Content

All issues / Volume 19 (2025) / Issue 6 (June)

Dániel Gere, Tamás Bárány

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

Vol. 19., No.6., Pages 554-555, 2025

DOI: 10.3144/expresspolymlett.2025.41

This is an editorial article. It has no abstract.

Syaifullah Muhammad, Rahul Dev Bairwan, H.P.S. Abdul Khalil, Marwan M, Mohd Syukri Baharudin, Mardiana Idayu Ahmad

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

Vol. 19., No.6., Pages 556-567, 2025

DOI: 10.3144/expresspolymlett.2025.42

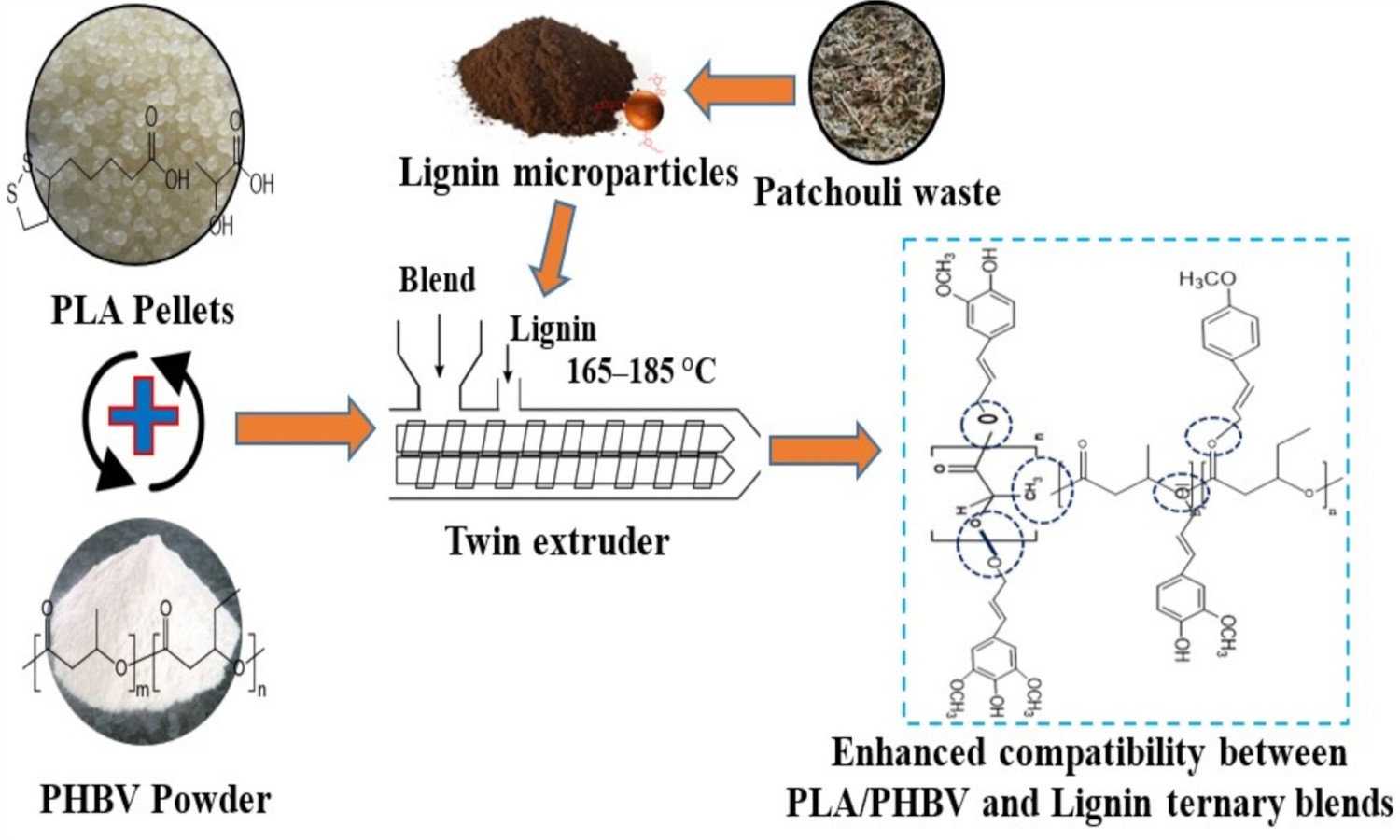

The study investigates a ternary biopolymer blend composed of biopolymers polylactic acid (PLA), polyhydroxybutyrate- co-valerate (PHBV), and lignin extracted from patchouli fiber waste for sustainable packaging applications. A PLA: PHBV blend (70:30) was enhanced by incorporating hydrophobic lignin as a filler in varying loadings of 0, 3, 6, 9, and 12 wt%. The ternary blend was prepared using twin-screw extrusion process, pelletized, and compression-molded into specimens. Comprehensive characterization of the ternary blend included evaluations of water barrier, mechanical, functional, thermal, and morphological properties. Results demonstrated that lignin addition notably improved the compatibility between PLA and PHBV, leading to enhanced barrier performance, mechanical strength, and thermal stability. SEM morphology confirmed improved interfacial adhesion due to hydrophobic nature of lignin, which facilitated better dispersion at lower filler loadings. However, at 12 wt% lignin, property reductions were observed, attributed to lignin agglomeration and poor dispersion. Optimal performance was achieved at 9 wt% lignin loading, offering a balance of improved properties without compromising processability or structural integrity. This study highlights the potential of the PLA/PHBV/lignin ternary blend as a viable, eco-friendly material for sustainable packaging, showcasing improved functionality and environmental compatibility compared to conventional polymers.

