Synthesis and characteristics of α-carboxylic, ω-hydroxyl natural rubber toughened poly(lactic acid)

Abdulhakim Masa, Varaporn Tanrattanakul, Ruedee Jaratrotkamjorn

Vol. 17., No.11., Pages 1121-1134, 2023

DOI: 10.3144/expresspolymlett.2023.85

DOI: 10.3144/expresspolymlett.2023.85

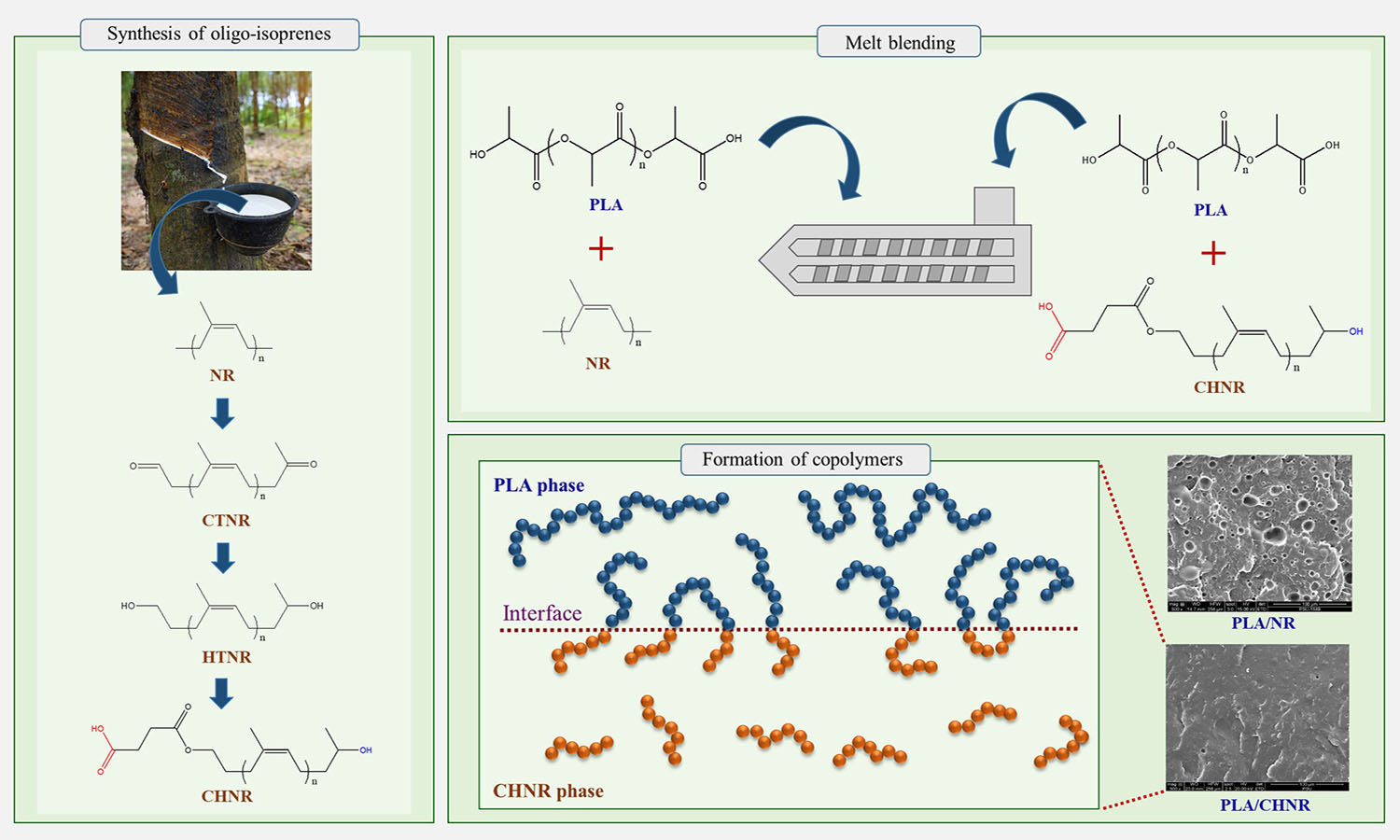

GRAPHICAL ABSTRACT

ABSTRACT

This work presented the synthesis of α-carboxyl, ω-hydroxyl natural rubber (CHNR) for use as an alternative toughening agent for poly(lactic acid) (PLA). The proton nuclear magnetic resonance spectroscopy (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) analyses verified the chemical structure of CHNR consisting of the hydroxyl and carboxyl end groups. The molecular weights of CHNR were set from 5000 to 15 000 g·mol–1 which were determined by gel permeation chromatography (GPC) and 1H-NMR. The PLA and CHNR were prepared by reactive blending using a twinscrew extruder. It was found that the reaction between PLA and CHNR proceeded through transesterification without a catalyst. The formation of copolymer (PLA-co-CHNR) at the interface of PLA and CHNR increased the interfacial adhesion between the two phases. Differential scanning calorimetry (DSC) analysis revealed that CHNR was more compatible with PLA than natural rubber (NR). The compatibilization affected the blend morphology by reducing the interfacial tension. It resulted in a reduction of rubber particle size. The CHNR with a molecular weight of 5000 g·mol–1 showed the greatest improvement in the toughness and ductility of PLA.

RELATED ARTICLES

Waleed Y. Rizg, Amerh Aiad Alahmadi, Mohammed Baradwan, Rahul Dev Bairwan, Marwan M, Ahmed K. Mohamed, Sherif El Saadany, CK Abdullah, H.P.S. Abdul Khalil

