Studies of the in vivo bioresorption rate of composite filaments on the basis of polylactide filled with chitin nanofibrils or silver nanoparticles

Konstantin Vadimovich Malafeev , Olga Andreevna Moskalyuk

, Olga Andreevna Moskalyuk , Vladimir Evgenyevich Yudin

, Vladimir Evgenyevich Yudin , Dmitry Nikolayevich Suslov

, Dmitry Nikolayevich Suslov , Elena Nikolaevna Popova

, Elena Nikolaevna Popova , Elena Mikhaylovna Ivan’kova

, Elena Mikhaylovna Ivan’kova , Alena Alexandrovna Popova

, Alena Alexandrovna Popova

, Olga Andreevna Moskalyuk

, Olga Andreevna Moskalyuk , Vladimir Evgenyevich Yudin

, Vladimir Evgenyevich Yudin , Dmitry Nikolayevich Suslov

, Dmitry Nikolayevich Suslov , Elena Nikolaevna Popova

, Elena Nikolaevna Popova , Elena Mikhaylovna Ivan’kova

, Elena Mikhaylovna Ivan’kova , Alena Alexandrovna Popova

, Alena Alexandrovna PopovaVol. 18., No.3., Pages 296-308, 2024

DOI: 10.3144/expresspolymlett.2024.21

DOI: 10.3144/expresspolymlett.2024.21

GRAPHICAL ABSTRACT

ABSTRACT

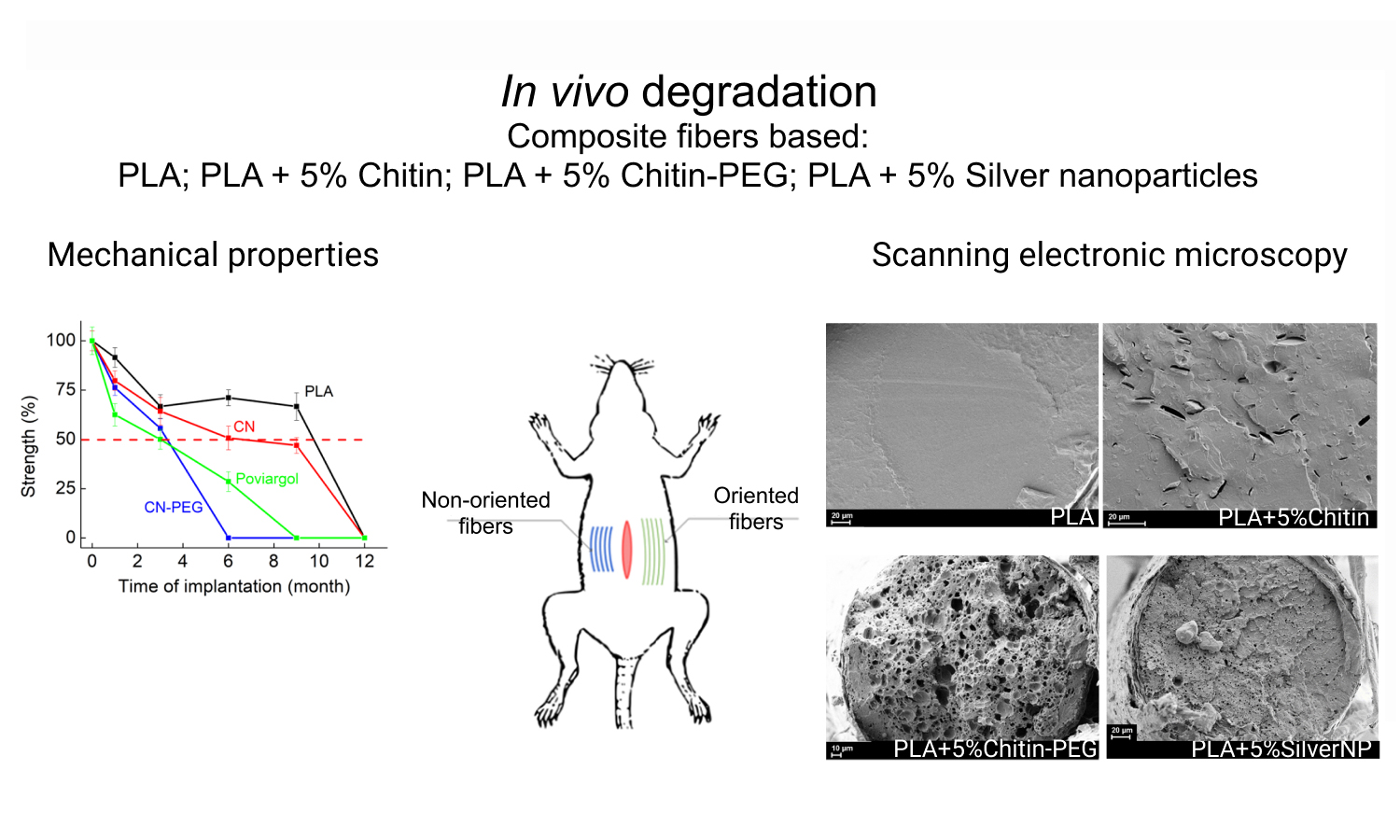

The rates of in vivo bioresorption of composite monofilaments based on polylactide (PLA) containing chitin nanofibrils of two types (pure chitin (CN) or chitin modified with poly(ethylene glycol) (CN-PEG)) or silver nanoparticles stabilized with poly(N-vinylpyrrolidone) (Poviargol) were studied. The in vivo bioresorption rate and its dependence on the degree of orientational drawing of the samples (which varied from 1 in non-oriented samples to 4 in oriented samples) were investigated up to 12 months after implantation. Bioresorption of the samples was monitored using differential scanning calorimetry, scanning electron microscopy, and mechanical tests. Using the differential scanning calorimetry (DSC) method, it was shown that there is a gradual decrease in molecular weight due to a decrease in the temperatures of phase transitions and changes in peak shapes. It has also been shown that the addition of fillers containing water-soluble polymers accelerates the bioresorption of composite sutures. A thread made from pure PLA lost half its strength by the 9th month of implantation, whereas for threads with the addition of CNPEG or Poviargol, this happened after 3.5 months. This causes leaching of water-soluble agents and changes in the supramolecular structure of the filament. This study shows the promise of using these composite threads as a suture material.

