Content

All issues / Volume 16 (2022) / Issue 3 (March)

Kolos Molnár

Vol. 16., No.3., Pages 220-220, 2022

DOI: 10.3144/expresspolymlett.2022.17

Vol. 16., No.3., Pages 220-220, 2022

DOI: 10.3144/expresspolymlett.2022.17

This is an editorial article. It has no abstract.

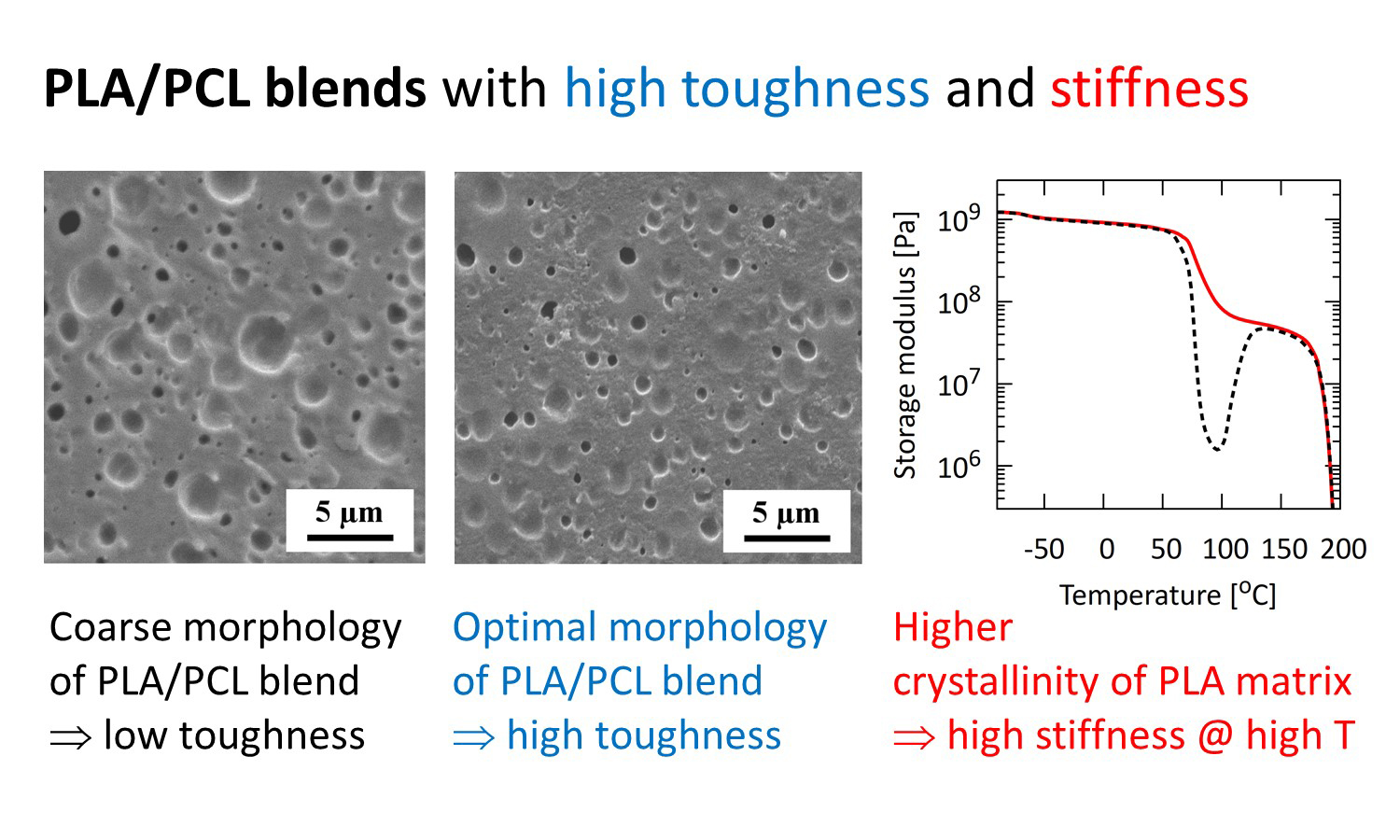

Aleksandra Ujcic, Ivan Fortelny, Sabina Krejcikova, Ewa Pavlova, Jiri Hodan, Miroslav Slouf