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

Vol. 19., No.3., Pages 294-310, 2025

DOI: 10.3144/expresspolymlett.2025.21

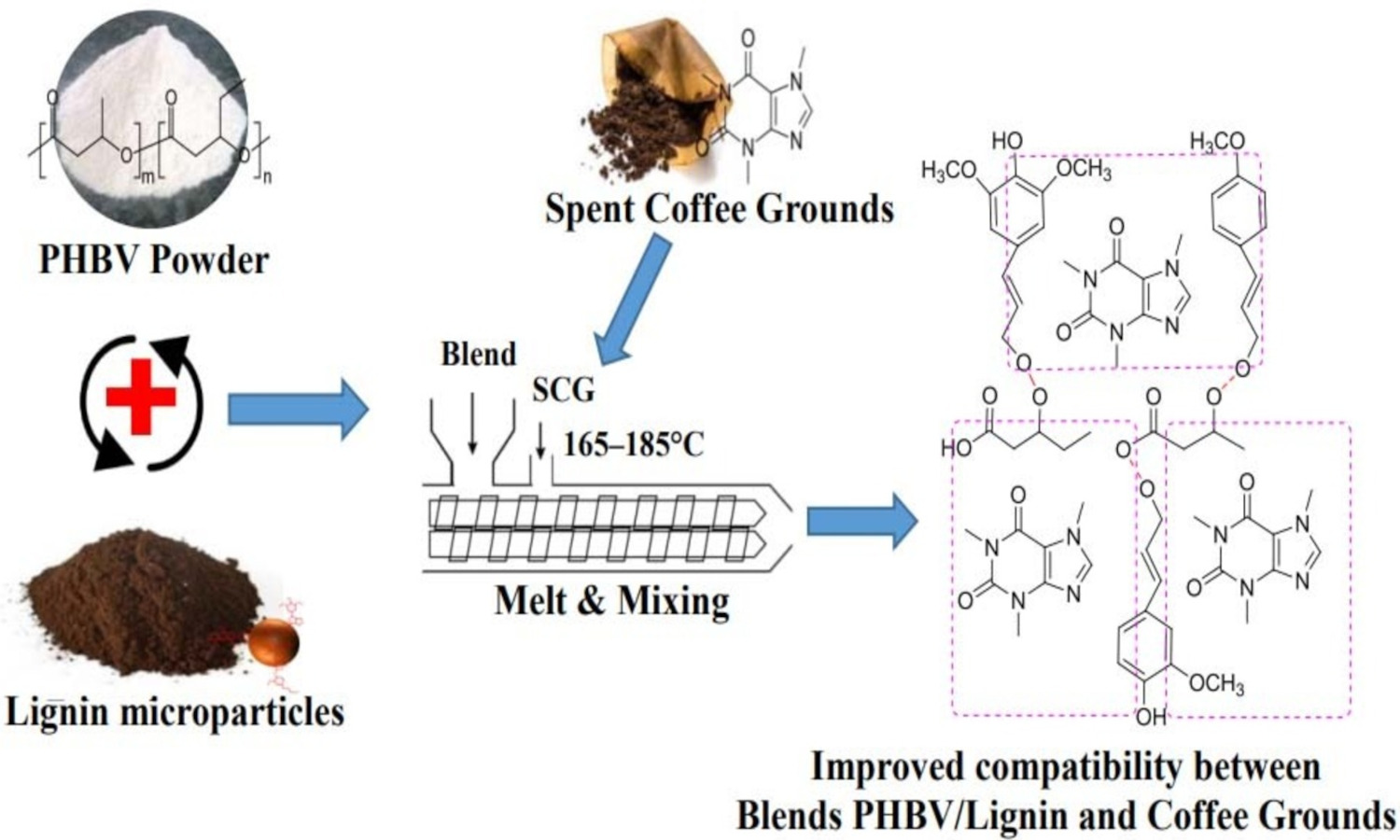

This study investigated the development of thermoplastic composites by incorporating crude lignin extracted from coir fiber waste, into poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a biodegradable polymer. The extracted crude lignin was blended with PHBV as a matrix, and spent coffee grounds (SCG) were used as biofillers. SCG were chemically modified through sodium hydroxide (NaOH) treatment and maleic anhydride (MA) grafting to enhance their compatibility with the PHBV/lignin blend. Raw and modified SCG were characterized for their functional, morphological, and thermal properties before being incorporated. Thermoplastic biocomposites were prepared via melt compounding and compression molding and evaluated for water barrier, morphological, mechanical, and thermal properties. Results showed that MA-grafted SCG significantly enhanced PHBV-lignin properties, increasing tensile strength by 23.7% and thermal stability by 11.9% compared to the control matrix. Optimal performance was observed at 5% MA-grafted SCG filler loading. However, higher SCG concentrations (7%) led to filler agglomeration, negatively affecting the material properties. This research demonstrated the potential of utilizing agricultural and food waste to create high-performance thermoplastic composites for future applications in biodegradable packaging, contributing to the advancement of a circular economy and environmental sustainability.

