Content

All issues / Volume 18 (2024) / Issue 5 (May)

Andrea Kohári, Tamás Bárány

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

Vol. 18., No.5., Pages 459-460, 2024

DOI: 10.3144/expresspolymlett.2024.33

This is an editorial article. It has no abstract.

Cansu Börüban Bingöl, Şeyda Polat, Ş. Hakan Atapek

Vol. 18., No.5., Pages 461-474, 2024

DOI: 10.3144/expresspolymlett.2024.34

Vol. 18., No.5., Pages 461-474, 2024

DOI: 10.3144/expresspolymlett.2024.34

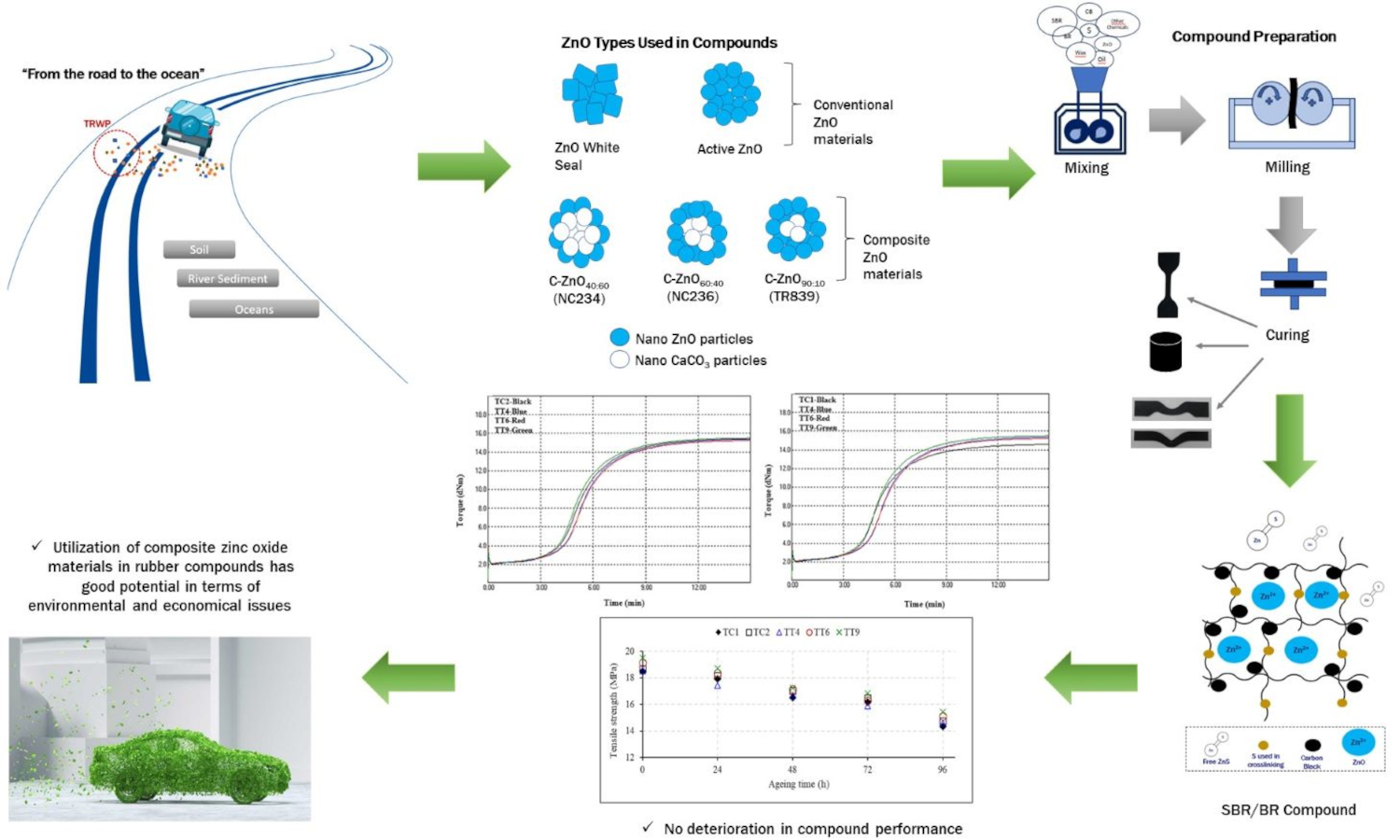

Zinc complexes have a considerable impact on human health and the environment, especially on aquatic wildlife. One of the primary sources of zinc release to the environment is worn rubber particles from tires. The environmental footprint of zinc oxide (ZnO) during production, use, and landfilling has prompted researchers to reduce its use in rubber formulations due to ecological and economic concerns. In this study, composite ZnO materials where ZnO particles are coated on precipitated calcium carbonate (CaCO3) are used in styrene butadiene rubber/butadiene rubber (SBR/BR) compounds, and their performance is compared with white seal ZnO and active ZnO. Trial compounds are prepared on a laboratory scale using composite ZnO materials with ZnO:CaCO3 ratios of 40:60, 60:40, and 90:10, and control compounds with white seal and active ZnO. All compounds are tested to evaluate their curing and physico-mechanical properties. It is observed that the surface area of ZnO plays an essential role in crosslink density and, hence, compound performance. Trial materials have no negative effect on the curing and mechanical properties of the compounds. Thus, it is concluded that composite ZnO materials can be used as alternatives to both white seal ZnO and active ZnO. They have environmental and economic advantages due to their lower ZnO content. The compound recipe has the potential to be used for tire tread compounds.

