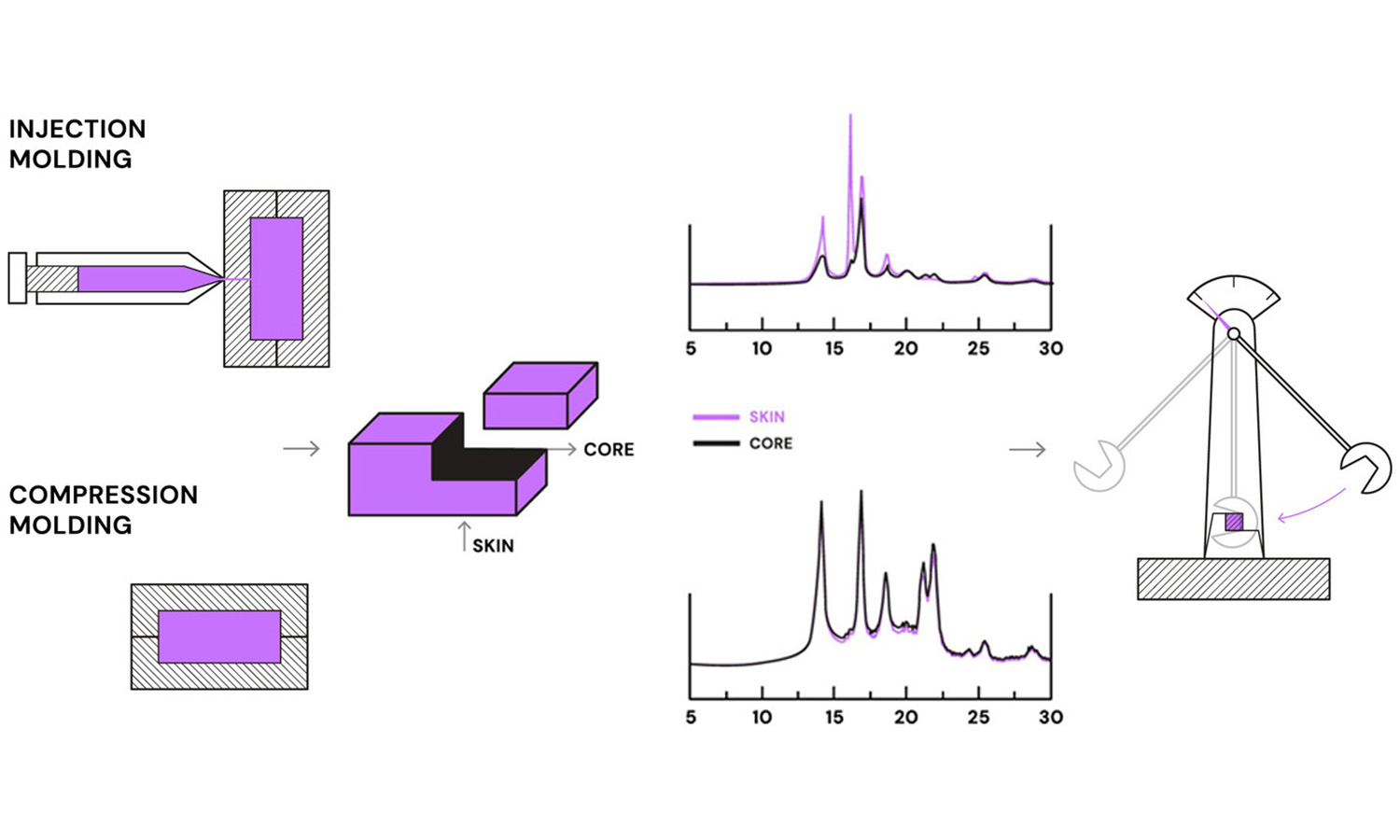

Lenka Gajzlerova, Jana Navratilova, Martina Polaskova, Lubomir Benicek, Roman Cermak