Cheng-Chieh Chang, Chang-Mou Wu, Kei-Chieh Chang

Vol. 19., No.6., Pages 568-577, 2025

DOI: 10.3144/expresspolymlett.2025.43

Vol. 19., No.6., Pages 568-577, 2025

DOI: 10.3144/expresspolymlett.2025.43

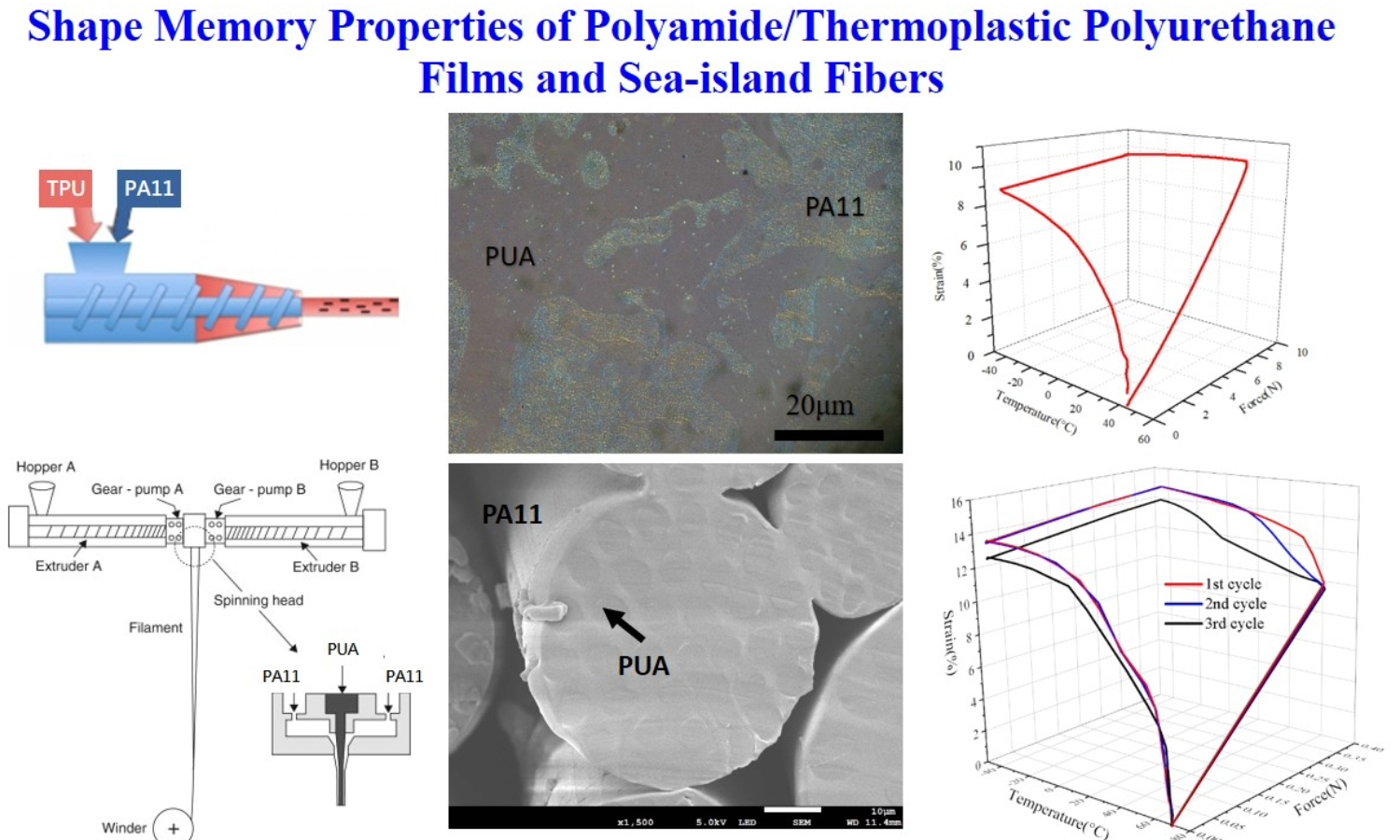

In this study, polyamide 11/thermoplastic polyurethane thermally responsive shape-memory composite fibers were fabricated using a bi-component melt-spinning machine with a sea-island spinning nozzle. Polyamide 11, a material with low water absorption and good oil resistance, was used as the ‘sea’, whereas the thermoplastic elastomer was used as the ‘island’ to provide shape memory performance. A film was prepared from these materials, and its suitability for preparing the fibers was determined using its shape memory behavior. The results demonstrated that the shape memory of the film fixation rate was 99.6% and the recovery rate was 92.3%, proving that polyamide 11/polyurea (PA11/PUA) has good shape memory fixation and recovery rates. During the melt-spinning and take-up processes, the as-spun fiber was collected into a roll with a certain draw ratio, resulting in a better molecular orientation and, consequently, an improved shape memory effect. After three shape memory cycles, the fixation rate of the PA11/PUA fiber was 98.8%, and the recovery rate was 99.9%. Thus, sea-island shape memory composite fibers were successfully produced, and are expected to enable shape memory materials to find a wider range of applications.