Wei-Hsiang Lin, Chang-Mou Wu, Shamik Chaudhuri, Ta-Chung An, Po-Hsun Huang

Vol. 18., No.5., Pages 475-486, 2024

DOI: 10.3144/expresspolymlett.2024.35

Vol. 18., No.5., Pages 475-486, 2024

DOI: 10.3144/expresspolymlett.2024.35

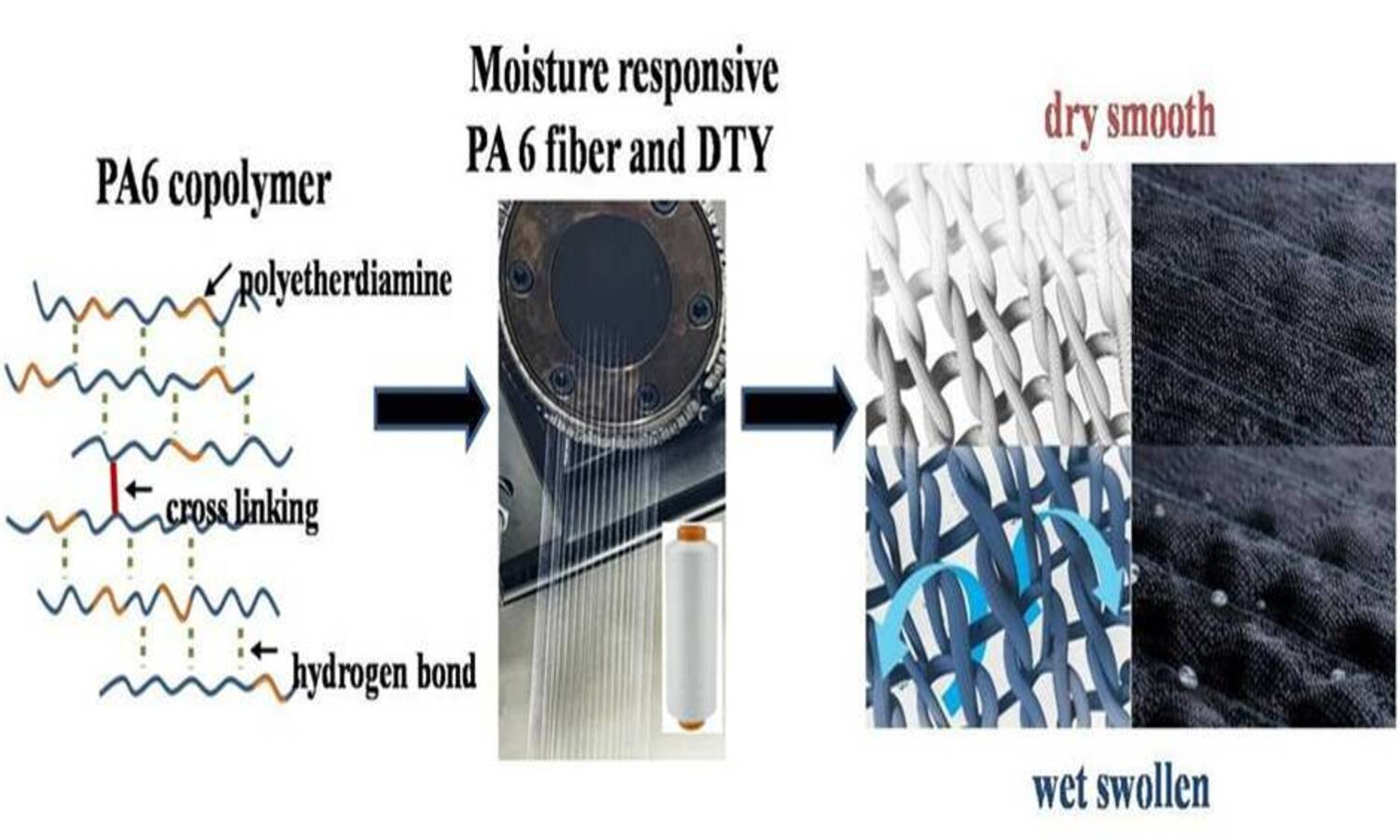

Smart materials represent an emerging and highly exploited category, particularly in the creation of textiles that can sense and respond to various external stimuli, such as temperature or humidity. This study introduces for the first time the hygroscopic elongation and drying shrinkage properties of stimulus-responsive single-component polyamide (PA) fibers copolymerized with polyetherdiamine and diethylenetriamine (DETA). PA copolymers containing 5–15% polyetherdiamine were comprehensively characterized, including nuclear magnetic resonance spectroscopy (NMR), Fourier transform infrared spectroscopy (FT-IR), relative viscosity, and differential scanning calorimetry (DSC) analyses. Subsequently, these PA copolymers were successfully melt-spun into fibers and knitted into double-layered fabrics. PA fibers containing 15% polyetherdiamine showed significant results, with a moisture-absorbing elongation of 15.6% and a drying shrinkage of 94.9%. The Qmax and moisture regain of the PA fabric are 0.206 W·cm–2 and 4.4%, respectively. These moisture-driven, fiber-based smart textiles exhibit changes in breathability and shape retention at different humidity levels, thereby maintaining a more comfortable microclimate. Such textiles have great potential for widespread use in clothing, helping to improve comfort and adaptability.

