Content

All issues / Volume 18 (2024) / Issue 4 (April)

Csenge Tóth, Ábris Dávid Virág, László Mészáros

Vol. 18., No.4., Pages 348-348, 2024

DOI: 10.3144/expresspolymlett.2024.25

Vol. 18., No.4., Pages 348-348, 2024

DOI: 10.3144/expresspolymlett.2024.25

This is an editorial article. It has no abstract.

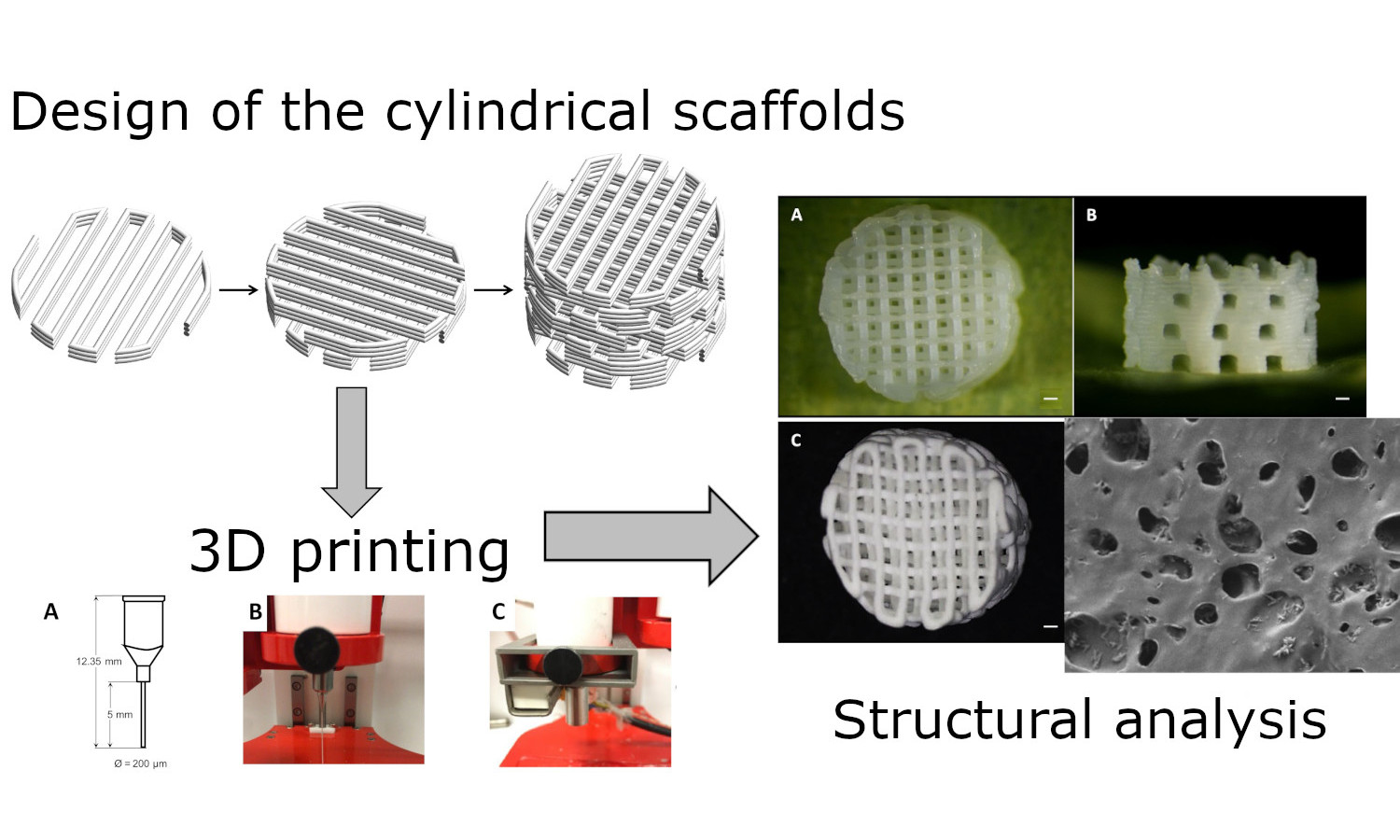

Aysun Güney, Lena Kernebeck, Dirk W. Grijpma

Vol. 18., No.4., Pages 349-358, 2024

DOI: 10.3144/expresspolymlett.2024.26

Vol. 18., No.4., Pages 349-358, 2024

DOI: 10.3144/expresspolymlett.2024.26

Biodegradable porous poly(ε-caprolactone)-poly(trimethylene carbonate)-poly(ε-caprolactone) triblock copolymers (PCL-b-PTMC-b-PCL) were synthesized by sequentεial polymerization of trimethylene carbonate (TMC) and ε-caprolactone (CL), and novel composites of PCL-b-PTMC-b-PCL with different amounts of nano-apatite (nAp) were prepared. This PTMC-based polymer matrix, which does not degrade into acidic compounds, together with the nanometer-sized apatite, which influences cell behavior, is an ideal