Xiaohua Li, Weiming Liu, Junlong Wang, Shanshan Shao, Weiliang Ding

Vol. 19., No.6., Pages 578-593, 2025

DOI: 10.3144/expresspolymlett.2025.44

Vol. 19., No.6., Pages 578-593, 2025

DOI: 10.3144/expresspolymlett.2025.44

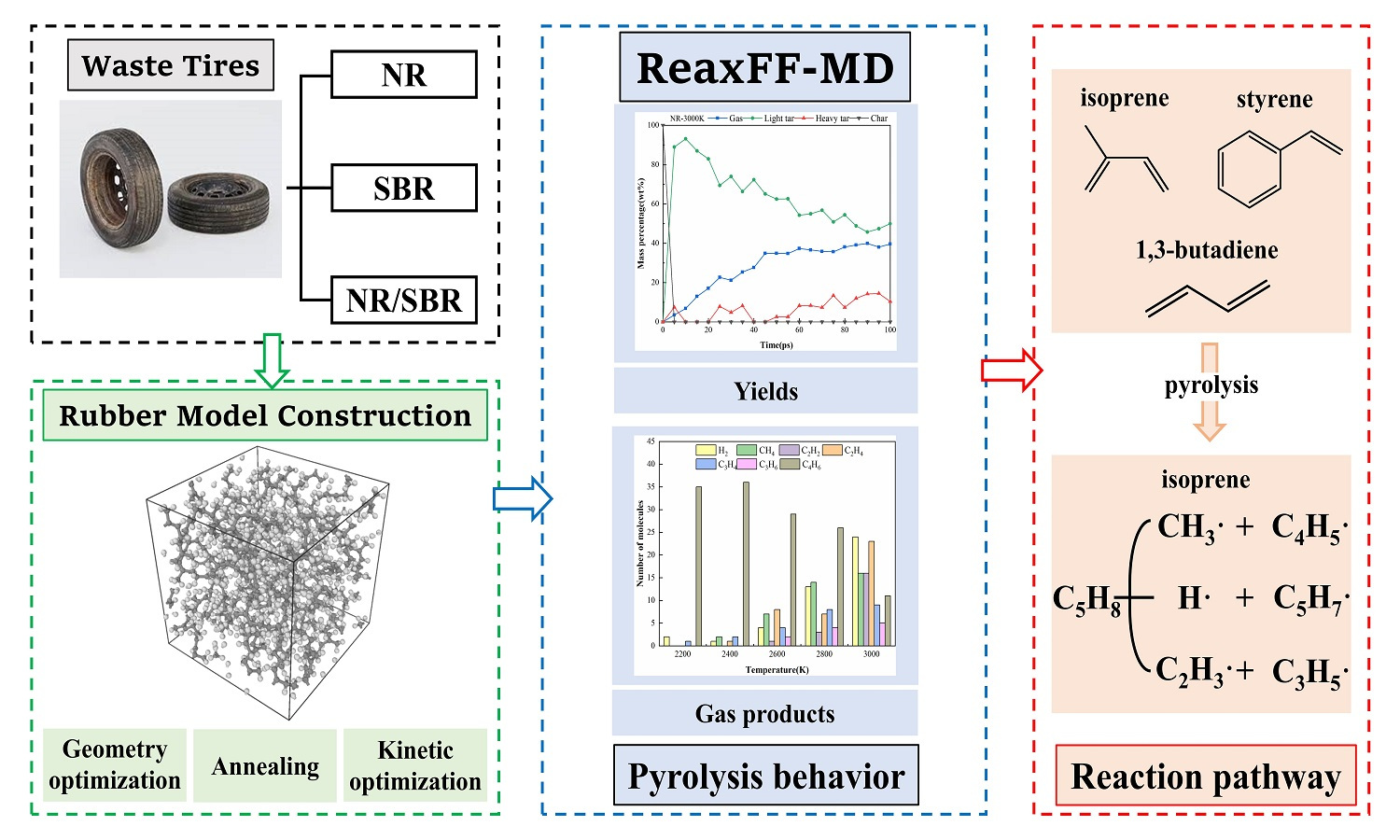

Pyrolysis is one of the effective methods for recycling waste tire rubber, and there are fewer studies on the simulation and mechanism of pyrolysis of multi-component mixed rubber. This study employs reactive force field molecular dynamics (ReaxFF-MD) simulations to analyze the pyrolysis product evolution processes of natural rubber (NR), styrene-butadiene rubber (SBR), and mixed rubber (NR/SBR). The results show that with increasing temperature, the gas yield of NR/SBR increases from 16.32% at 2000 K to 37.01% at 3000 K, and the molecular numbers of gas products such as H2 and small-molecule hydrocarbons increase with temperature. The co-pyrolysis of NR/SBR accelerates solid rubber pyrolysis time and promotes the formation of main gas products (excluding C4H6). Using simulation results, the reaction pathways of pyrolysis intermediates were analyzed: the main intermediates of NR are isoprene monomers and C10H16• short-chain radicals, while those of SBR are styrene and butadiene. The bond cleavage mechanisms of intermediates were compared through reaction energy barrier calculations. This study systematically reveals the pyrolysis product characteristics and reaction mechanisms of rubbers, providing theoretical support for the selective pyrolysis recycling of various waste rubbers.