Charoen Nakason, Chanida Manleh, Natinee Lopattananon, Azizon Kaesaman

Vol. 18., No.5., Pages 487-503, 2024

DOI: 10.3144/expresspolymlett.2024.36

Vol. 18., No.5., Pages 487-503, 2024

DOI: 10.3144/expresspolymlett.2024.36

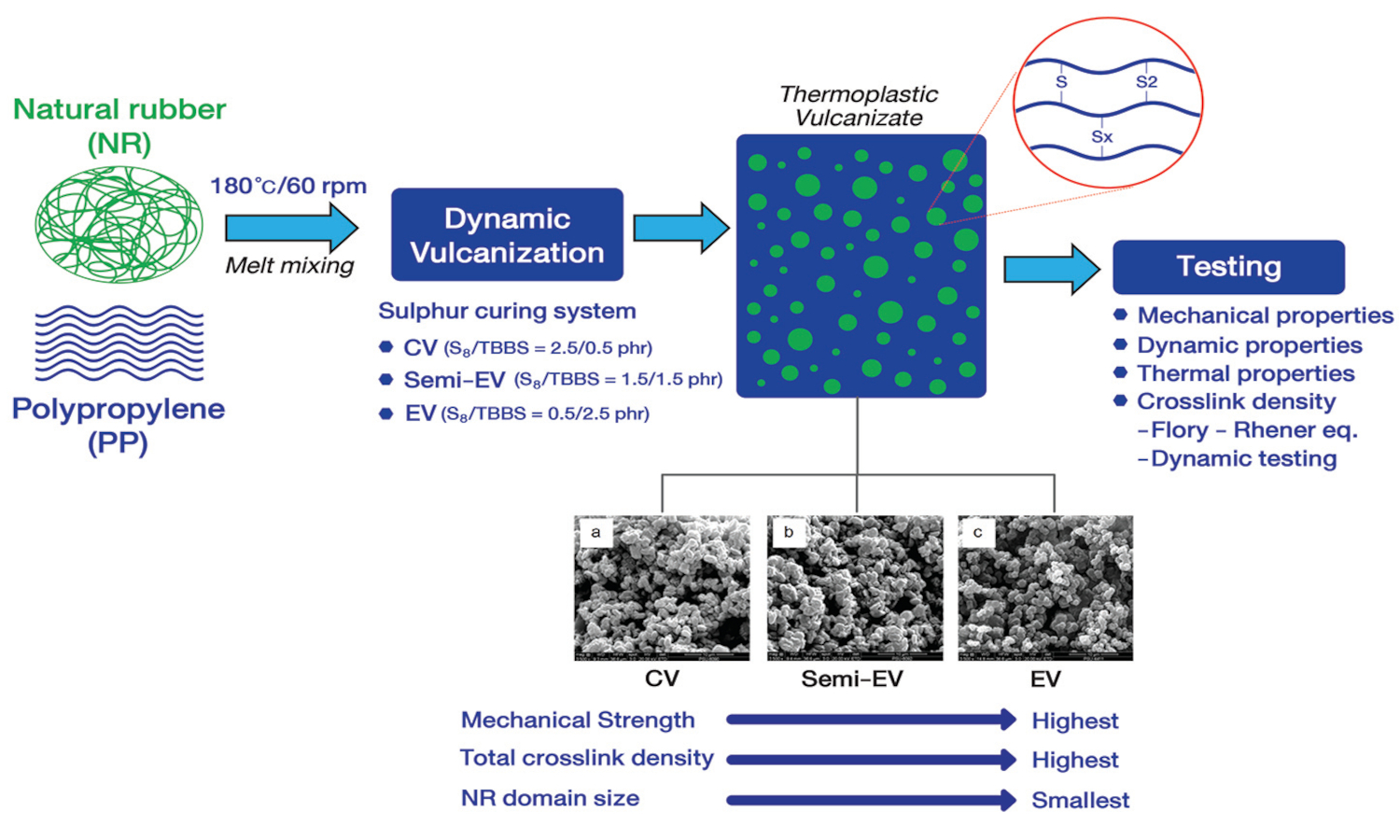

Thermoplastic

vulcanizates (TPVs) were prepared by blending natural rubber (NR) and

polypropylene (PP) using dynamic sulfur curing systems with varying

accelerator/sulfur ratios: 0.5/2.5, 1.5/1.5, and 2.5/0.5 phr, categorized as

conventional (CV), semi-efficient (semi-EV), and efficient (EV). The onset of

dynamic vulcanization closely corresponded with scorch time in statically cured

NR compounds. Mixing torque decreased over time, reflecting reversion patterns

in static curing. The CV system exhibited the highest reversion tendency due to

polysulfide linkage breakdown, forming stronger but shorter crosslinks. Dynamic

vulcanization induced higher reversion than static curing, influenced by shear

and extensional forces. Curing systems caused crosslinking rates, reversion,

and crosslink density and distribution variations. Unlike statically cured NR,

PP-extracted TPVs exhibited an inverse trend in total crosslink densities and

distributions; TPVs primarily comprised shorter crosslinks with opposed total

crosslink densities ranked EV > semi-EV > CV. This trend is strongly

correlated with superior mechanical strength, toughness, storage modulus,

viscosity, and rubber elasticity in the EV-cured TPV. EV system also had the

smallest vulcanized NR domains in the PP matrix.

