Content

All issues / Volume 18 (2024) / Issue 8 (August)

Stoyko Fakirov

Vol. 18., No.8., Pages 778-778, 2024

DOI: 10.3144/expresspolymlett.2024.57

Vol. 18., No.8., Pages 778-778, 2024

DOI: 10.3144/expresspolymlett.2024.57

This is an editorial article. It has no abstract.

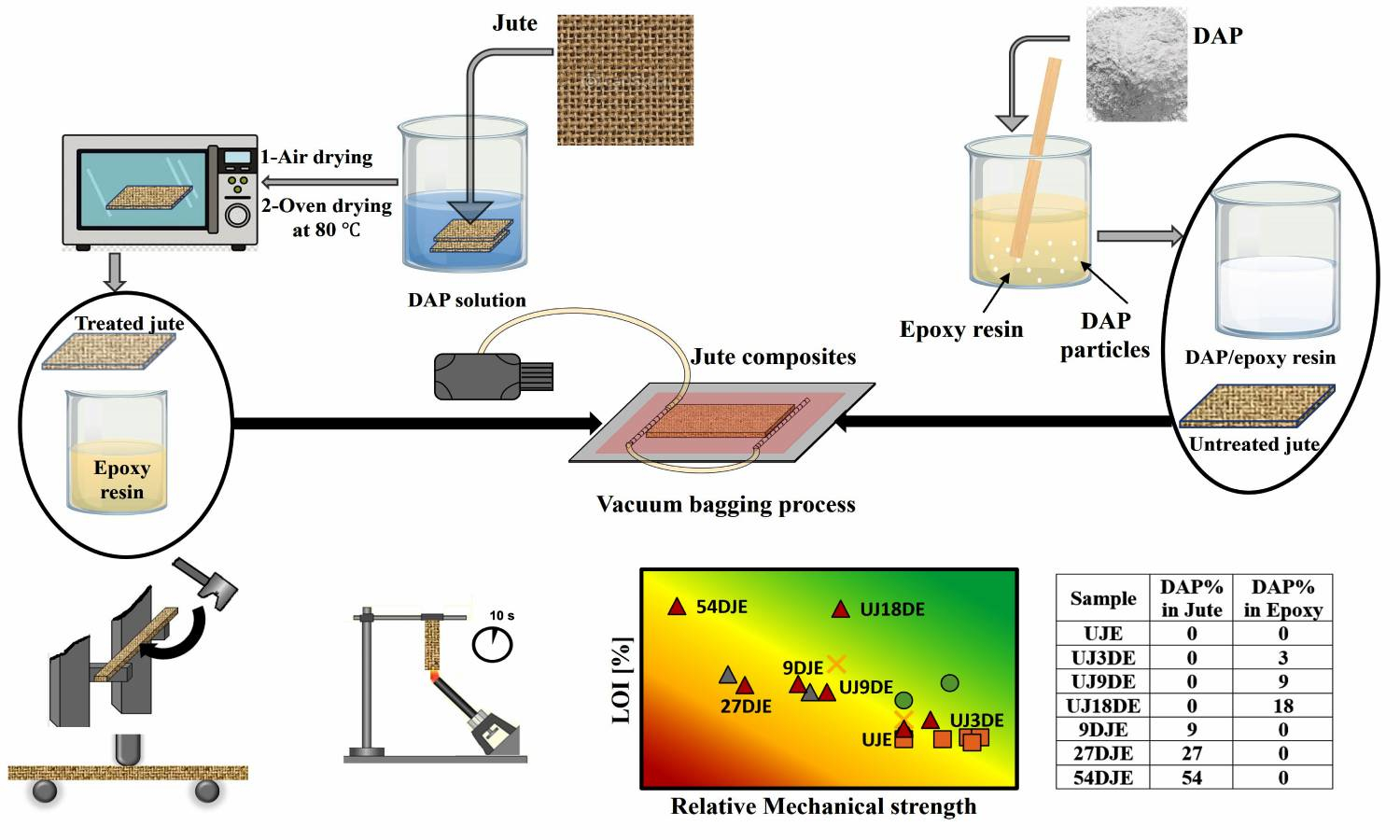

Noha Ramadan, Mohamed Taha, Ahmed Elsabbagh

Vol. 18., No.8., Pages 779-795, 2024

DOI: 10.3144/expresspolymlett.2024.58

Vol. 18., No.8., Pages 779-795, 2024

DOI: 10.3144/expresspolymlett.2024.58

Natural fibre-reinforced polymer composite (NFRPC) has been introduced as one of the solutions to overcome the ecological and environmental problems accompanying the widespread usage of polymeric materials in every facet of life. However, the organic nature of both natural fibres (NFs) and polymers increases their flammability behaviour, and this, in turn, limits their application. In this regard, this work concentrates on studying the effect of adding flame retardants (FR) to jute-reinforced epoxy composites (JRECs), either by treating the jute fabric with diammonium phosphate (DAP) or adding DAP powder to the epoxy resin matrix on the flame retardancy performance as well as the mechanical properties. The results showed that the effect of the incorporation method of DAP either to jute fabric or to resin matrix has a significant difference on the flammability test results at low concentrations; however, at higher concentrations, the flame retardancy performance is not affected by the technique of adding FR to the composite system. On the other hand, the mechanical properties are significantly affected by the method of incorporating FR to JRECs at all concentrations. Moreover, the results obtained from JRECs with FR systems were evaluated and compared with the literature by constructing selection charts that relate the flame retardancy level to mechanical properties.

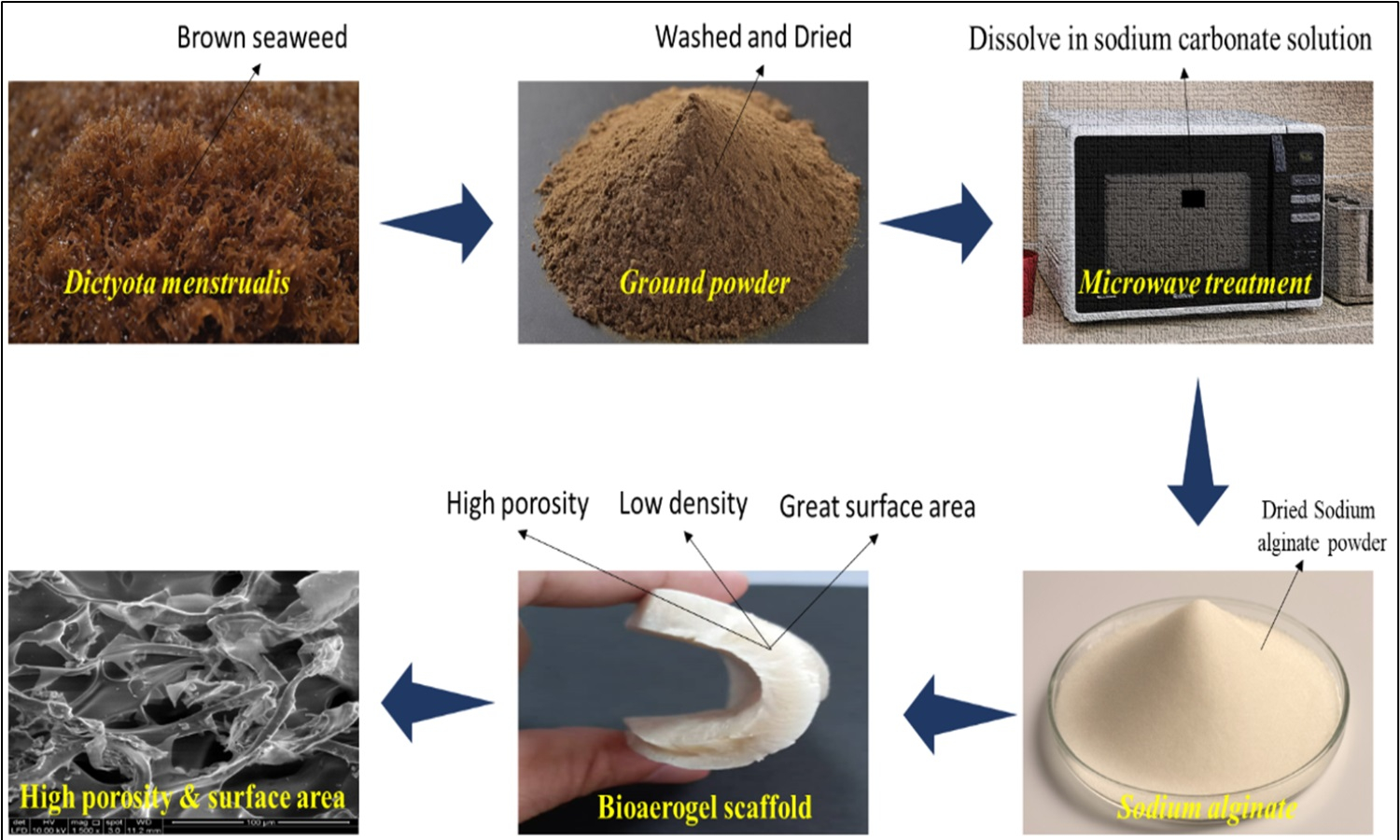

Abdul Khalil H. P. S., Abdussalam Giuma, Esam Bashir Yahya, Indra Surya, Arif Nuryawan, Tata Alfatah, Mardiana Idayu Ahmad