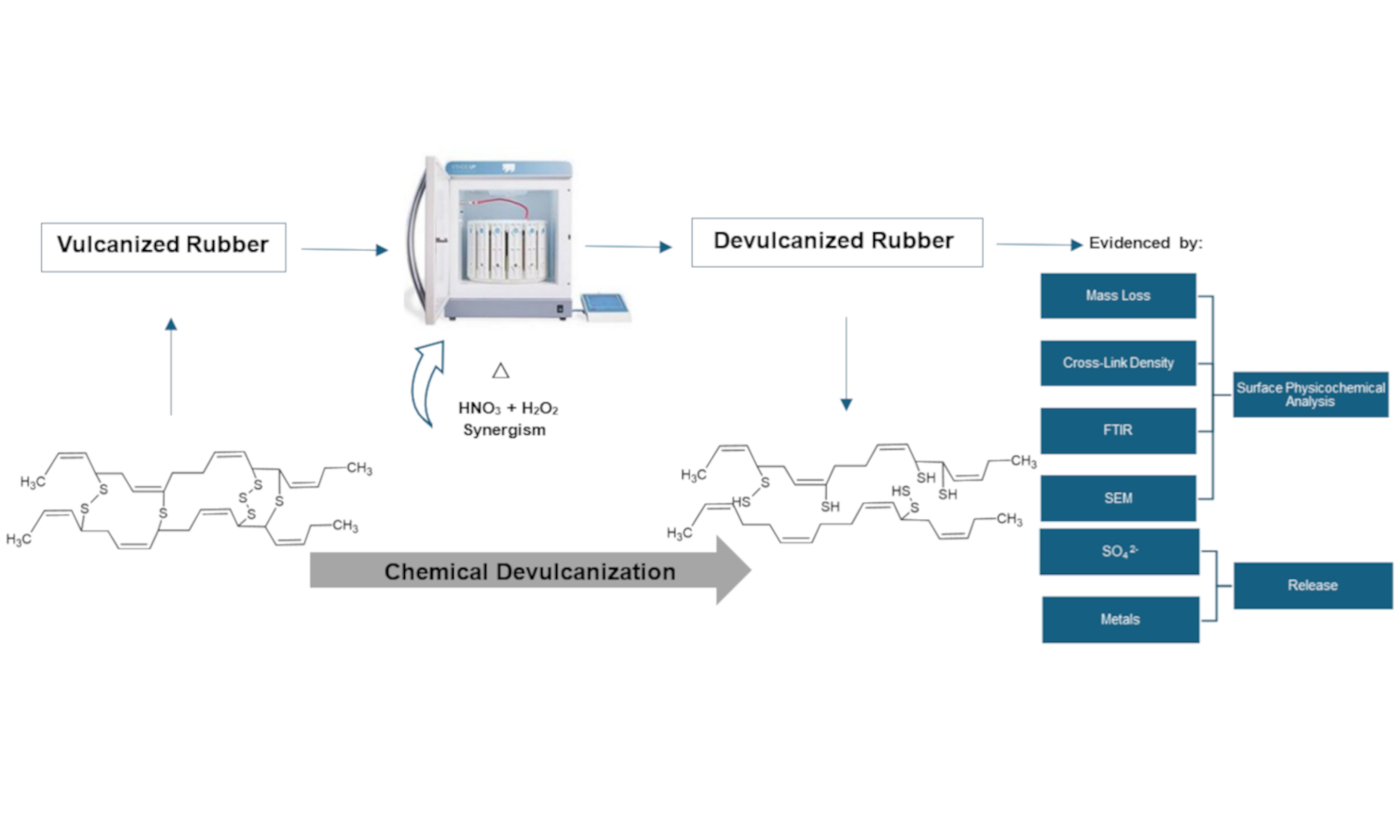

Cristian Valdés, Valentina Guzmán, Camila Ponce, Maribel Mamani, Juan Guevara, Claudia Vergara, Rodrigo Andler

Vol. 19., No.6., Pages 594-609, 2025

DOI: 10.3144/expresspolymlett.2025.45

Vol. 19., No.6., Pages 594-609, 2025

DOI: 10.3144/expresspolymlett.2025.45

Waste rubber disposal causes considerable negative environmental impacts due to its increase worldwide, mainly in the automotive industry. Therefore, the search for technological solutions for rubber waste is a priority, and the first step in this material degradation is devulcanization due to its difficult degradation. This study evaluated rubber devulcanization using a closed vessel microwave digestion system with nitric acid (HNO3) and hydrogen peroxide (H2O2) through chemical characterization, aiming at verifying the synergistic effect between these oxidizing agents. Microwave irradiation was applied as a heating method to facilitate the chemical reactions, focusing on the synergism between HNO3 and H2O2. Results showed that 5 M H2O2 in combination with 1% HNO3, presented better results. A greater decrease in cross-link density was demonstrated as the concentration of H2O2 increased (3.96·10–5±1.99·10–6 mol/cm3), likewise, higher sulfates released (926.8±53.4 mg/L), increased mass loss (12.184±1.06%), rubber surface fragmentation, and important variations in the C–S, C=O bands, showing better results when devulcanization is carried out in synergism between HNO3 and H2O2.