Ruedee Jaratrotkamjorn, Abdulhakim Masa

Vol. 18., No.5., Pages 504-515, 2024

DOI: 10.3144/expresspolymlett.2024.37

Vol. 18., No.5., Pages 504-515, 2024

DOI: 10.3144/expresspolymlett.2024.37

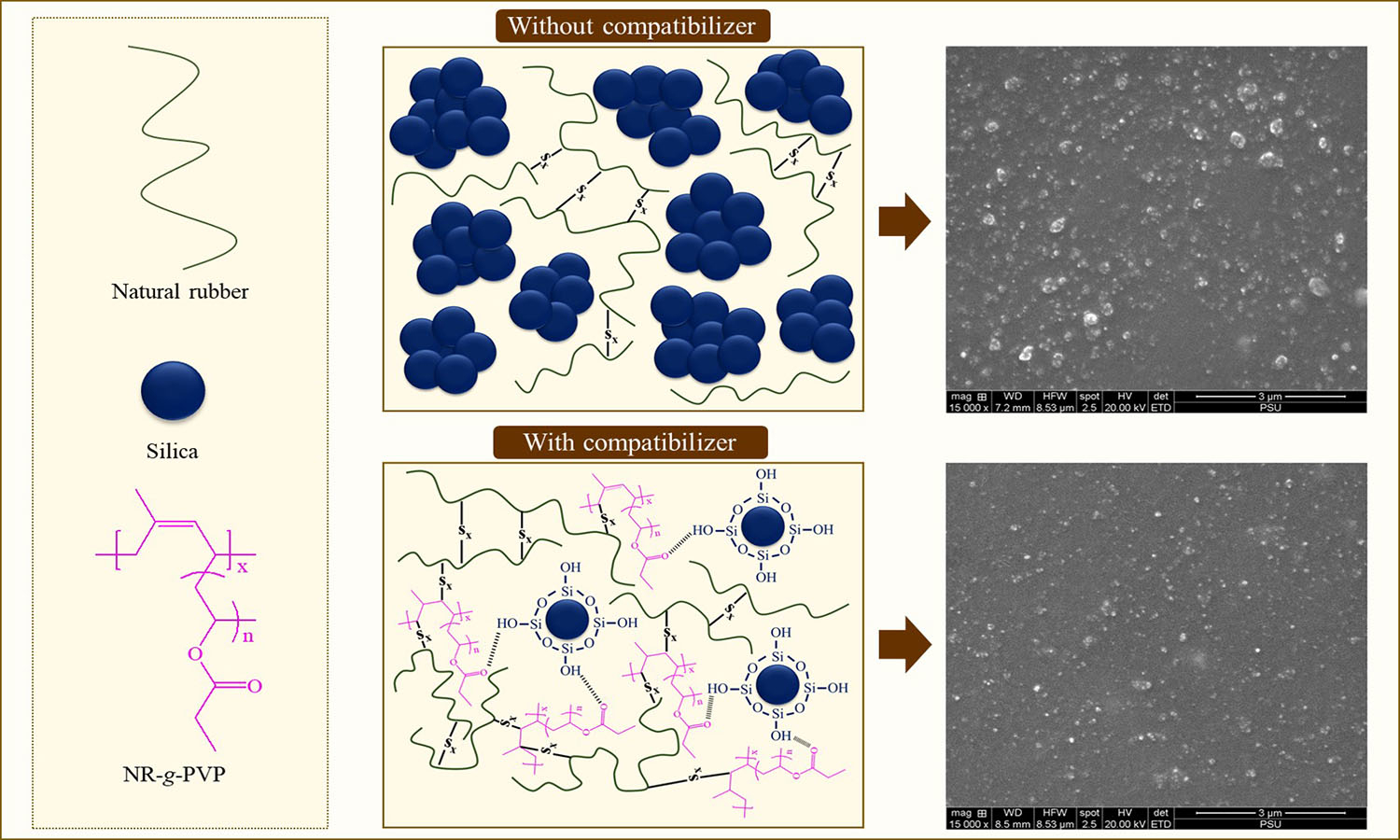

This work presents the use of natural rubber (NR) grafted with poly(vinyl propionate) (NR-g-PVP) as an alternative compatibilizer in silica-filled NR compounds. The effects of NR-g-PVP with 10, 20 and 30% grafting on the properties of NR compounds were studied and compared with a commercial coupling agent (bis[3-(triethoxysilyl)propyl] tetrasulfide, TESPT). NR-g-PVP was compatible with silica and NR. The NR-g-PVP reduced filler-filler interactions and increased fillerrubber interactions. The crosslink density decreased with the percentage of grafting due to the steric hindrance. The compatibilization affected the physical and mechanical properties. The interactions of NR-g-PVP with silica via hydrogen bonding and subsequent vulcanization prevented undesirable filler-filler interactions and reduced the absorption of accelerators or basic materials. It caused a good dispersion of silica in the NR matrix and improved physical and mechanical properties. A 10% grafting (G10) was suitable for the compatibilizer in a silica-filled NR compound, showing the largest improvements in tensile properties, tear strength, and hardness. However, TESPT provided better properties than G10.

Maciej Kisiel, Weronika Zając, Magdalena Włodarska, Łukasz Byczyński, Dominika Czachor-Jadacka, Beata Mossety-Leszczak, Gabriela Pietruszewska, Magda Droździel-Jurkiewicz, Jarosław Bieniaś