Vol. 17., No.10., Pages 1031-1041, 2023

DOI: 10.3144/expresspolymlett.2023.77

Vol. 17., No.10., Pages 1031-1041, 2023

DOI: 10.3144/expresspolymlett.2023.77

The impact of injection molding processing parameters, including mold temperature, injection speed, and holding pressure, on the supermolecular structure of long-chain branched polypropylene (LCB-PP) was investigated. Commercial LCB-PP was processed under different conditions, with four sets of processing parameters applied. Holding pressure was varied from 30–70 MPa by 10 MPa in the P-SET, mold temperature was raised from 40 to 120°C in 20°C steps in the T-SET,and injection speed increased from 20 to 140 mm/s in 30 mm/s steps in S-SET1 and S-SET2, with mold temperatures at 40 or 120 °C. The polymorphic composition of the specimens was analyzed using wide-angle X-ray scattering, demonstrating a strong dependence on the processing parameters. The skin of the specimens showed an increase in β-phase content with higher mold temperature and injection speed. Conversely, growing holding pressure slightly suppressed β-phase content and promoted the formation of the γ-phase, which was predominantly manifested in the core of the specimens. The polymorphic composition, with both β- and γ-phases present in notable amounts, had a beneficial effect on the impact strength of the specimens.

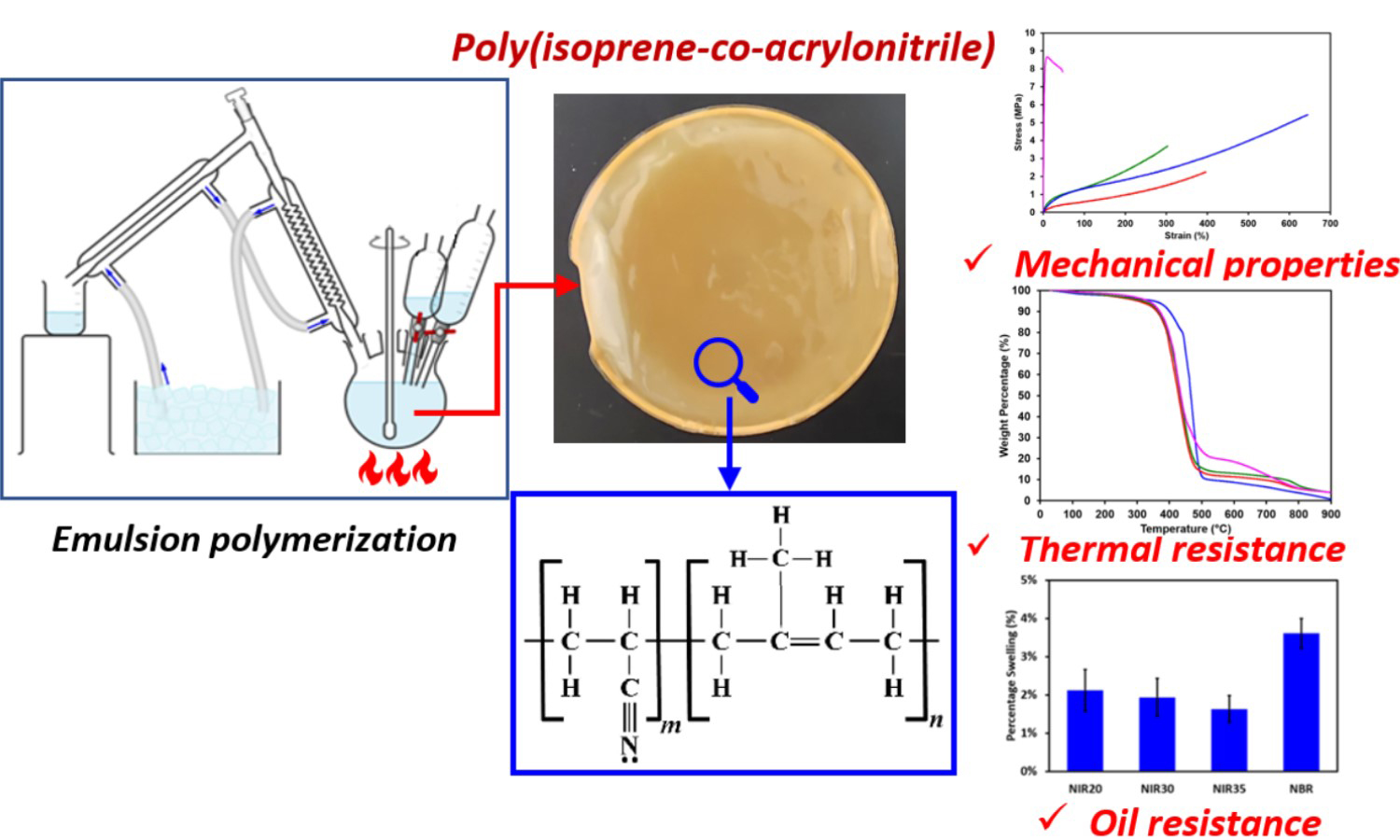

Zhen Hern Boon, Yin Yin Teo, Desmond Teck-Chye Ang

Vol. 17., No.10., Pages 1042-1055, 2023

DOI: 10.3144/expresspolymlett.2023.78