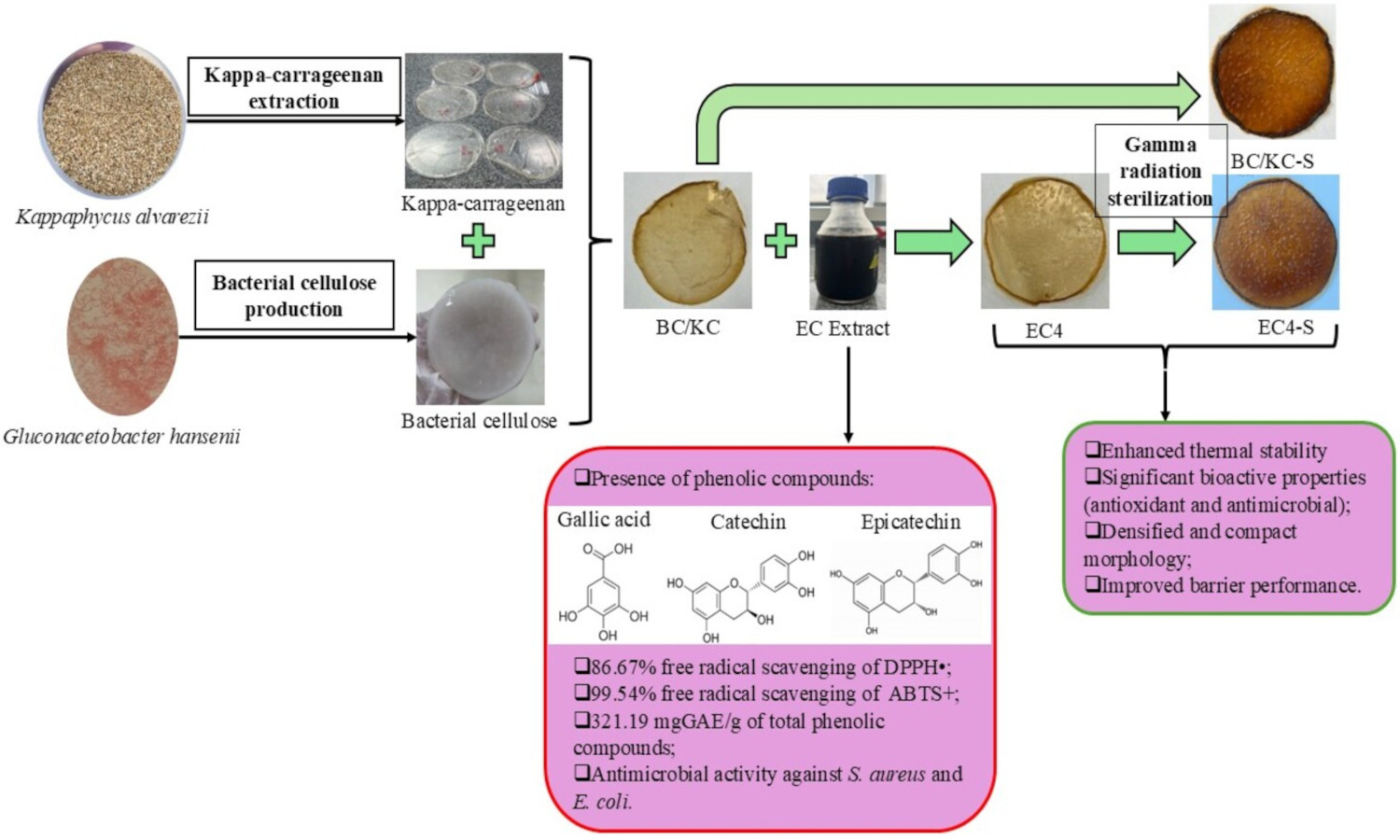

Alice da Conceição Alves de Lima, Andréa Monteiro Santana Silva Brito, Viviane Fonseca Caetano, Glória Maria Vinhas

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

Vol. 19., No.6., Pages 610-627, 2025

DOI: 10.3144/expresspolymlett.2025.46

Biopolymer-based packaging, such as bacterial cellulose (BC) and kappa-carrageenan (KC), offers a sustainable solution to environmental challenges. The incorporation of bioactive extracts enhances antioxidant and antimicrobial properties, while gamma radiation sterilization ensures microbiological safety, improving functionality for food preservation and promoting sustainability in the packaging industry. The objective of this work was to develop a BC film incorporated with KC solution (1%, v/v) and cashew bark extract (EC) at concentrations of 1, 2, and 4% (v/v) for use as active food packaging. EC exhibited a total phenolic content of 321.19 mgGAE/g and showed 86.67 and 99.54% radical scavenging activity for 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2″-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS), respectively. EC also displayed antimicrobial activity against S. aureus and E. coli, confirming its antimicrobial potential. BC/KC films incorporated with EC and irradiated with gamma radiation exhibited a thermal degradation in the range of 275–287 °C, maintaining good thermal stability. The water vapor permeability decreased by 55.12%, indicating improved barrier properties and the film’s morphology became more compact after EC incorporation and irradiation. BC/KC films show promises for extending the food shelf life as active packaging.