RELATED ARTICLES

Eva Kuželová Košťáková

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

Vol. 20., No.1., Pages 1-2, 2026

DOI: 10.3144/expresspolymlett.2026.1

This is an editorial article. It has no abstract.

Widtawad Reantong, Siriluk Chiarakorn, Muthita Vanaporn, Natee Srisawat

Vol. 19., No.12., Pages 1256-1273, 2025

DOI: 10.3144/expresspolymlett.2025.93

Vol. 19., No.12., Pages 1256-1273, 2025

DOI: 10.3144/expresspolymlett.2025.93

The development of functional antibacterial spunbond fabrics is critical for improving indoor environmental treatment. This study presents the fabrication of polypropylene (PP) fibers embedded with silane-modified Zr/Ag co-doped TiO2 nanoparticles. The Zr (5 mol%) and Ag (3 mol%) co-doped TiO2 nanoparticles were synthesized via a solvothermal method and subsequently modified with 5 wt% hexadecyltrimethoxysilane (HDTMS), referred to as ZATS5. The solvothermal method enables the controlled synthesis of phase-pure, well-dispersed nanostructures and facilitates dopant incorporation in the photocatalysts completely. Additionally, HDTMS surface modification improved compatibility with the polypropylene matrix, enhancing dispersion and interfacial bonding and improving overall composite performance. ZATS5 was incorporated into the PP matrix through melt spinning to produce composite fibers. The minimum of ZATS5 at 1 wt% embedded in spunbond nonwoven composite (PP/ZATS5-1) demonstrated the fiber’s structural integrity and remarkable antibacterial activity. The PP/ZATS5-1 nonwoven fabric achieved 99.98% inactivation of Legionella pneumophila under dark conditions and complete inhibition under visible light. This research offers a scalable and effective strategy for developing antibacterial spunbond nonwoven fabrics with potential applications in medical textiles, as well as air and water purification systems operating under ambient indoor lighting.