Vol. 16., No.3., Pages 221-233, 2022

DOI: 10.3144/expresspolymlett.2022.18

Vol. 16., No.3., Pages 221-233, 2022

DOI: 10.3144/expresspolymlett.2022.18

The effects of the thermal treatment and nucleating agents on the morphology, crystallinity, and mechanical propertiesp of poly(lactic acid)/poly(ε-caprolactone) (PLA/PCL) blends were studied in order to obtain PLA/PCL blends with both high stiffness and toughness. The standard thermal treatment of the melt-mixed blends (a compression molding without annealing) resulted in the systems with optimized morphology (at PLA/PCL ratio 80/20) and very high toughness (ca 16×higher with respect to neat PLA), but the stiffness at elevated temperatures (above Tg of PLA at 65 °C) was low due to the low crystallinity of the PLA matrix (<10%). The compression molding with annealing at 110 °C could increase the crystallinity of PLA (up to ~40%), but the toughness decreased steeply due to morphological changes (a coalescence of PCL particles associated with the structure coarsening). The lowering of the annealing temperature (to 80 °C) and addition of the PLA nucleating agent (1 wt% of talc) led to the blends showing both high toughness (9× with respect to neat PLA) and crystallinity (~35%). Dynamic mechanical analysis evidenced that the higher PLA crystallinity improved the storage modulus at temperatures >60 °C by ca two orders of magnitude. The achieved combination of the PLA/PCL toughness and stiffness was one of the highest, according to the available literature.

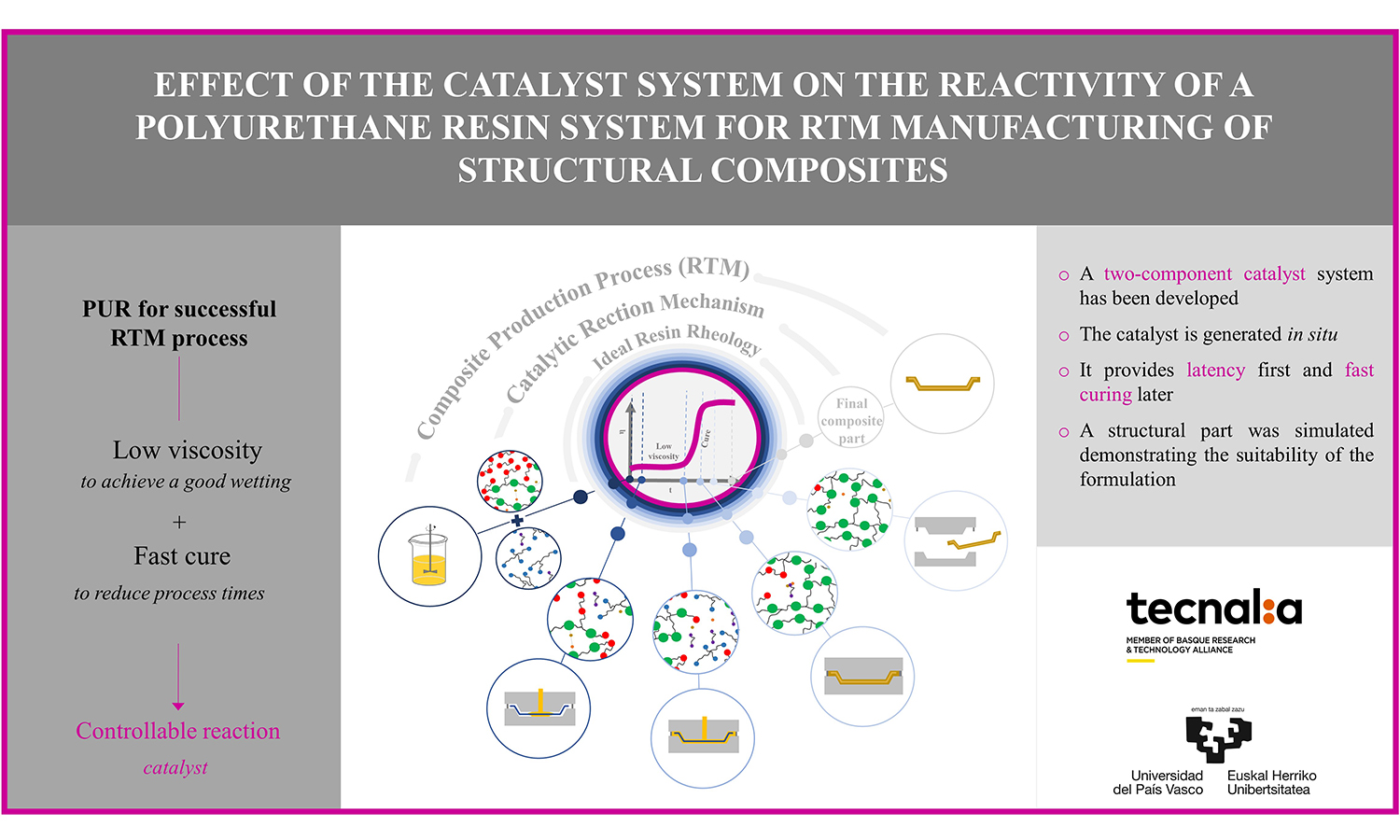

Oihane Echeverria-Altuna, Olatz Ollo, Tamara Calvo-Correas, Isabel Harismendy, Arantxa Eceiza