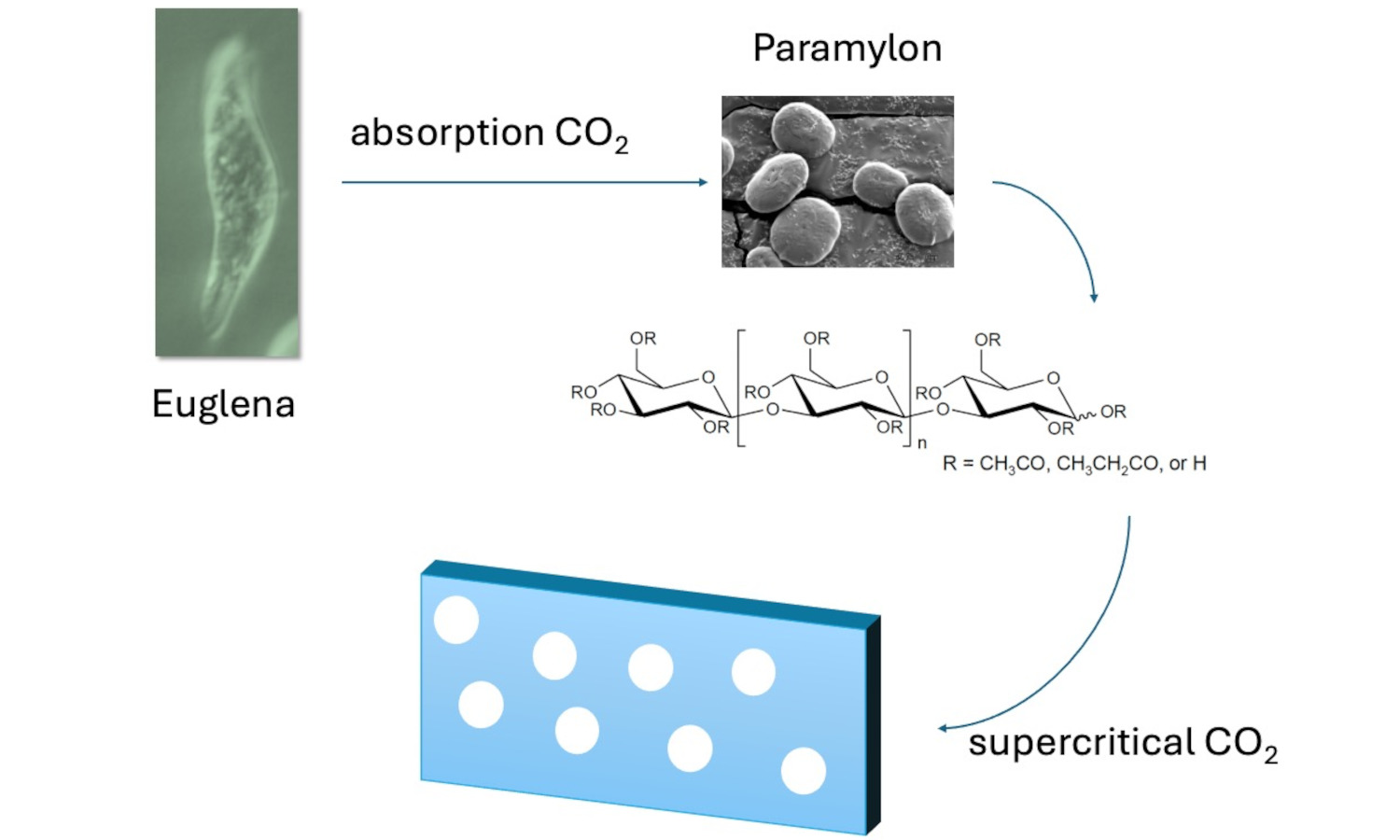

Seisuke Ata, Takumi Ono, Motonari Shibakami

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

Vol. 19., No.6., Pages 628-635, 2025

DOI: 10.3144/expresspolymlett.2025.47

This study demonstrated, for the first time, the successful formation of porous paramylon esters, which were made from euglenoid polysaccharide known as paramylon and short-chain fatty acids, through supercritical CO2 processing. By maintaining a constant ester functional group attached to the paramylon and varying its proportion, distinct porous structures were selectively produced. Solubility parameter estimations indicated that changes in esterification had no significant effect on the solubility of the paramylon esters used in the experiment. Thus, these structural differences are likely attributed to variations in the viscoelastic properties of paramylon esters under supercritical CO2 conditions. Furthermore, thermal conductivity measurements revealed reductions of up to 20%. Intriguingly, substantial decreases in thermal conductivity were observed even at low foaming ratios, achieved through precise control of the porous structure.