Quentin Watel, Aurélie Cayla, Fabien Salaün, François Boussu

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

Vol. 19., No.5., Pages 494-503, 2025

DOI: 10.3144/expresspolymlett.2025.36

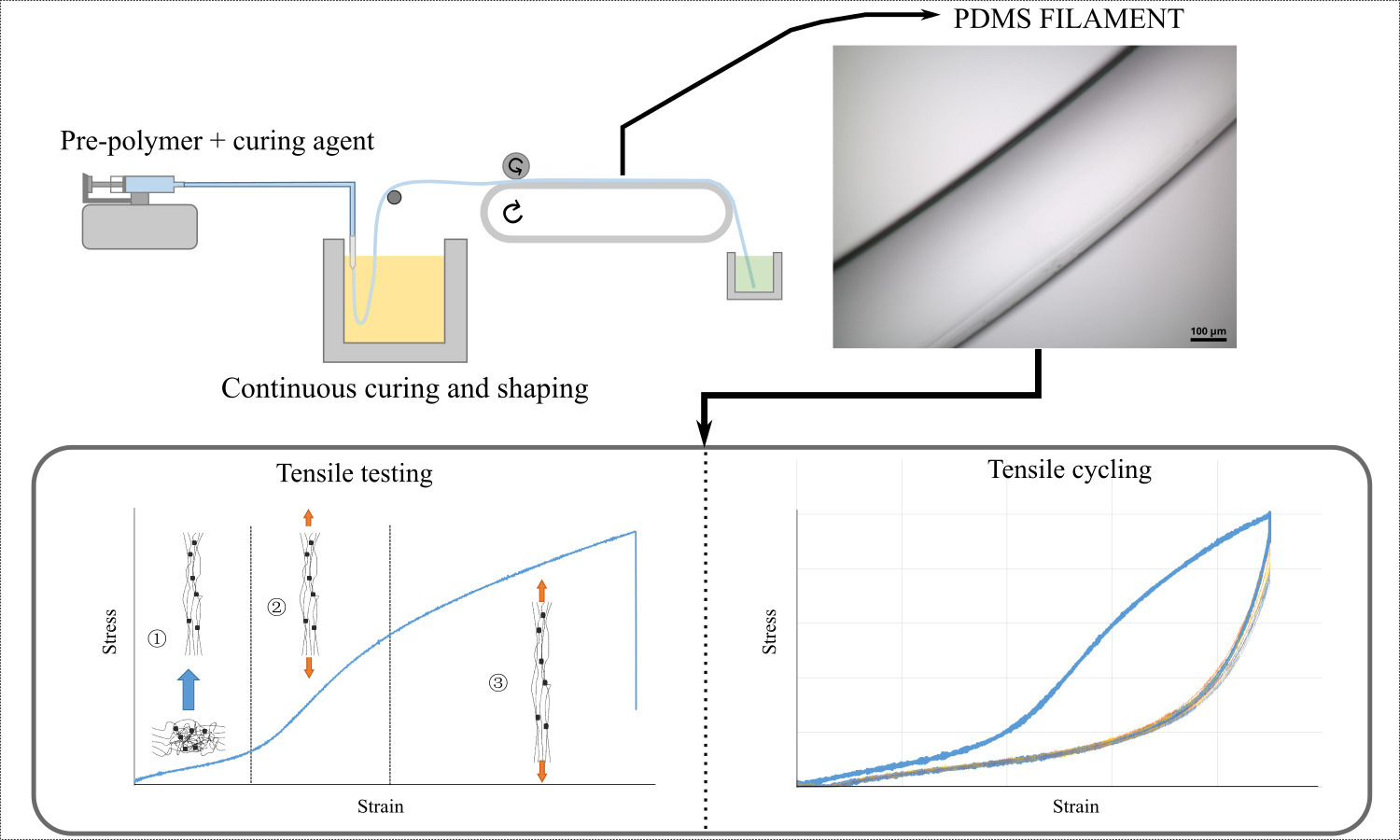

In this work, a PDMS spinning technique is developed and enables the continuous production of a filament with a circular cross-section (~500 μm diameter). The production of continuous silicone polymer filaments can be useful in the textile field to provide new properties in applications such as weaving, knitting or composite reinforcement. The method involves injecting the pre-polymer and curing agent mixture into a heated oil bath (202–215 °C) to simultaneously shape and cure the PDMS. The morphological and mechanical properties of the filament are studied regarding the production parameters (formulation, needle diameter, bath temperature, conveyor belt speed). The most homogeneous filament is produced at the highest temperature (215°C) and conveyor belt speed (13.6 m∙min–1). When subjected to cyclic mechanical stress, the PDMS filament produced exhibits stable mechanical behavior, making it suitable for a wide range of applications.

Jian Zhao, Xun Meng, Hongwei Piao, Hao Zhang, Zhibo Ren, Qi Han, Qinglin Huang, Hanli Wang

