Content

All issues / Volume 18 (2024) / Issue 11 (November)

Tamás Tábi

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

Vol. 18., No.11., Pages 1063-1064, 2024

DOI: 10.3144/expresspolymlett.2024.81

This is an editorial article. It has no abstract.

Yuanyuan Zhang, Xiaojian Wang, Honghong Li, Xinru Fu, Simin Huang, Hao Zhou

Vol. 18., No.11., Pages 1065-1076, 2024

DOI: 10.3144/expresspolymlett.2024.82

Vol. 18., No.11., Pages 1065-1076, 2024

DOI: 10.3144/expresspolymlett.2024.82

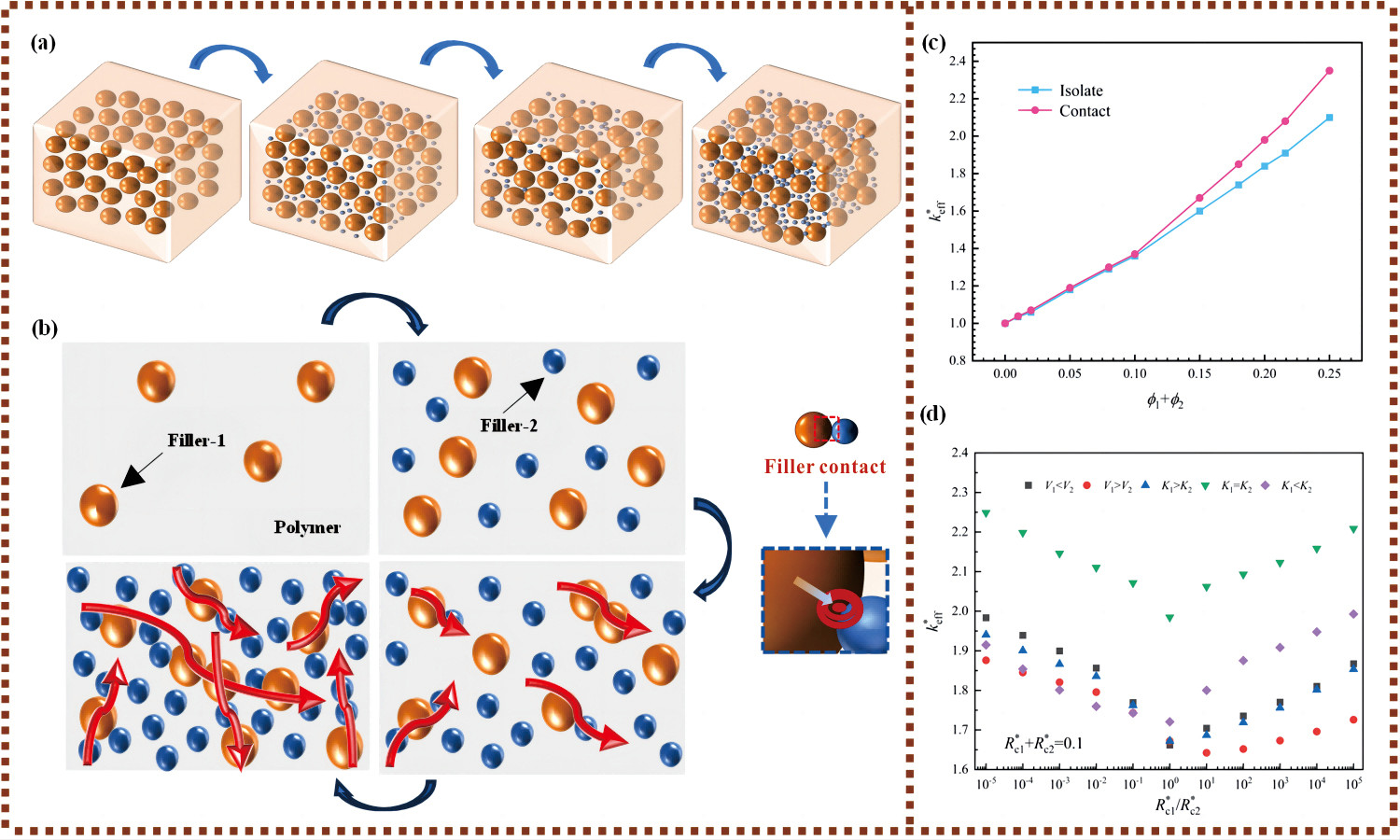

Adding heterogeneous fillers with high thermal conductivity (TC) to polymer has been recognized as an effective way to increase the effective thermal conductivity (ETC) of polymer composites. Extensive researches have been conducted on the ETC of composites with heterogeneous fillers. However, the heat transfer enhancement mechanism of heterogeneous fillers remains unknown, and the combined effects of filler size, filler contact, interface thermal resistance (Rc) and other parameters on the ETC have not been explored. In this study, above combined effects are investigated. The results show that the filler contact and Rc are the key factors determining the ETC. The ETC of composite with filler contacts reaches 2.35 at filler content of 25%, which is 11.9% higher than that without filler contacts. The ETC also strongly depends on the R*c (dimensionless form of Rc) ratio (R*c1/R*c2) between two fillers, with it becoming asymmetrical when the amount of R*c(R*c1 + R*c2) is larger. The ETCs decrease with the increase of R*c1/R*c2 when the R*c1/R*c2<1, while they increase with R*c1/R*c2 when the R*c1/R*c2>1. When R*c1 + R*c2 is a constant, the ETC increases with the competing effects of R*c. The models with filler contacts exhibit higher accuracy than other classical models in calculating the ETC across the entire range of filler content.

Rattanawadee Ninjan, Bencha Thongnuanchan, Natinee Lopattananon, Subhan Salaeh, Phakawat Thongnuanchan, Pornsuwan Buangam