Vol. 18., No.8., Pages 796-806, 2024

DOI: 10.3144/expresspolymlett.2024.59

Vol. 18., No.8., Pages 796-806, 2024

DOI: 10.3144/expresspolymlett.2024.59

This study investigates the enhanced extraction of sodium alginate (SA) from Dictyota menstrualis using microwave-assisted techniques and its subsequent application in fabricating green thermal insulators. Utilizing optimized microwave parameters, we achieved a notable increase in SA yield, peaking at 18.5%, significantly higher than the 14.2% obtained through conventional methods. This process not only underscores the efficiency of microwave-assisted extraction by improving yield by approximately 30% but also highlights its environmental sustainability due to reduced solvent use and shorter processing times. The study demonstrates that increasing sodium alginate concentration from 1 to 5% enhances the mechanical strength and thermal insulation properties of bioaerogel scaffolds, evidenced by an increase in density from 0.171 to 0.234 g/cm3 and a decrease in porosity from 93.6 to 89.6%. Additionally, the thermal conductivity and diffusivity measurements of 0.065 W/(m·K) and 0.294 mm2/s, respectively, affirm the excellent thermal insulation stability of these scaffolds. The study demonstrates the potential of microwave-assisted extraction as a scalable and eco-friendly approach for biopolymer recovery, and the feasibility of using the extracted SA in creating effective, green thermal insulators, marking a significant step towards sustainable material development.

