Content

All issues / Volume 17 (2023) / Issue 11 (November)

Andrea Toldy

Vol. 17., No.11., Pages 1081-1081, 2023

DOI: 10.3144/expresspolymlett.2023.81

Vol. 17., No.11., Pages 1081-1081, 2023

DOI: 10.3144/expresspolymlett.2023.81

This is an editorial article. It has no abstract.

Kianoosh Soltanmohammadi, Mohammad Aberoumand, Davood Rahmatabadi, Elyas Soleyman, Sogol Ghasemi, Ismaeil Ghasemi, Majid Baniassadi, Karen Abrinia, Mahdi Bodaghi, Mostafa Baghani

Vol. 17., No.11., Pages 1082-1095, 2023

DOI: 10.3144/expresspolymlett.2023.82

Vol. 17., No.11., Pages 1082-1095, 2023

DOI: 10.3144/expresspolymlett.2023.82

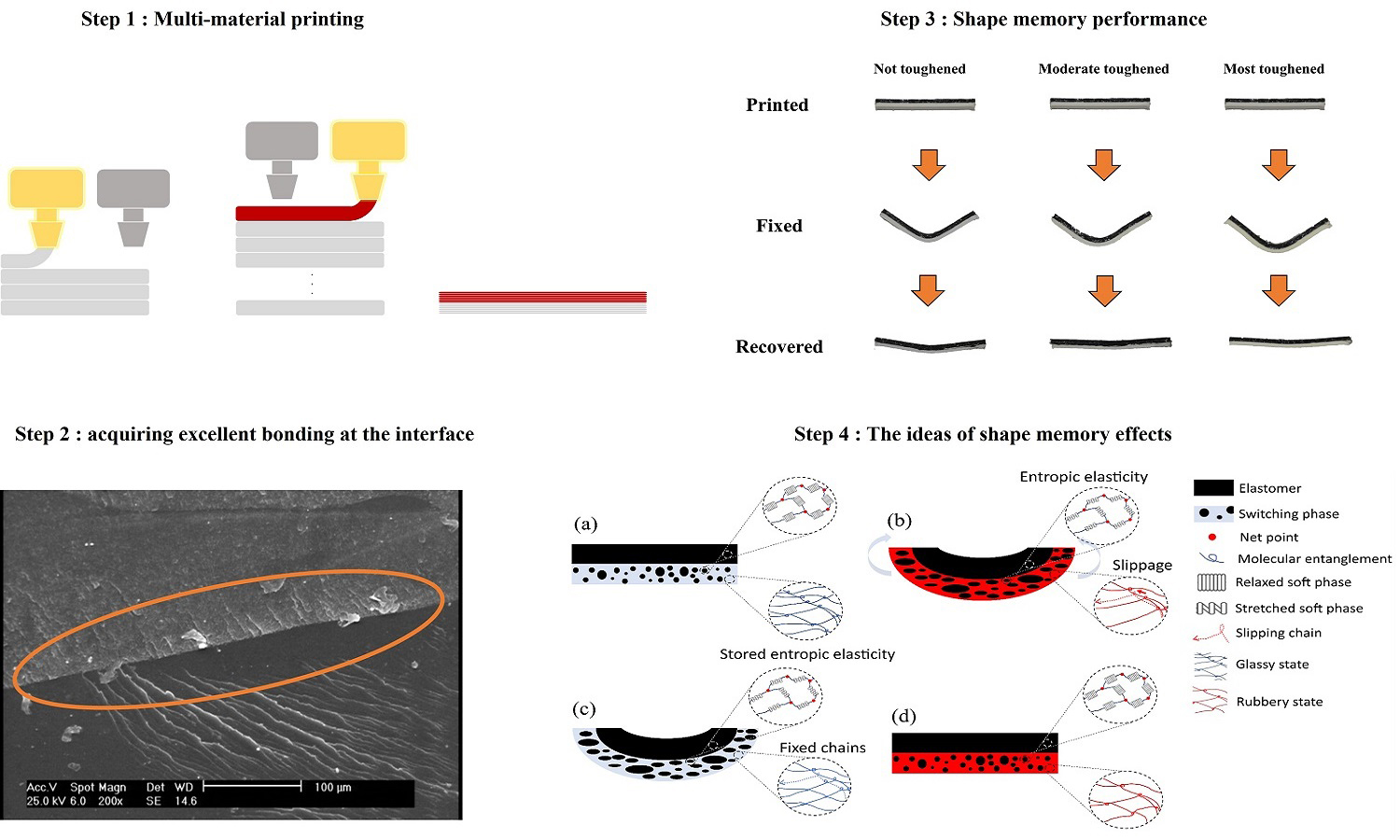

There

are a limited number of thermoplastics with intrinsic shape memory effect (SME)