Vol. 16., No.3., Pages 234-247, 2022

DOI: 10.3144/expresspolymlett.2022.19

Vol. 16., No.3., Pages 234-247, 2022

DOI: 10.3144/expresspolymlett.2022.19

The high versatility of polyurethanes (PU’s) is encouraging the development of new formulations for new applications, like their use as a matrix for structural composites. PU’s based technology offers some advantages, such as fatigue resistance and fast curing cycles. However, their high reactivity hinders some manufacturing processes like Resin Transfer Moulding (RTM). This work aimed to achieve a PU resin (PUR) formulation with the required latency and reactivity for the RTM. For this purpose, different catalytic systems based on an epoxide and LiCl were investigated. The reactivity of the systems was evaluated through Differential Scanning Calorimetry (DSC) and rheology tests, and the curing reaction and viscosity were modelled. Furthermore, the RTM process of a representative composite part was simulated. Results demonstrated the processability improvements when the LiCl was incorporated into the isocyanate component of the formulation combined with a monool or a diol. It was observed that these combinations contribute to the encapsulation of the LiCl between the as formed urethane groups by hydrogen bonding, providing the desired latency and acting as a delayed action catalyst. Once the reaction started and the encapsulation was deactivated, an alkoxide was formed to act as a catalyst. Encapsulation was more effective with the diol, providing a higher latency.