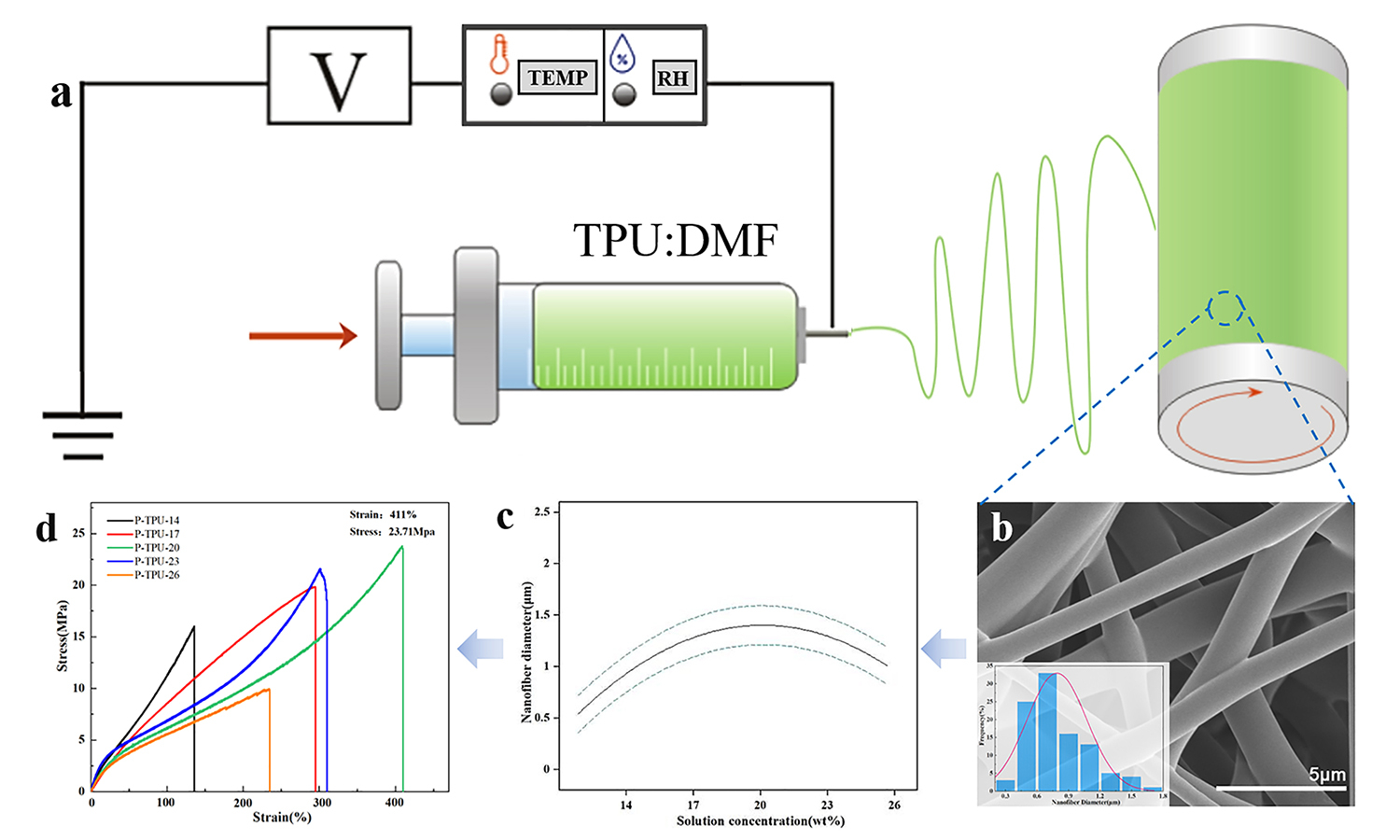

Lu Liu, Tian Luo, Xiaoju Kuang, Xiaoqian Wan, Xinhua Liang, Gaoming Jiang, Honglian Cong, Haijun He

Vol. 18., No.8., Pages 807-818, 2024

DOI: 10.3144/expresspolymlett.2024.60

Vol. 18., No.8., Pages 807-818, 2024

DOI: 10.3144/expresspolymlett.2024.60

Thermoplastic polyurethanes (TPU) have attracted increasing attention due to their excellent flexibility, chemical stability, processability and greenness. The traditional processes generally limit them to civil and industrial applications, but electrospun TPU nanofibers with high porosity, high specific surface area and superior mechanical properties are promising in emerging fields. TPU nanofibers’ properties are affected by various electrospinning parameters, such as solution concentration, applied voltage, flow rate and rotational speed. Thus, 29 sets of experiments were designed here by the efficient and low-cost response surface methodology (RSM). The analysis of variance (ANOVA) revealed that the model agrees well with experimental results, and solution concentration is the most crucial parameter affecting nanofibers’ morphology and diameter. Based on it, the impacts of solution concentration and orientation on the mechanical properties of the TPU nanofiber membrane were investigated. Benefiting from the stress transfer and network deformation, the TPU nanofiber membranes parallel to the collection direction possessed the highest stress strength (23.71 MPa), while the nanofiber membranes vertical showed the widest strain range (485%). This study provides useful guidance for the preparation of high-performance TPU nanofibers, contributing to expanding its applicability in emerging fields such as biomedical, filtration and separation, and flexible sensing.