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

Vol. 18., No.11., Pages 1077-1093, 2024

DOI: 10.3144/expresspolymlett.2024.83

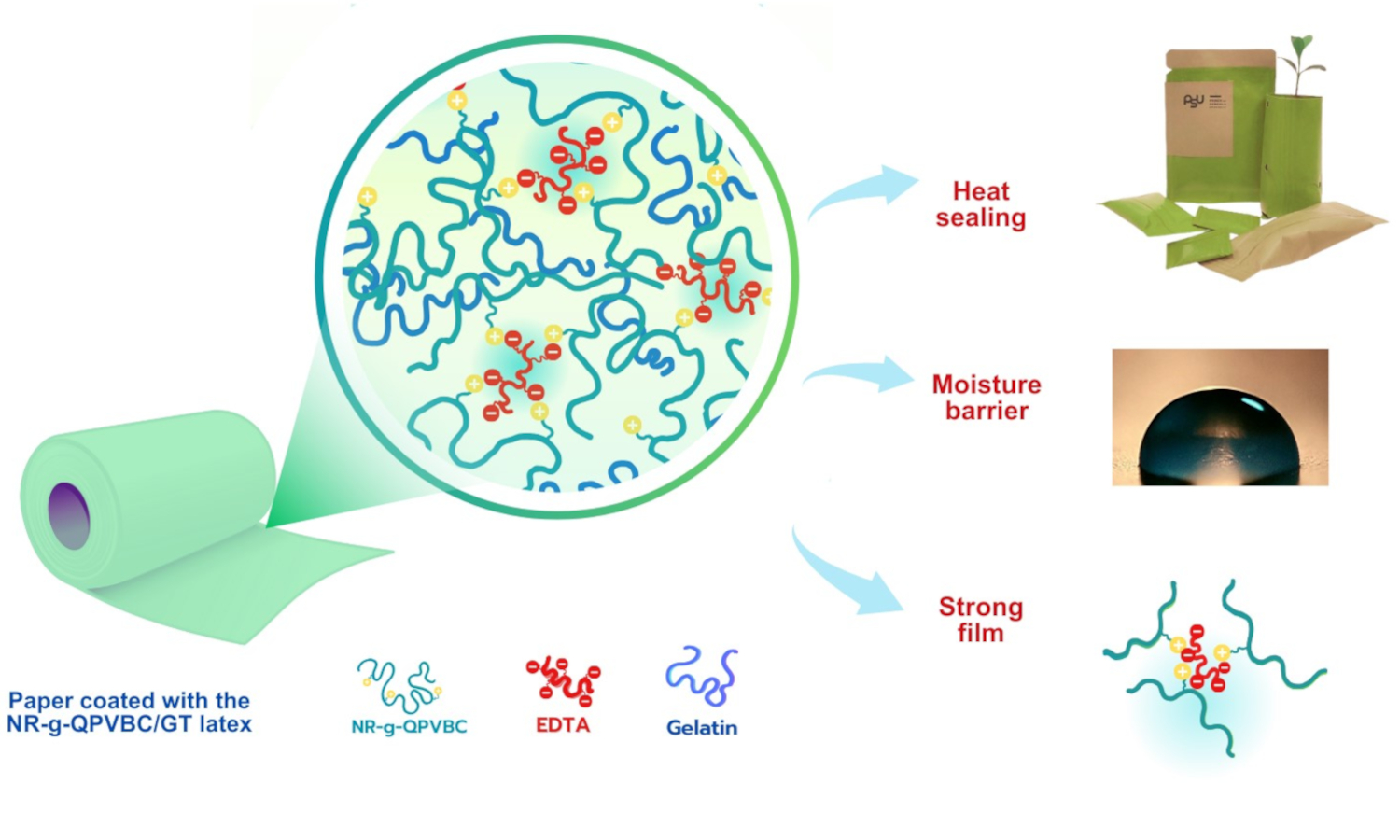

Research into sustainable packaging materials has gained increasing importance due to the pressing environmental concerns related to plastic waste. The present study focused on developing a sustainable paper coating based on modified natural rubber (NR) latex filled with gelatin (GT). The graft copolymer latex of NR and poly(vinylbenzyl chloride) bearing quaternary ammonium groups, abbreviated as NR-g-QPVBC, was first synthesized. GT was then incorporated into the latex, and the combination of these materials resulted in a heat-sealable film with good tensile properties and a water barrier. The ionic crosslinking of the latex film was achieved by the reaction with ethylenediaminetetraacetic acid (EDTA). Heat-sealing studies of the NR-g-QPVBC latex film filled with GT (NR-g-QPVBC/GT) revealed its heat-sealability at 160 °C. Scanning electron microscope (SEM) analysis further confirmed the diffusion of the chains across the interface during heat sealing. Dip coating was a method for depositing latex film on kraft paper. The paper coated with the NR-g-QPVBC/GT latex showed a significant increase in dry and wet-tensile strength compared to the uncoated paper. The sealing process was optimized to achieve a heat-seal strength of 755.31 N/m at a dwell time of 3 s and a temperature of 160 °C. The research's practical application was demonstrated by transforming the coated paper into various heat-sealable bags using a handheld bag sealer.

Hajime Kishi, Ayana Kubo, Yohei Miyaji, Ayu Mochizuki, Ryoko Hara, Katsuya Tanaka, Takeshi Kakibe, Satoshi Matsuda