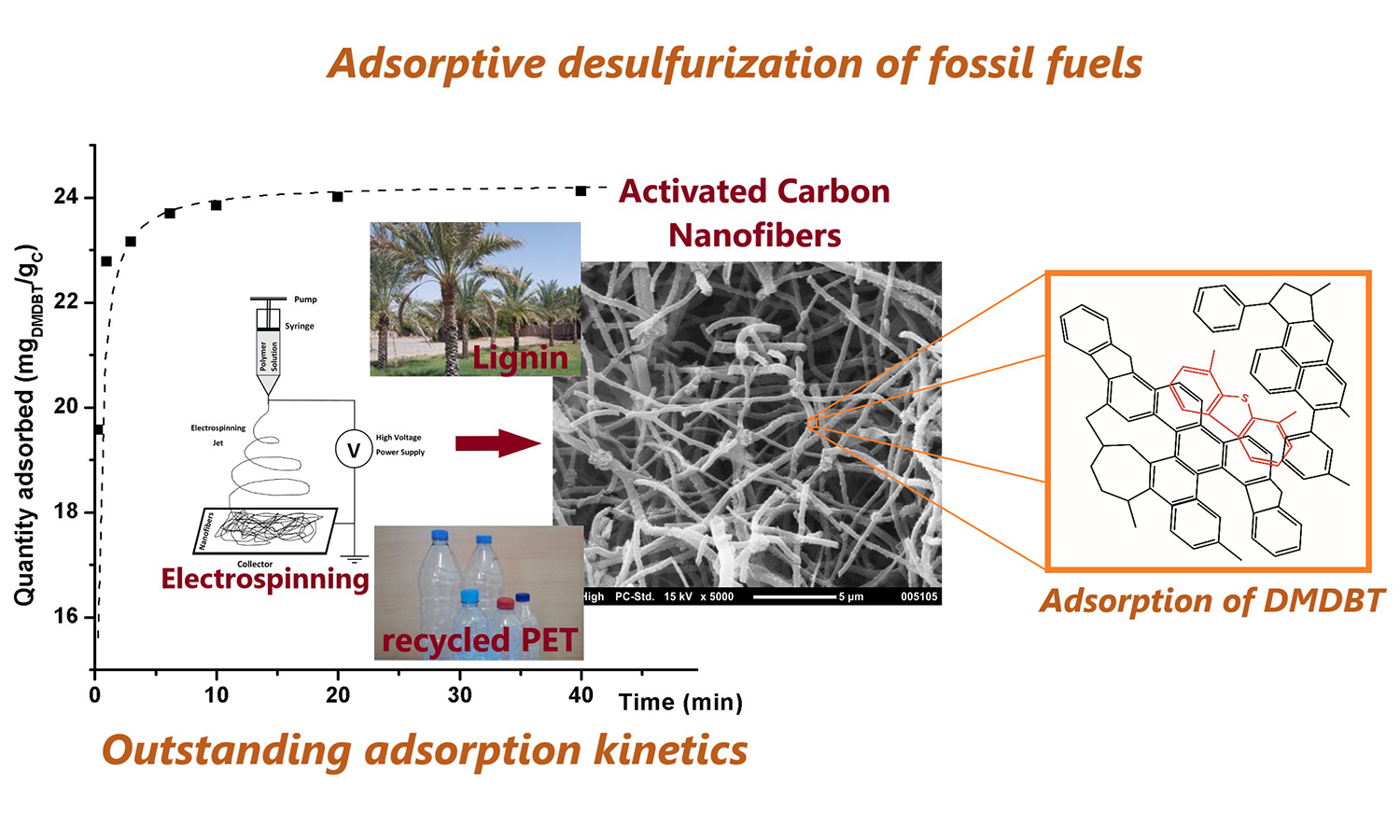

Efstratios Svinterikos, Ioannis Zuburtikudis, Mohamed Al-Marzouqi

Vol. 16., No.3., Pages 248-264, 2022

DOI: 10.3144/expresspolymlett.2022.20

Vol. 16., No.3., Pages 248-264, 2022

DOI: 10.3144/expresspolymlett.2022.20

Carbon nanofibers (CNFs) from a blend of lignin with recycled poly(ethylene terephthalate) (r-PET) were produced from the thermal treatment of precursor electrospun lignin/r-PET nanofibrous mats. The impact of the lignin/r-PET mass ratio (ranging from 50/50 to 90/10) on the morphology, porosity and carbon structure of the CNFs was thoroughly investigated. The CNFs produced from a lignin/r-PET mass ratio of 50/50 possess the highest BET surface area (353 m2/g) as the presence of r-PET contributes to the development of microporosity, while all CNFs consist of disordered carbon structure. Their chemical activation with KOH boosted their BET surface area to 1413 m2/g and further treatment with HNO3 anchored oxygen functional groups on their surface. These activated CNFs were used for the adsorption of 4,6-dimethyldibenzothiophene (DMDBT) from a model diesel fuel (n-dodecane) and it was found that they exhibit a high adsorption capacity at ambient conditions (120.3 mgDMDBT/gC). This is combined with remarkably fast adsorption kinetics as 94% of the equilibrium concentration is reached after just 1 min. These outstanding kinetics are justified by the nano-structured morphology of the activated CNFs which translates into a very large specific surface area that minimizes mass transfer limitations.