that are four-dimensional (4D) printable. Development of other shape memory

polymers (SMPs) entails synthesis with a complicated chemical experimental lab

effort. In this paper, for the first time, a novel layered multi-material

structure is developed based on a deep comprehension of SMEs’ macromolecular

requisites. The fused deposition modeling (FDM) method is used for the

four-dimensional printing of layered structures whose base materials show no

SME. Commercial acrylonitrile butadiene styrene (ABS), toughened

ABS-thermoplastic polyurethane (TPU) blend, and TPU, all with no SME, are used

to fabricate bi-layers of ABSTPU blends and TPU with different volumetric

proportions. Different thermo-mechanical tests, including dynamic mechanical thermal

analysis (DMTA), and constrained and free shape recovery, are conducted. Also,

the interfacial properties of the layered 4D printed structure are assessed by

the mean of shear testing and scanning electron microscopy (SEM). Experimental results

reveal that the 4D printed bi-layer composites possess a high level of

programmability, SME (90–96%), and perfect interfaces without any porosity and

detachment between layers. The results of this research can potentially

eliminate the desperate need for SMPs for 4D printing and broaden the

opportunity to have smart parts using commercial thermoplastics.

Jareerat Ruamcharoen, Ruszana Munlee, Lapporn Vayachuta, Polphat Ruamcharoen

Vol. 17., No.11., Pages 1096-1109, 2023

DOI: 10.3144/expresspolymlett.2023.83

Vol. 17., No.11., Pages 1096-1109, 2023