bone regenerative material. Solvent casting these composites from chloroform solutions yielded solid films with excellent handling properties. The E-modulus of the nano-composite materials increases with nAp content, while toughness, tensile strength and elongation at break decrease. Using EC as solvent, porous composite films of PCL-b-PTMC-b-PCL and nAp could readily be prepared. The composites in EC were processed into form-stable designed tissue engineering scaffolds by 3D printing at relatively mild conditions. Besides the pore network structure with pores of 530 to 620 μm which corresponded to the design, smaller pores of 5–30 μm (due to EC crystallization) and even smaller ones of 200–500 nm (resulting from liquid-liquid exchange upon extraction of the solvent in the polymer rich phase) were observed in the printed composite scaffolds.

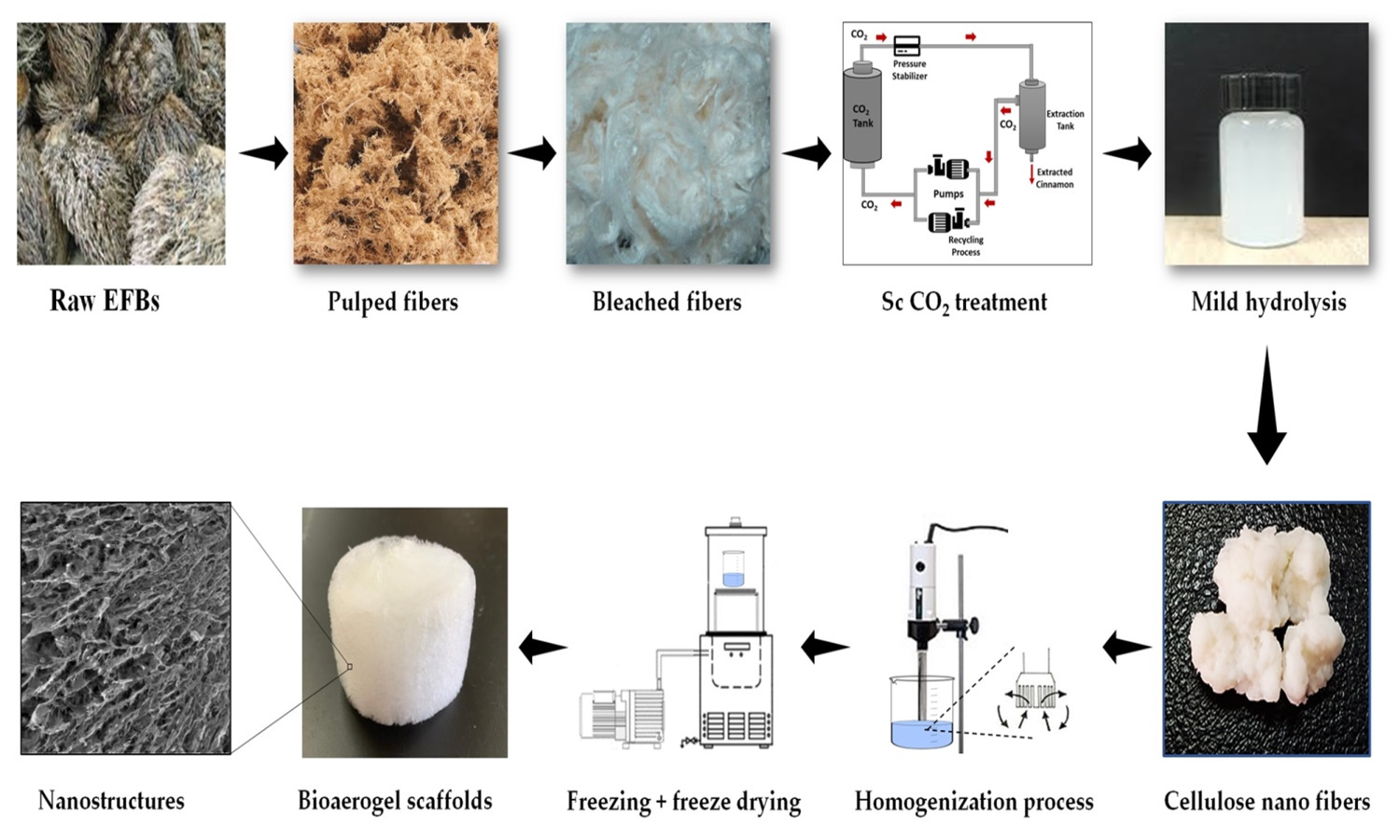

Rahadian Zainul, Yonss Mbrook Albadn, Esam Bashir Yahya, Salim Manoharadas, Nur Izzaati Saharudin, Abdul Khalil H. P. S., Mohammad Rizwan Khan, Mohamed Jaber