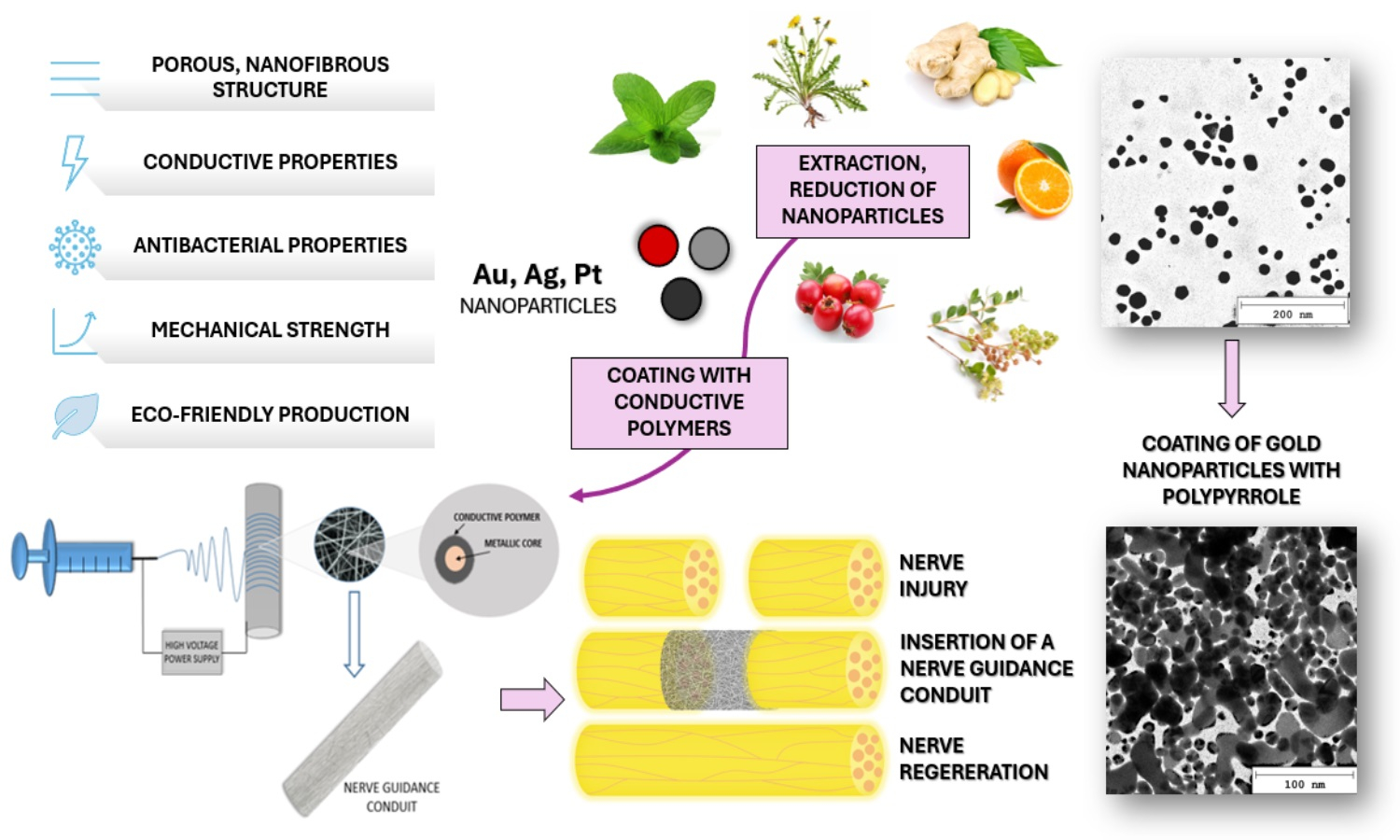

Aleksandra Sierakowska-Byczek, Julia Radwan-Pragłowska, Łukasz Janus, Tomasz Galek, Karol Łysiak, Mirosław Tupaj, Dariusz Bogdał

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Vol. 18., No.8., Pages 819-834, 2024

DOI: 10.3144/expresspolymlett.2024.61

Appropriate protection and guiding are crucial during peripheral nerves repair. New generation nerve guidance conduits (NGCs) should not only provide mechanical support for the damaged nerve but also support healing processes. One of the most promising tissue regeneration applications is fibrous biomaterials since they are characterized by high porosity, flexibility, and strength. Additionally, they enable cell adhesion and proliferation. In this study, novel fibrous nanocomposites were obtained by applying the electrospinning technique, using polylactic acid (PLA) as a polymeric matrix which was further modified with metallic nanoparticles coated with conductive polymers. Such an approach resulted in the obtainment of biomaterials with a potential ability to conduct nerve impulses. The chemical structure of the obtained composites, as well as the morphology of ready products and separate nanocomponents, were investigated using Fourier-transform infrared spectroscopy (FTIR), transmission electron microscope (TEM) and scanning electron microscope (SEM) techniques. Furthermore, conductive and swelling properties in various media were determined. Finally, biomaterials were confirmed to be non-cytotoxic to L929 mouse fibroblasts and 1321N1 human glial cells. Based on the presented results, it can be concluded that nanofibrous nerve guidance conduits have all the key properties in the process of peripheral nerve regeneration and may constitute an important step in novel NGCs development.