Vol. 18., No.5., Pages 516-532, 2024

DOI: 10.3144/expresspolymlett.2024.38

Vol. 18., No.5., Pages 516-532, 2024

DOI: 10.3144/expresspolymlett.2024.38

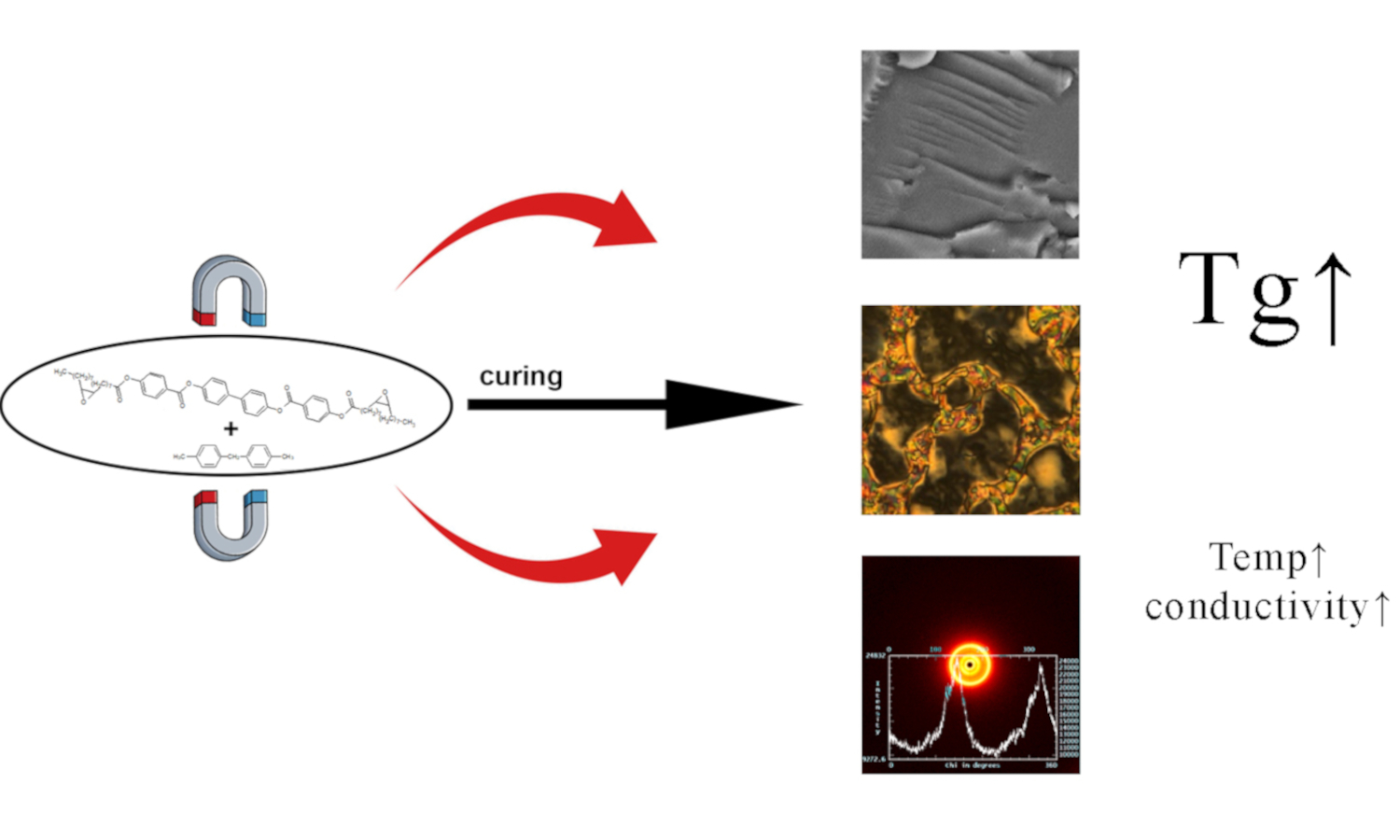

Novel nonterminal liquid crystalline epoxy resin has been synthesized, and its structure and nature have been determined via nuclear magnetic resonance (NMR) and polarized optical microscopy (POM). Then, it was cured with the use of 4,4′-diaminodiphenylmethane (4,4′-DDM). The curing process has been investigated via differential scanning calorimetry (DSC) and infrared spectroscopy (FTIR) methods. Polymerization has been conducted with (1.2 T) and without the presence of a strong magnetic field. The properties of the obtained polymers have been described using DSC, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), dielectric spectroscopy (DS) and X-ray scattering studies (WAXS/SAXS). It has been proved that the magnetic field induces molecular ordering and increases the glass transition temperature (Tg) by over 20 °C. The obtained ordered polymers are thermally stable up to over 300 °C, undergo vitrification at slightly elevated temperature (37.5 °C), and their electrical conductivity rises significantly at the transition to an elastic state, which, among other possibilities, makes them a proper candidate for a smart, lightweight polymers with tuneable properties by a subtle temperature rise and possibility of tailoring its structure by a magnetic field.

Ashwini Rayar, Naveen Chikkahanumajja Surendranatha, Honnebagi Shivamurthy Onkarappa, Pradeep Heregangur Keshavamurthysetty, Prasanna Gunderi Dhananjaya