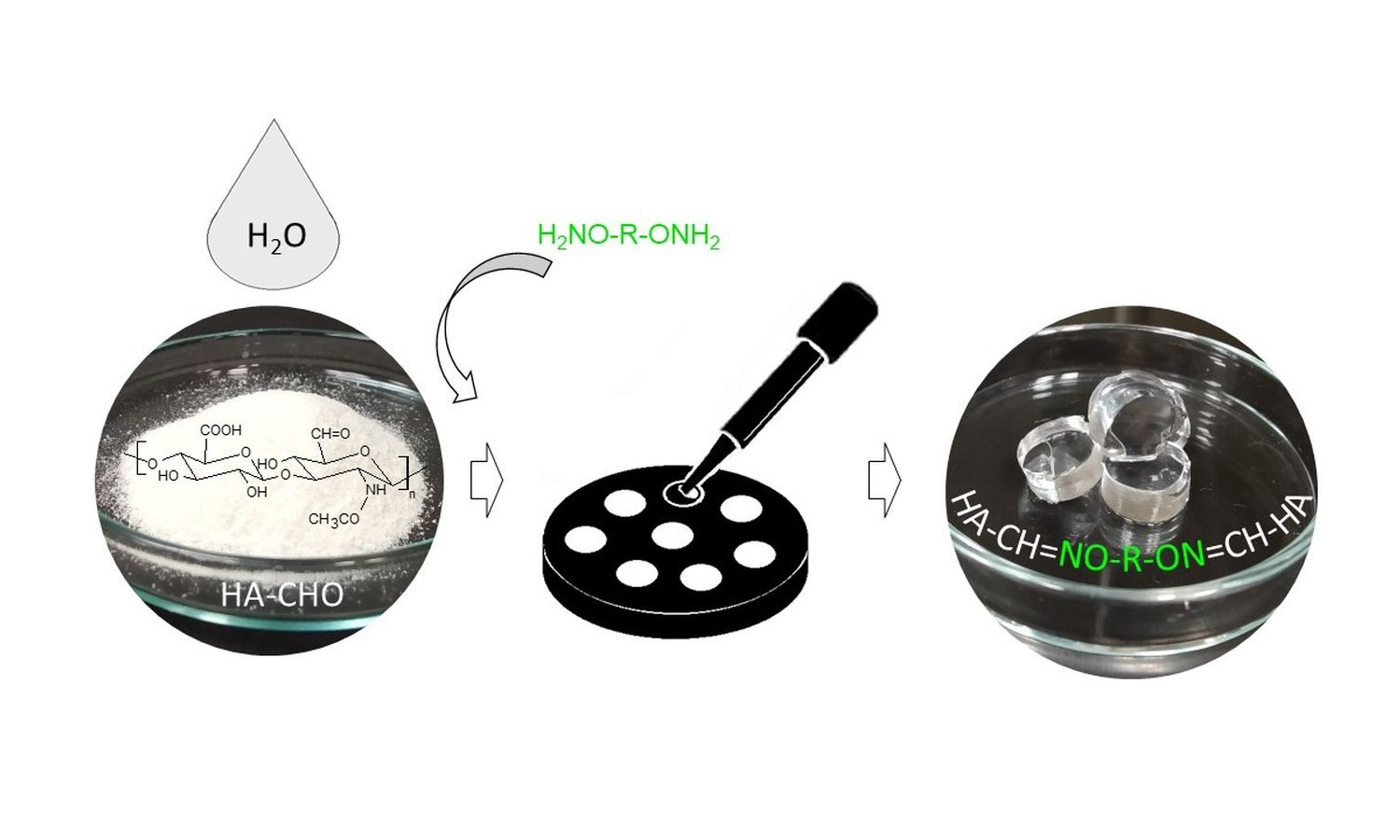

The effect of aminooxy-linkers’ structure on the mechanical properties of hyaluronan-oxime hydrogels

Petra Sedova, Radovan Buffa, Tereza Koci, Lenka Kovarova, Jiri Bednarik, Hana Vagnerova, Vladimir Velebny

Vol. 16., No.3., Pages 265-278, 2022

DOI: 10.3144/expresspolymlett.2022.21

Vol. 16., No.3., Pages 265-278, 2022

DOI: 10.3144/expresspolymlett.2022.21

The wide range of hydrogel applications is a result of the optimization of gelation. Herein, the various aminooxylinkers were synthesized to study the kinetics of gelation and mechanical properties of hydrogels prepared by crosslinking of aldehyde-modified N-acetylglucosamine (GlcNAc) of hyaluronan (ΔHA-CHO: 4,5-anhydro-6-(GlcNAc)-oxo hyaluronan or HA-CHO: 6-(GlcNAc)-oxo hyaluronan). Structural characteristics of the linkers (length, number of functional groups and rigidity) and the polymer (effect of the –C=C- double bond) were investigated in detail and showed decreasing mechanical stiffness with increasing hydrophobic character of linker and effect of its rigidity/flexibility on imine conversion. Besides known linear bis(aminooxy)alkanes with different lengths of the chain, new multifunctional aminooxy-linkers: 1,3,5-tris(aminooxymethyl)benzene and multikis(6-aminooxy-6-deoxy)-β-cyclodextrin were prepared and shortened the gelation time. The MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) analysis showed that despite the aminooxylinkers ´ cytotoxicity at higher concentrations, the final oxime hydrogels are non-cytotoxic and therefore are suitable for medicinal applications.