Emir Avcioglu

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

Vol. 19., No.1., Pages 3-14, 2025

DOI: 10.3144/expresspolymlett.2025.2

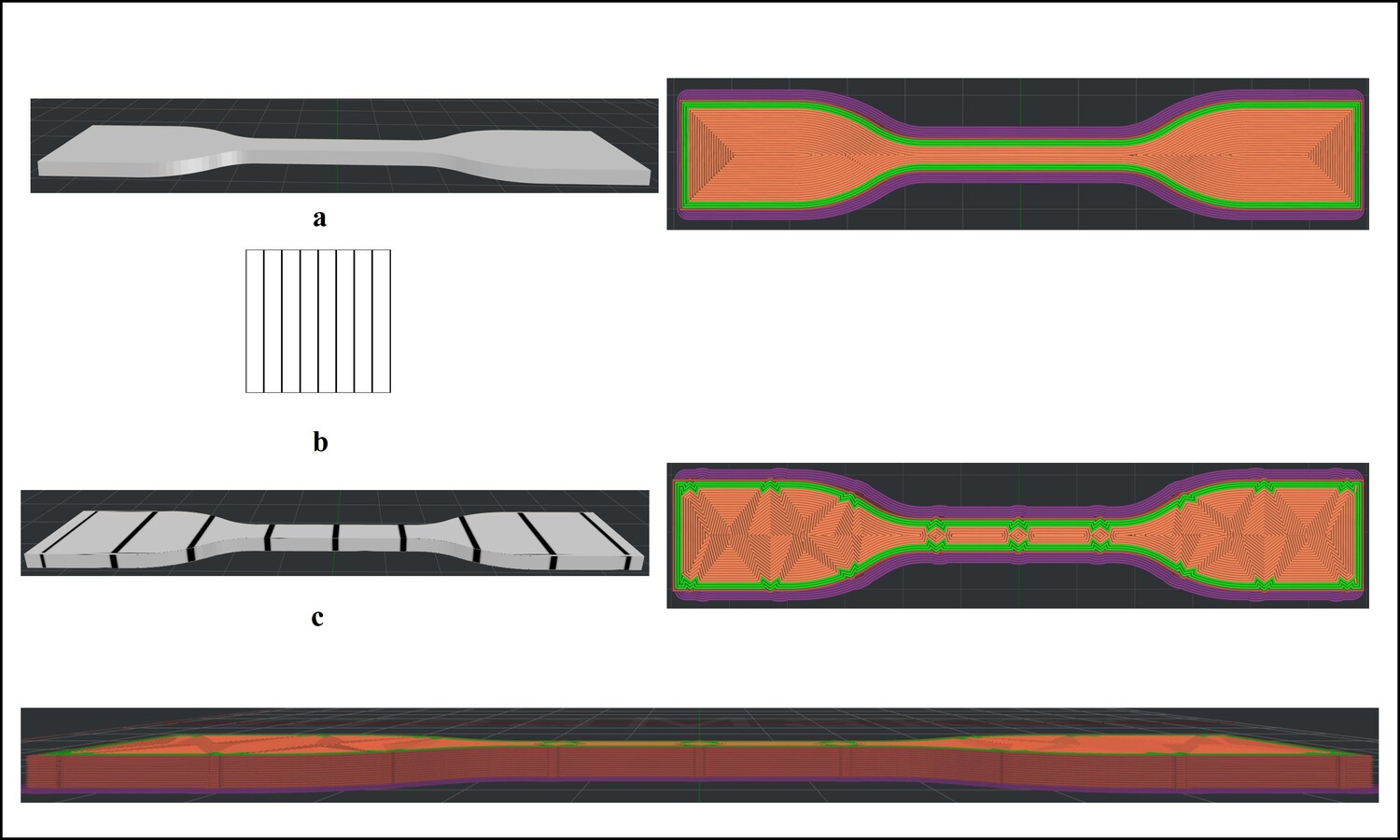

Additive manufacturing is favored for its capacity to create intricate geometries and enhance component functionality more efficiently than traditional methods. Applying texture to materials is one of the processes used to add functionality to products, wherein it can improve adhesion and tribological behavior in biomedical applications while also controlling mechanical properties and providing perceptual and aesthetic improvements. In this study, custom black-white images containing vertical lines were prepared and added as textures to the design of tensile test specimens during slicing. Custom textured and untextured tensile test specimens were fabricated using the Fused Deposition Method with polylactic Acid filament to evaluate the effect of texture parameters, such as protrusion offset (0.25, 0.50, 0.75 mm), number of protrusions (3, 6) and infill pattern (rectilinear, line, concentric), on the tensile strength of the specimens. Through the analysis of tensile test results and examination of microscopic and slicing software images, it was found that texturing resulted in a reduction in ultimate tensile strength due to nozzle trajectory deviations and stress concentration. The least detrimental texturing parameters observed in this study were 0.5 mm protrusion offset and 3 protrusions with concentric and line infill patterns, resulting in a reduction in tensile strength of 2.36 and 5.79%, respectively when compared to untextured specimens.

Tamás Tábi

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

This is an editorial article. It has no abstract.