Vol. 18., No.4., Pages 359-370, 2024

DOI: 10.3144/expresspolymlett.2024.27

Vol. 18., No.4., Pages 359-370, 2024

DOI: 10.3144/expresspolymlett.2024.27

In this study, we employed supercritical carbon dioxide (scCO2) treatment under varying conditions: low-pressure treatment at 30 MPa and high temperature at 80°C (LPHT group) and high-pressure treatment at 60 MPa and low temperature at 50°C (HPLT group) for nanocellulose isolation. The scCO2 treatment resulted in smaller particle sizes and enhanced crystallinity. Notably, HPLT exhibited superior efficiency compared to LPHT treatment. Utilizing temperatures and pressures above the critical point effectively penetrated natural fibers, reducing nanocellulose particle sizes. Moreover, high-pressure and low-temperature nanocellulose demonstrated the highest crystallinity and negative zeta potential values (78.2% and –32.4±4.01 mV), surpassing those of the low-pressure and high-temperature group (77.9% and 26.0±2.34 mV) and control (77.3% and 25.9±3.13 mV). The concentration of nanocellulose significantly impacted the porosity, pore size, and water absorption of the bioaerogel scaffolds, indicating the potential for sustainable and environmentally friendly approaches in material fabrication for diverse applications.

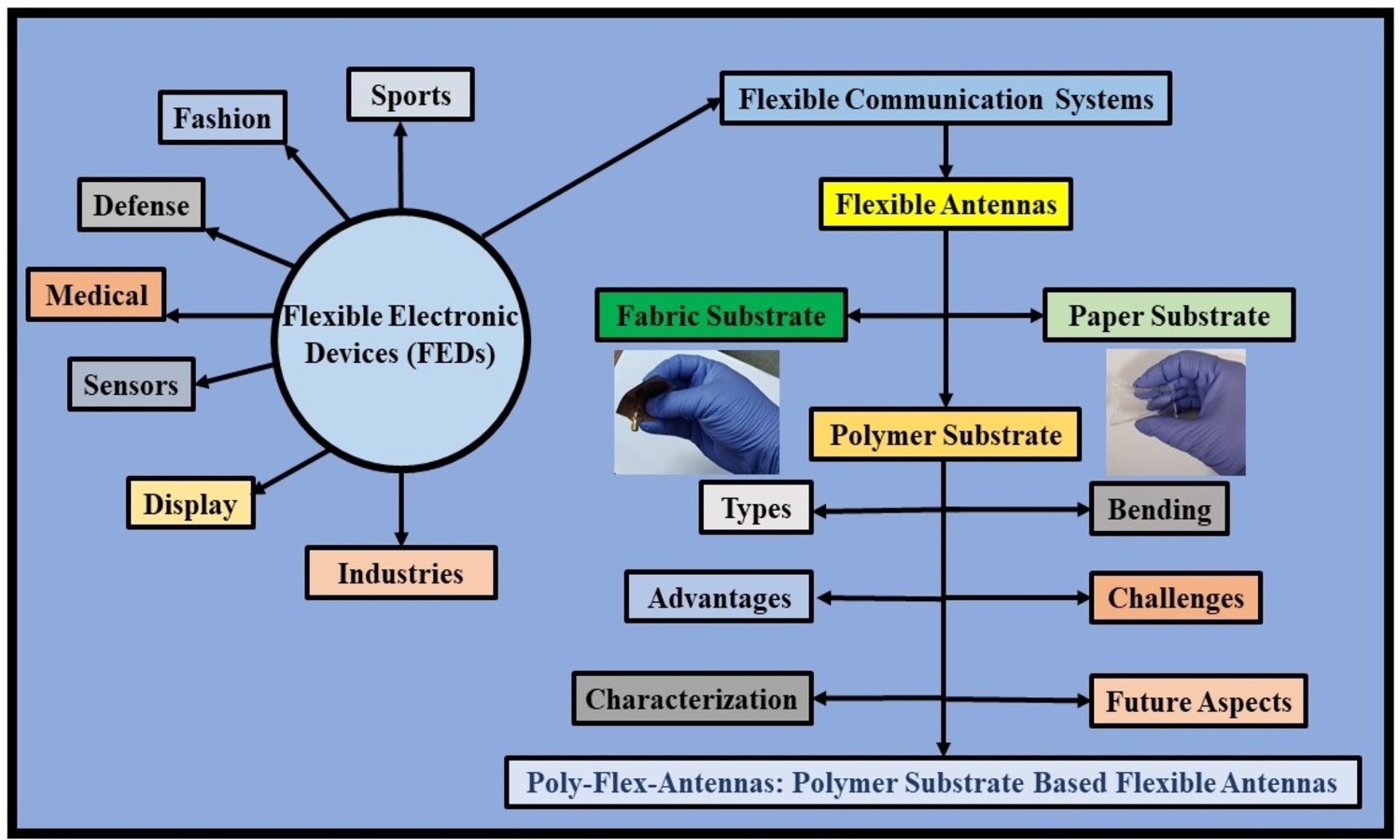

Praveen Kumar Sharma, Jae-Young Chung

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

Vol. 18., No.4., Pages 371-390, 2024

DOI: 10.3144/expresspolymlett.2024.28

The

proliferation of flexible electronics has entirely transformed the field of

antenna design and paved the door for cutting-edge uses in communication,

sensing, and other areas. The present research lends a succinct overview of the

intriguing advancements in flexible antenna technology, with specific emphasis

on the implementation of polymer substrates. As we refer to poly-flex antennas in

this article, they stand for the incorporation of polymer substrates in antenna

design. Polymer substrates are the optimum candidate for flexible antenna

applications as they have specific advantages, including being lightweight,

conformable, and inexpensive. The main features of poly-flex antennas, such as

their design concepts, fabrication processes, and performance characteristics,

are being explored in this proposed article. We delve into the wide variety of

polymer substrates that are appropriate for antennas, taking into account their

dielectric characteristics, flexibility, and environmental resistance. Their

dielectric characterization, bending effects, challenges, and future prospects

of this burgeoning field are also addressed. We conclude by emphasizing the

immense potential of poly-flex-antennas to shape the future of wireless

communication and sensing systems, and how the adoption of polymer substrates

is driving innovation in antenna engineering.