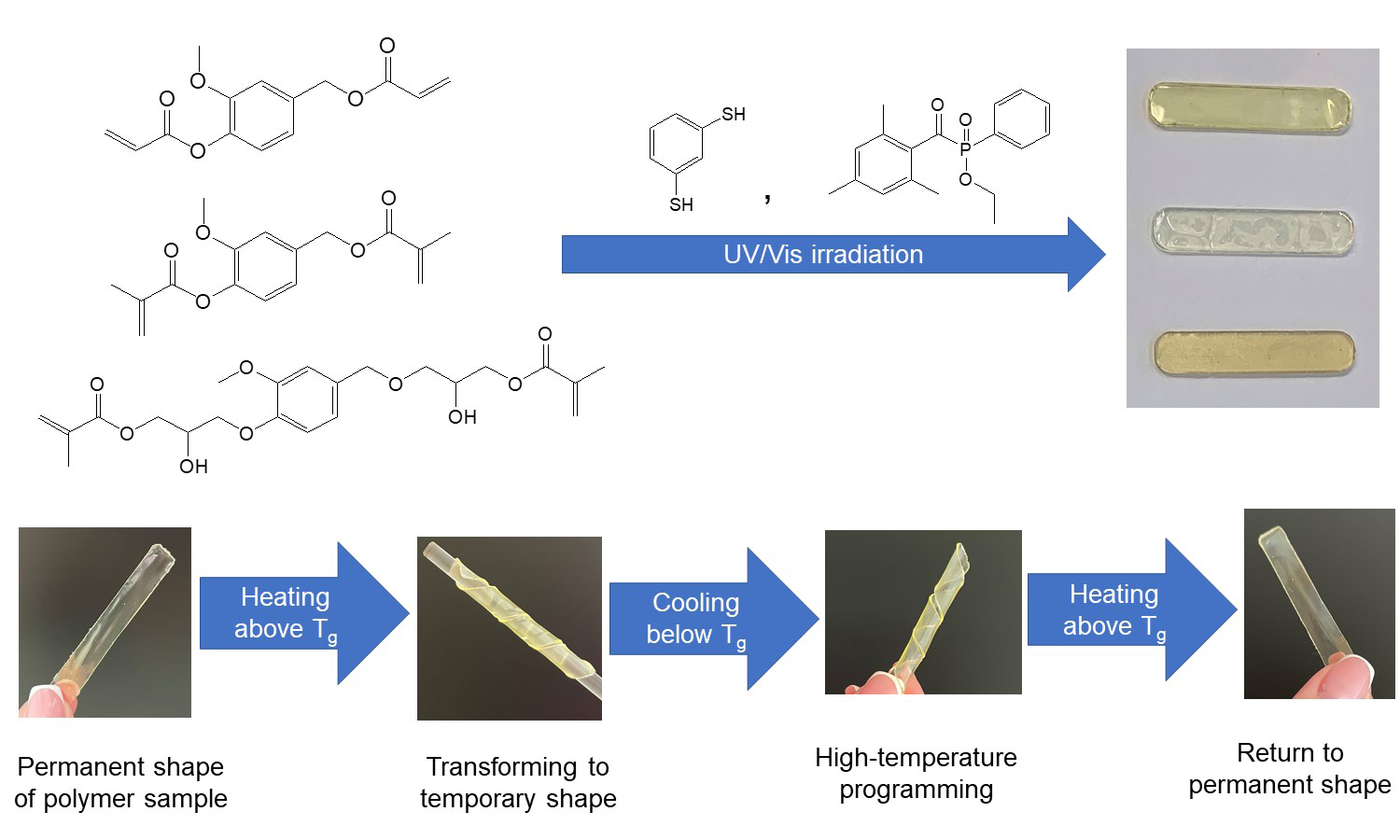

Aukse Navaruckiene, Danguole Bridziuviene, Vita Raudoniene, Egidija Rainosalo, Jolita Ostrauskaite

Vol. 16., No.3., Pages 279-295, 2022

DOI: 10.3144/expresspolymlett.2022.22

Vol. 16., No.3., Pages 279-295, 2022

DOI: 10.3144/expresspolymlett.2022.22

Vanillin acrylate-based thermo-responsive shape memory photopolymers with high thermal stability, tunable mechanical properties, and antimicrobial activity have been developed. Photocurable resins containing one of the three commercial vanillin derivatives, vanillin diacrylate, vanillin dimethacrylate, and vanillin hydroxypropane dimethacrylate, and 1,3-benzenedithiol were tested. The results of dual curing systems with different ratios of thiol and acrylate (1:1 and 0.5:1) were compared. The reduction of thiol content increased the rate of photocuring, improved the mechanical performance of polymers (Young’s modulus was increased from 1.4–3.5 to 3952.3–11339.4 MPa), and their heat resistance (the 10% weight loss increased from 277–327 to 294–341 °C). All polymers were able to return to their primary shape after deformation and maintain their temporary shape at a temperature lower than their glass transition temperature (–3–46 °C). Furthermore, allpolymer films exhibited significant antibacterial activity against Escherichia coli and Staphylococcus aureus (cell reduction reached 99.8–100% after 24 h) and antifungal activity against Aspergillus flavus and Aspergillus niger (cell reduction reached 72.3–100% after 24 h).