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

Vol. 19., No.5., Pages 531-543, 2025

DOI: 10.3144/expresspolymlett.2025.39

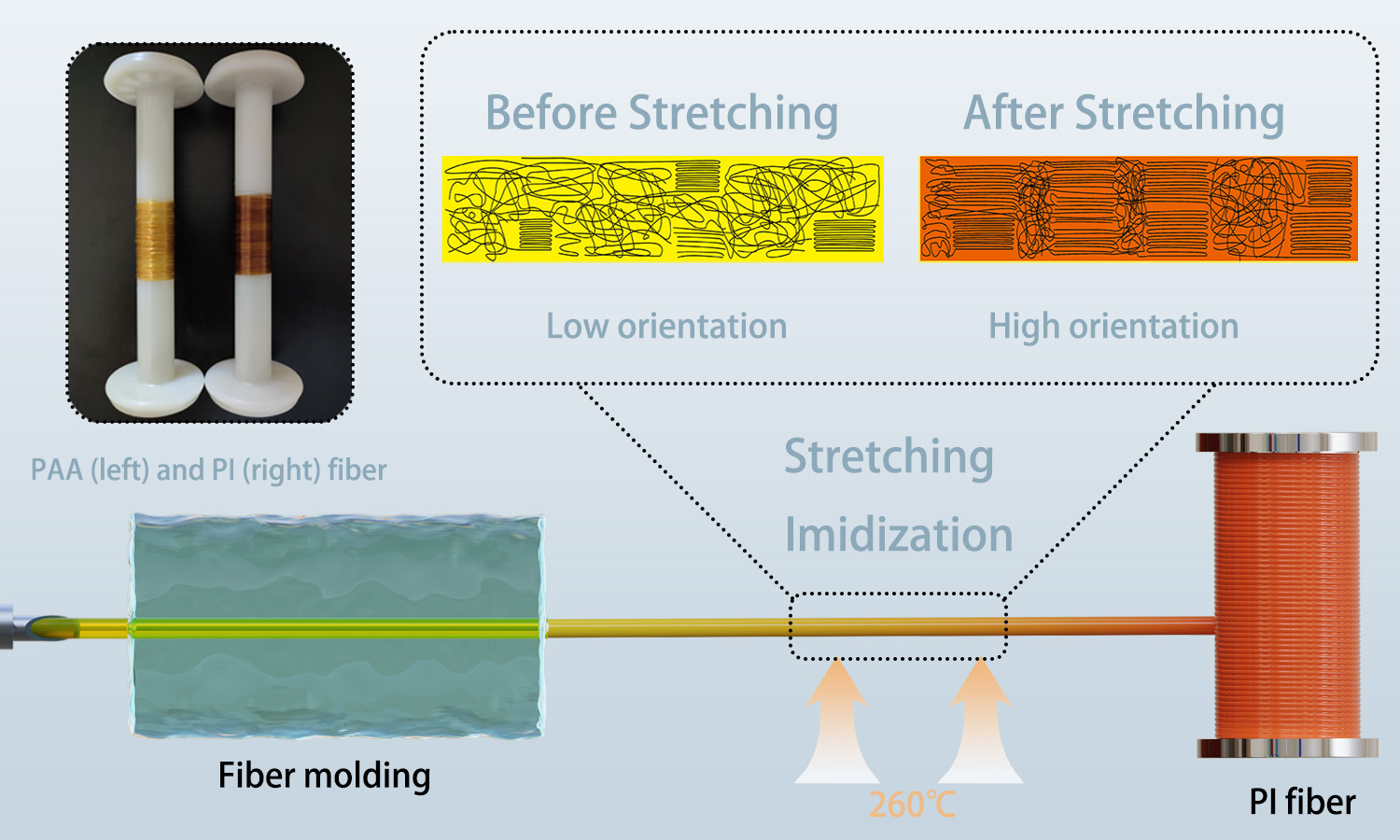

Polyimide (PI) fiber is a promising and high-performance polymer fiber with high temperature resistance and low density; however, much energy is needed during the thermal imidization process. Here, PI fiber with excellent mechanical properties and high-temperature resistance was fabricated via the dry-jet wet spinning method for polyamic acid (PAA) precursor fiber, followed by stretching and thermal imidization reaction at a lower temperature. With the increase of the stretching ratio, the mechanical properties of the PI fiber increase significantly. When the stretching was twice as long, the tensile strength and initial modulus of the fiber were as high as 6.23 and 114.13 cN·dtex–1, respectively. Fourier transform infrared results revealed that all samples were completely imidized at 260 °C. The resulting PI fibers exhibit only 5% weight loss at 539.53 °C, and its limiting oxygen index (LOI) can reach up to 32.6%, showing excellent high temperature resistance and flame-retardant properties as well as commendable mechanical performance, which compare favorably with those of other imidization methods.