DOI: 10.3144/expresspolymlett.2023.83

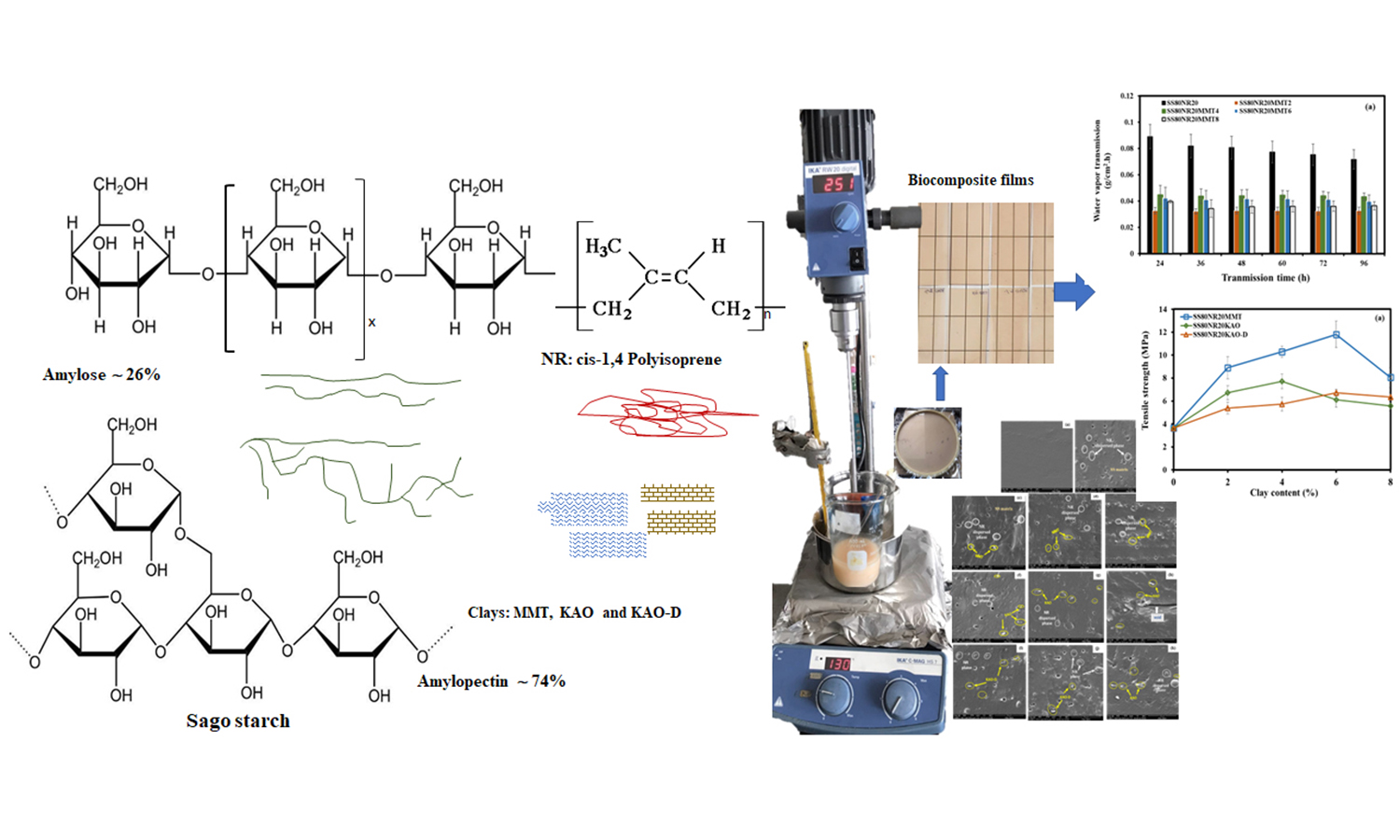

Sago

starch (SS) was blended with natural rubber (NR) using nanoclays, namely

montmorillonite (MMT), kaolinite (KAO), and kaolinite modified by dimethyl

sulfoxide (KAO-D) to enhance its physical and mechanical properties. Each nanoclay

was incorporated at 2, 4, 6, and 8 wt%, respectively. The SS80NR20 (80 wt% of

sago starch and 20 wt% of natural rubber) biocomposites were characterized by

solubility of water, water vapor transmission, mechanical and thermal

properties. The constituent interaction and morphology of the SS80NR20

biocomposites were also presented by using X-ray diffraction (XRD) technique

and scanning electron microscope (SEM). The findings demonstrated that the

inclusion of clays significantly improved both the water resistance and tensile

properties when compared to the SS80NR20 blend. In the SS80NR20 biocomposites,

MMT at 6 wt% exhibited the lowest moisture content, solubility in water, and

water vapor transmission. As the amount of nanoclay in the biocomposites

increased, their tensile strength dramatically increased whilst their strain at

break had a tendency to diminish. Strong interaction by establishing the

intercalated structure of MMT, and KAO within SS80NR20 biocomposites were

attributed to both physical and mechanical properties, while the weak

interaction at the interface of SS and NR was attributed to KAO-D.

Sona Zenzingerova, Michal Kudlacek, Jana Navratilova, Lenka Gajzlerova, David Jaska, Lubomir Benicek, Roman Cermak