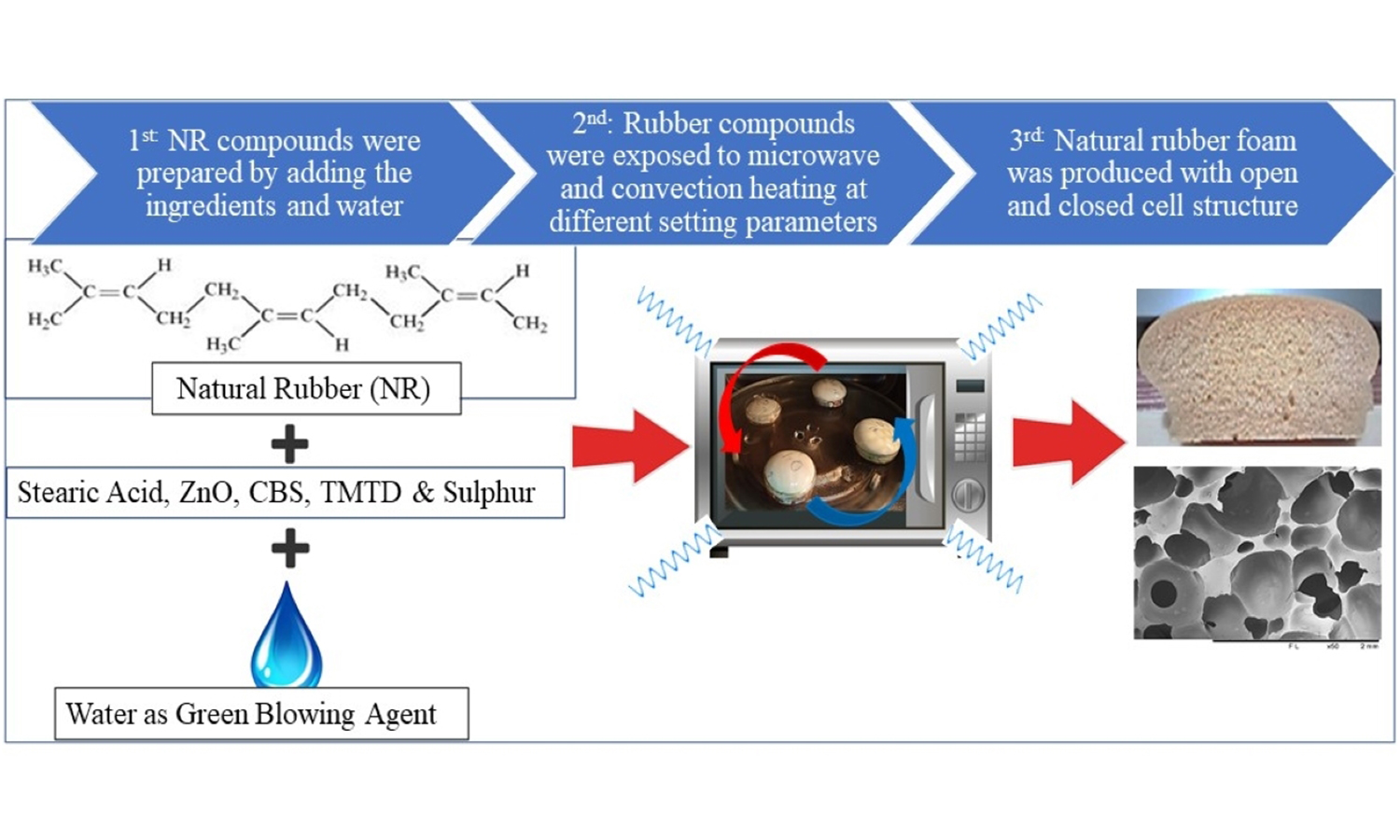

Nur Syuhada Ahmad Zauzi, Zulkifli Mohamad Ariff, Raa Khimi Shuib

Vol. 16., No.3., Pages 296-317, 2022

DOI: 10.3144/expresspolymlett.2022.23

Vol. 16., No.3., Pages 296-317, 2022

DOI: 10.3144/expresspolymlett.2022.23

This study used water as the physical blowing agent as well as microwave heating (MH) and convection heating (CH) to simultaneously foam and cure natural rubber foam (NRF). Various processing methods and parameters, such as single heating and sequential heating using a mix of CH and MH; were investigated. The correlation between these processing methods as well as different water loadings was then evaluated and compared in terms of physical appearance, density, and morphology. The NRF samples produced using sequential MH and CH (SMC) heating exhibited better shape and structure than samples produced using single heating of either CH or MH only as well as sequential CH and MH (SCM) heating at all water loadings. NRF samples with water loadings of 1.5 and 2.0 phr had a density of less than 0.1 g/cm3. The potential heating mechanism of all the heating methods explored in this study was proposed and discussed to further understand the microwave heating process. The findings of this study proved that water could be utilized as a physical blowing agent in the production of NRF products with microwave-assisted foaming.