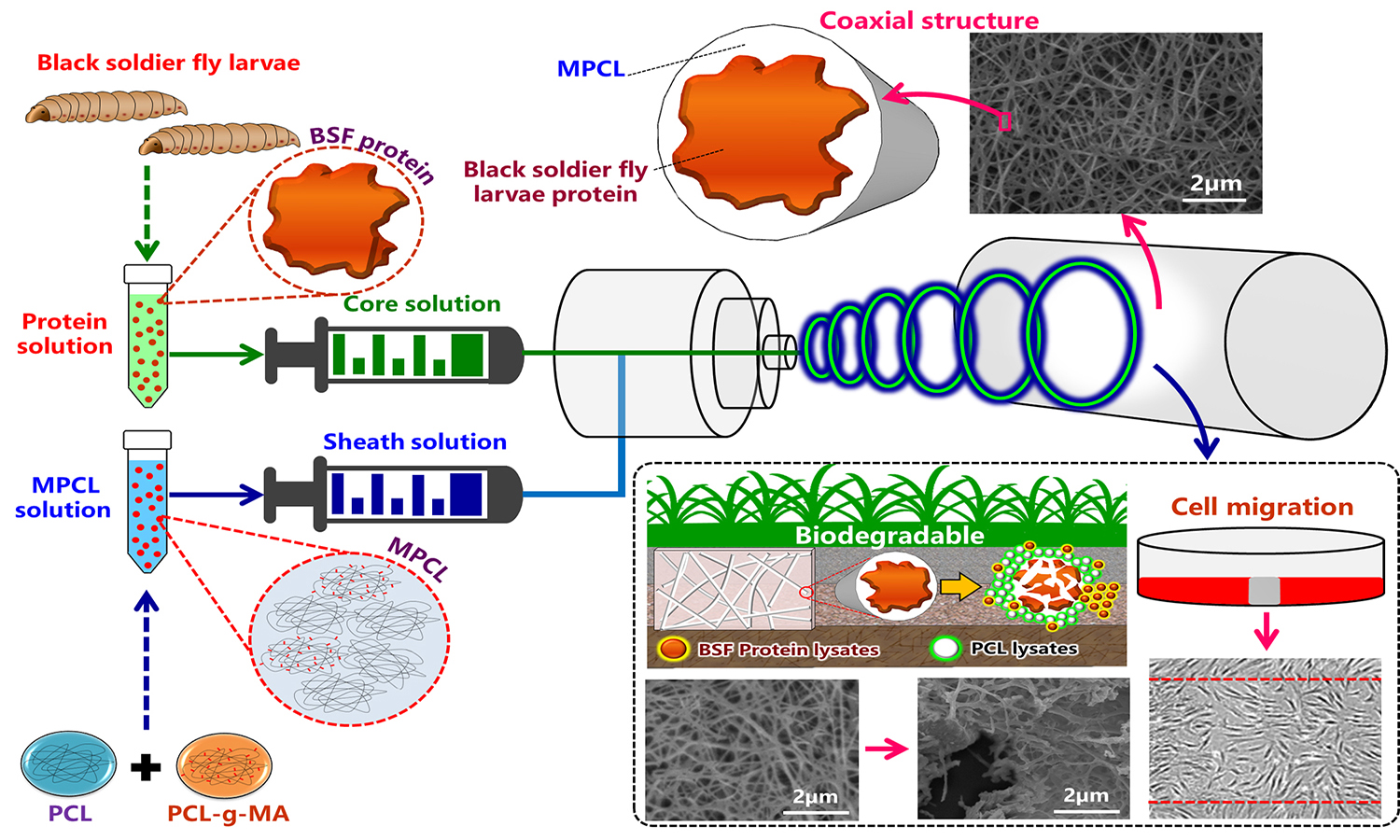

Chin-San Wu, Shan-Shue Wang, Dung-Yi Wu, Wanwen Gu

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

Vol. 18., No.8., Pages 835-850, 2024

DOI: 10.3144/expresspolymlett.2024.62

The protein from black soldier fly larvae was used as a functional ingredient of a novel green nanofiber. Larvae protein powder (LP) was blended with biodegradable poly(ε-caprolactone) (PCL) and processed in an electrospinning machine using a coaxial feeding/mixing method to produce nanofibers approximately 100–350 nm in diameter. To improve the dispersion and interface bonding of various PCL/LP nanofiber components, a homemade compatibilizer, maleic anhydridegrafted poly(ε-caprolactone) (MPCL), was added to form MPCL/LP nanofibers. The structure, morphology, mechanical properties, water absorption, cytocompatibility, wound healing, and biodegradability of PCL/LP and MPCL/LP nanofiber mats were investigated. The results showed enhanced adhesion in the MPCL/LP nanofiber mats compared to PCL/LP nanofiber mats; additionally, the MPCL/LP nanofibers exhibited increases of approximately 0.7–2.2 MPa in breaking strength and 9.0–22.8 MPa in Young’s modulus. Decomposition tests using a simulated body fluid revealed that the addition of LP enhanced the decomposition rate of both PCL/LP and MPCL/LP nanofiber mats and in vitro protein release. Cell proliferation and migration analysis indicated that PCL, MPCL, and their composites were biocompatible for fibroblast (FB) growth. Biodegradability was tested in a 30 day soil test. When the LP content was 20 wt%, the degradation rate exceeded 50%.