Vol. 18., No.5., Pages 533-545, 2024

DOI: 10.3144/expresspolymlett.2024.39

Vol. 18., No.5., Pages 533-545, 2024

DOI: 10.3144/expresspolymlett.2024.39

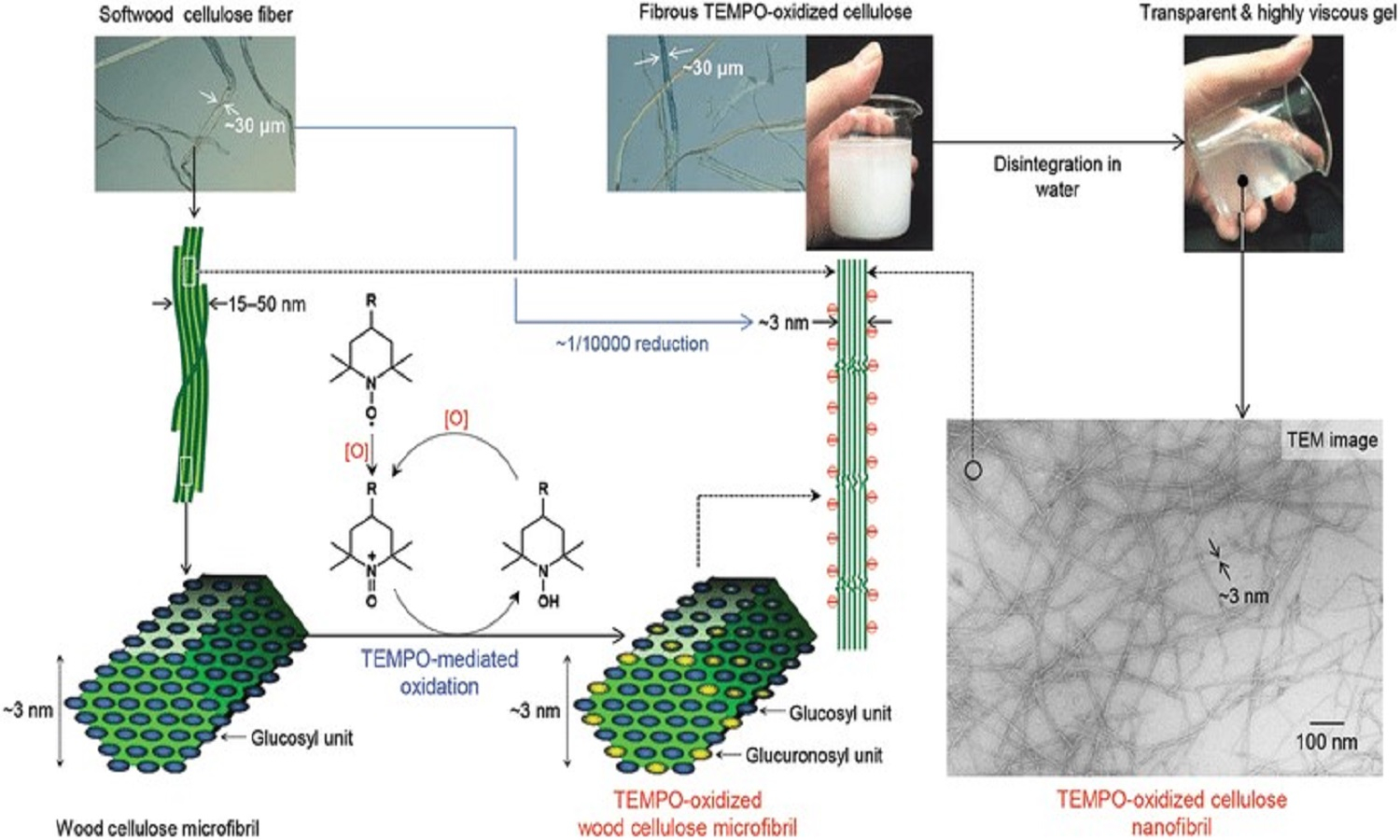

Controlled

development of novel materials fosters innovation in the electrical sector. The

hybrid materials based on magnetic nanocellulose are intriguing since they have

many uses in electronics, catalysis, medicine, and ecology. The study

investigated the structure and morphology of hybrid nanomaterials made from

nanocellulose and cobalt ferrite. The nanocellulose was prepared by

TEMPO-oxidation and the cobalt ferrite was prepared by sol-gel auto-combustion

method. Using X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy

(FTIR) techniques, it was determined how nanocellulose loading affected the

crystal structure of the synthesized composite. To ascertain the variation in

the component concentrations, scanning electron microscope (SEM) and

energy-dispersive X-ray analysis (EDAX) are used. Composite with a higher

concentration of nanocellulose fibers (NCF) show lesser particle size, and this

may account for the smaller size of nanocellulose fibers, and attachment of

nanocellulose nanofibers over the surface of porous cobalt ferrite (CF) found in

SEM images.