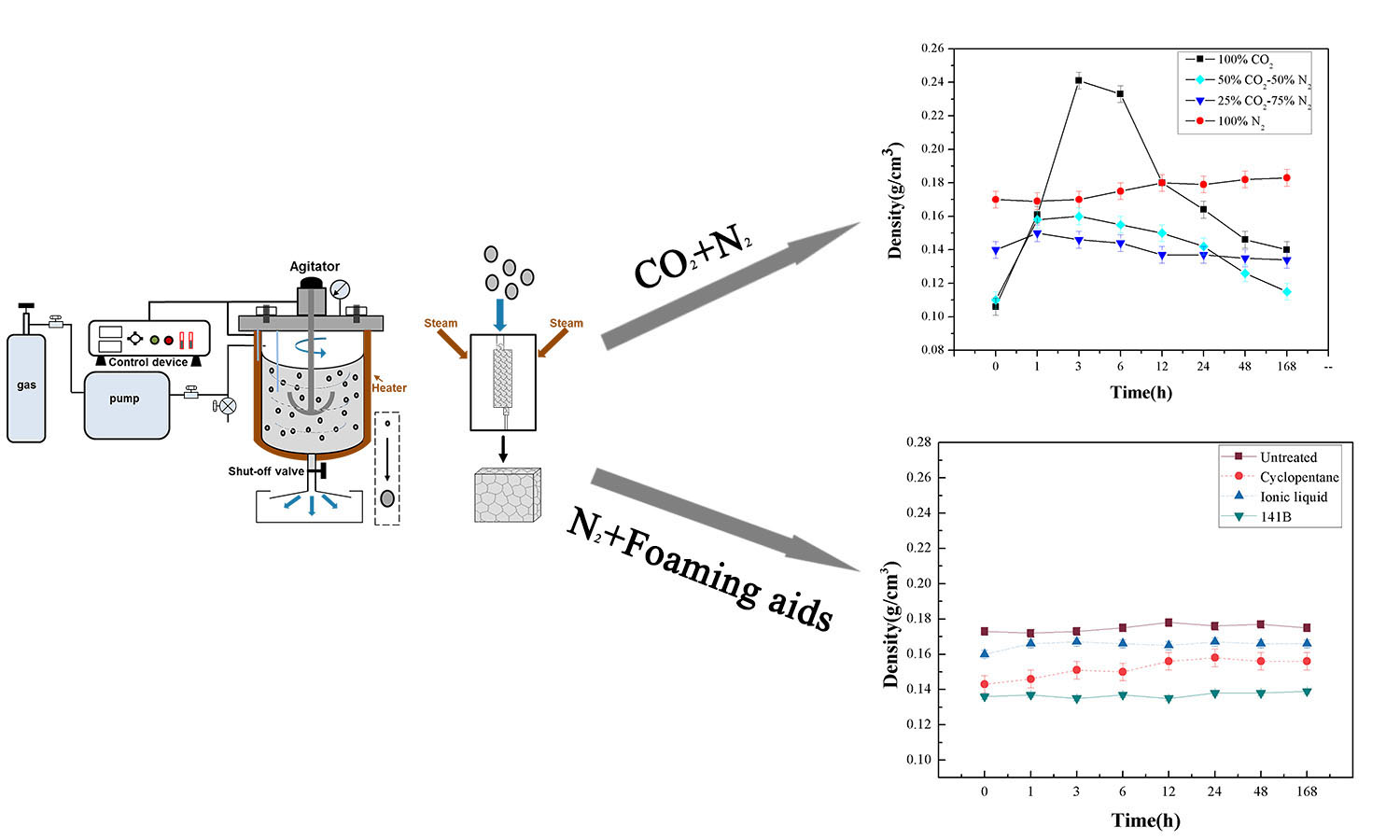

Wei Peng Zhong, Zhen Yu, Tongyu Zhu, Yongxian Zhao, Ajit Dattatray Phule, Zhen Xiu Zhang

Vol. 16., No.3., Pages 318-336, 2022

DOI: 10.3144/expresspolymlett.2022.24

Vol. 16., No.3., Pages 318-336, 2022

DOI: 10.3144/expresspolymlett.2022.24

Expanded thermoplastic polyurethane (ETPU) foam materials with superelasticity for footwear application were developed and investigated. ETPU foams with different ratios of CO2/N2 as foaming agents and ETPU foams prepared by pure nitrogen foaming with different kinds of foaming additives were prepared by supercritical (Sc) foaming technology, which further made into sheet forms through the steam molding process. TPU foam exhibits better cell structure, crystallization performance, and mechanical strength with the increased CO2 proportion. Further, the foams using 25% CO2–75% N2 and 50% CO2–50% N2, showed a lower density and excellent resilience and cyclic-compression performance. However, an increase of N2 ratio improves the dimensional stability and compression set of the foam. The introduction of foaming aids enhances the interaction between Sc-N2 and TPU. The ETPU foam prepared under the same conditions has a smaller density and a larger expansion ratio. Especially the ETPU foam prepared by Sc-N2 using monofluorodichloroethane as the foaming assistant as a co-blowing agent, the decrease in cell size (from 117.9 to 19.6 μm) and density (from 0.175 to 0.139 g/cm3) has observed. The study revealed the high potential of these materials in footwear applications and offered sound evidence for mass production in the industry.