Vol. 17., No.11., Pages 1110-1120, 2023

DOI: 10.3144/expresspolymlett.2023.84

Vol. 17., No.11., Pages 1110-1120, 2023

DOI: 10.3144/expresspolymlett.2023.84

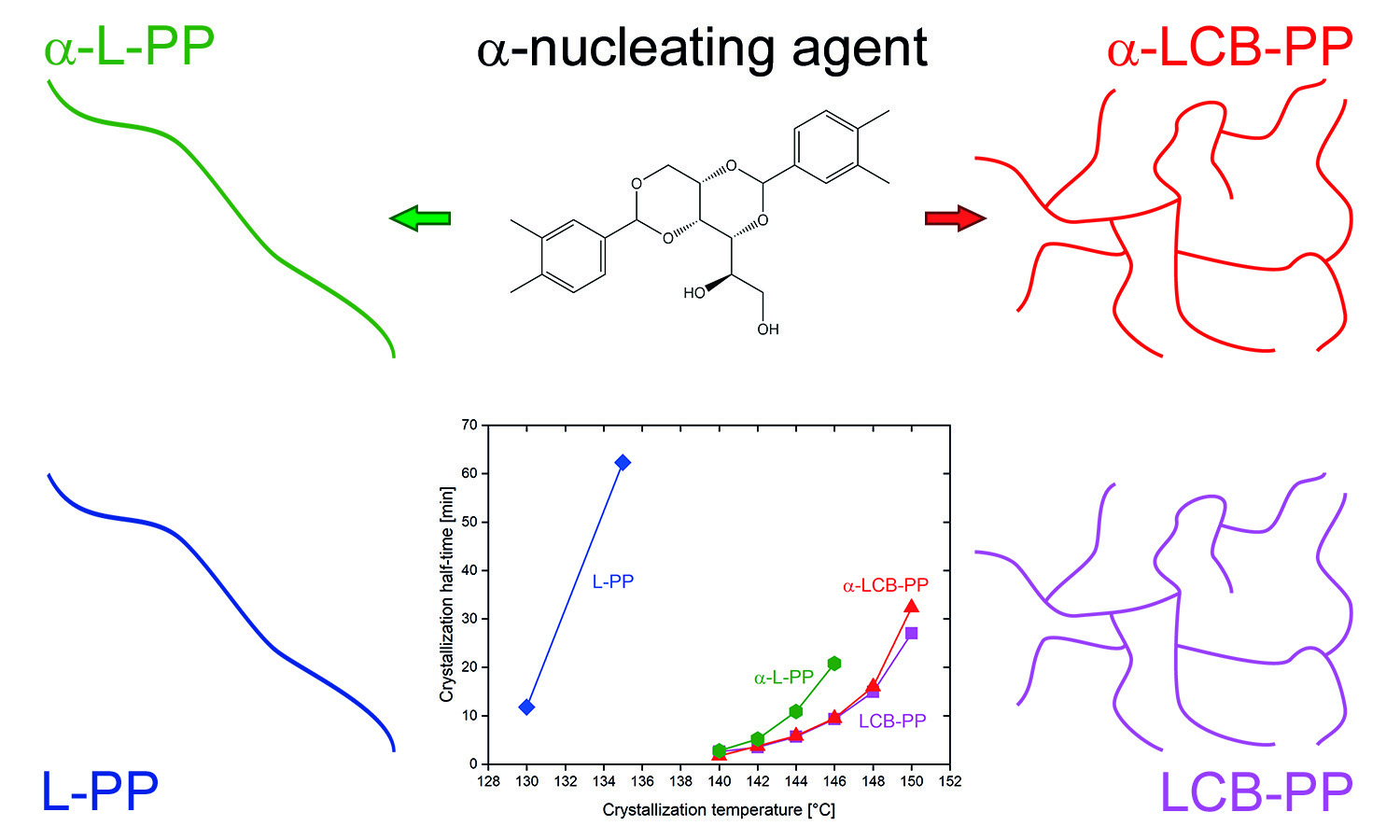

The

main purpose of this work is to present the effect of long-chain branching and

specific α-nucleation on the optical properties, crystallization and

supermolecular structure of polypropylene (PP). Commercially available α-nucleating/clarifying

agent 1,3;2,4-bis(3,4-dimethylbenzylidene)sorbitol (Millad 3988) was mixed into

linear PP and long-chain branched PP (LCB-PP) in the concentration of 0.2 wt%.

For the study of polymorphic composition, crystallinity, and crystallization process

under isothermal conditions in the temperature range of 130–150 °C,

differential scanning calorimetry and wide-angle X-ray scattering were used.

Although the used nucleating/clarifying agent appears to have a slight effect

on the optical properties of long-chain branched polypropylene, it does not

appear to affect the crystallization kinetics significantly. LCB-PP exhibited

self-nucleation, favored over nucleation by a specific nucleating agent.

Synthesis and characteristics of α-carboxylic, ω-hydroxyl natural rubber toughened poly(lactic acid)