Nabil Hayeemasae, Siriwat Soontaranon, Abdulhakim Masa

Vol. 18., No.5., Pages 546-558, 2024

DOI: 10.3144/expresspolymlett.2024.40

Vol. 18., No.5., Pages 546-558, 2024

DOI: 10.3144/expresspolymlett.2024.40

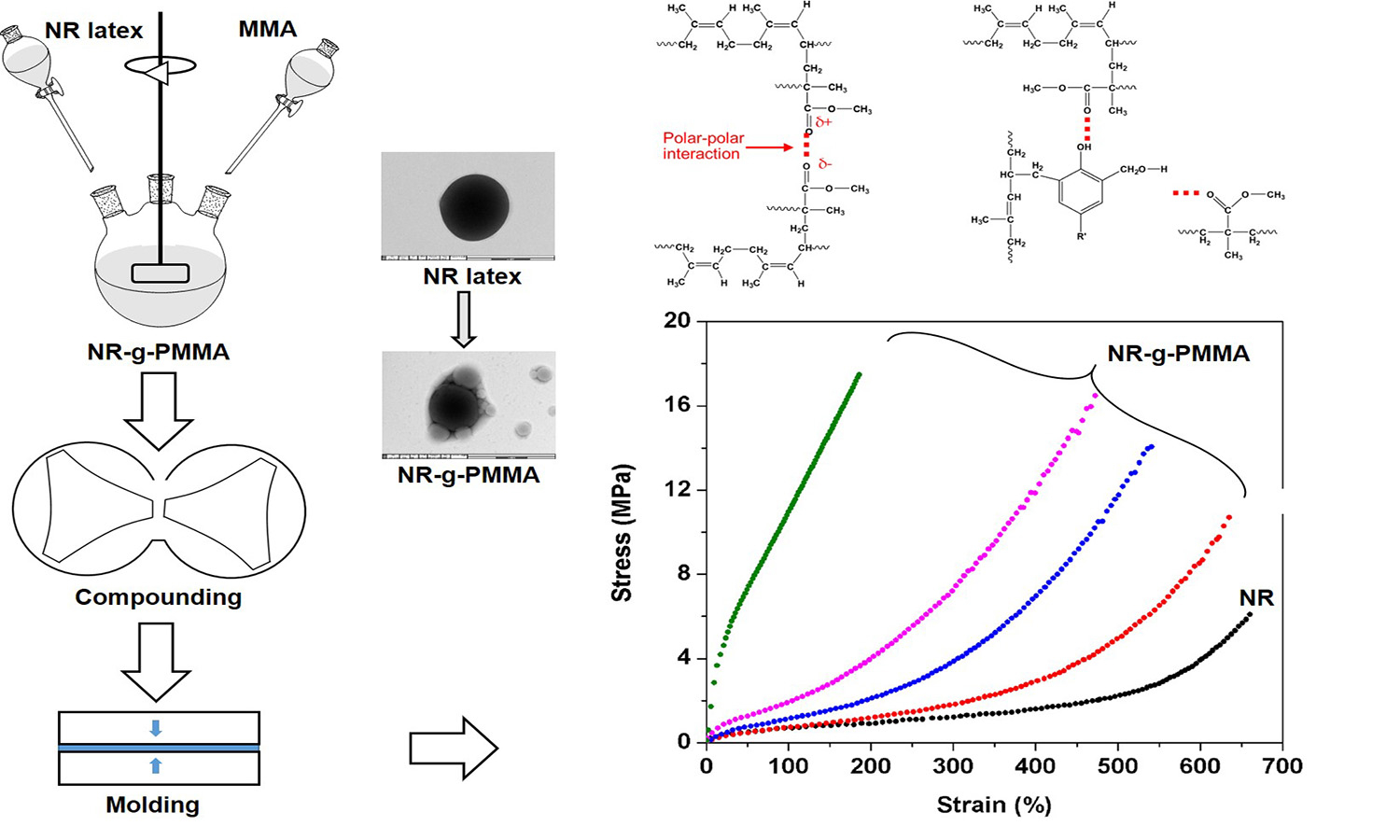

The structure and property relationships of graft copolymers from natural rubber (NR) and polymethyl methacrylate (PMMA) crosslinked with a phenolic resin were investigated. The NR grafted with PMMA (NR-g-PMMA) having different grafting levels was initially prepared by emulsion polymerization before compounding and vulcanization. Then, proton nuclear magnetic resonance and transmission electron microscopy were used to verify the resultant NR-g-PMMAs. The graft copolymers crosslinked with phenolic resin exhibited improvements in various properties. Tensile modulus and tensile strength increased at least 18 and 95%, respectively, over the un-grafted counterpart and further improved with grafting percentage, while the elongation at break decreased accordingly. Storage modulus in rubbery plateau increased while tanδ peak height decreased with PMMA content. Moreover, the thermal stability of the graft copolymers was also improved over that of the plain NR at least 23 °C, depending on MMA contents. These improvements are tentatively attributed to the strong adhesion between NR and PMMA phases, based on interactions between the functional groups of PMMA and hydrogen bonding between phenolic resin crosslinker and PMMA. The results clearly suggest that the phenolic resin could be an effective crosslinker for NR-g-PMMA.