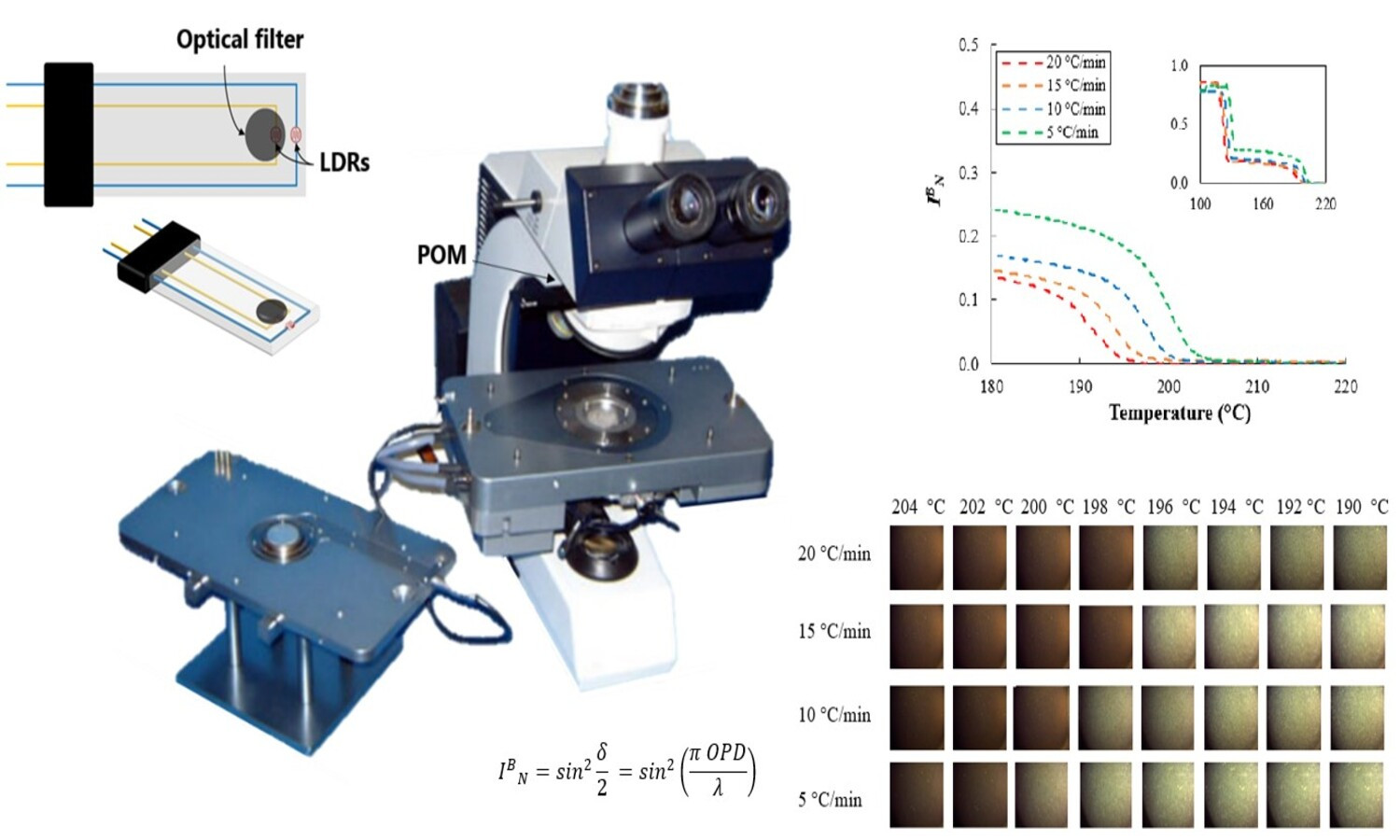

Felipe Oliveira Campos Bernardo, Sebastião Vicente Canevarolo

Vol. 19., No.6., Pages 636-650, 2025

DOI: 10.3144/expresspolymlett.2025.48

Vol. 19., No.6., Pages 636-650, 2025

DOI: 10.3144/expresspolymlett.2025.48

The use of rheo-optical techniques to evaluate crystallization in polymer processing has many advantages; however, it is still little seen. Shear-induced crystallization of polyamide 6 (PA6) was here proposed and studied with these techniques. Mixtures of PA6 in a polypropylene (PP) matrix were also studied. A polarized light optical microscope, with an AxioVision system attached to its top allowing the acquisition of photos at any time during the measurement and a Linkam hot stage device to control shear and temperature, was modified to receive a specially built quantitative rheo-optical detector. Temperature was variable, characterizing non-isothermal analysis. The experiments consisted of varying the shear rate on the polymer system while collecting the respective cross-polarized transmitted light intensity response by LabVIEW software. Shear rates of 1, 10, 100 and 180 s–1 were applied to all samples. Differential scanning calorimetry (DSC) analysis was also performed to predict crystallization behavior. PA6’s crystallization increased with the increase of shear rate; however, for the PP/PA6 mixtures under the highest rates, crystallization intensity falls from a specific temperature in which the polymer’s viscosity is not enough to maintain the structural integrity. Data related to PP/PA6 mixtures showed that shear increases crystallization if the polymer has time to organize itself.