Abdulhakim Masa, Varaporn Tanrattanakul, Ruedee Jaratrotkamjorn

Vol. 17., No.11., Pages 1121-1134, 2023

DOI: 10.3144/expresspolymlett.2023.85

Vol. 17., No.11., Pages 1121-1134, 2023

DOI: 10.3144/expresspolymlett.2023.85

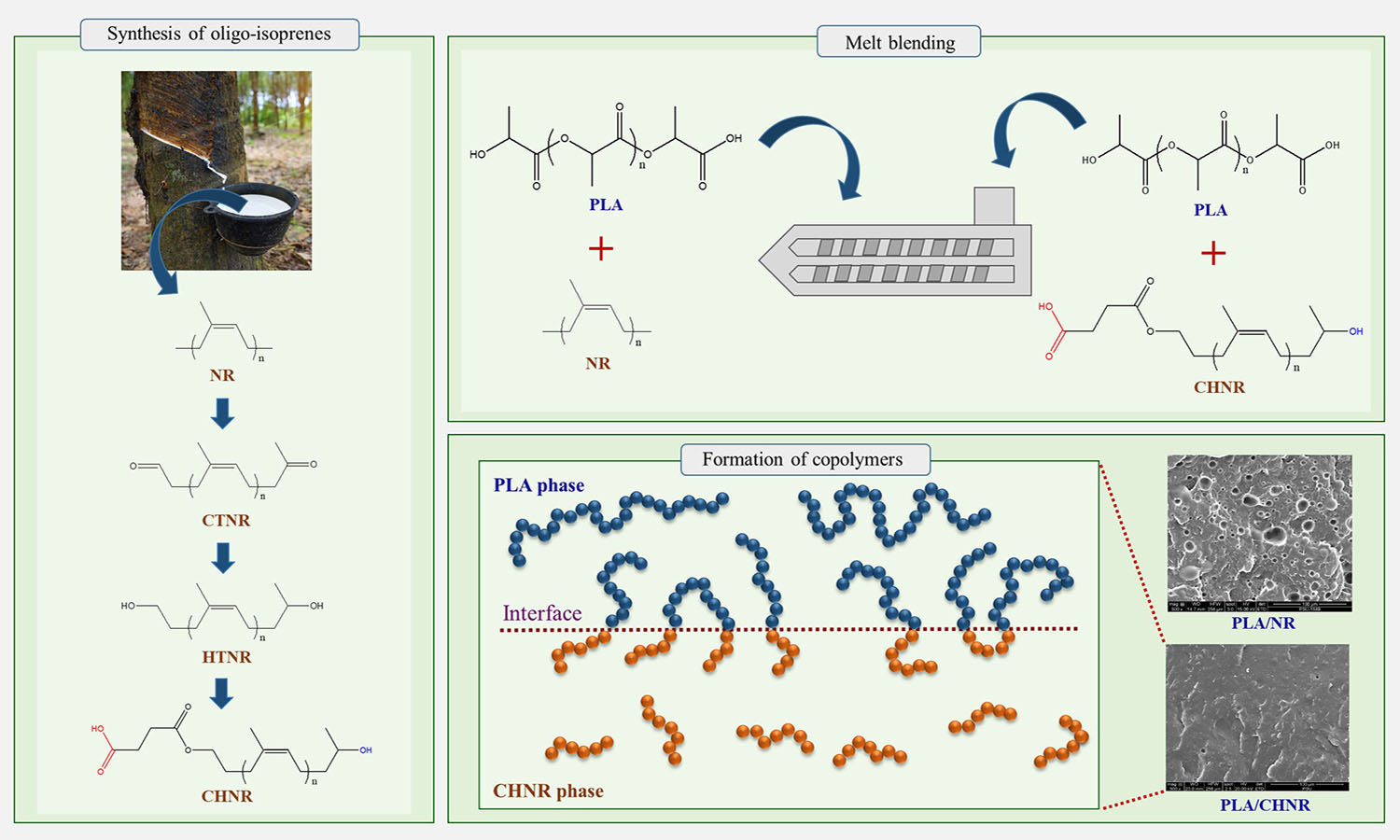

This work presented the synthesis of α-carboxyl, ω-hydroxyl natural rubber (CHNR) for use as an alternative toughening agent for poly(lactic acid) (PLA). The proton nuclear magnetic resonance spectroscopy (1H-NMR) and Fourier transform infrared spectroscopy (FTIR) analyses verified the chemical structure of CHNR consisting of the hydroxyl and carboxyl end groups. The molecular weights of CHNR were set from 5000 to 15 000 g·mol–1 which were determined by gel permeation chromatography (GPC) and 1H-NMR. The PLA and CHNR were prepared by reactive blending using a twinscrew extruder. It was found that the reaction between PLA and CHNR proceeded through transesterification without a catalyst. The formation of copolymer (PLA-co-CHNR) at the interface of PLA and CHNR increased the interfacial adhesion between the two phases. Differential scanning calorimetry (DSC) analysis revealed that CHNR was more compatible with PLA than natural rubber (NR). The compatibilization affected the blend morphology by reducing the interfacial tension. It resulted in a reduction of rubber particle size. The CHNR with a molecular weight of 5000 g·mol–1 showed the greatest improvement in the toughness and ductility of PLA.