Mohammad Mehdi Alighanbari, Firoozeh Danafar, Araam Namjoo, Asma Saeed

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

Vol. 19., No.1., Pages 15-46, 2025

DOI: 10.3144/expresspolymlett.2025.3

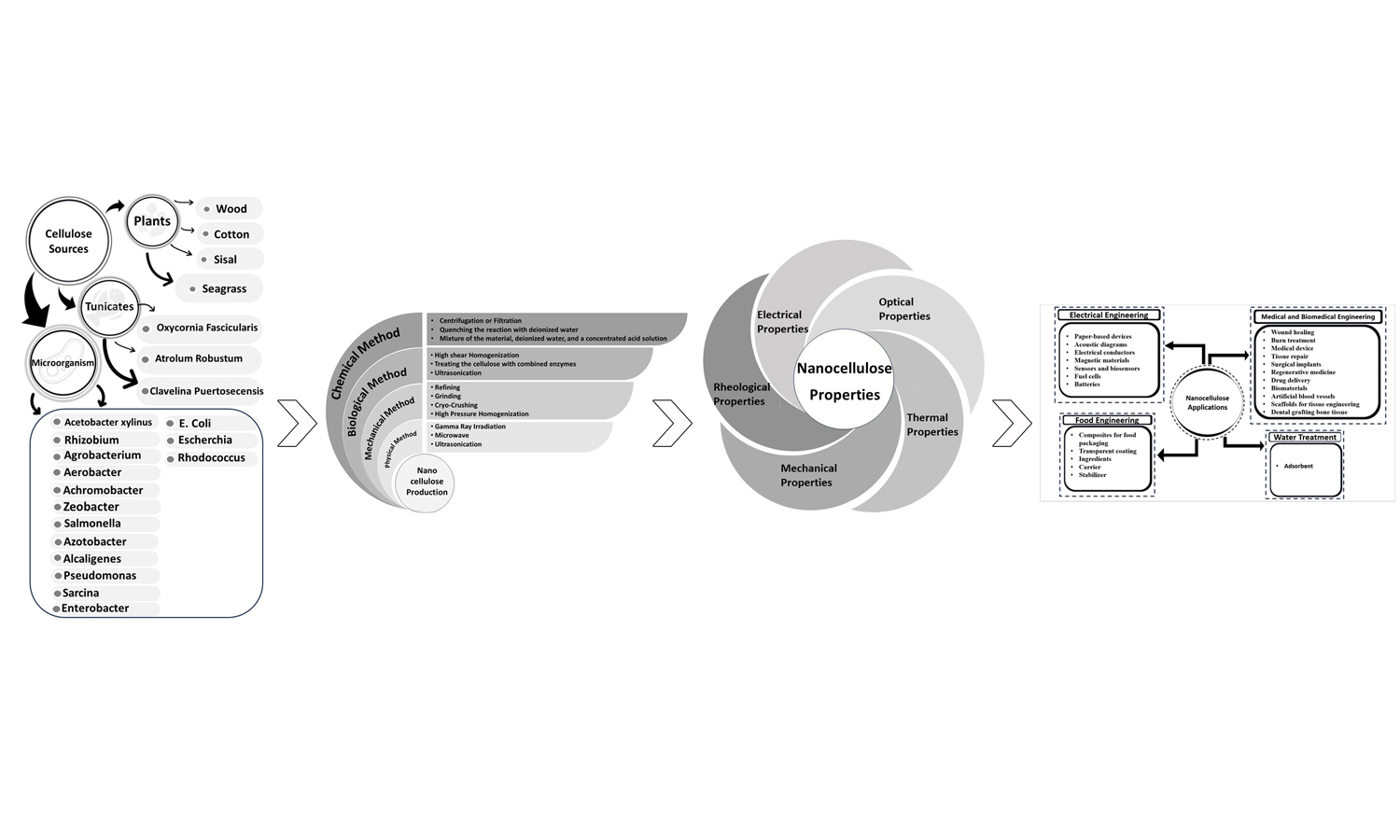

The environmental and ecological concerns drive researchers to synthesize functional materials using components from natural resources. Nanocellulose (NC), derived from plants, marine animals, or microorganisms, is a green material attracting attention due to its abundance, biocompatibility, and biodegradability. NC’s interstice properties enable the synthesis of functional nanocomposites in forms like aerogels, foams, paper, sheets, or hollow filaments. This review briefly describes NC classification and production while comprehensively presenting its mechanical, rheological, optical, and electrical properties, offering foundational knowledge for future research. Additionally, it highlights recent developments in NC-based products across fields such as papermaking, water treatment, civil engineering, electronics, cosmetics, food, and medicine. For the first time, this paper explores recent advances in NC molecular simulation, providing insights into structure, arrangement, and interactions through molecular dynamic simulation. Finally, future prospects for NC-based applications are discussed to encourage studies addressing current challenges.