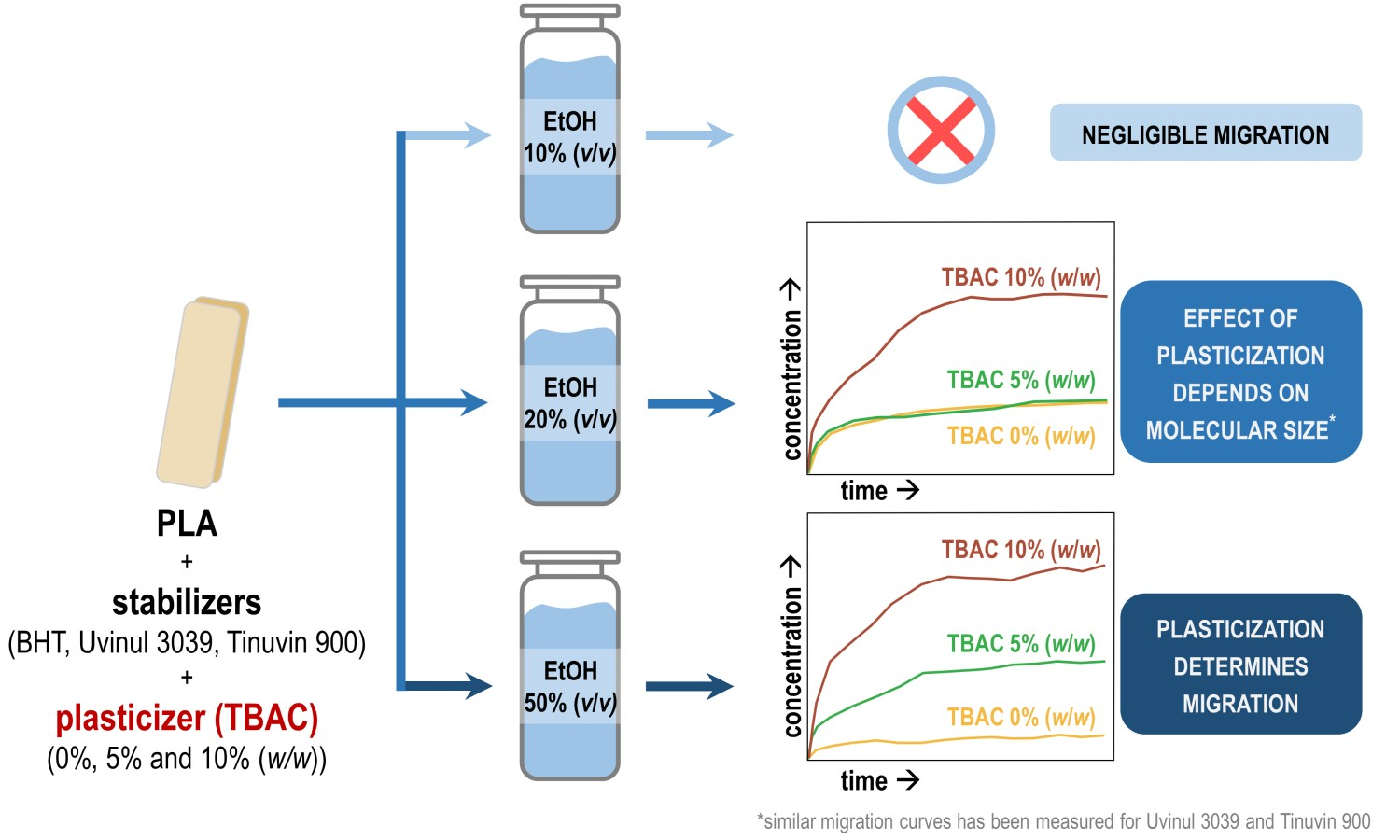

Viktor Konstantin Dragan, Noémi Petrovics, Csaba Kirchkeszner, Tamás Tábi, Bálint Sámuel Szabó, Zsuzsanna Eke

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

The

effect of swelling and plasticizer content of a plastic, as well as the ethanol

content of the food simulant on the migration kinetics of three stabilizer-type

additives from polylactic acid (PLA)-based food contact plastics has been

investigated. The results proved that the parameters that affect the diffusion

of substances inside the polymer matrix, i.e.,

swelling, plasticization, and the size of migrants, are the decisive factors in

the migration from PLA to ethanolic food simulants. Both swelling and migration

were negligible when ethanol 10% (v/v) was used. Contrarily, the specific

migration limits of Commission Regulation (European Union, EU) No. 10/2011 were

exceeded in ethanol 50% (v/v) for all investigated stabilizers. Migration was

promoted by plasticization, but this effect could only be observed when the

applied food simulant swelled the plastic (at least 20% (v/v) ethanol content).

The dependence of the plasticizer’s migration-enhancing effect on the swelling

has not been shown before. When the plasticization caused increased migration,

it also led to specific migration limit exceeding within a shorter period of

time. It happens even if PLA-based plastics are dedicated to the storage of

hydrophilic food, which is the most common application area of these products.

These results can support the improvement of both consumer safety and active

packaging development.