Nicolas Candau, Rachel LeBlanc, Maria Lluisa Maspoch

Vol. 17., No.11., Pages 1135-1153, 2023

DOI: 10.3144/expresspolymlett.2023.86

Vol. 17., No.11., Pages 1135-1153, 2023

DOI: 10.3144/expresspolymlett.2023.86

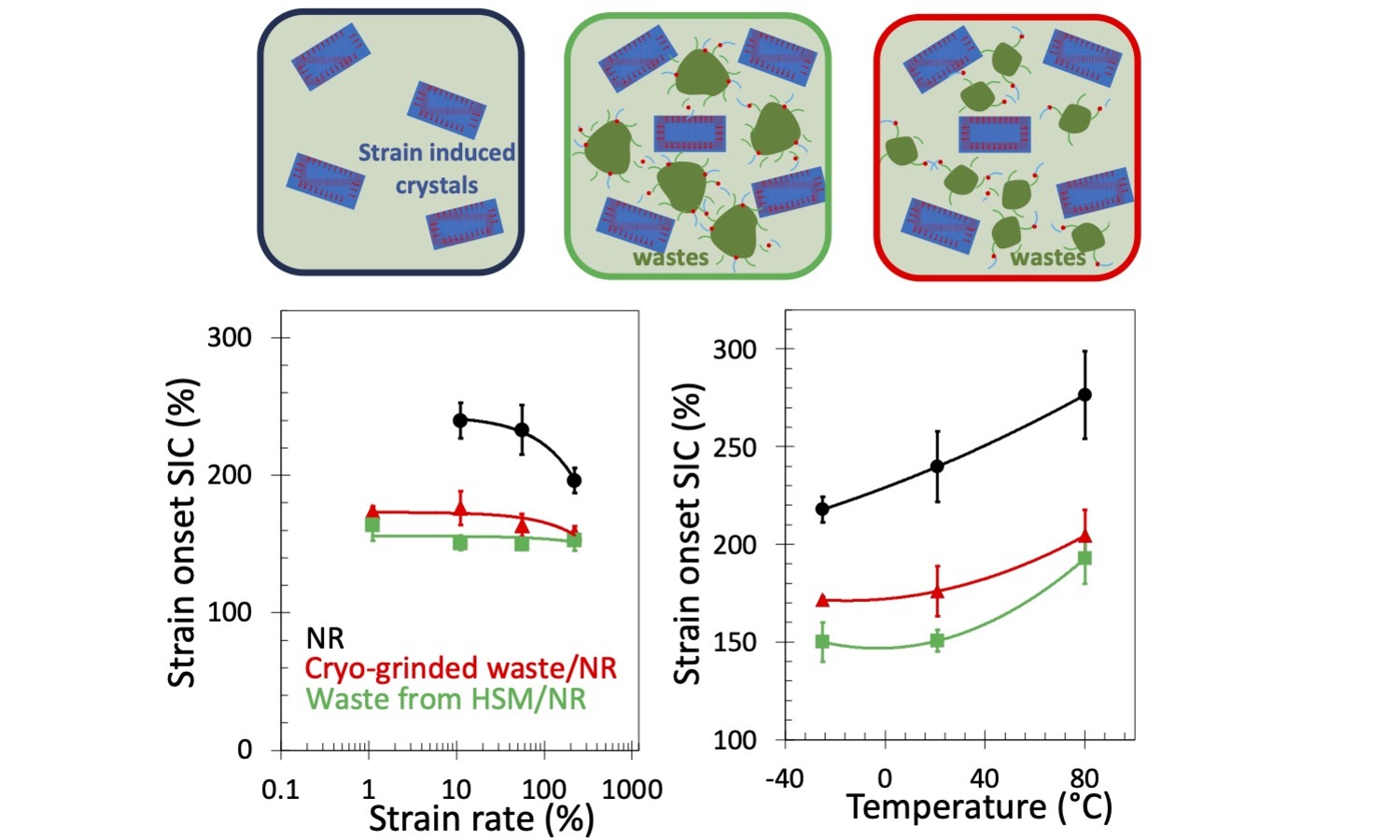

The

influence of the type of mechanical recycling of waste rubber particles on the

tensile properties of waste/natural rubber blends has been investigated. The

wastes originating from ground tyre rubber (GTR) had been treated by two

distinct processes: cryo-grinding and high shear mixing (HSM). For both

processes, the resulting composites show enhanced stiffness and strength for

all strain rates and temperatures tested. This is attributed to both the

reinforcing effect of the waste as well as the nucleation ability of the wastes

on strain induced crystallization (SIC) in the natural rubber (NR) matrix.

Cryo-grinding was shown to provide the finest particle size with an average

diameter of 34 μm, while the HSM process was found to show an elastic modulus

of aggregated GTR powder of 7 MPa at 1 Hz at room temperature. Within these

characteristics, the NR/GTR blends using the HSM process show the best tensile

performance under single loading, with the highest strength and highest ability

to crystallize under strain. Under cyclic loading, NR/GTR blends using

cryo-ground GTR particles show the best performance, which we ascribed to their

ability to better distribute and accommodate the stress from one cycle to another

owing to their finest size. Both explored recycling techniques provide the

natural/waste rubber blends interesting properties such as mechanical

reinforcement and strain-induced crystallization ability under various testing

conditions.