Vol. 17., No.10., Pages 1042-1055, 2023

DOI: 10.3144/expresspolymlett.2023.78

Increasing demand for durable rubber and rapid advancement in the automotive sector has made oil-resistant rubber an increasingly important material. Among them, nitrile rubber (NBR) is the most iconic due to its extraordinary oil resistance contributed by the polar nitrile pendant groups. Synthesis of NBR, however, is highly hazardous due to the explosive nature of the gaseous monomer butadiene. In this work, poly(isoprene-co-acrylonitrile) (NIR) was synthesized using free radical emulsion polymerization, with liquid monomer isoprene as the diene in the rubber formulation. The spectroscopic analysis confirmed the formation of NIR and indicated that the polymerized isoprene in the rubber is predominantly of 1,4-microstructure. A series of rubbers with different contents of acrylonitrile were produced and the mechanical, thermal, as well as oil resistant property of the resultant rubber films were evaluated. Vulcanized NIR films displayed glass transition temperatures from –9.4 to 20.2 °C, suggesting that the polymers are rubbery at ambient and higher temperatures. The NIR rubber films exhibited excellent oil resistance with less than 2% swelling in mineral oil, good thermal stability with onset degradation temperature in the range of 361.3 to 369.9 °C, and adequate mechanical strength from 1.61 to 8.23 MPa. The synthesized NIR rubber has the potential to serve as an alternative to NBR which had been traditionally used for oil resistance applications.