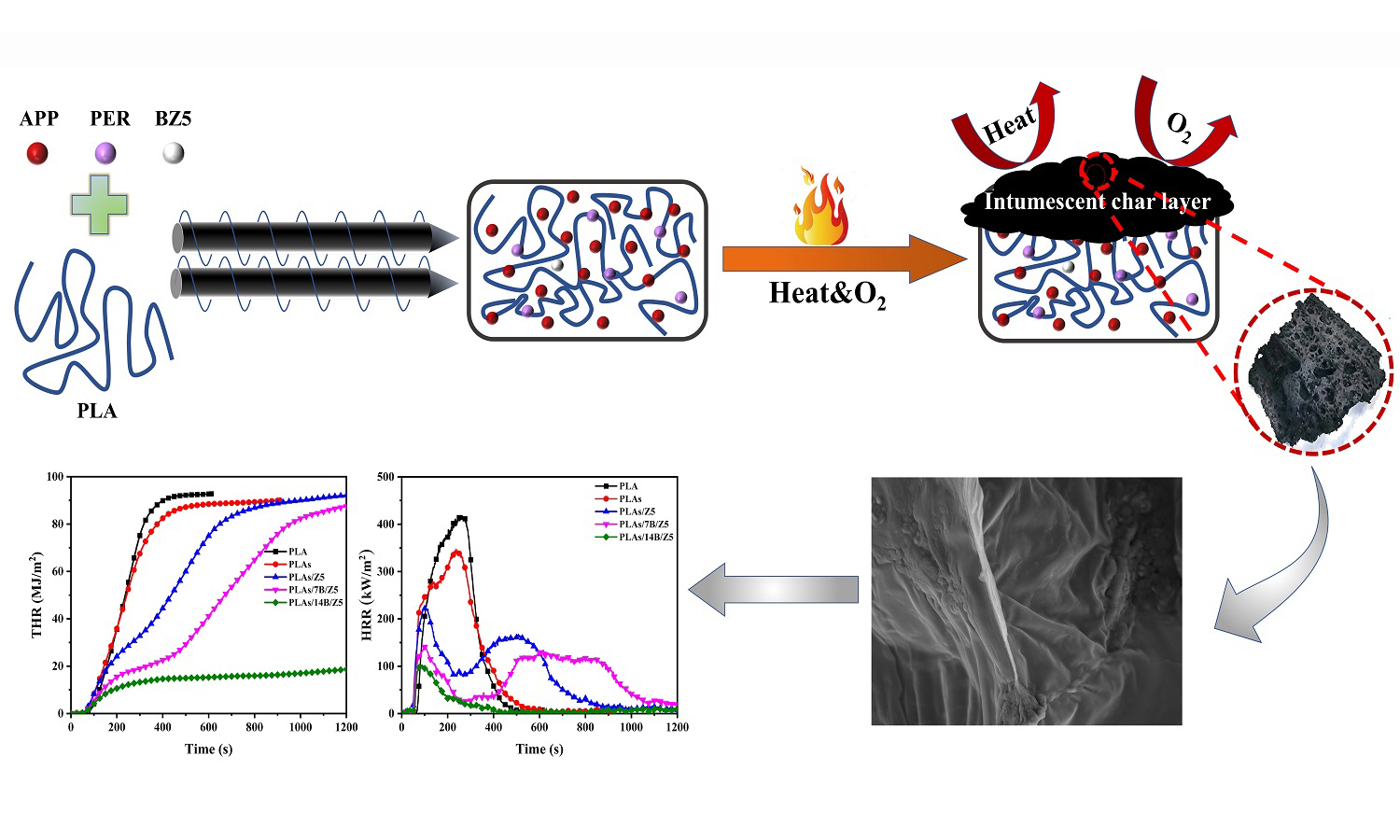

Xiaokun Zhai, Qin Ma, Jing Lu, Yuwei Jin, Ruiyan Zhang, Faliang Luo

Vol. 18., No.3., Pages 326-336, 2024

DOI: 10.3144/expresspolymlett.2024.23

Vol. 18., No.3., Pages 326-336, 2024

DOI: 10.3144/expresspolymlett.2024.23

In order to improve the inherent flammability of polylactic acid (PLA) and make this new biodegradable material more widely used, B-modified ZSM-5 (B/Z5) was designed as synergistic agent of intumescent flame retardant (IFR), composed of ammonium polyphosphate (APP) and pentaerythritol (PER), and introduced into PLA/IFR (PLAs) to fabricate PLAs/B/Z5 composites by melt extrusion. The flame retardancy, surface morphology, and thermal stability of the composites were investigated by TG, LOI, UL-94, CCT, and SEM. The addition of B/Z5 makes the decomposition temperature of T5% as well as T10% of PLAs reduction in nitrogen atmosphere and carbon layer form in advance. UL-94 test shows the composites reach V-0 rating. LOI value also steadily increases, and the maximum value is 36.0% with B actual loading of 5.26% (recoded as 14B/Z5) in B/Z5. The PHRR decreases by 75% from 417.77 kW/m2 for pure PLA to 103.19 kW/m2 for PLAs/14B/Z5, and THR reduces from 92.78 to 19.26 MJ/m2, which decreases by about 80% and the char yield reaches 50%. This study provides a simple and green method for the preparation of high flame-retardant PLA, which has a broad practical application prospect.