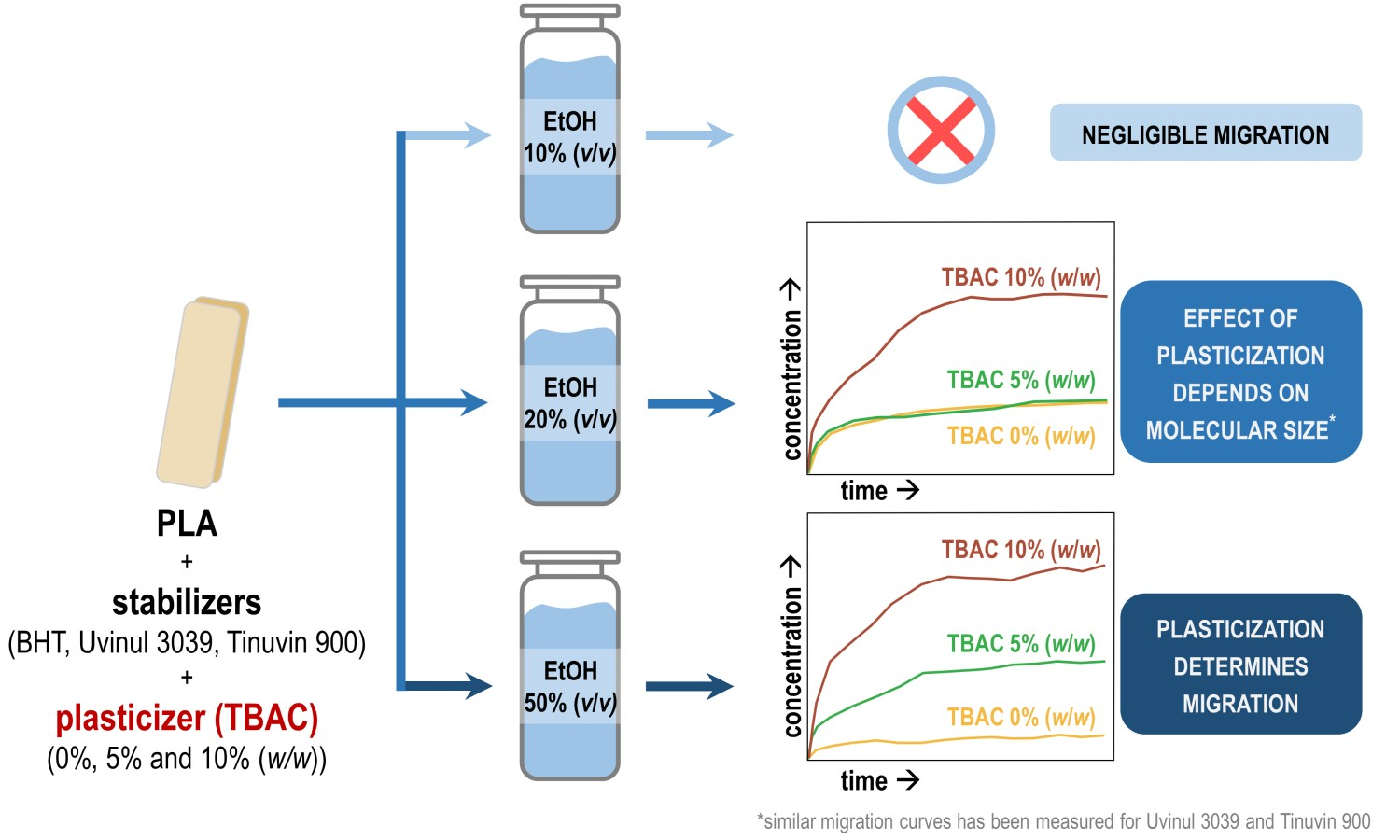

Viktor Konstantin Dragan, Noémi Petrovics, Csaba Kirchkeszner, Tamás Tábi, Bálint Sámuel Szabó, Zsuzsanna Eke

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

Vol. 18., No.4., Pages 391-405, 2024

DOI: 10.3144/expresspolymlett.2024.29

The

effect of swelling and plasticizer content of a plastic, as well as the ethanol

content of the food simulant on the migration kinetics of three stabilizer-type

additives from polylactic acid (PLA)-based food contact plastics has been

investigated. The results proved that the parameters that affect the diffusion

of substances inside the polymer matrix, i.e.,

swelling, plasticization, and the size of migrants, are the decisive factors in

the migration from PLA to ethanolic food simulants. Both swelling and migration

were negligible when ethanol 10% (v/v) was used. Contrarily, the specific

migration limits of Commission Regulation (European Union, EU) No. 10/2011 were

exceeded in ethanol 50% (v/v) for all investigated stabilizers. Migration was

promoted by plasticization, but this effect could only be observed when the

applied food simulant swelled the plastic (at least 20% (v/v) ethanol content).

The dependence of the plasticizer’s migration-enhancing effect on the swelling

has not been shown before. When the plasticization caused increased migration,

it also led to specific migration limit exceeding within a shorter period of

time. It happens even if PLA-based plastics are dedicated to the storage of

hydrophilic food, which is the most common application area of these products.

These results can support the improvement of both consumer safety and active

packaging development.