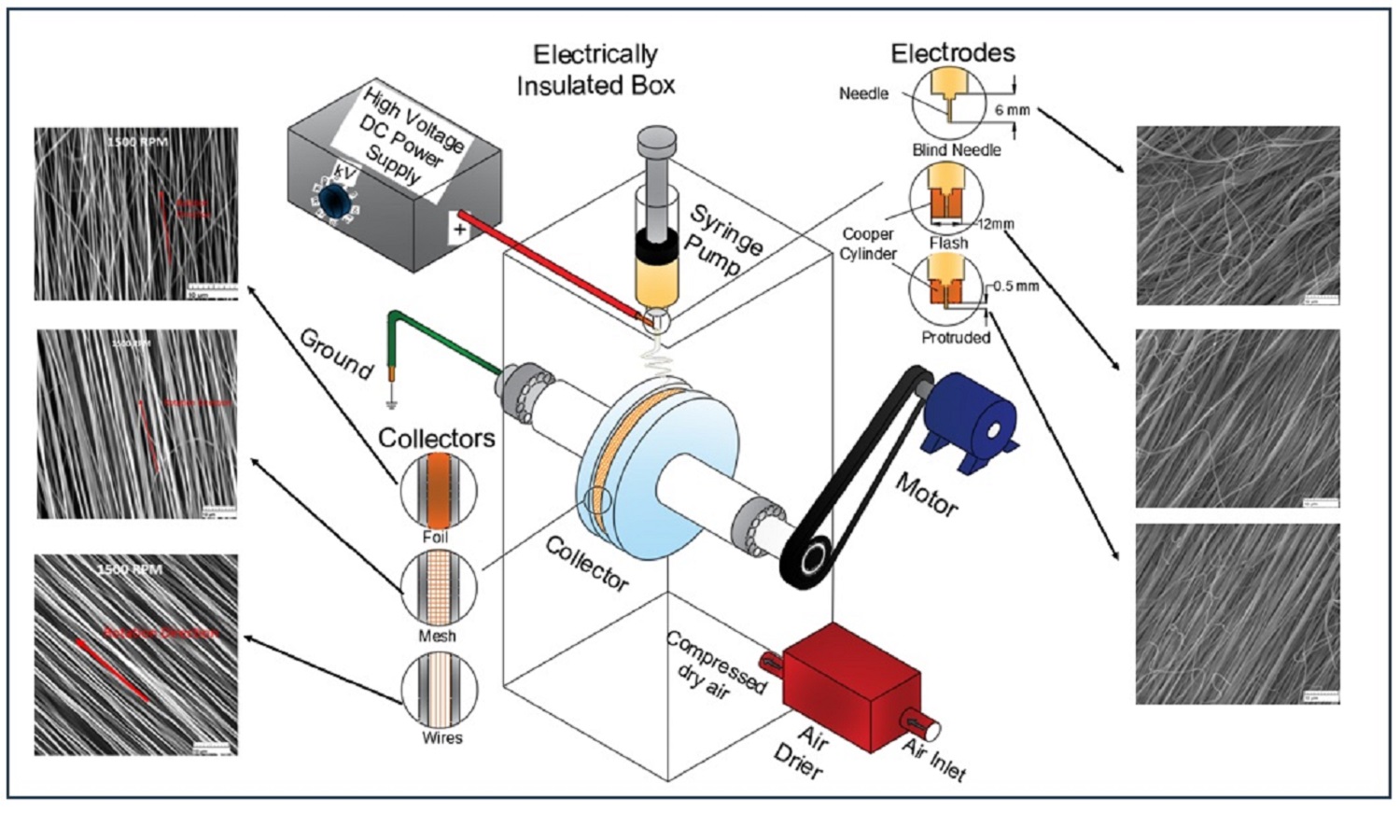

Mehmet Selim Demirtaş, Mrinal C. Saha

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

Vol. 18., No.8., Pages 851-867, 2024

DOI: 10.3144/expresspolymlett.2024.63

Nanomaterials, particularly nanofibers produced through electrospinning, have garnered significant attention due to their unique properties and diverse applications. This research explores the influence of collector design, electrode geometry, and collector speed on the properties of electrospun polyacrylonitrile (PAN) nanofibers. Finite element analysis (FEA) was employed to simulate electric fields, revealing the impact of collector geometry on field intensity. The experimental setup, enclosed in an isolated chamber, employed various collector types and electrode configurations. Scanning electron microscope (SEM) analysis showcased the effect of collector speed on fiber alignment and diameter. Furthermore, FEA simulations elucidated the role of electrode geometry and voltage in shaping the electric field, impacting fiber properties. The study introduces a novel, in-house method for producing highly aligned nanofibers and provides insights into optimizing electrospinning parameters for enhanced fiber properties. A testing protocol is devised to minimize surface damage when conducting mechanical tests on nanofiber films, employing a dynamic mechanical analyzer (DMA). Mechanical testing demonstrated the correlation between alignment and tensile strength. Overall, this research contributes valuable insights for tailoring electrospinning processes for tissue engineering and energy storage.