Vol. 18., No.11., Pages 1094-1108, 2024

DOI: 10.3144/expresspolymlett.2024.84

Vol. 18., No.11., Pages 1094-1108, 2024

DOI: 10.3144/expresspolymlett.2024.84

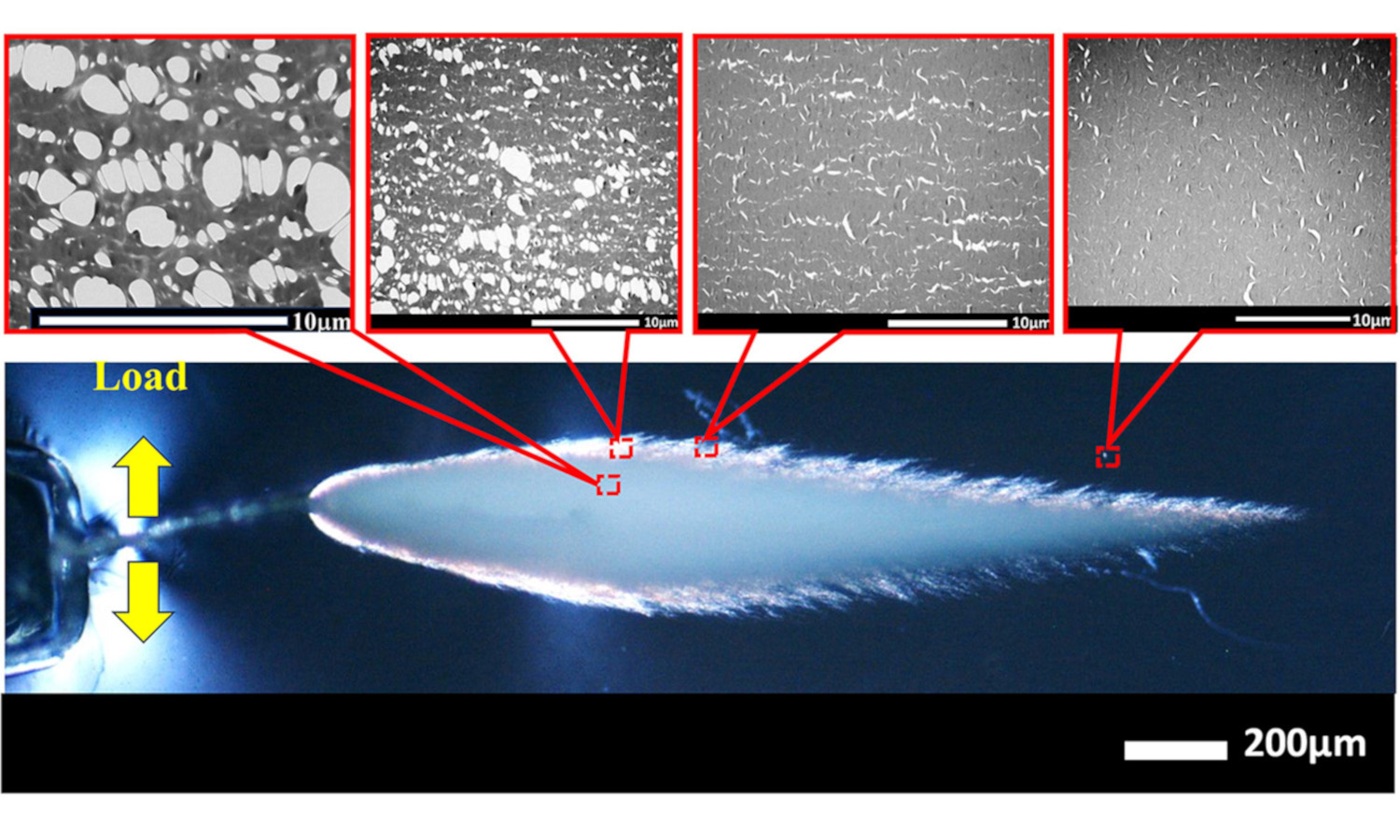

Functional triblock copolymers (BCPs), i.e., poly(glycidyl methacrylate/methyl methacrylate)-b-poly(lauryl methacrylate)-b-poly(glycidyl methacrylate/methyl methacrylate) triblock copolymers [(P(GMA/MMA)-b-PLMA-b-P(GMA/MMA)], were investigated as toughening modifiers for all-methacrylate polymer blends. Methyl methacrylate (MMA) was copolymerized with methacrylic acid (MAA) in the presence of the BCPs. Without MAA in the polymethacrylate matrices, the BCP blends formed micron-scale phase structures by polymerization-induced phase separation. In matrices copolymerized with MAA, self-assembled nanostructures, such as curved lamellae, worm-like cylindrical micelles, or spherical micelles were formed. The BCP blends with worm-like cylindrical nano-micelles achieved much higher fracture toughness than those with spherical nano-micelles. The toughening mechanisms were elucidated by transmission electron microscopy. Cavitation was initiated in worm-like cylindrical nano-micelles, and the aligned cavitation formed craze-like deformation with increased loads. This relieves hydrostatic tensile stress in front of the crack tip, forming a large shear yield zone within the craze-like deformation region, contributing to high toughness.