Azizon Kaesaman, Rawviyanee Romin, Charoen Nakason

Vol. 17., No.10., Pages 1056-1069, 2023

DOI: 10.3144/expresspolymlett.2023.79

Vol. 17., No.10., Pages 1056-1069, 2023

DOI: 10.3144/expresspolymlett.2023.79

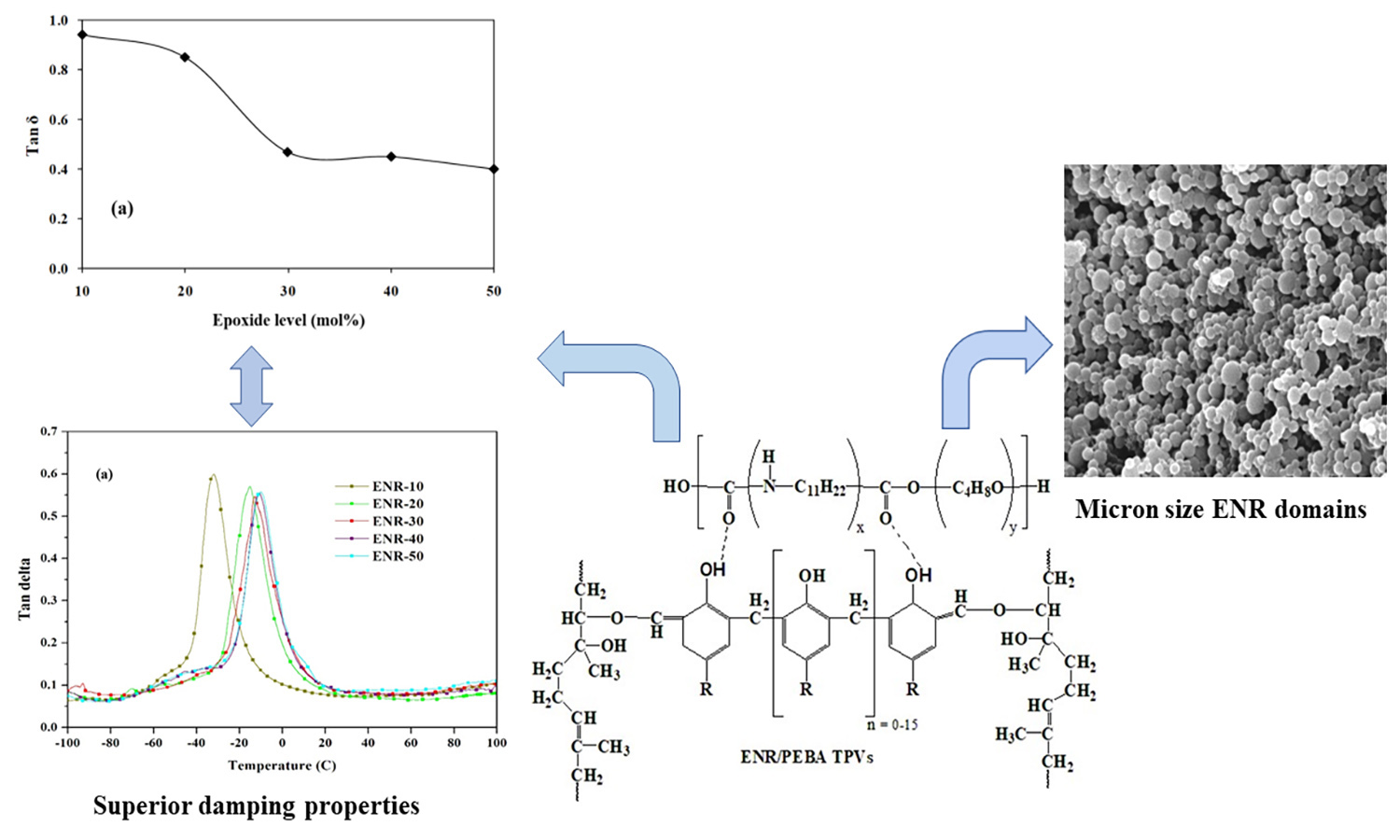

Epoxidized natural rubber (ENR) with varying levels of epoxide groups ranging from 10 to 50 mol% was prepared and dynamically phenolic vulcanized by blending it with poly(ether-block-amide) copolymer (PEBA). The results indicate that the thermoplastic vulcanizates (TPVs) of ENR/PEBA blends display a sea-island morphology and enhance a number of properties. Specifically, increasing the epoxide content and PEBA proportion enhances strength properties, including higher Young’s modulus (stiffness), toughness, tensile properties, and hardness, along with smaller vulcanized ENR domains dispersed in the PEBA matrix. Moreover, the decrease in tension set values indicates an improvement in the elastic properties. The attributed cause of this is the interaction between the polar groups present in the phenolic-cured ENR domains and the PEBA molecules. As a result, interfacial adhesion between the ENR domains and PEBA interfaces improved, contributing to the observed enhancements in the strength and elastic properties of the TPVs with smaller ENR domains. Furthermore, an increase in the epoxide content was found to be correlated with a decrease in tanδ and tension set, which further supported the observed improvements in strength and elasticity. Additionally, the ENR/PEBA blends showed a single glass transition temperature (Tg), while pure PEBA exhibited two Tgs. The presence of a single Tg in the ENR/PEBA blend is attributed to the overlapping of the Tg of the ENR and PEBA immiscible blend components.

Vakkoottil Sivadasan Abhisha, Krishanagegham Sidharathan Sisanth, Sabu Thomas, Ranimol Stephen