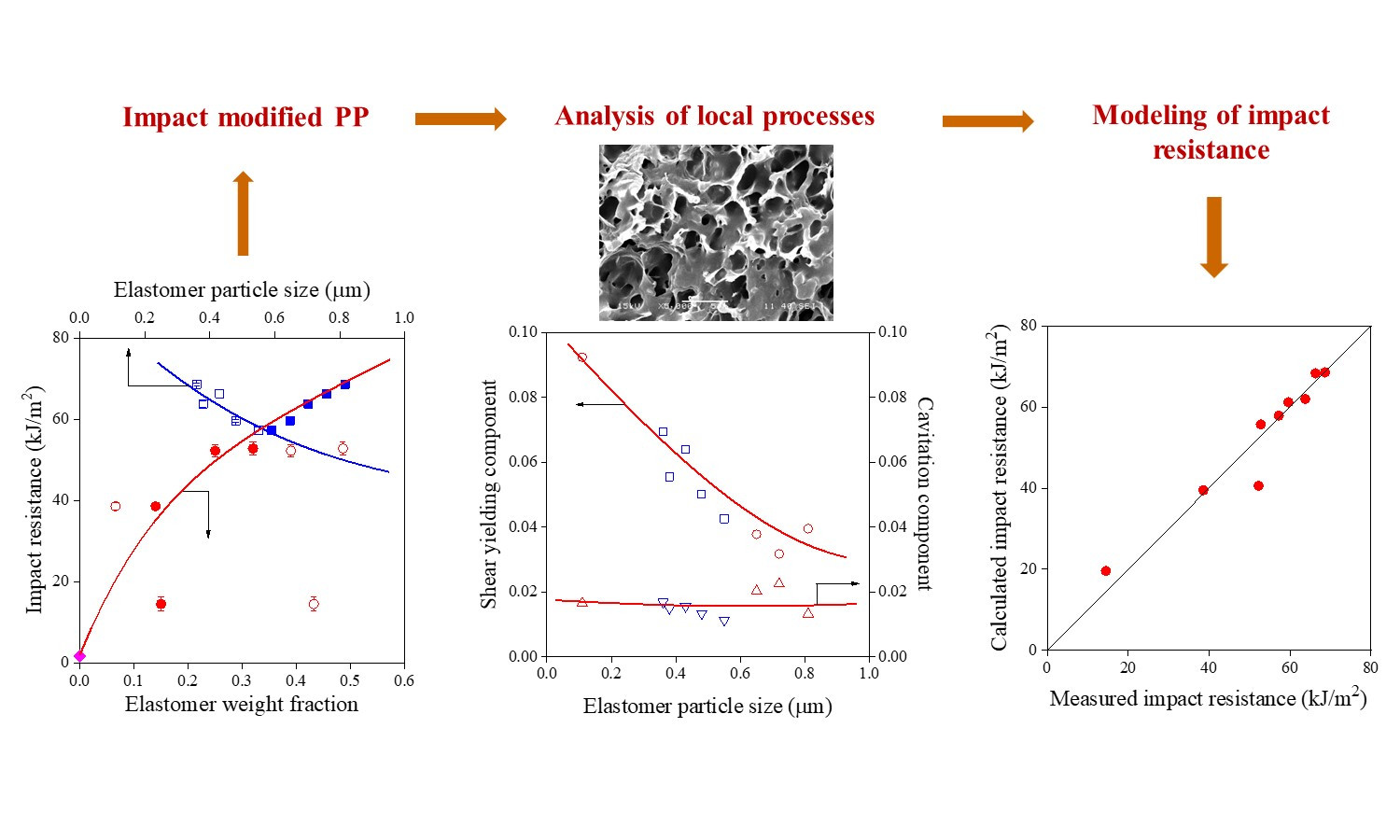

Milán Ferdinánd, Michael Jerabek, Róbert Várdai, Emese Pregi, Thomas Lummerstorfer, Markus Gahleitner, Gábor Faludi, János Móczó, Béla Pukánszky

Vol. 18., No.4., Pages 406-419, 2024

DOI: 10.3144/expresspolymlett.2024.30

Vol. 18., No.4., Pages 406-419, 2024

DOI: 10.3144/expresspolymlett.2024.30

The

impact resistance of four polypropylene impact copolymers (ICPs) with

multi-phase structures and widely differing characteristics was related to

their structure. Blends were prepared from one of them and a high-density

polyethylene (HDPE) to improve impact strength further. The structure of the

materials was characterized by microscopy and dynamic mechanical thermal

analysis. Mechanical properties were determined by tensile and impact testing,

while local deformation processes were followed by volume strain measurements.

The results obtained in the study proved that the shear-yielding of the matrix

contributes the most among local processes to the increase of impact strength,

while cavitation has a small effect on this latter property since its energy

absorption is negligible. Both increasing elastomer content and decreasing

particle size favor shear-yielding, thus improving impact strength. Considering

the importance of elastomer content and elastomer particle size, a simple but

very good model was created describing the dependence of the impact strength of

ICPs on these latter two factors by using linear regression analysis. Although

the addition of HDPE increases the fracture resistance of ICPs further, the

extent of improvement is moderate, and the approach is economically

disadvantageous.