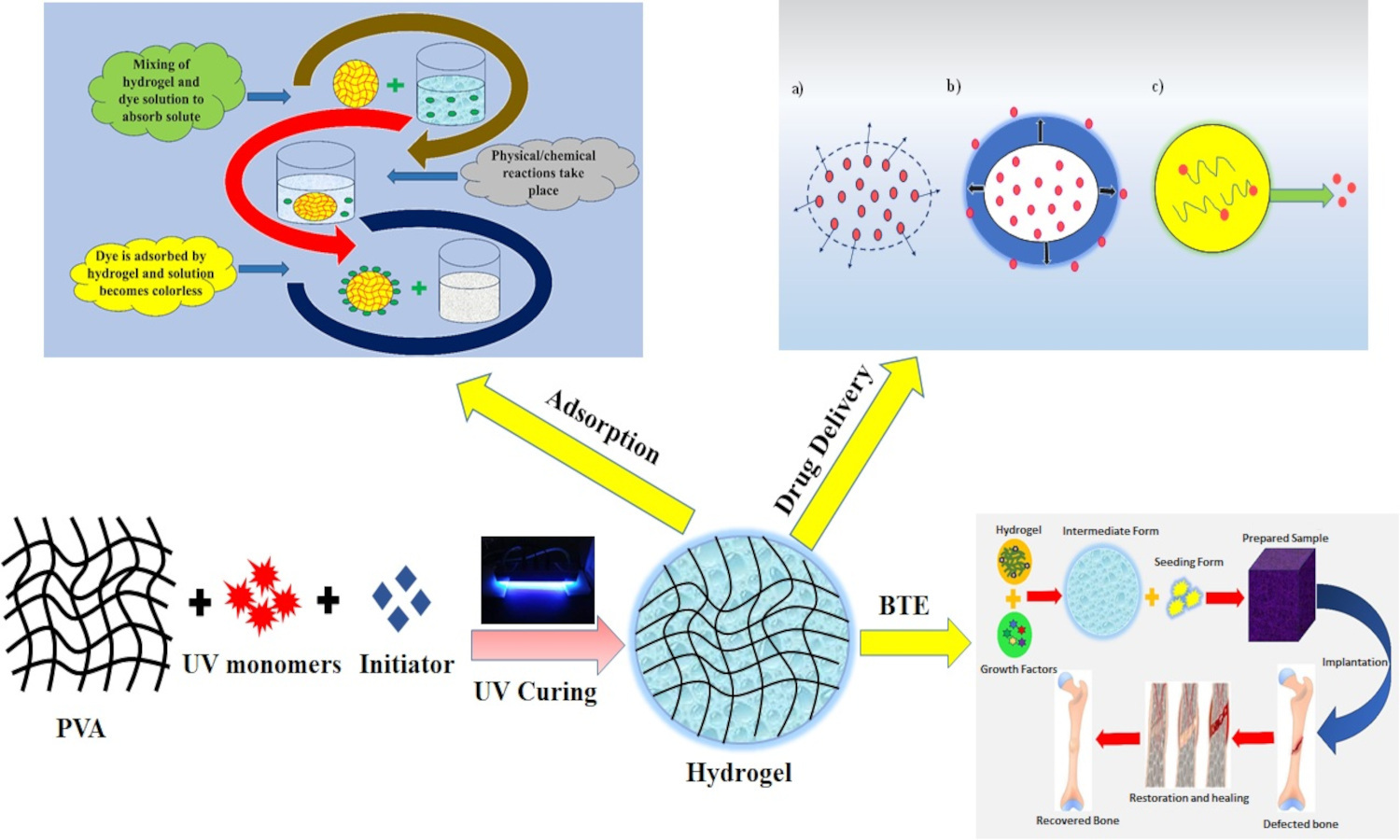

Muhammad Akmal, Hafiza Mehtab, Rimsha Amjad, Fauzia Iqbal, Ahmad Irfan, Robina Begum, Zahoor H. Farooqi

Vol. 18., No.11., Pages 1109-1134, 2024

DOI: 10.3144/expresspolymlett.2024.85

Vol. 18., No.11., Pages 1109-1134, 2024

DOI: 10.3144/expresspolymlett.2024.85

Poly(vinyl alcohol) (PVA) based hydrogels have gained more interest in the field of biomaterials because of their many biomedical uses (i.e., wound healing, drug delivery, and tissue engineering) and intrinsic physicochemical and biological characteristics. They can be made using a variety of synthetic techniques, but all of them are very time-consuming. Among them, photopolymerization also referred to as light-induced polymerization, has drawn a lot of attention because of its benefits, which include not requiring the use of solvents, easy and quick network formation, energy efficiency, quick processing, control over both space and time and reliability of crosslinking density and matrix strength. Ultraviolet (UV)-curable hydrogels containing PVA as a main component are gaining interest because of their excellent properties, including biodegradability, biocompatibility, less cytotoxicity and remarkable mechanical strength. This review highlights the significance of UV curable systems and their components, types, advantages and disadvantages of photoinitiators (PIs), UV curable monomers and their structures, properties of UV-cured PVA hybrid hydrogels, and their characterizations and applications in different fields. The photopolymerization mechanisms, tunable properties, and unique advantages of these hydrogels have been explored in detail. Furthermore, it sheds light on recent advancements in PVA-based hydrogels research and future exploration in this domain.