Limin You, Shifan Zhang, Zhuoxiong Huang, Wanle Pi, Jiaqi Liu, Rui Ma

Vol. 17., No.11., Pages 1154-1165, 2023

DOI: 10.3144/expresspolymlett.2023.87

Vol. 17., No.11., Pages 1154-1165, 2023

DOI: 10.3144/expresspolymlett.2023.87

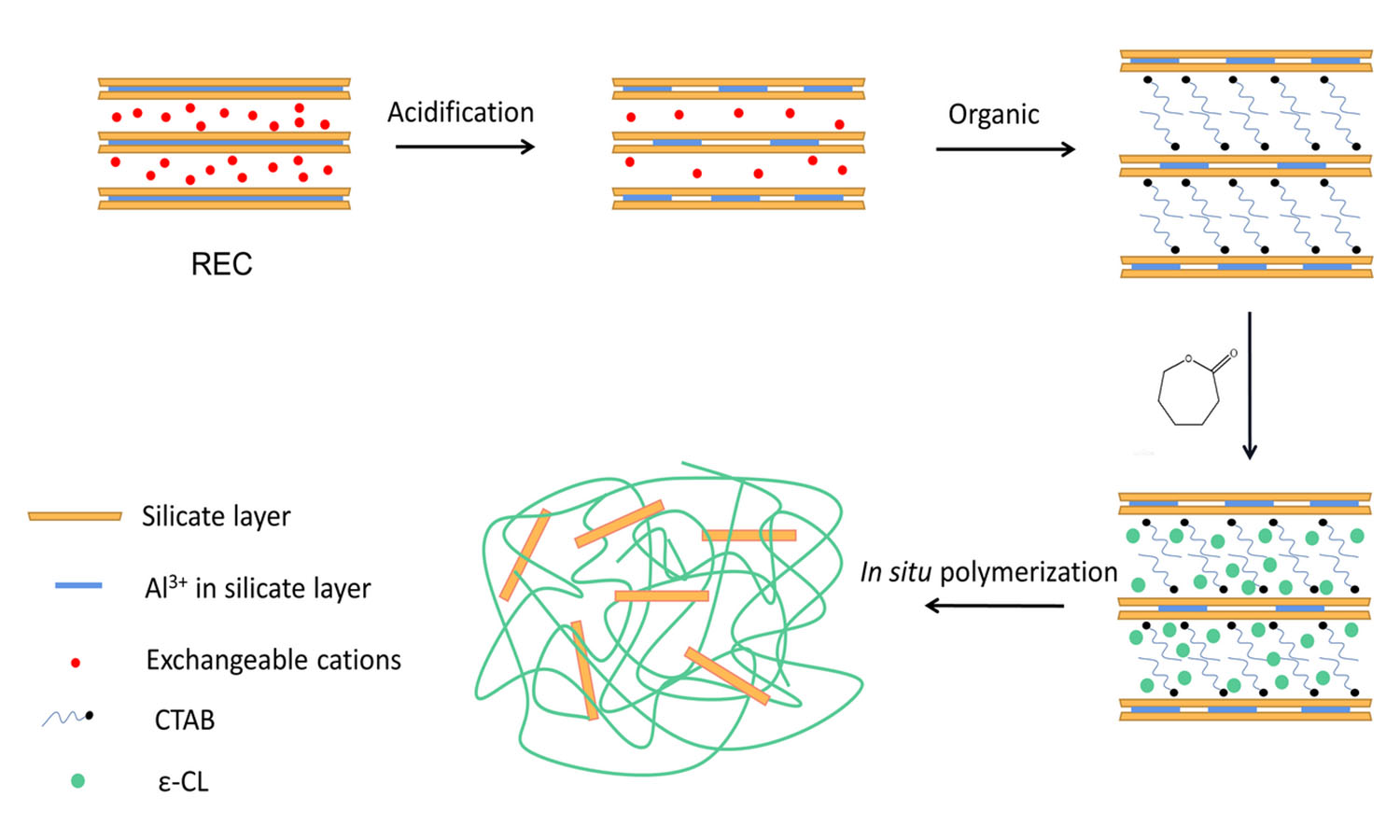

In recent years, solid polymer electrolytes (SPE) has attracted much attention because of its good safety and environmental stability, among which poly(ε-caprolactone) (PCL) based solid electrolyte film is one of the most potential materials. We have adopted the method of synthesizing polymer nanocomposites with natural clay, which can effectively meet the needs of electrolytes. In this study, cetyl trimethyl ammonium bromide (CTAB) was used to modify rectorite (REC), and the ε-CL monomer is inserted between the rectorite silicate layers. PCL/organic rectorite (OREC) nanocomposites were synthesized by in situ intercalation polymerization. The yield of the polymer nanocomposite could reach 93.6% when the molecular weight of the polymer nanocomposite was 39 000. The effects of OREC addition on the morphology, thermal stability, and electrochemical properties of PCL/OREC nanocomposites were investigated by various characterization methods. The temperature can be increased by 50 °C when the thermal decomposition is 50 wt%, and the crystallinity decreases by 4.6%. Composite polymerelectrolytes (CPEs) (PCL/OREC) showed a good electrical conductivity of 1.13·10–4 S·cm–1 at 60 °C and an excellent capacity retention rate of 96.7% after 100 cycles at 0.5 C current density. This study has important guiding significance for the development of polymer nanocomposites as solid electrolytes.