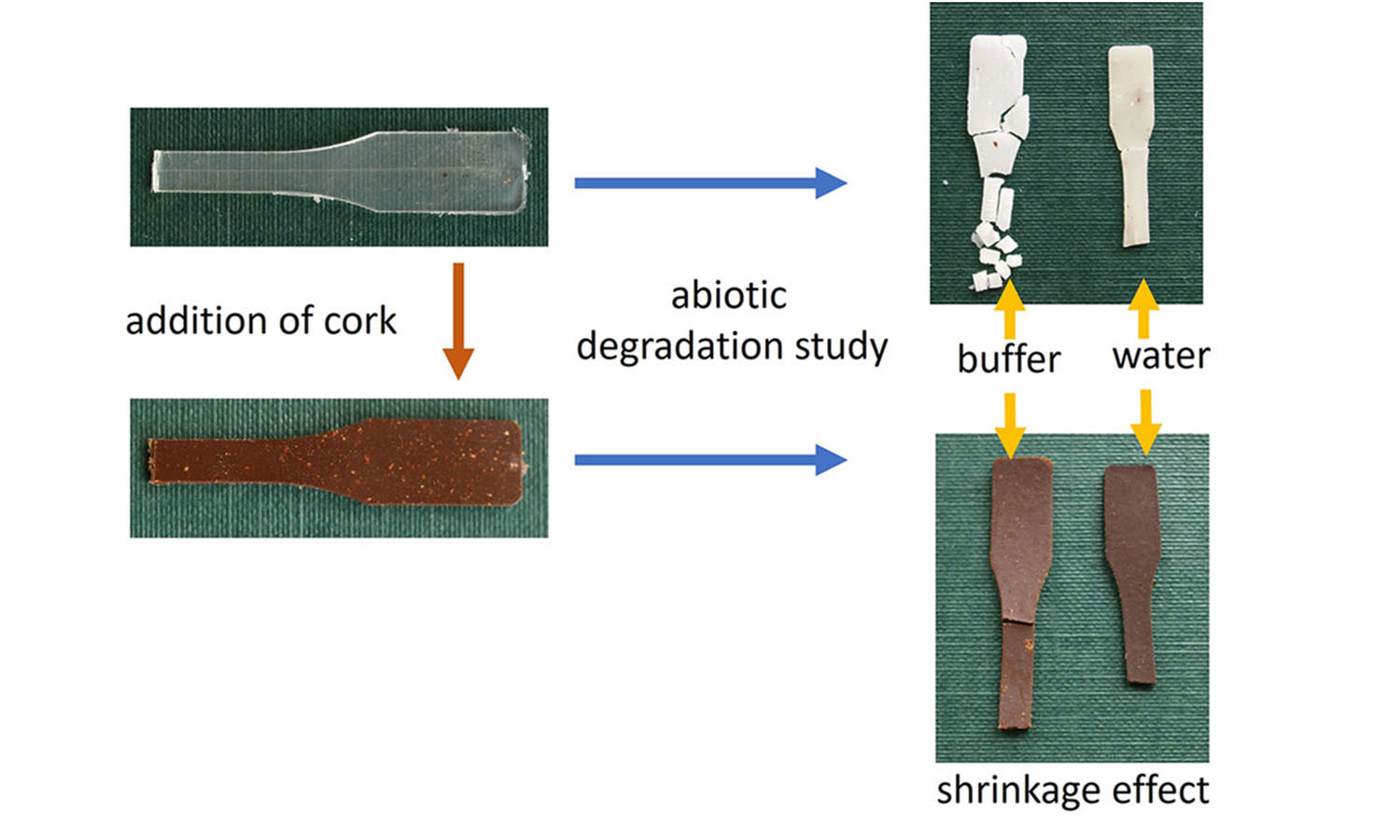

Marta Musioł, Joanna Rydz, Wanda Sikorska, Henryk Janeczek, Sebastian Jurczyk

Vol. 18., No.8., Pages 868-880, 2024

DOI: 10.3144/expresspolymlett.2024.64

Vol. 18., No.8., Pages 868-880, 2024

DOI: 10.3144/expresspolymlett.2024.64

The drastic increase in the amount of packaging waste from conventional plastics, caused by improper waste management, is a serious challenge for the planet. It is therefore worth considering how we can solve this problem. Thus, it is necessary to develop new polymeric materials that retain the functional properties of traditional plastics but are susceptible to degradation with the participation of microorganisms. The development of new eco-friendly materials requires a holistic approach in terms of their disposal. Organic recycling enables the disposal of biodegradable packaging along with food remains that are difficult to remove. The article presents a study on the degradation of biocomposites of polylactide with cork in various environments (water, buffer, and compost). The obtained results indicate a clear influence of the presence of the filler and its amount on the degradation profile of the composites. In addition, the effect of sample shrinkage was observed, especially during degradation in water, where the pH decreases during the process due to the appearance of degradation products. This effect may be important not only for the degradation profile of the packaging but also during its use. Packaging distorted due to shrinkage may be a sign of improper product storage.