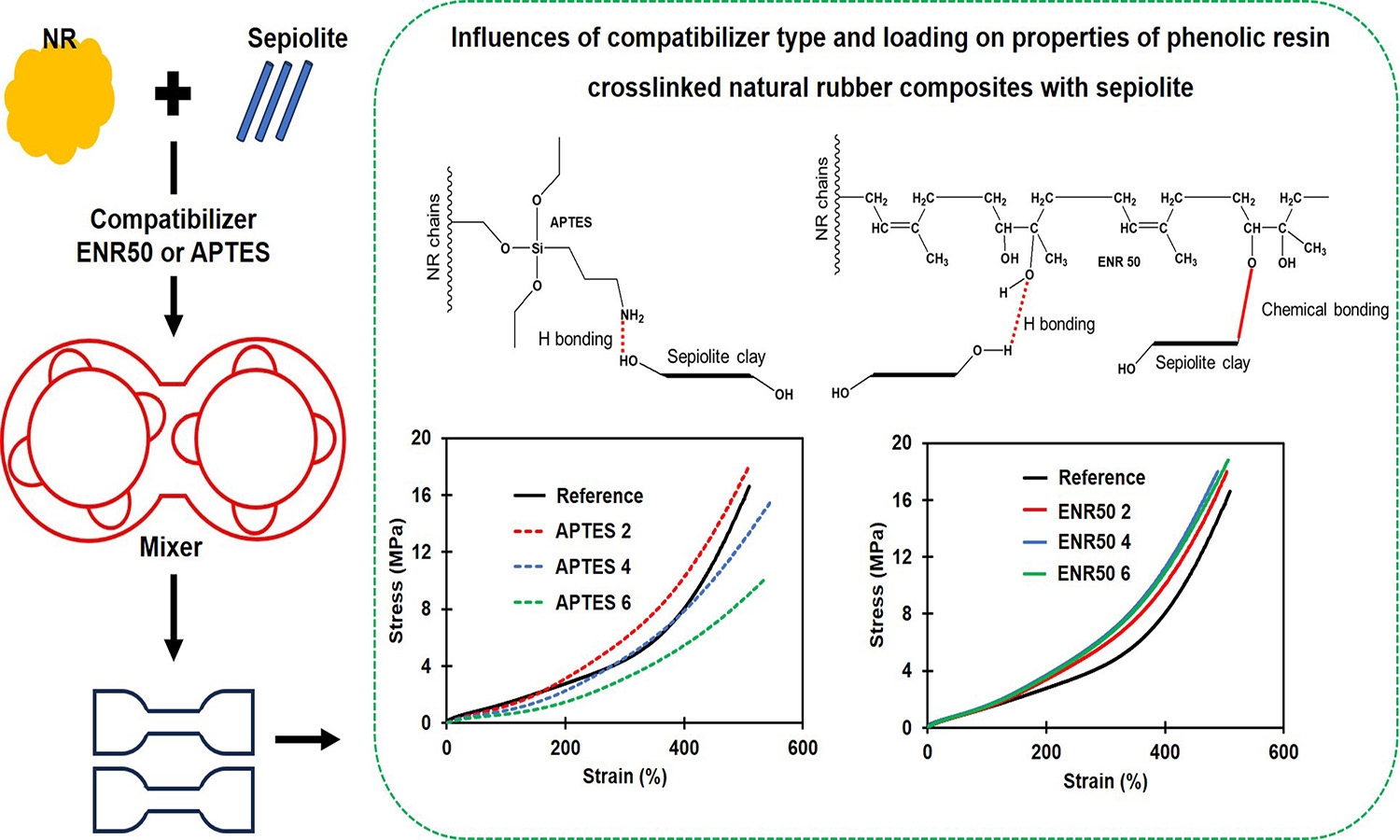

Nabil Hayeemasae, Siriwat Soontaranon, Abdulhakim Masa

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

Vol. 18., No.11., Pages 1135-1148, 2024

DOI: 10.3144/expresspolymlett.2024.86

Natural rubber (NR) composites reinforced with sepiolite and crosslinked with phenolic resin were prepared. Effects of compatibilizer types and contents, namely 3-aminopropyl triethoxysilane (APTES) or epoxidized NR (ENR50), on curing, tensile, strain-induced crystallization, and stress relaxation were investigated. Compared to APTES, ENR50 provided a greater compatibilizing effect in the NR composites. The ENR50 introduced strong physical and chemical interactions between sepiolite and NR, while only physical interaction was present in the APTES compatibilized composites. Stronger interaction between rubber and sepiolite improved filler dispersion, swelling resistance, and tensile strength; and delayed stress relaxation of the composite. Increased addition of ENR50 improved the modulus and tensile strength, and the greatest tensile strength was achieved at 2 phr ENR50 with a 15% improvement over composite without compatibilizer. In the case of APTES, 2 phr level enhanced tensile strength, but a further increase in APTES content degraded tensile, swelling resistance, and stress relaxation responses, due to its plasticizing effect. Moreover, ENR50 enhanced the strain-induced crystallization and delayed stress relaxation of the composites more than APTES. Weaker interaction between rubber and filler in APTES filled composites was due to having only hydrogen bonds formed between rubber and filler, in addition to crosslinks.