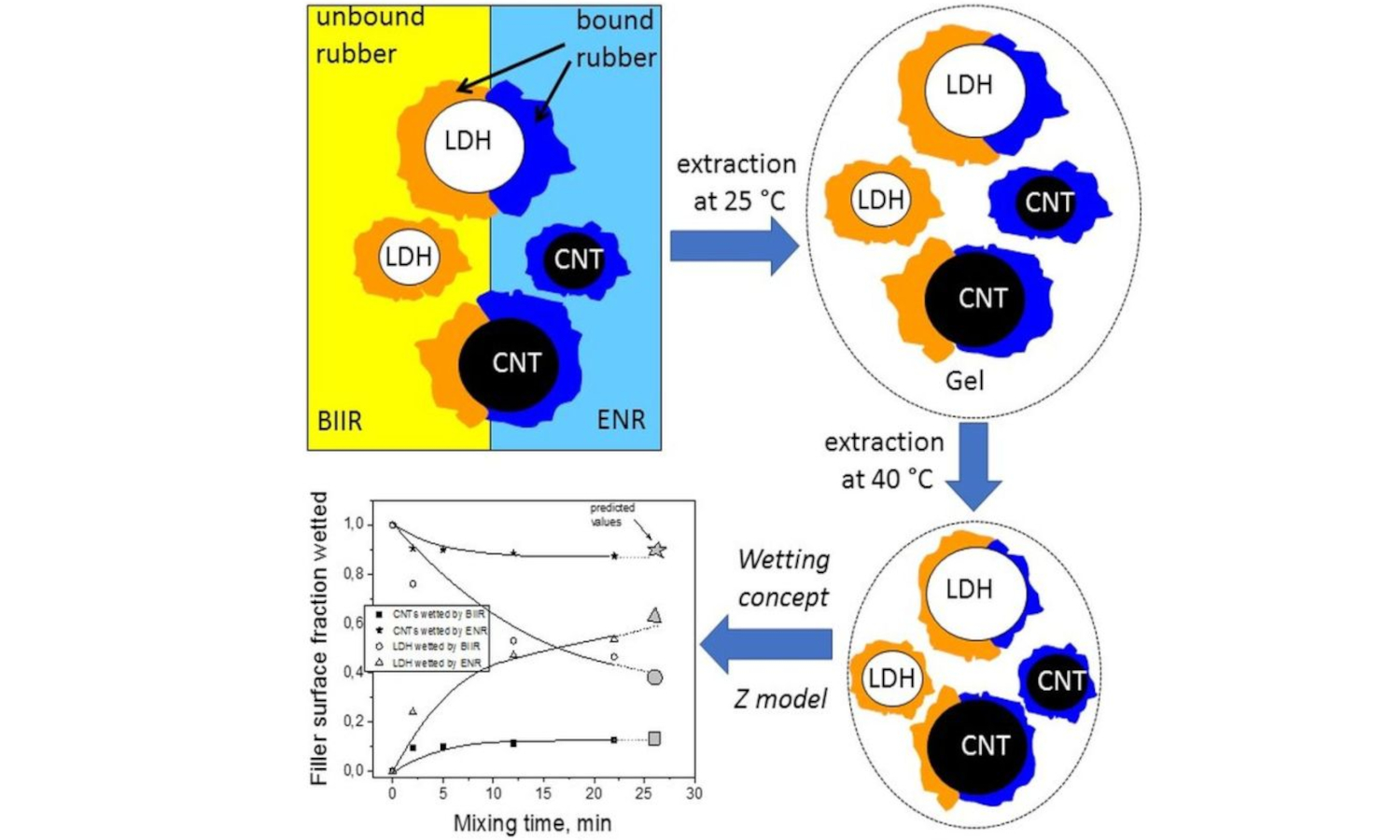

Le Hong Hai, Hoang Xuan Tung, Yashwanth Sai Anjaneya Varma Kosuri, Subhradeep Mandal, Kedar Nath Dhakal, Rameshwar Adhikari, Beate Langer, Sven Wiessner

Vol. 18., No.4., Pages 420-440, 2024

DOI: 10.3144/expresspolymlett.2024.31

Vol. 18., No.4., Pages 420-440, 2024

DOI: 10.3144/expresspolymlett.2024.31

Flexible rubber composites based on blends of bromobutyl rubber (BIIR)/epoxidized natural rubber (ENR) filled with a hybrid filler of layered double hydroxides (LDH)/carbon nanotubes (CNT) were prepared, which may be of interest for use in tires and inner liner. An imidazole mixture of butyl-imidazole and 1H-imidazole was proposed to achieve reversible non-covalent networks consisting of ionic clusters and hydrogen bonding that led to the self-healing properties of each blend phase. The objective of the present work was to characterize the effects of selective modification of the rubber blends by imidazole and selective wetting of the hybrid filler on the mechanical and electrical properties and the self-healing effectivity. The wetting concept used to characterize the selective wetting of a single filler in a rubber blend was further developed for a hybrid filler in BIIR/ENR blends. During the one-step mixing and the masterbatch mixing process, re-localization of the hybrid filler between the blend phases under thermodynamic driving forces was observed. Within the specified mixing time, the thermodynamic equilibrium state of filler localization could not be reached. The nearly uniform distribution of LDH in both blend phases and the preferential localization of CNTs in the ENR matrix were found to be essential in giving the BIIR/ENR blends the best combination of self-healing properties and electrical conductivity. The high electrical conductivity of the composites can be exploited to generate a high temperature locally at the damage site inside the rubber samples when an electrical voltage is applied, resulting in an acceleration of the self-healing process.