Janka Bobek-Nagy, Róbert Kurdi, András Kovács, Lilla Simon-Stőger, Márton Szigeti, Csilla Varga

Vol. 17., No.11., Pages 1166-1179, 2023

DOI: 10.3144/expresspolymlett.2023.88

Vol. 17., No.11., Pages 1166-1179, 2023

DOI: 10.3144/expresspolymlett.2023.88

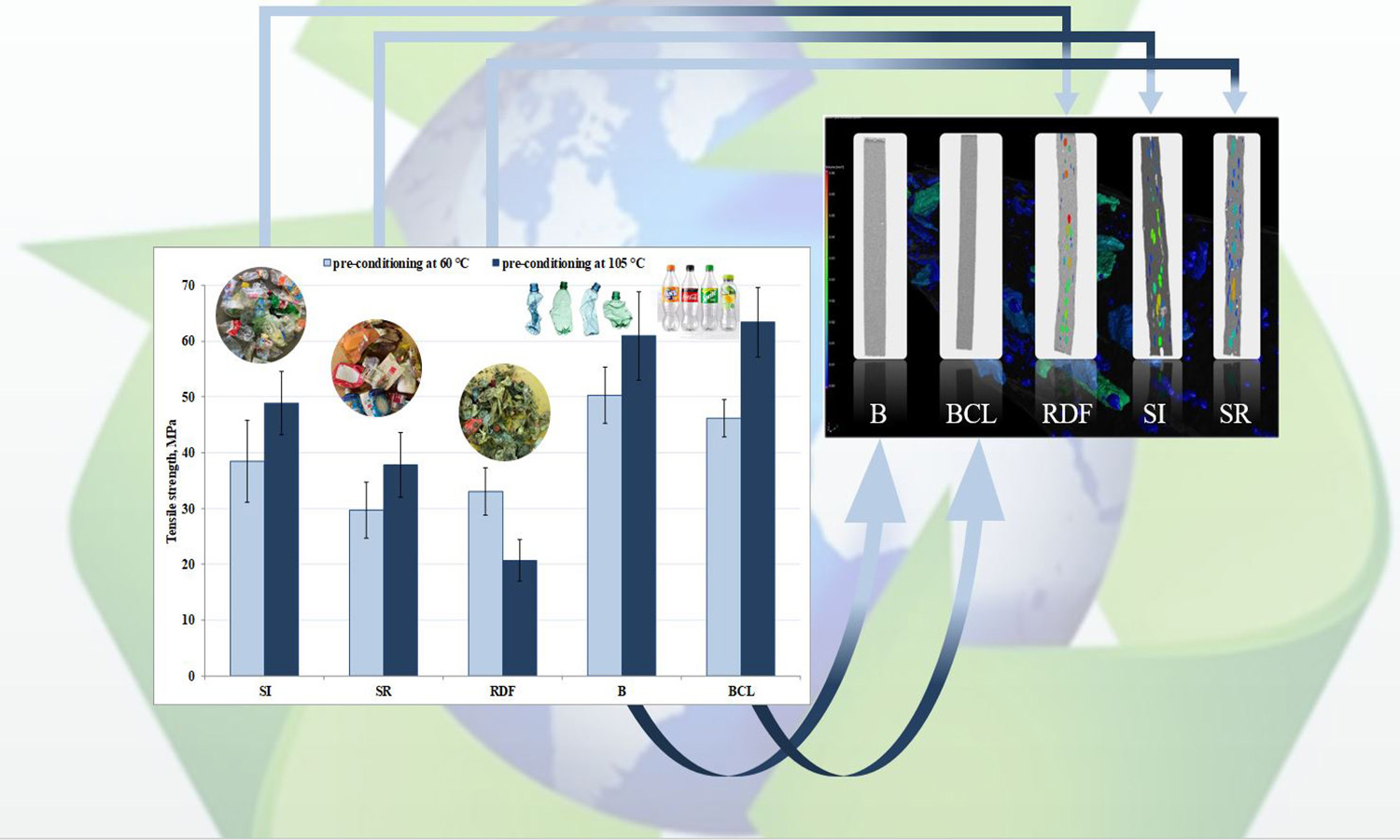

Under

the era of circular economy, the deposit-refund system (DRS) for e.g. polyethylene

terephthalate (PET) is thought to be a good choice to achieve a more structured

plastic recycling. The present research has the aim to make a comprehensive description

and a practical guideline in order to evaluate how collection and separation

system influence the quality and efficiency of mechanical recycling of PET. The

DRS has been symbolized by manually collected bottles with (BCL) and without

(B) caps and labels. Samples have been given from the selective income (SI) and

the sorting residue (SR) of a manual selective waste sorting plant and PET

fraction of refuse derived fuel (RDF). Based on preliminary qualification results

such as melt flow indices (MFI), PET bottles are worth selecting into the main

colours like water clear, blue, and all the others together, referred to as

PET-A, PET-B, and PET-D fractions of the sorting plant. The SR seemed to be a beneficial

raw material for PET recycling as both mechanical and rheological properties

were proper enough. PET separated from the Mechanical Biological Treatment

(MBT) plant as RDF showed the worst processing and mechanical properties, but

both can be improved with deeper precleaning. X-ray tomography (CT) scans have

shown a correlation between the source of waste and the gas void structure

which influence the macroscopic mechanical properties.