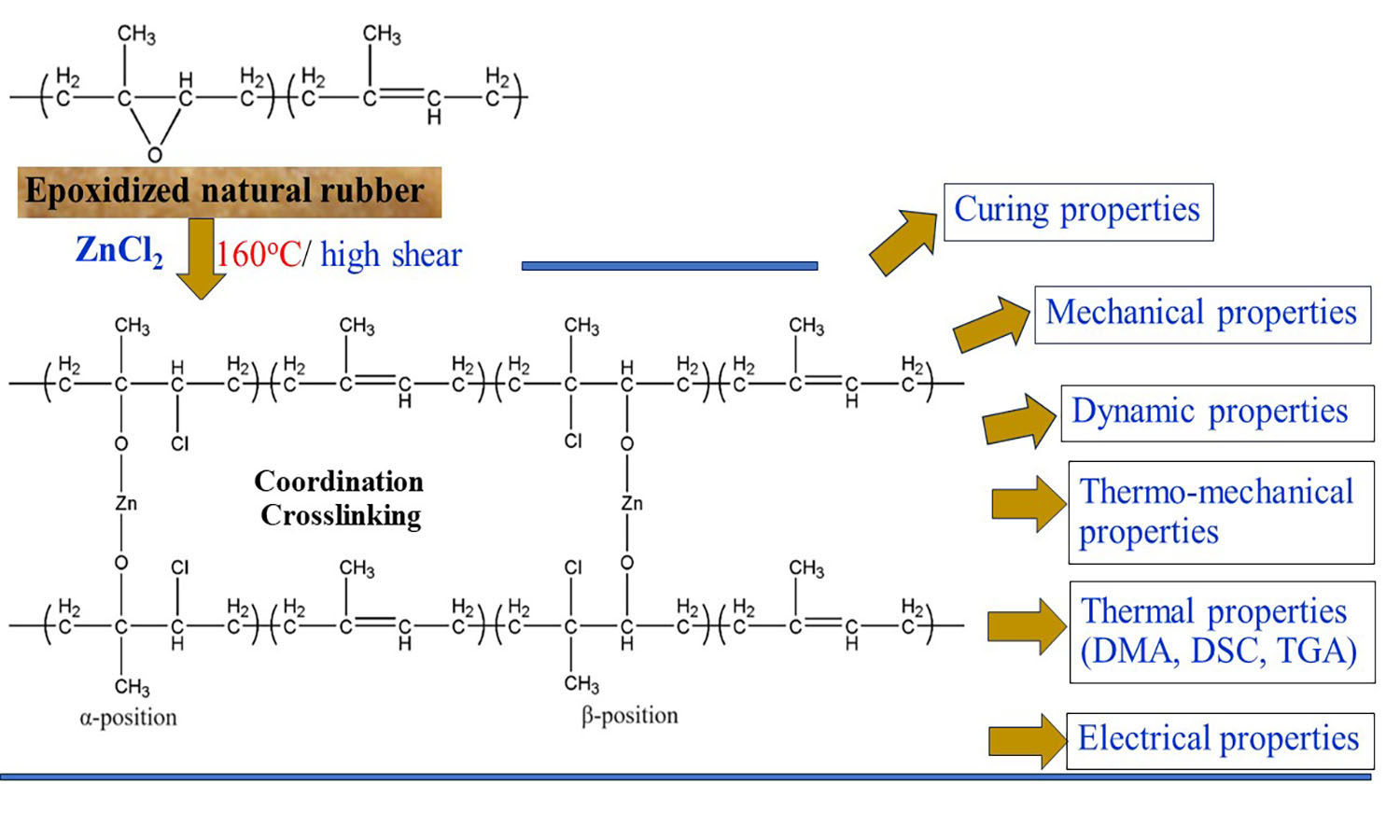

Kamonthip Rittimas, Skulrat Pichaiyut, Charoen Nakason

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

Vol. 18., No.11., Pages 1149-1163, 2024

DOI: 10.3144/expresspolymlett.2024.87

Epoxidized natural rubber with 50 mol% epoxide (ENR-50) was compounded with zinc chloride (ZnCl2) and subjected to torque response analysis using a moving die rheometer. It was found that different ZnCl2 concentrations (3, 5, 7, 9, and 12 millimoles (mmol)) mixed in ENR-50 exhibited positive torque responses, prompting further molecular characterization using Fourier transform infrared spectroscopy. The results indicated distinct absorption peaks at wavenumbers of 442 and 809 cm–1, which signify the presence of –O–Zn–O– coordination linkages. The curing characteristics of ENR and ZnCl2 compounds showed that increasing ZnCl2 content resulted in higher minimum and maximum torque values, but also led to a decrease in scorch time and cure rate index (CRI). Moreover, higher ZnCl2 concentrations enhanced the strength properties (tensile strength, moduli, stiffness, toughness, and hardness), crosslink densities, dynamic shear moduli, initial modulus during relaxation experiments, and thermal resistance, as evidenced by temperature scanning stress relaxation (TSSR), thermogravimetric analysis, and dynamic mechanical analysis. However, an increase in ZnCl2 content led to a reduction in elongation at break due to the higher crosslink density within the coordination networks in the ENR matrix, which resulted in the movement constraint of the rubber vulcanizate.