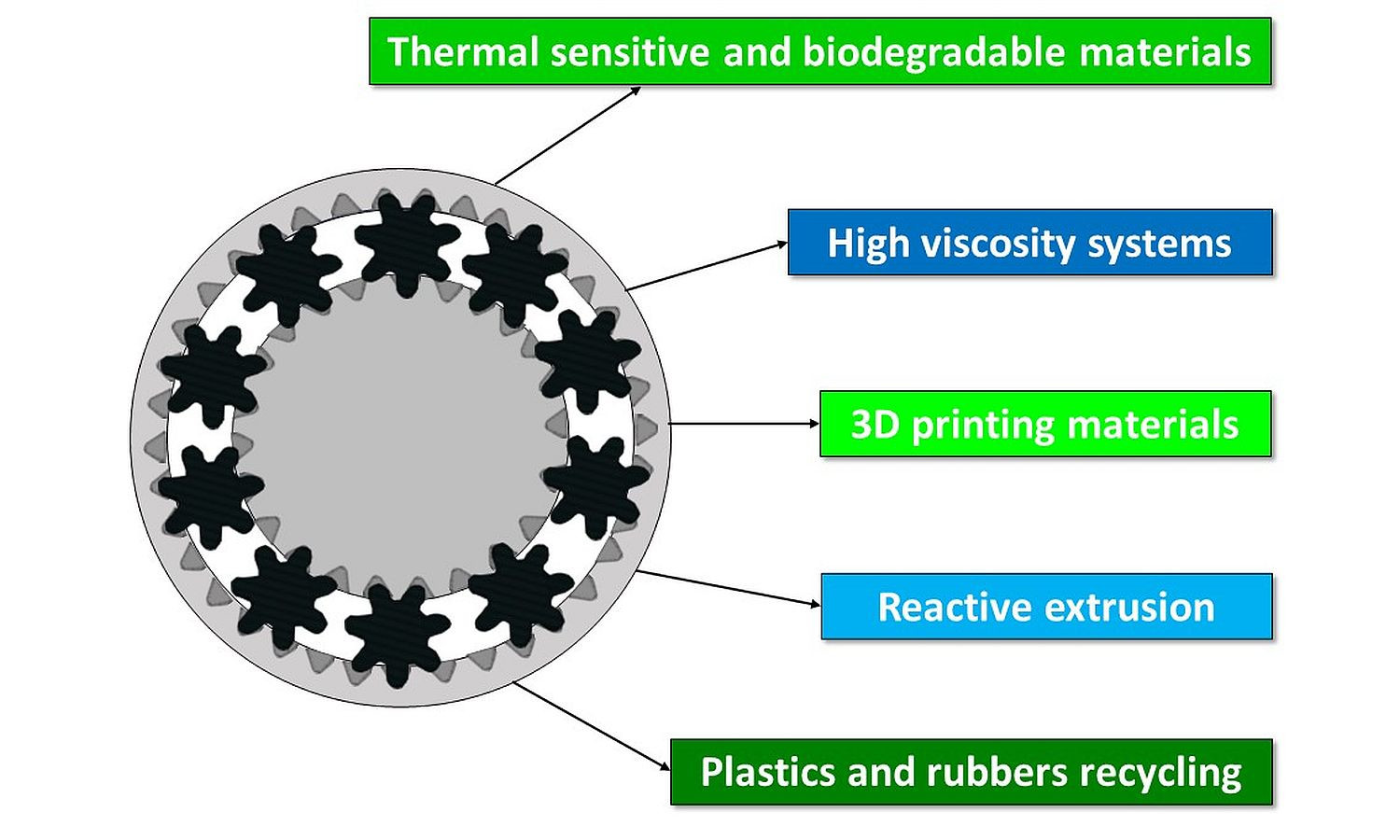

Krzysztof Formela, Barış Eyigöz

Vol. 18., No.4., Pages 441-458, 2024

DOI: 10.3144/expresspolymlett.2024.32

Vol. 18., No.4., Pages 441-458, 2024

DOI: 10.3144/expresspolymlett.2024.32

Screw extruders as continuous flow reactors allow the synthesis of new polymers, preparation of polymer blends and composites, and modification or functionalization of commercially available polymers. Literature data shows that the twin screw extrusion is the most popular solution used for this purpose. In contrast, the number of scientific papers on alternative methods, such as multi-screw extruders, is somewhat limited. This paper is the first review of the application of planetary roller extruders in the compounding and reactive processing of polymer blends and composites. To fill current knowledge gaps, we discuss the advantages and disadvantages of planetary roller extruders compared to other screw extruders. Moreover, we summarize recent advances in planetary roller extrusion in producing thermal sensitive and biodegradable polymeric materials, rubber compounds, materials for 3D printing, or plastics and rubber recycling. This work also proposes the possible scenarios for further sustainable development of polymer blends and composites using planetary roller extruders.