Vol. 17., No.10., Pages 1070-1080, 2023

DOI: 10.3144/expresspolymlett.2023.80

Vol. 17., No.10., Pages 1070-1080, 2023

DOI: 10.3144/expresspolymlett.2023.80

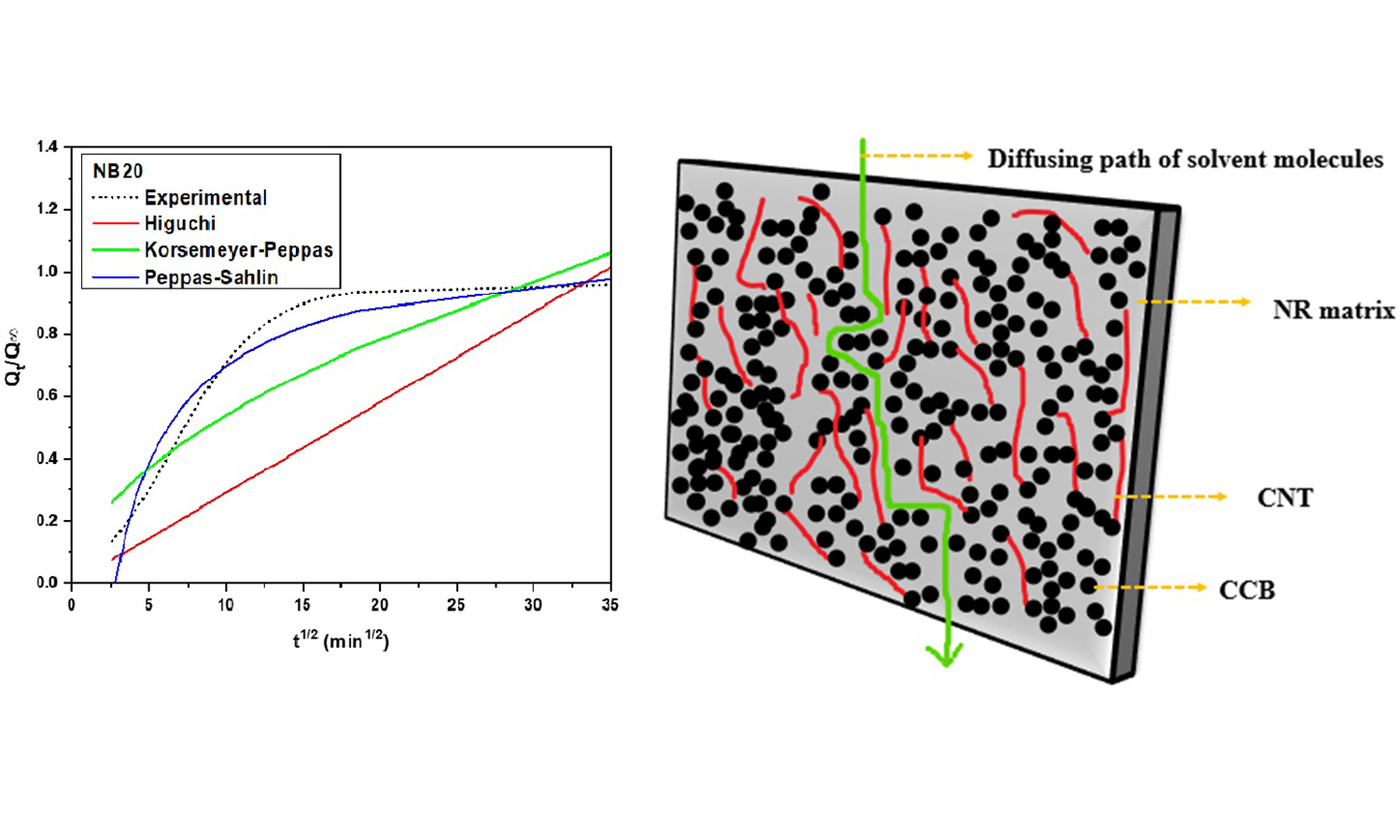

Conductive carbon black (CCB), carbon nanotubes (CNT) and its hybrids are introduced into the natural rubber (NR) matrix aiming to explore the effect of filler ratio on the transport properties. Solvent transport of NR is found to decrease for hybrid filler systems as compared to single filler incorporated systems. Kinetic parameters of solvent transport behavior of filled NR systems are analyzed using various kinetic models. Upon the computation of kinetic parameters of transport data, it is found that the Peppas-Sahlin model is in good agreement with experimental observations, which suggests that the transport mechanism is diffusion controlled. Rubber–filler interaction parameters are computed and analyzed from the swelling experiments using Kraus, Cunneen-Russel, and Lorenz-Park equations