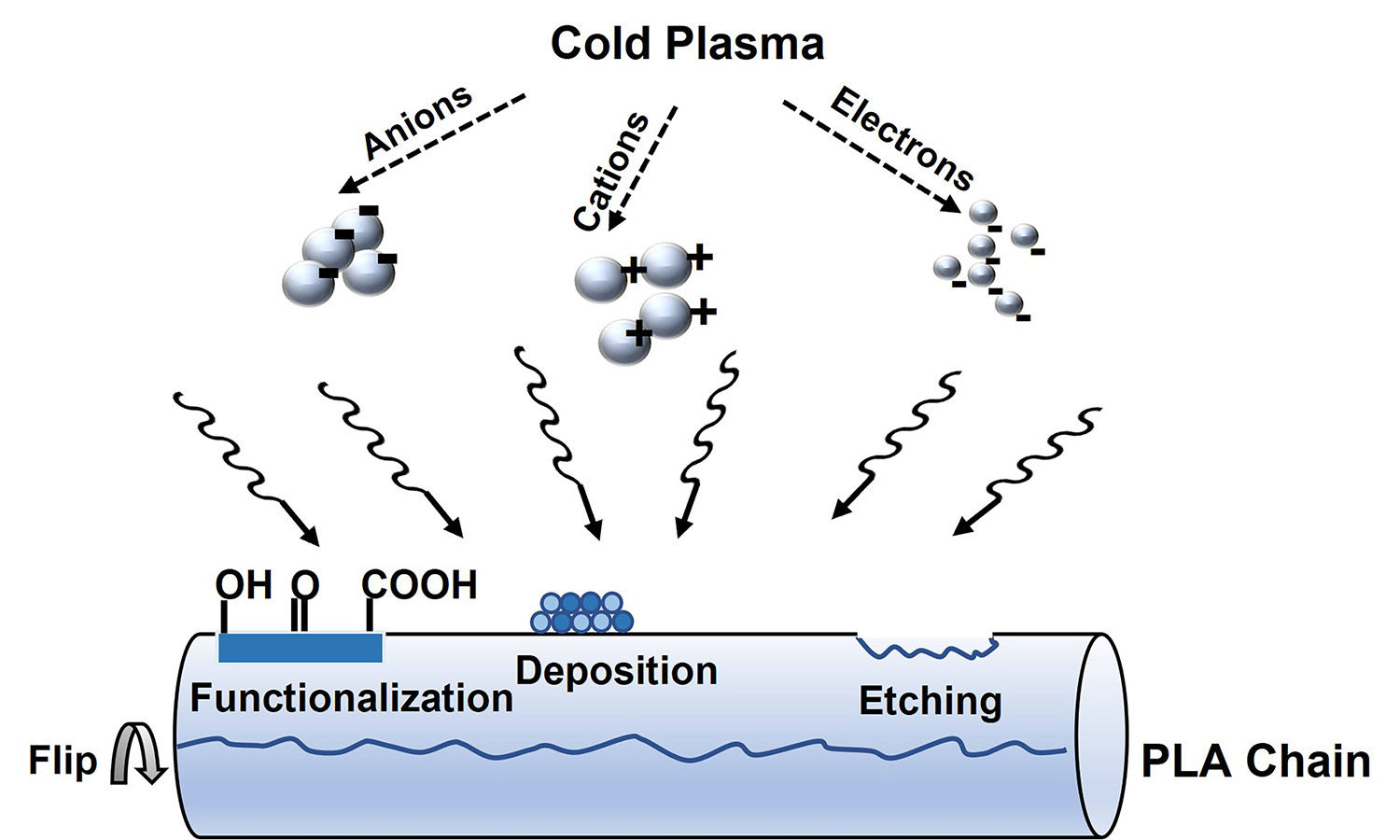

Yiqing Xu, Haiyan Liu, Shuni Ying, Qunfang Lin, Huihuang Ma, Xiaodong Zhou

Vol. 18., No.11., Pages 1164-1175, 2024

DOI: 10.3144/expresspolymlett.2024.88

Vol. 18., No.11., Pages 1164-1175, 2024

DOI: 10.3144/expresspolymlett.2024.88

This study examines the interface of biodegradable polylactic acid (PLA) fiber-reinforced thermoplastic starch composites to address market demand for their mechanical properties. We first used a combination of solution treatment (acid/alkali) and plasma modification to modify fibers. This method improves surface roughness and increases oxygen-containing groups of the fibers, which enhances the mechanical interlocking at the interface and promotes stronger hydrogen bonds between fibers and starch, respectively. Their synergy effect significantly strengthens interfacial adhesion and interfacial shear strength (IFSS). In contrast, cold plasma modification alone results in a smaller increase in IFSS because of its lower roughness and fewer oxygen-containing groups. Alkaline treatment and increased cold plasma power level are more conducive to higher IFSS through stronger synergistic effects. Although IFSS improved from 2.41 to 4.40 MPa after alkali and plasma treatments of 200 W, the tensile strength decreased from 811.46 to 351.55 MPa. To optimize the mechanical properties of composite materials, it is crucial to choose a kind of modification method that balances IFSS enhancement and tensile strength reduction.